Member for miniaturizing molten glass droplet, method for producing glass gob, method for producing glass molding, and method for producing minute glass droplet

A technology of molten glass and a manufacturing method, which is applied in the fields of molten glass drop miniaturization components, glass clot manufacturing, glass forming body manufacturing, and glass micro droplet manufacturing, which can solve problems such as a large amount of labor and time, and achieve position deviation reduction, The effect of sufficient stability of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

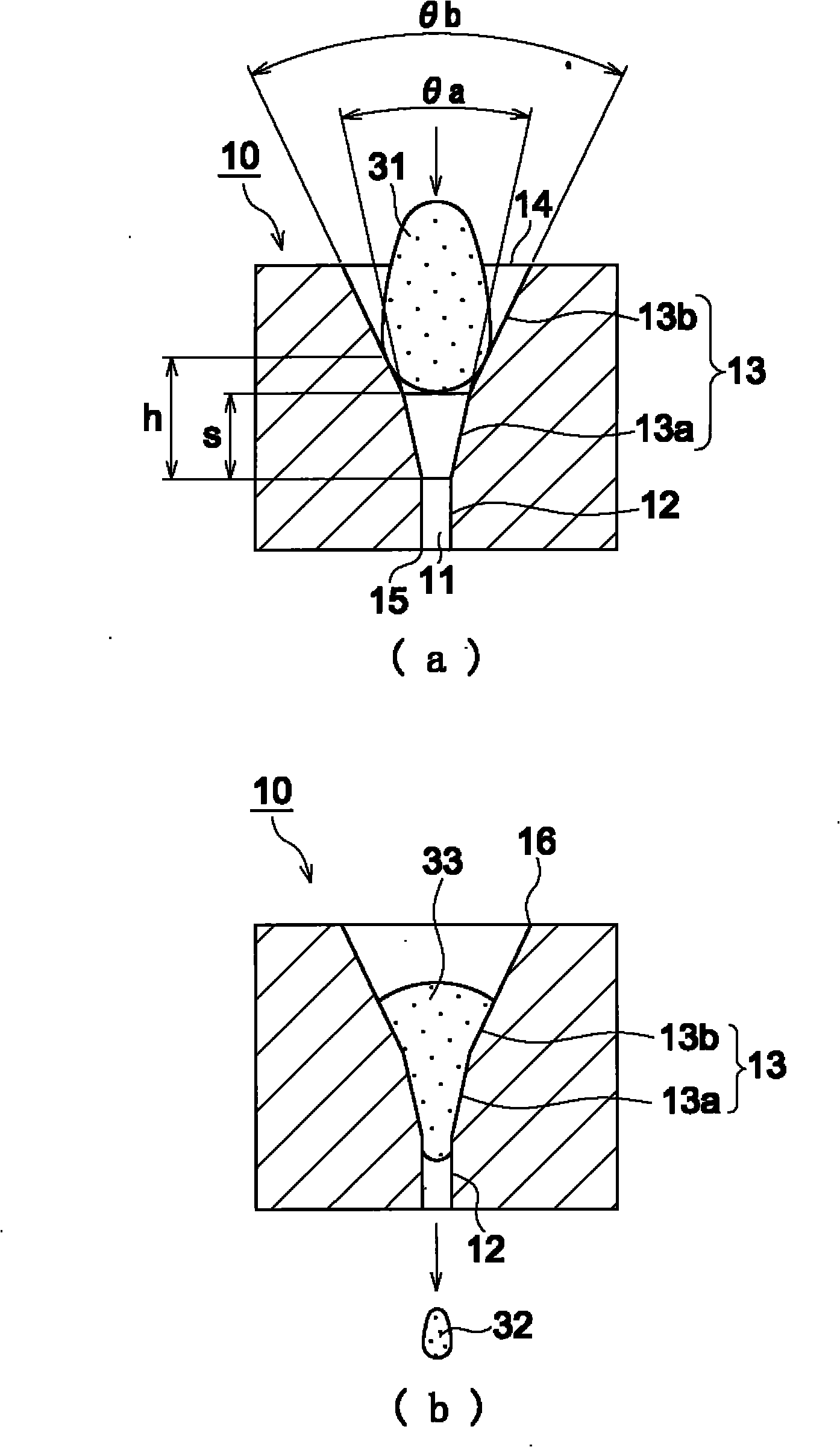

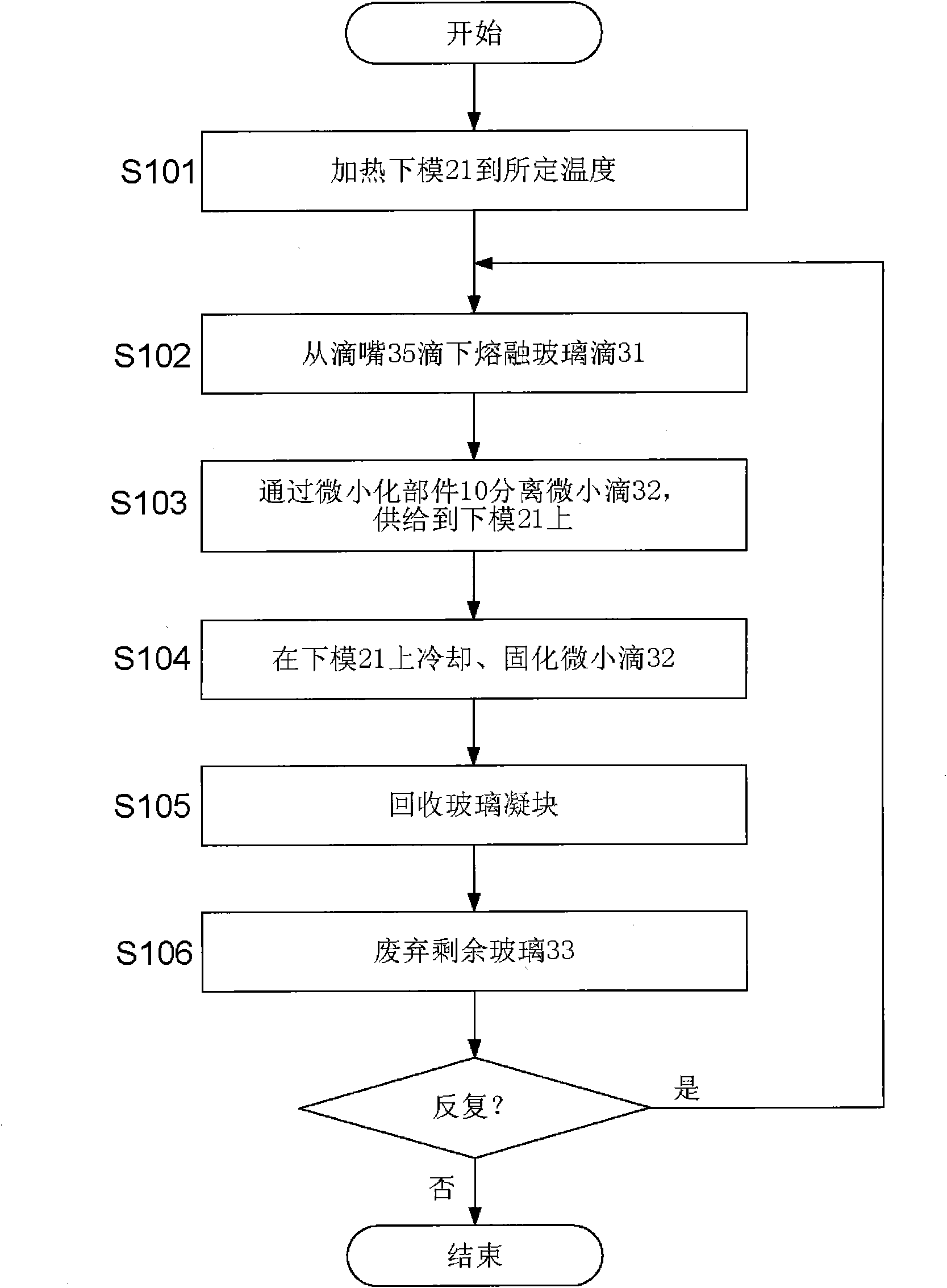

[0116] use as figure 1 The illustrated miniaturized component 10 having a conical portion 13 composed of two regions 13a, 13b with different conical opening angles is shown in accordance with image 3 In the flow shown, microdrops 32 are dropped on the lower mold 21 to make a glass gob.

[0117] Phosphoric acid-based glass with a Tg of 530° C. was used as the glass material, and molten glass drops 31 were dropped from a platinum drip nozzle 35 with an outer diameter of φ6 mm. The mass of the molten glass drop 31 dripped from the drip nozzle 35 was 250 mg.

[0118] The miniaturized component 10 employs nine types of cone portions 13 with different cone opening angles and heights (Examples 1 to 9). In Table 1, the cone opening angle θb of the area 13b that first contacts the molten glass drop 31, the cone opening angle θa of the area 13a closest to the straight portion 12, the height h of the entire area of the conical portion 13 that contacts the molten glass 31, The heigh...

Embodiment 10、11

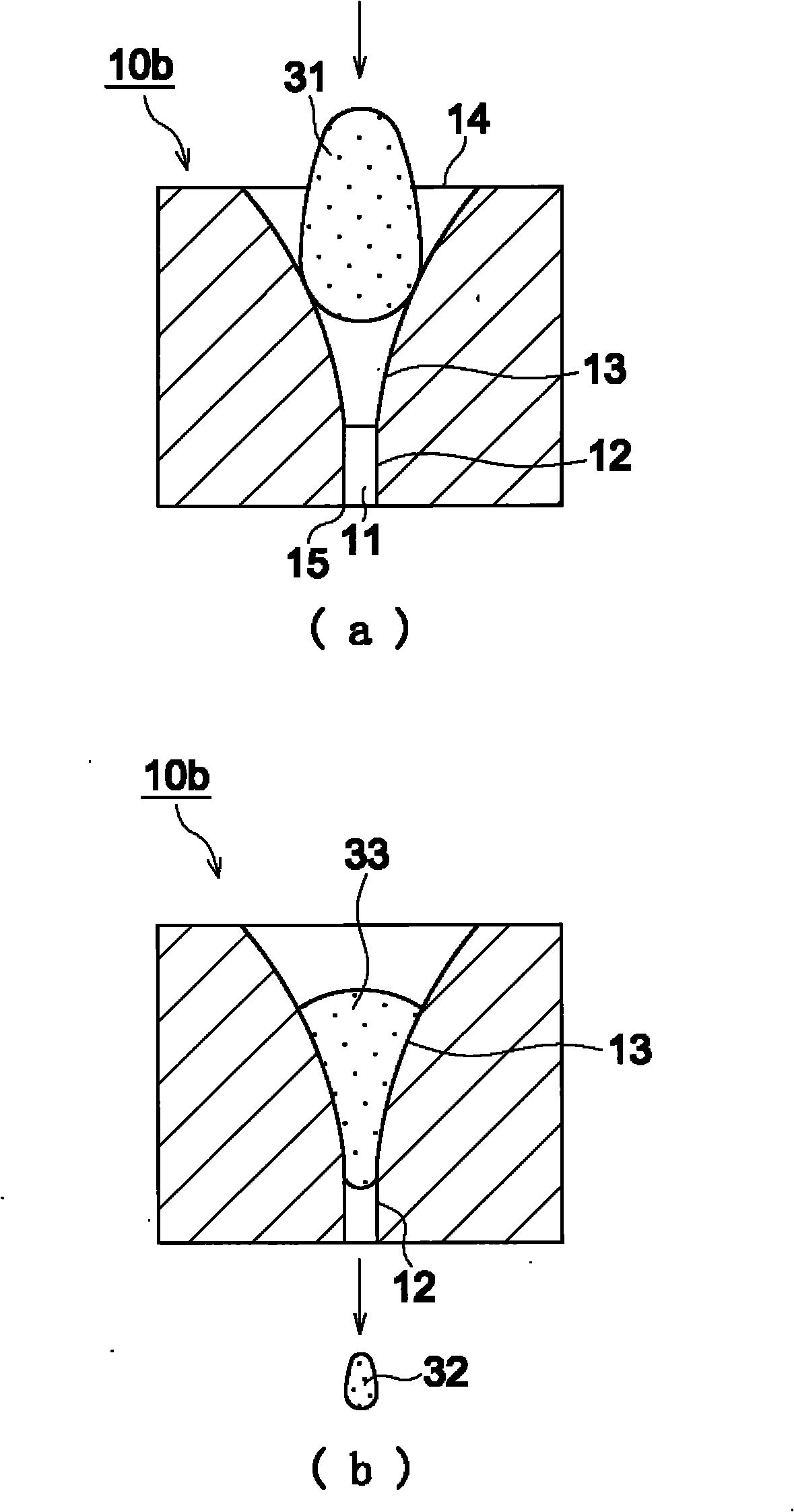

[0123] Adopted as a miniaturized part figure 2 The miniaturized component 10b is shown. The cross-sectional shape of the conical portion 13 including the central axis of the through hole 11 is substantially arc-shaped. There are two types of cone opening angles at the position of contacting the molten glass drop 31 first: 45° (Example 10) and 60° (Example 11). The opening angle of the cone decreases continuously as the straight portion approaches, and the boundary portion with the straight portion 12 is almost 0°. The straight portion 12 has a diameter of φ2 mm and a length of 5 mm.

[0124] Using the two types of miniaturized components 10b described above, 100 glass molded bodies were produced in the same manner as in Examples 1 to 9, and mass deviation and positional deviation were determined. The results are also presented in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com