A kind of manufacturing process of low wind resistance filter screen based on graphene modified activated carbon material

A graphene modification and production process technology, applied in filtration separation, dispersed particle filtration, separation methods and other directions, can solve the problems of large wind resistance, insufficient adsorption of organic harmful substances in polluted air, etc., and achieves low wind resistance, good pass rate, The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following describes in detail the embodiments of the present invention, examples of which are illustrated in the accompanying drawings, wherein the same or similar reference numerals refer to the same or similar elements or elements having the same or similar functions throughout. The embodiments described below with reference to the accompanying drawings are exemplary, and are intended to explain the present invention and should not be construed as limiting the present invention.

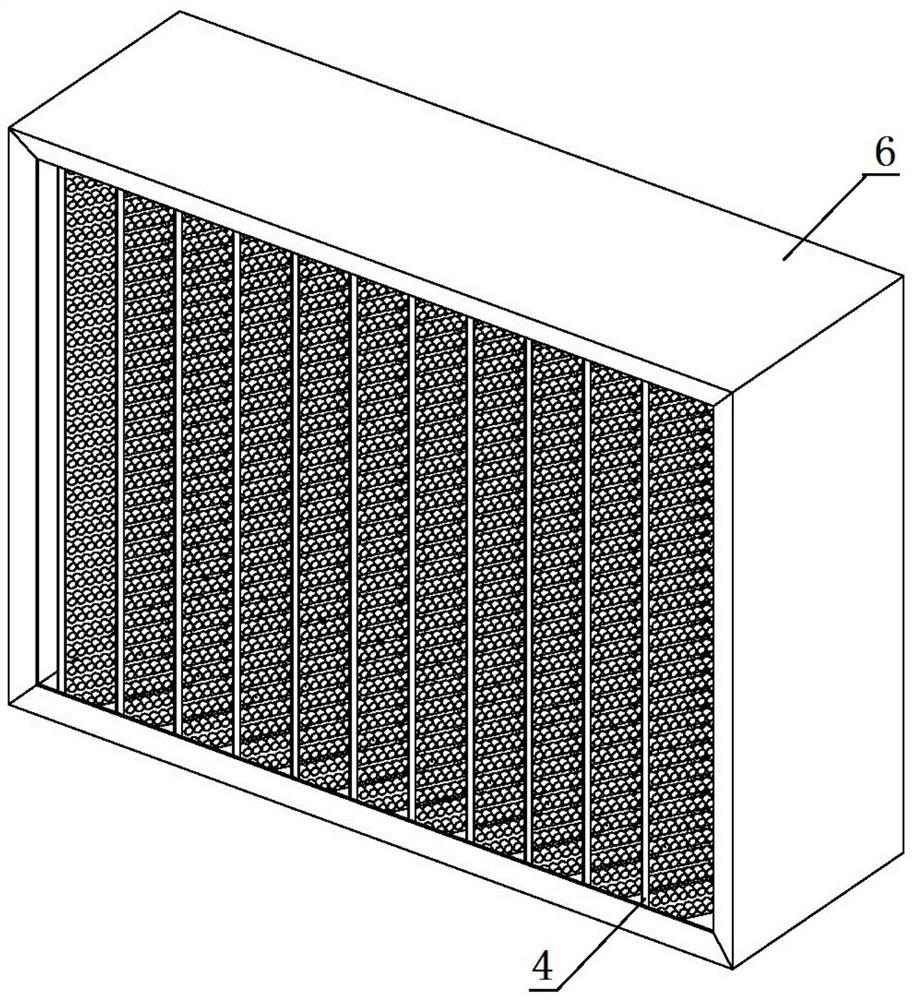

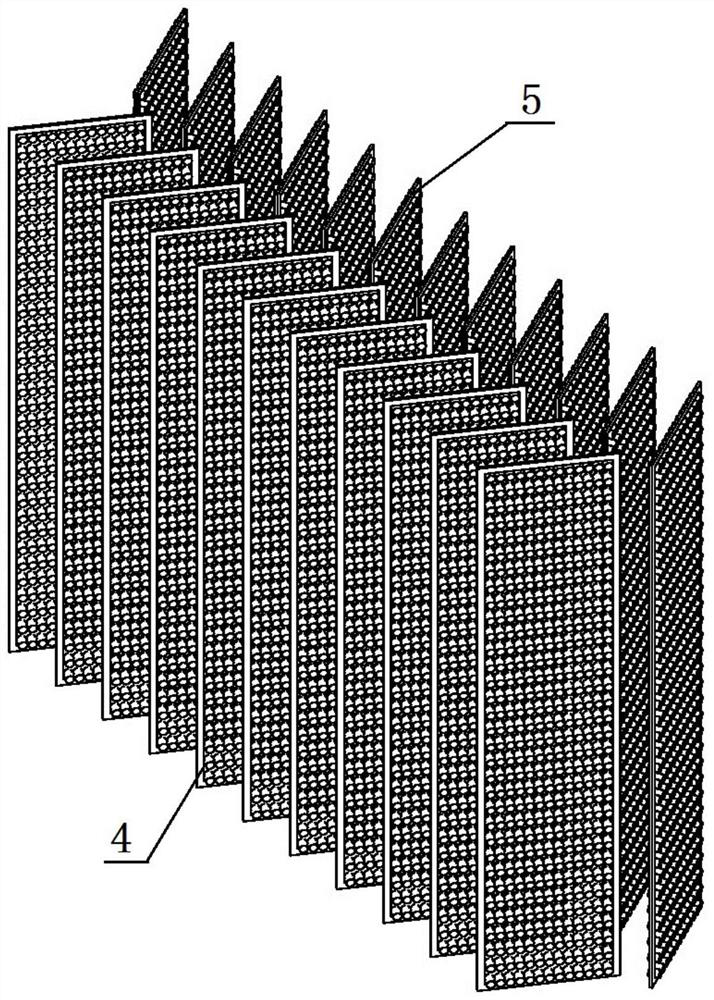

[0027] like Figure 1 to Figure 4 As shown, a low wind resistance filter screen manufacturing process based on graphene modified activated carbon material, comprising the following steps:

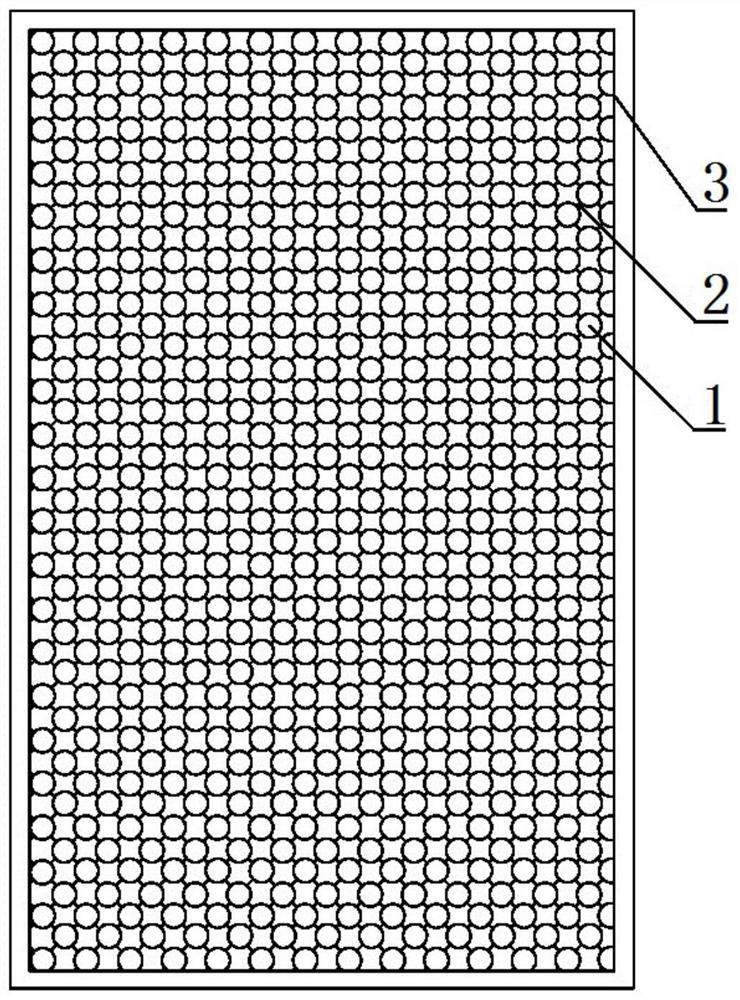

[0028] S100, select a graphene-modified activated carbon column 1 of a predetermined size;

[0029] S200, making a filter grid substrate 2;

[0030] S300, the selected graphene-modified activated carbon column 1 is uniformly adhered to the filter grid substrate 2 with predetermined rules to make the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com