Image display system and manufacture method thereof

A technology of an image display system and a manufacturing method, which is applied in the manufacture of semiconductor/solid-state devices, radiation control devices, electrical components, etc., can solve the problems of inability to improve yield, long process time, uneven light emission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical content of the present invention will be described in detail below with reference to the accompanying drawings.

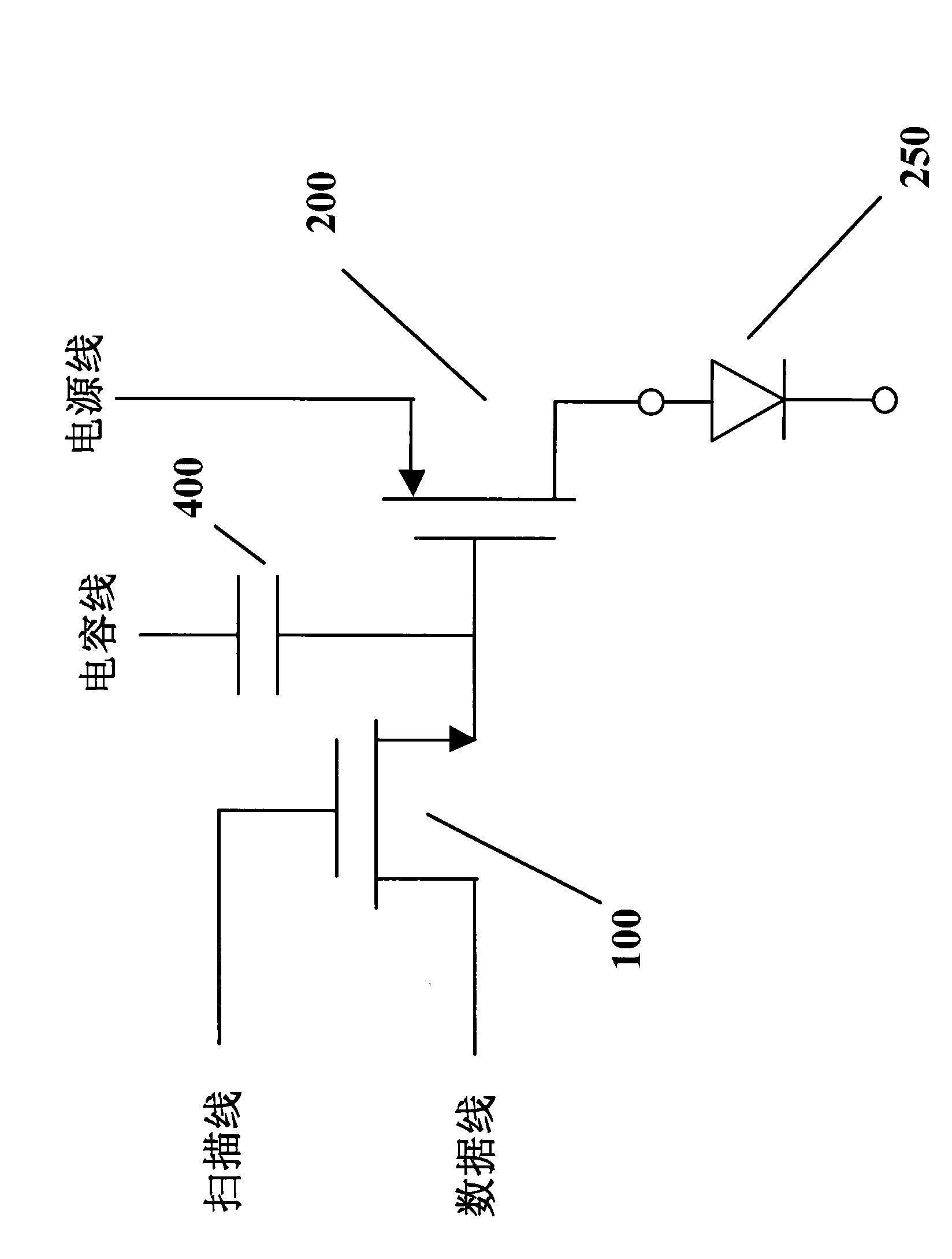

[0018] Please refer to figure 1 , which shows a simple structure diagram of an active matrix organic light emitting diode display (AMOLED). A pixel unit of an active matrix organic light emitting diode (AMOLED) display may include a switching TFT 100 , a driving TFT 200 , a light sensing element 250 and a capacitor 400 .

[0019] As mentioned above, the requirements for its electrical performance are quite different: for switching TFTs, low sub-threshold swing and high carrier mobility are required. For driving TFTs, a high sub-threshold swing is required to meet the requirement of uniformity among transistors, so as to transmit the conduction current for driving the photo-sensing element 250 . However, the current driving is very sensitive to the difference of the individual photo-sensing elements 250 , and the existence of the difference be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com