Low-temperature polycrystalline silicon thin film transistor, array substrate and manufacturing method of array substrate

A thin-film transistor, low-temperature polysilicon technology, applied in transistors, semiconductor/solid-state device manufacturing, electrical solid-state devices, etc., can solve the problems of unsuitable thin-film transistors and high temperature, avoid related defects and undesirable phenomena, improve performance, and simplify production. The effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

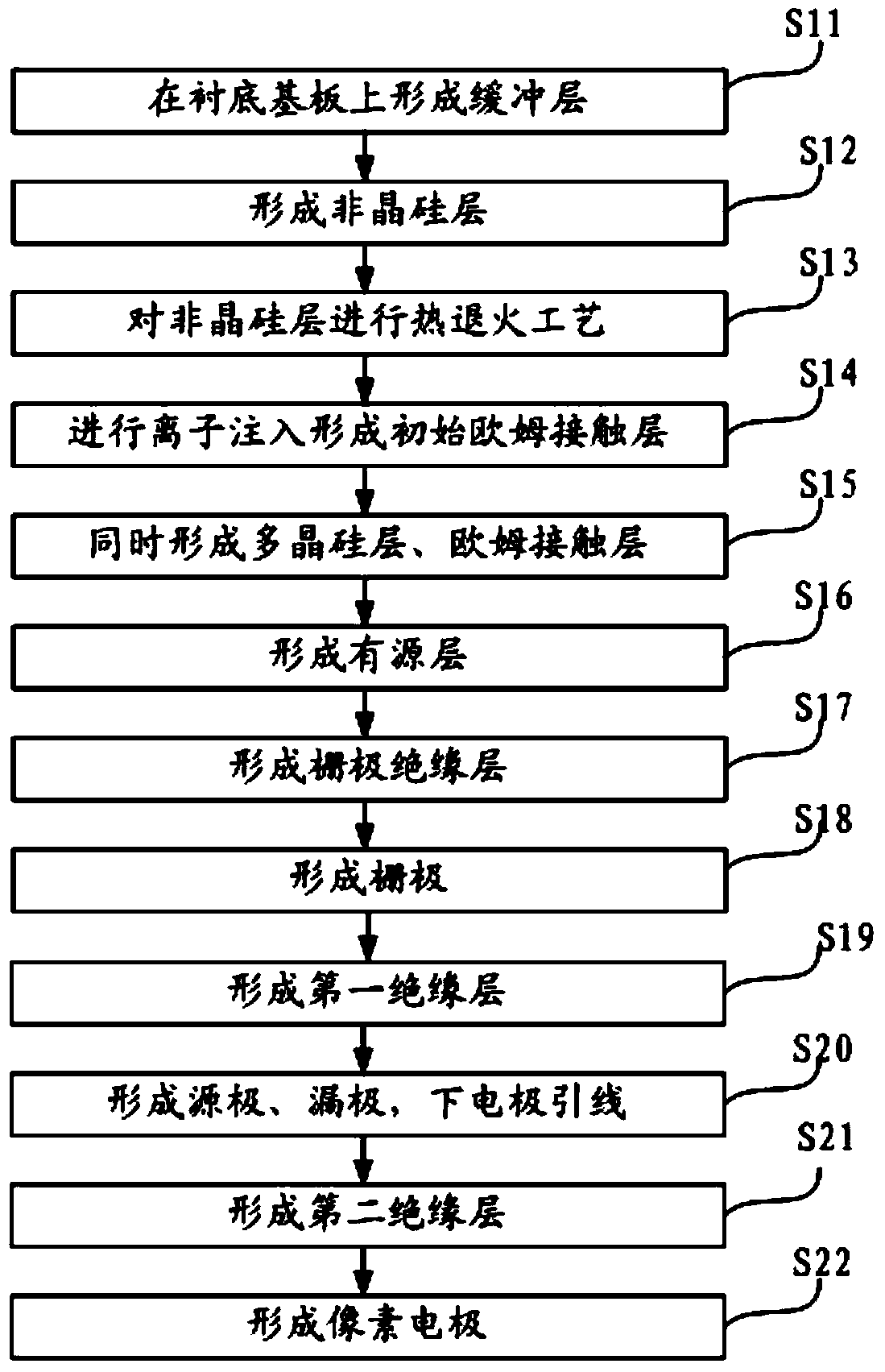

[0037] Embodiments of the present invention provide a low temperature polysilicon thin film transistor, an array substrate and a manufacturing method thereof, which are used to simplify the manufacturing process of the low temperature polysilicon thin film transistor and improve the performance of the low temperature polysilicon thin film transistor.

[0038] In the manufacturing method of the low-temperature polysilicon thin film transistor provided by the embodiment of the present invention, before the polysilicon layer is formed from the amorphous silicon layer, the amorphous silicon is ion-implanted to form an initial ohmic contact layer, and the polysilicon layer is formed from the amorphous silicon layer at the same time. Forming an ion-activated ohmic contact layer simplifies the manufacturing process.

[0039] The ohmic contact layer of the present invention is also called source-drain doped layer, and the ohmic contact layer includes two mutually independent regions, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com