Wiring forming system and method

A technology of wiring and wiring patterns, applied in the field of wiring forming systems, can solve problems such as different degrees of occurrence, deformation of wiring patterns or uneven etching, and unclear specific structure of size adjustment standards, so as to ensure clearance, realize productivity, and realize quality Keep the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

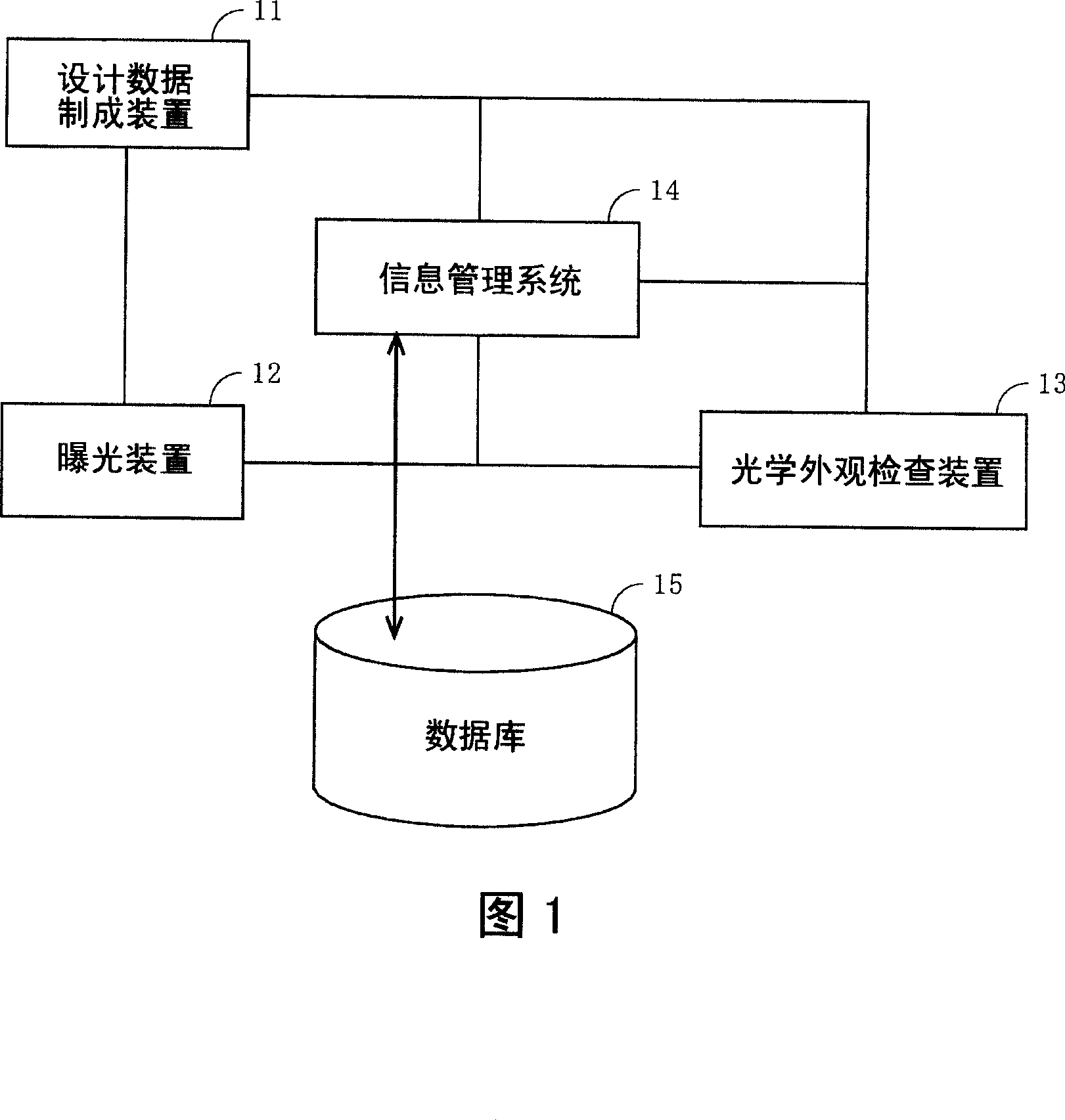

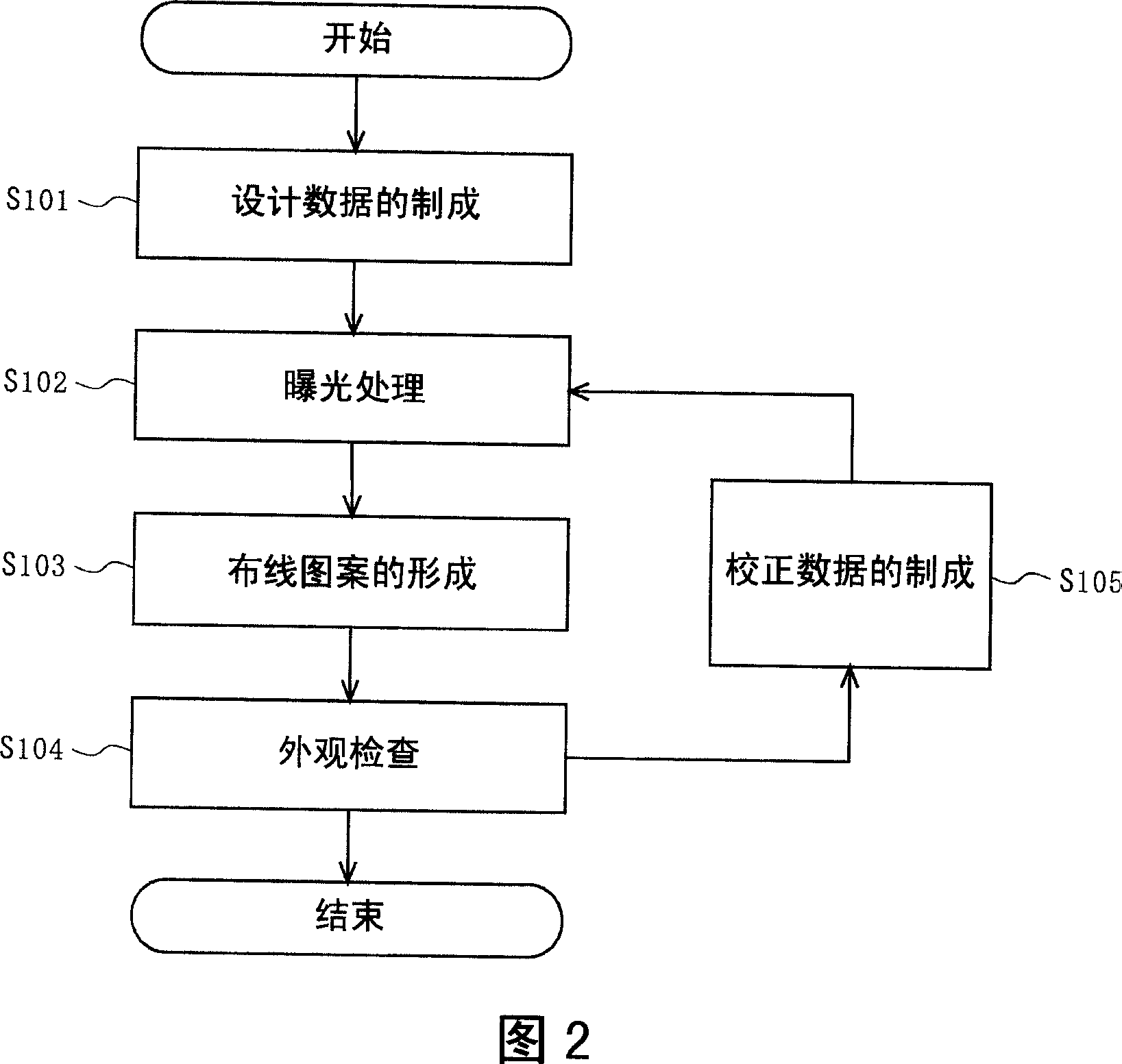

[0057] First, a wiring forming system according to a first embodiment of the present invention will be roughly described with reference to FIGS. 1 and 2 . FIG. 1 is a block diagram showing the configuration of a wiring forming system according to the first embodiment. 2 is a flowchart schematically showing the flow of processing in the wiring forming system according to the first embodiment.

[0058] In FIG. 1 , the wiring forming system according to this embodiment is a system configured by connecting a design data creating device 11 , an exposure device 12 , an optical appearance inspection device 13 , an information management system 14 , and a database 15 in a network.

[0059] In FIG. 2, the design data creating means 11 creates design data (step S101). The design data is image data representing a wiring pattern of a printed circuit board produced by CAD, CAM, or the like. The exposure device 12 creates image data for exposure (for example, RIP data) according to the de...

no. 2 Embodiment approach

[0080] Next, a wiring forming system according to a second embodiment of the present invention will be described. In this embodiment, a method of correcting defects due to the proximity effect will be described. In addition, since the wiring forming system according to this embodiment has the same configuration and processing flow as those in FIGS. 1 and 2 described in the first embodiment, description of the functions of each configuration and a rough processing flow will be omitted.

[0081] First, a defect in a wiring pattern due to the proximity effect will be described with reference to FIG. 8 . FIG. 8 is a diagram schematically showing a defect in a wiring pattern due to the proximity effect. (a) of FIG. 8 is a diagram showing a part of the wiring pattern of the mask image data. The line pitch of the two wiring patterns shown in (a) of FIG. 8 is α1. (b) of FIG. 8 is a diagram showing how a defect occurs in a wiring pattern due to the proximity effect during exposure. ...

no. 3 Embodiment approach

[0094] Next, a wiring forming system according to a third embodiment of the present invention will be described. In this embodiment, a method of correcting missing and protrusions of a wiring pattern will be described. In addition, the wiring forming system according to this embodiment is the same as the structure and process flow of FIGS. 1 and 2 described in the first embodiment except for the specific inspection method of the optical appearance inspection device 13 . Therefore, in the following description, the description of the functions of each structure other than the specific inspection method of the optical appearance inspection device 13 and a rough processing flow will be omitted.

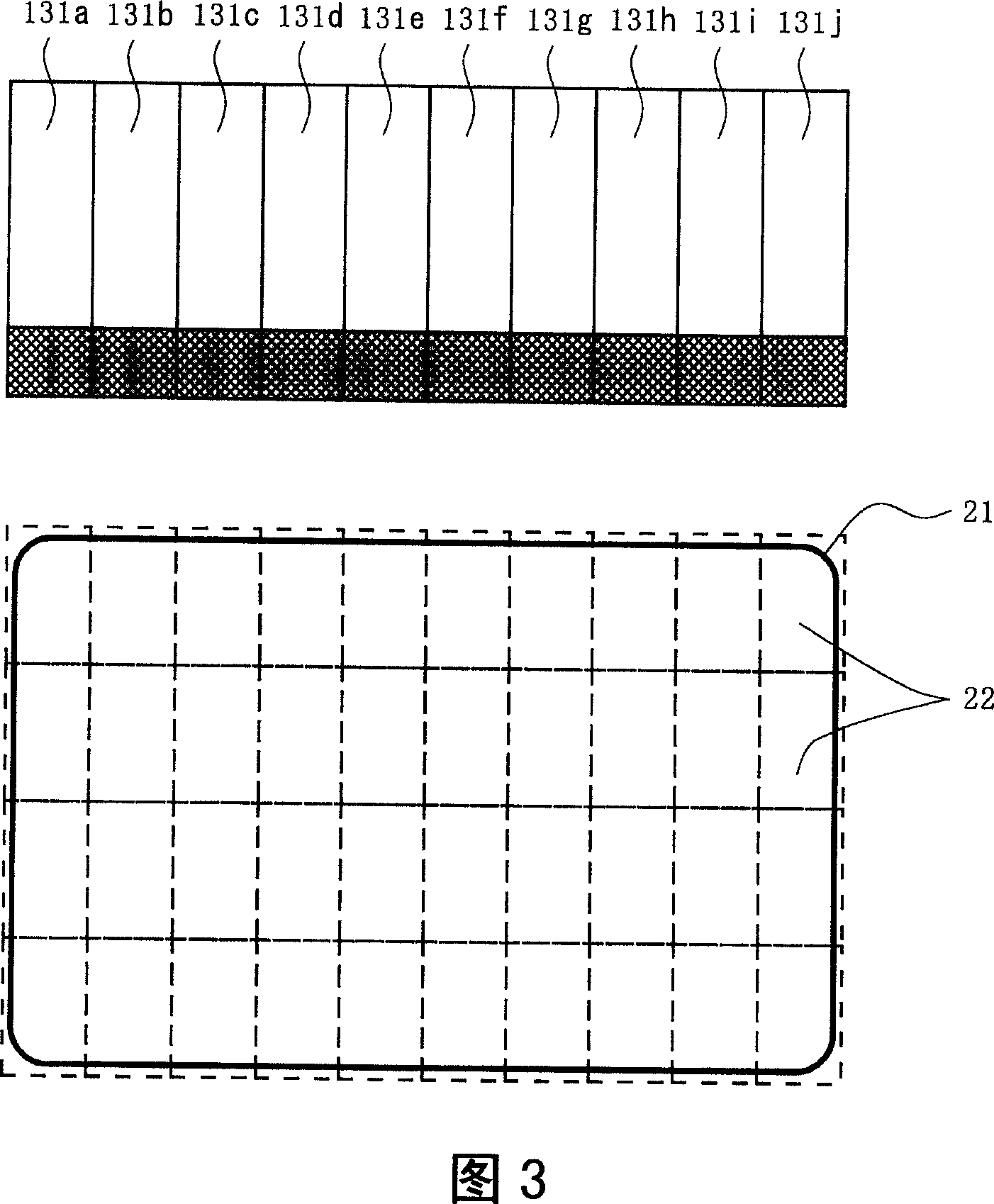

[0095] In the present embodiment, the optical appearance inspection device 13 shown in FIG. 1 uses, for example, a plurality of cameras to photograph the printed circuit board 21 after the wiring pattern has been formed, and acquires image data of the printed circuit board 21 . The opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com