Forming machine servo feeding mechanism with controllable feeding process

A technology of servo feeding and molding machine, applied in impedance network, loading/unloading, electrical components, etc., can solve the problem of unadjustable feeding angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

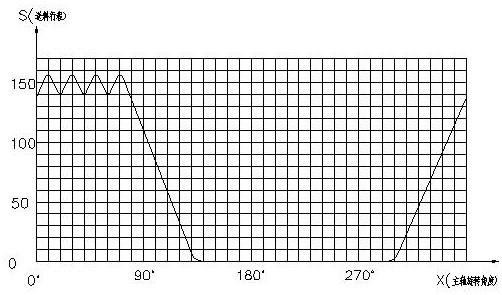

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

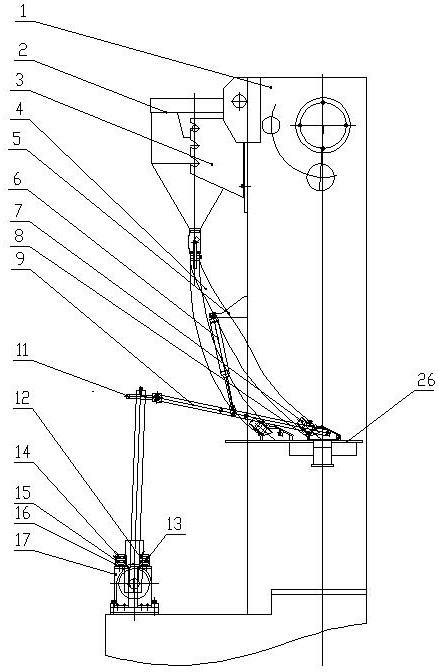

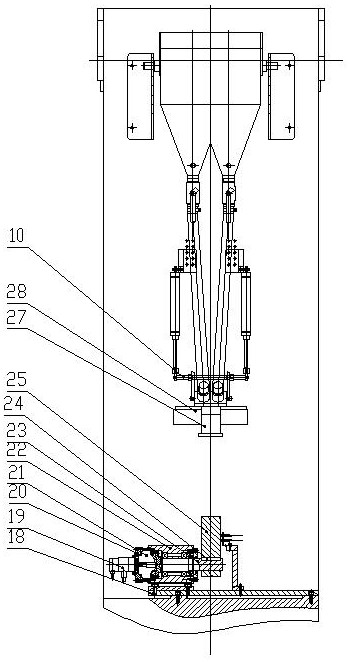

[0022] A forming machine servo feeding mechanism with controllable feeding process, including a bed, the lower part of the bed is provided with a reducer, the reducer is connected to a servo motor, and a swing rod is sleeved on the output shaft of the reducer. The upper end of the swing rod is hinged with a connecting plate, and the front end of the connecting plate is hinged with a feeding shoe. The female formwork of the bed formwork is provided with a feeding panel. The tensioning cylinder on the body, the lower end of the tensioning cylinder is hingedly connected with the middle part of the connecting plate, the lower punch is arranged under the female mold cavity of the female template, the upper part of the bed is provided with a hopper, the lower end of the hopper is provided with a rubber hose, and the rubber hose Connect with shoe.

[0023] As a further improvement of the above technical solution, the servo motor is connected to the reducer through a motor connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com