Low-temperature polycrystalline silicon film pre-cleaning method, low-temperature polycrystalline silicon film preparation method and low-temperature polycrystalline silicon film manufacturing system

A low-temperature polysilicon, pre-cleaning technology, applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems affecting the uniformity of the polysilicon layer and the uneven thickness of the amorphous silicon film, and achieve Improve the uneven thickness, narrow the gap between thickness and thickness, and improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

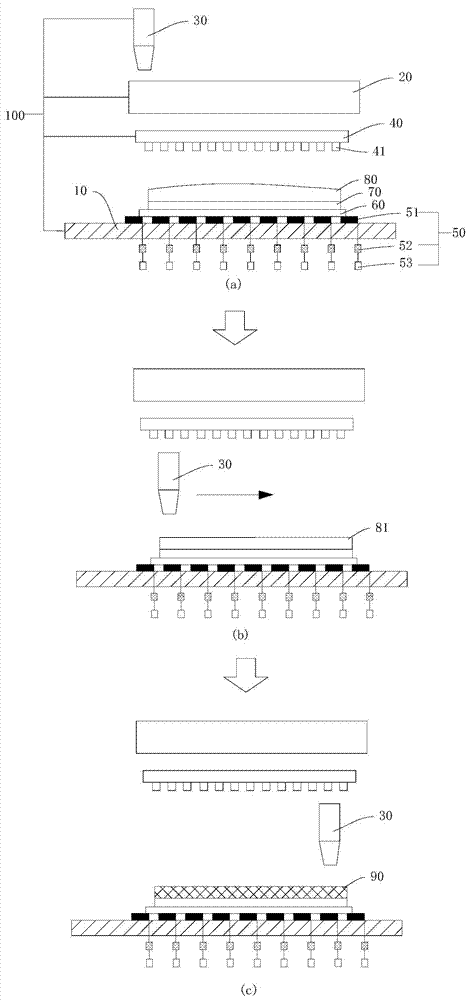

[0027] In the following, the embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0028] The present invention provides a low-temperature polysilicon thin film fabrication system 100, such as figure 1 As shown, it at least includes a sample stage 10 , an epitaxial growth device 20 , an excimer laser beam 30 , a pre-cleaning device 40 , and a temperature control device 50 . in,

[0029] The epitaxial growth device 20 is correspondingly arranged above the sample stage 10 for growing an amorphous silicon layer (not shown in the figure) and other necessary material layers for forming a polysilicon thin film on the sample stage 10 .

[0030] The pre-cleaning device 40 is correspondingly arranged above the sample stage 10, and it includes several evenly arranged shower heads 41, through which the cleaning agent is controllably sprayed out to clean the amorphous silicon material. pre-cleaned.

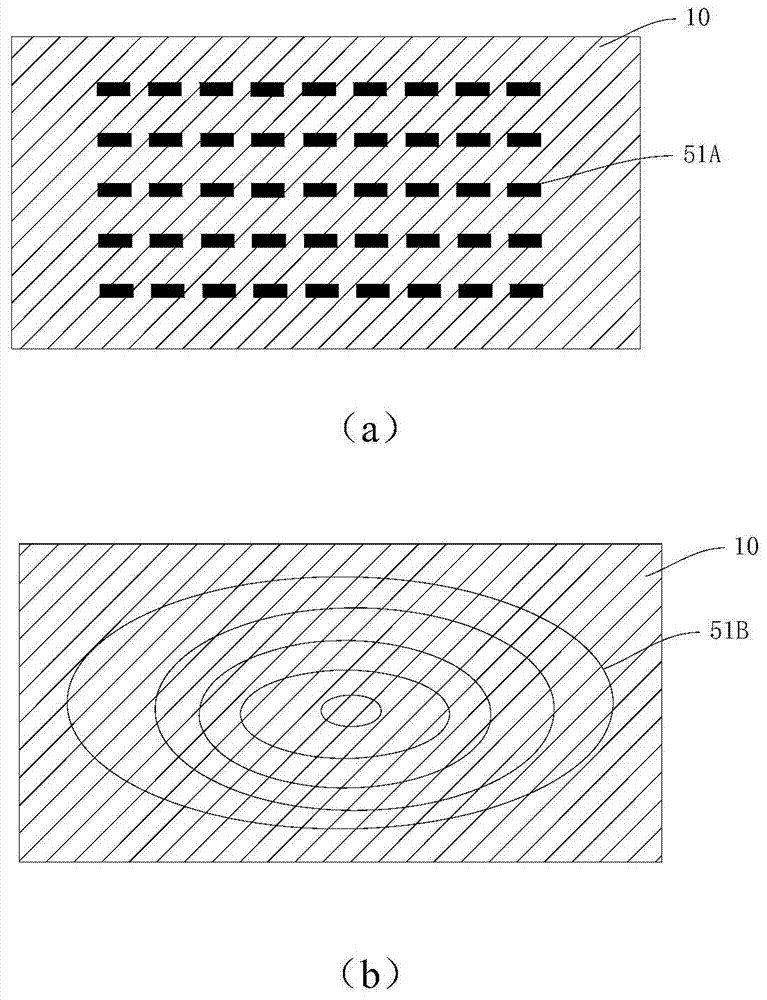

[0031] The temperature contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com