Adhesive resin composition containing an amine-based accelerator, and a decorative film including same

A technology of adhesive resin and decorative film, applied in the field of decorative film and adhesive resin composition, can solve the problems of reducing processing efficiency and reducing the effect of fine lines on the surface of PET, so as to ensure coating stability and small quality deviation. , the effect of increasing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

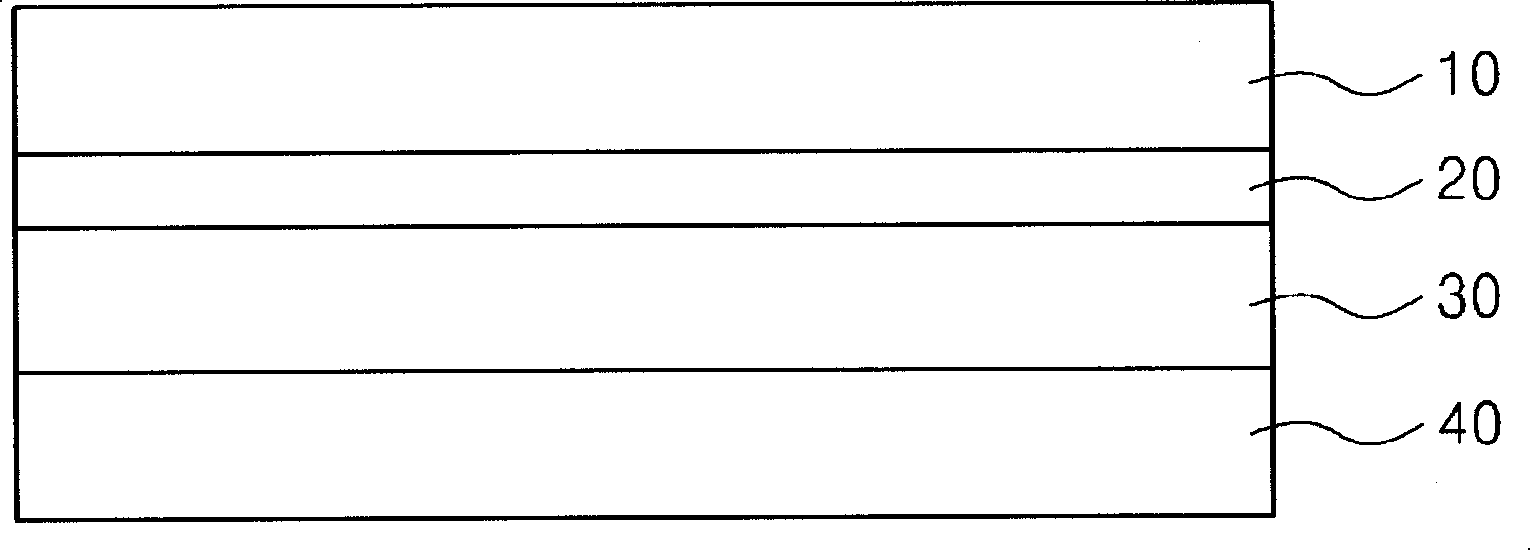

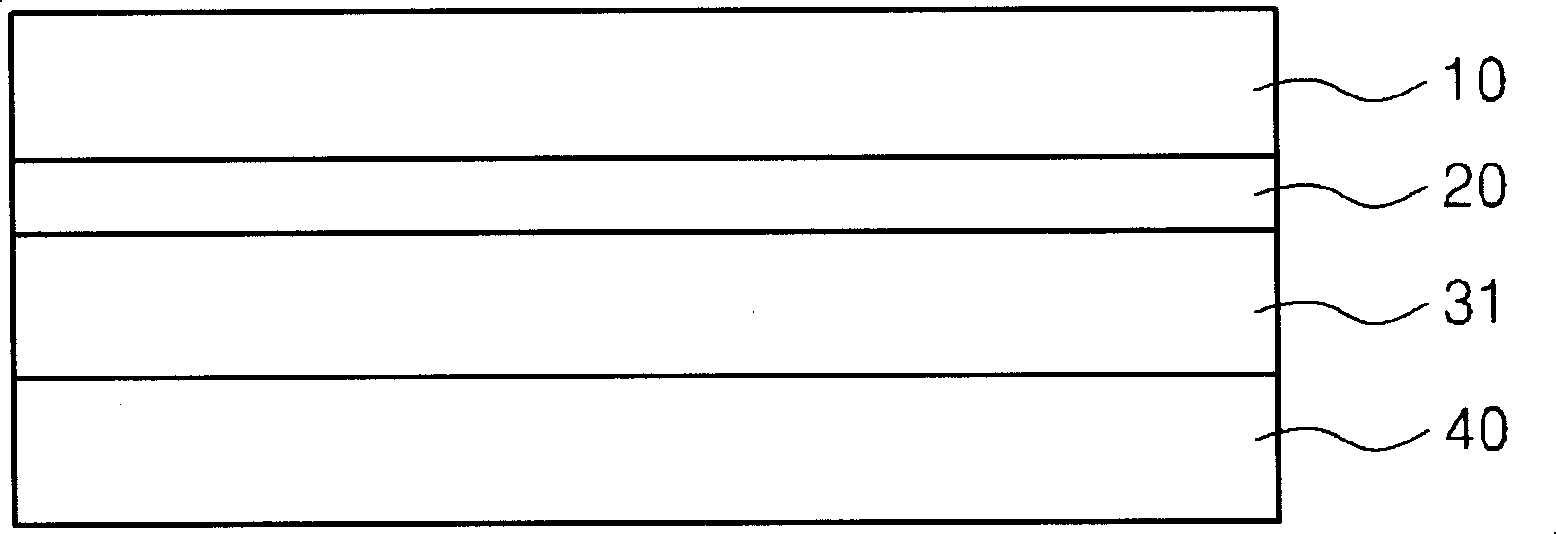

[0119] at 10 -4 Aluminum was vacuum-deposited at 1400° C. on a generally untreated PET film with a thickness of 30 μm as the base layer, thereby forming a layer with a thickness of layer of metal treatment. Then, the binder resin composition was applied to a 100 μm thick soft PV film (including 25 wt % of a plasticizer) as a coating film layer, thereby forming a 10 μm thick binder resin layer. Subsequently, the base layer formed of the metal-treated layer and the binder resin layer was dry-laminated, thereby manufacturing a decorative film.

[0120] One binder resin is an ester resin (solution with a solid content of 30 wt%), which includes NPG, EG, isophthalic acid, and terephthalic acid. The curing agent was of the TDI adduct type (solution with NCO content 7 wt%). The coupling agent was epoxysilane compound KBM403 (Shin-Etsu Chemical Co., Ltd.). The accelerator is an aziridine compound shown in Formula 4.

[0121] The composition of the components is listed in Table 1...

Embodiment 2

[0125] A decorative film was produced in the same manner as in Example 1 except that a glycidylamine compound represented by Formula 10 was used as an accelerator.

Embodiment 3

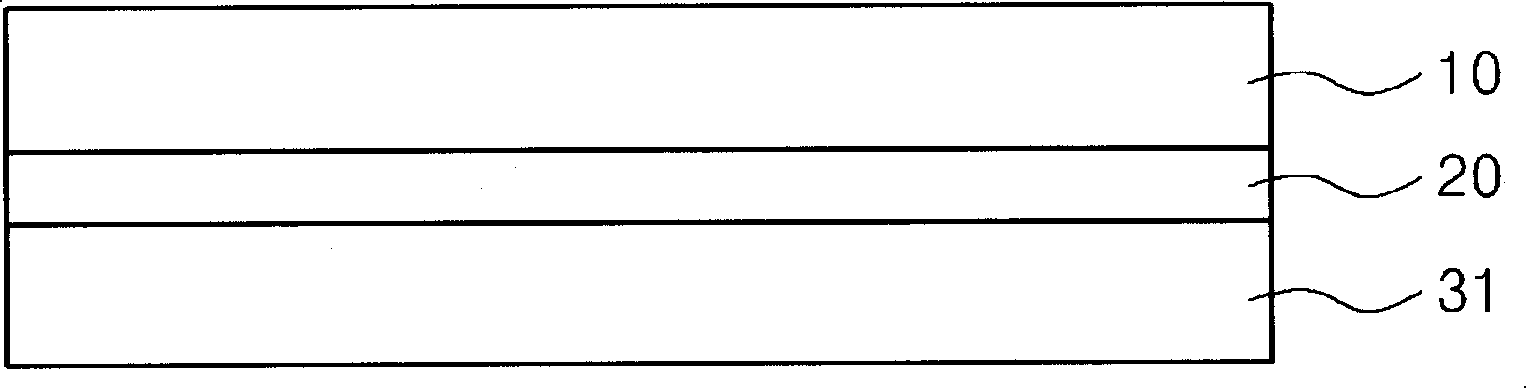

[0127] A decorative film was manufactured in the same manner as in Example 1 except that SL10 (a co-extruded sheet of PET and polyester resin having a thickness of 30 μm) manufactured by SKC Inc. was used as the base layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com