Sintering device and method for producing reduced iron

A manufacturing method and technology of reducing iron, applied in the direction of furnace control devices, furnaces, lighting and heating equipment, etc., to achieve the effect of reducing production costs and improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

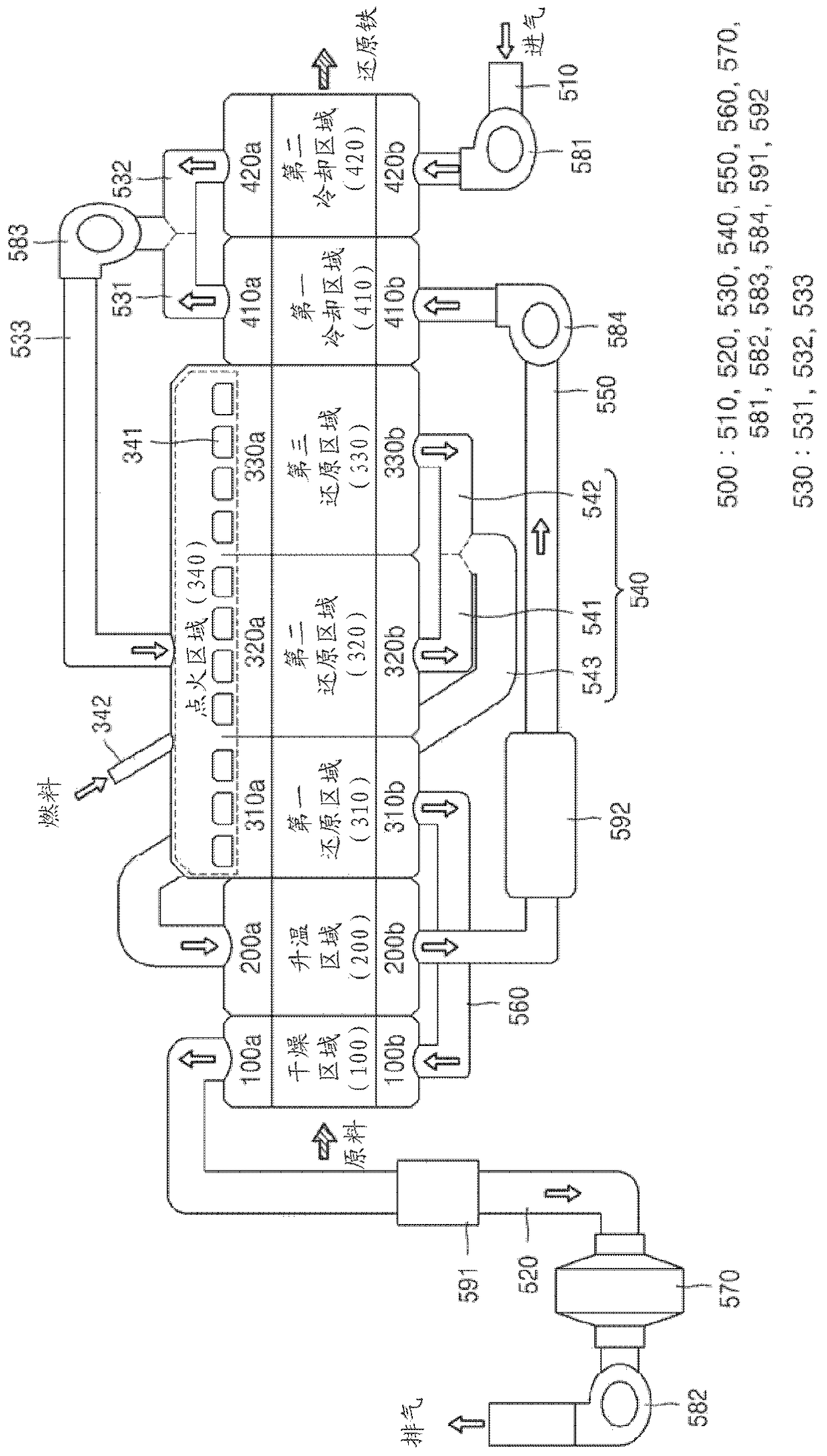

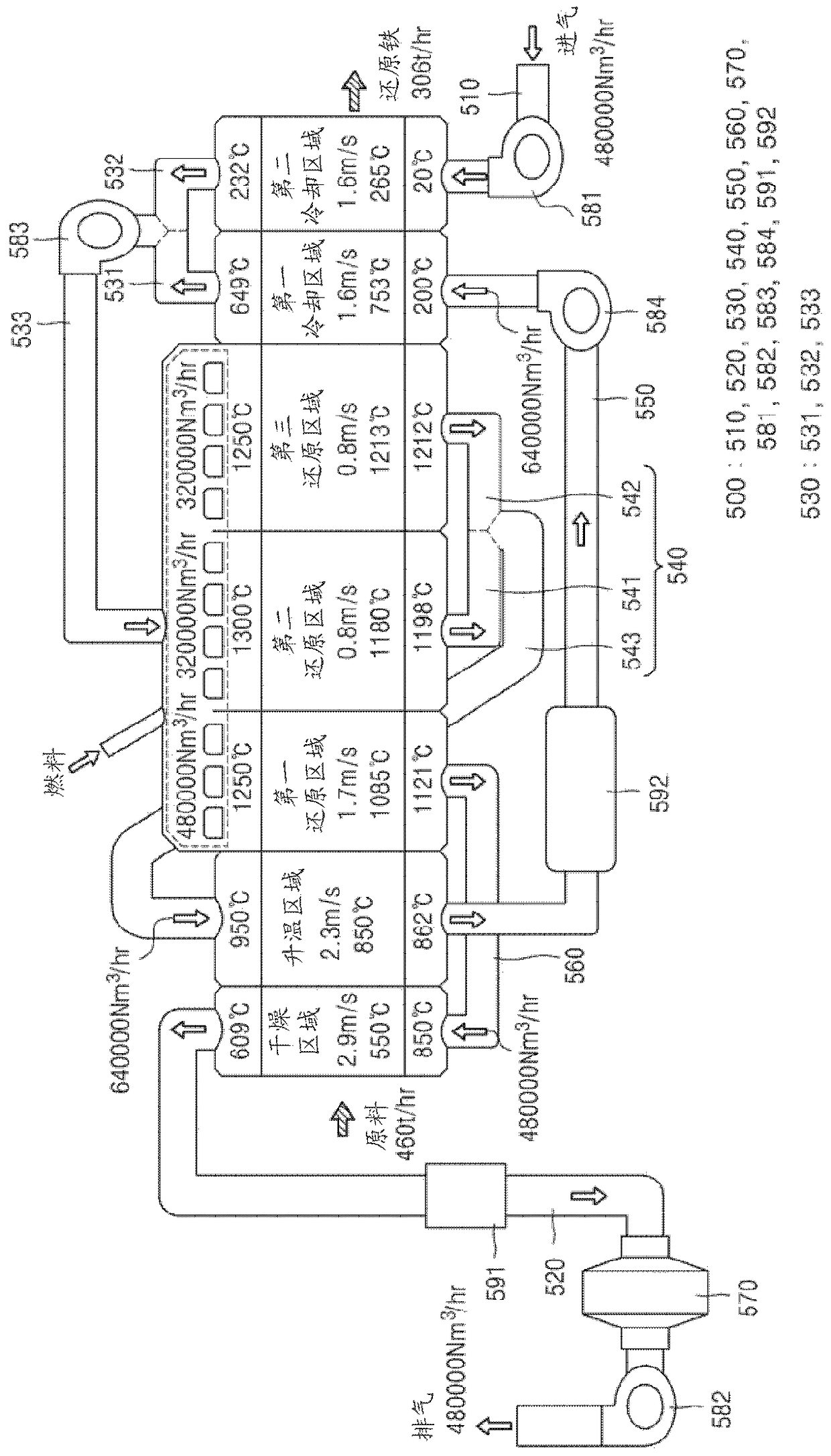

[0035]Embodiments of the present invention will be described in detail below with reference to the drawings. However, the present invention is not limited to the following examples, and can be implemented in various forms. Among them, the purpose of providing the embodiments of the present invention is to fully disclose the present invention and fully explain the scope of the invention to those skilled in the art. The dimensions in the drawings may be exaggerated for explaining the embodiments, and the same reference numerals in the drawings denote the same elements.

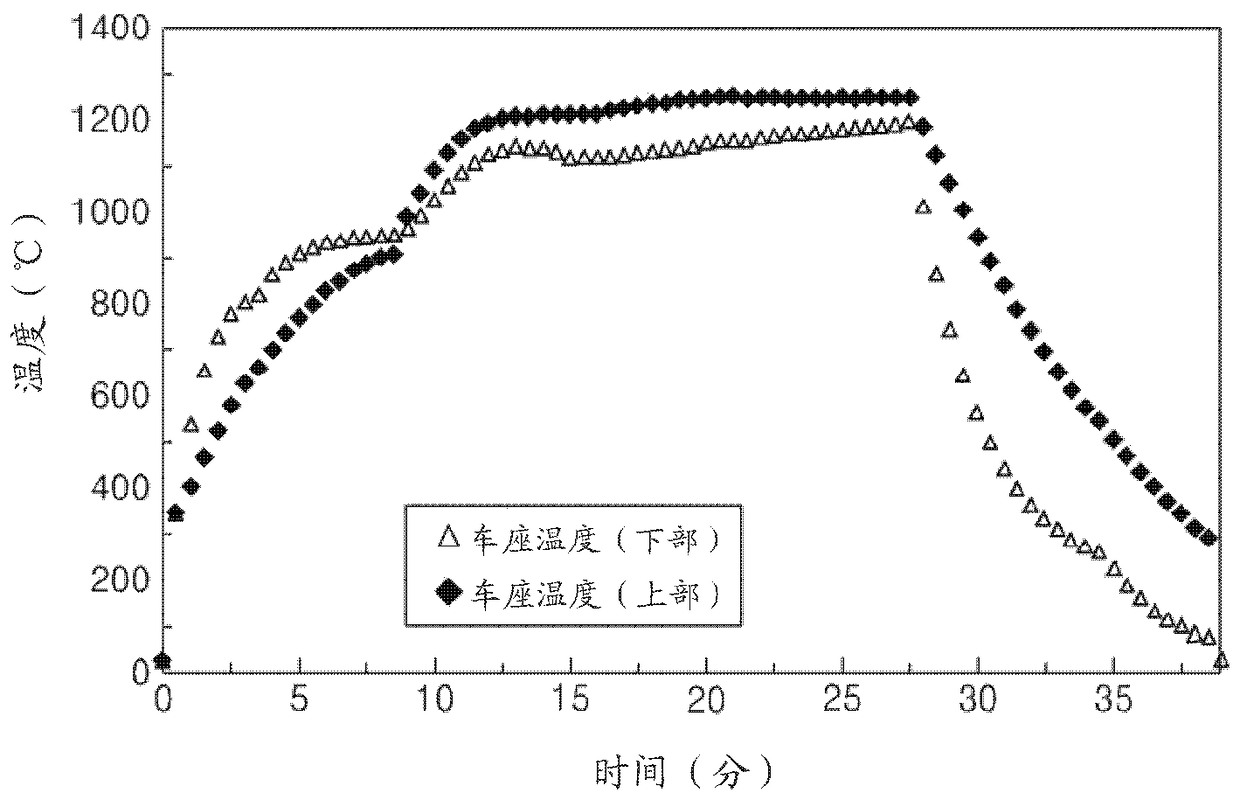

[0036] The firing apparatus according to the embodiment of the present invention is a firing apparatus for firing raw materials to produce reduced iron. The raw material to be heat-treated in the firing apparatus is, for example, carbon-containing briquettes. Carbon-containing pellets can be produced, for example, by adding coal to iron ore powder, mixing them uniformly, and forming them into lumps at normal t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com