Iron based powder for powder metallurgy

A powder metallurgy and mixed powder technology is applied in the field of iron-based powder mixed powder for powder metallurgy, and can solve the problems of increasing manufacturing cost and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0159] To No. 1 to No. 4 water atomized iron powders shown in Table 1, irons (a) to (g) of different types and particle sizes shown in Table 1 were added in the mixing amounts shown in Table 1 powder, stirring and mixing to make a mixed powder. Then, in this mixed powder, a heat treatment is carried out to make the copper powder partially alloyed and adhered, and then pulverized and classified, and then, atomized iron powder (atomized iron powder with copper partially alloyed and adhered) No.1 to No.7 is made. , which has the particle size distribution and apparent density shown in Table 2, and the copper powder is partially alloyed and adhered to the surface. In addition, the particle size distribution adopted the sieve distribution method prescribed|regulated by Japan Powder Metallurgy Industry Association standard JPMA P02-1992. The apparent density was measured in accordance with JPMA P06-1992, Japan Powder Metallurgy Association standard.

[0160] Partial alloying and a...

Embodiment 2

[0214] 990 g of iron-based powder shown in Table 4, 10 g of graphite powder (average particle diameter: 23 μm), and binders of the type and amount shown in Table 9 were charged into the heating mixer, stirred and mixed thoroughly, and then continued to stir. , heated to the primary mixing heating temperature shown in Table 8, and primary mixing was performed.

[0215] Next, the primary mixture was cooled to below 85°C while stirring. After cooling to 40° C., lubricants of the type and amount shown in Table 9 that form free lubricants were added, and secondary mixing was performed to make them uniform, and then discharged from the heating mixer to obtain iron-based mixed powder.

[0216] In addition, in the iron-based mixed powder No.2-16 (conventional example), as the iron-based mixed powder, the iron-based powder No.N (only atomized pure iron powder) is used, and the iron-based powder No.N is not used The atomized iron powder to which the copper powder is partially alloyed i...

Embodiment 3

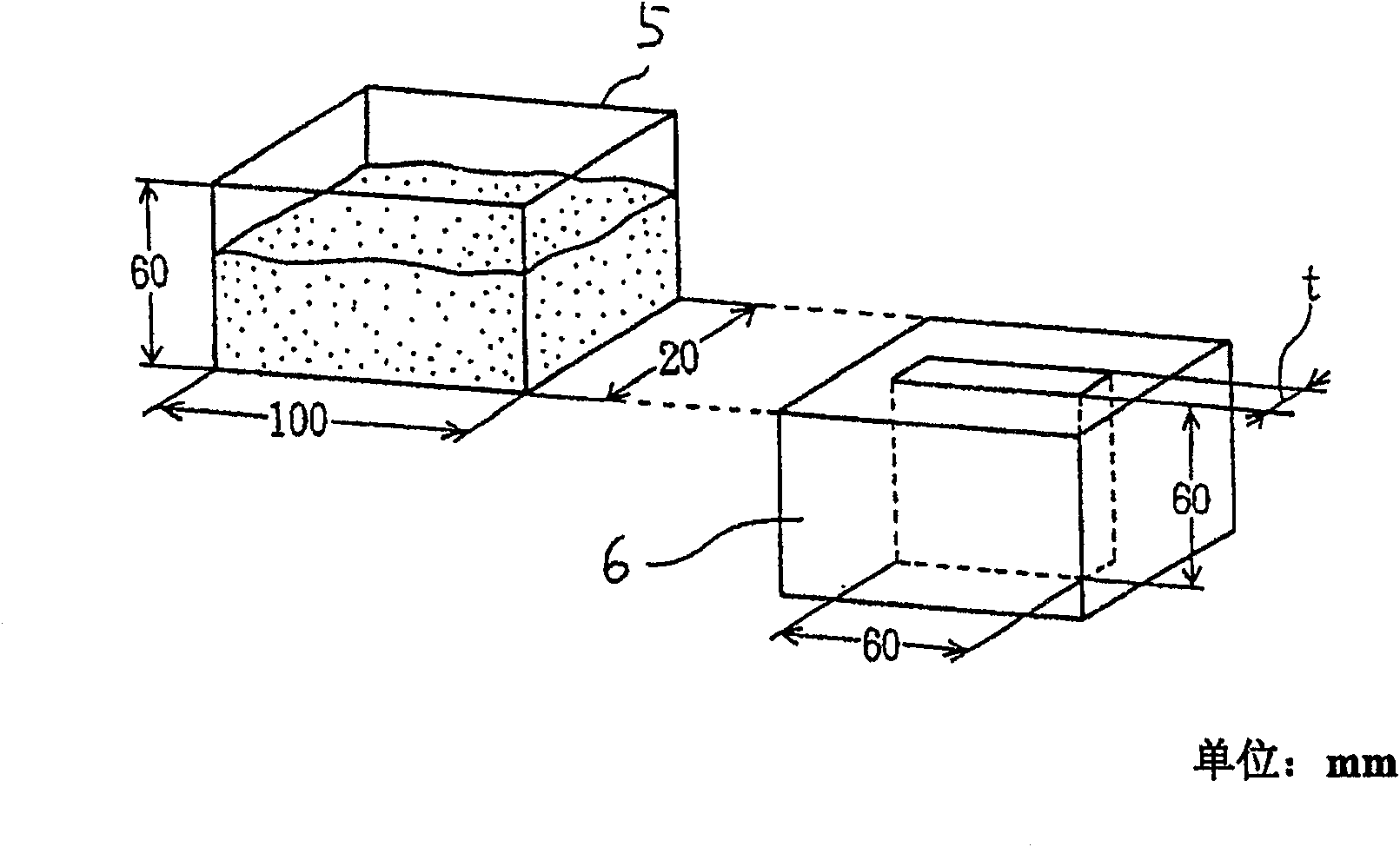

[0227] 1 ton of iron-based mixed powder Nos. 1, 16, and 19 of Example 1 and iron-based mixed powder Nos. 2-1 and 2-16 of Example 2 were produced, respectively. By powder metallurgy using each mixed powder, with Figure 3A and Figure 3B 1000 spur gears (dimension unit: mm) are manufactured continuously in the metal casting mold of the metal casting hole shape shown. Figure 3A The tooth part of is shown in abbreviated form, which is a tooth with a reference pitch circle diameter (the reference pitch circle diameter indicated by a single dotted line) of 38 mm, a tooth tip diameter of 40 mm, and a number of teeth of 38 (module = 1). In addition, the tooth shape is made into an involute tooth shape.

[0228] Fill the gear shape with powder mix using the following Figure 3A A metal mold for the flat shape of the metal casting hole, and figure 1 A similar filling device is used for filling. After the powder box reaches the top of the metal casting hole at a moving speed of 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com