Multi-station charging equipment of packaging machine

A feeding equipment and multi-station technology, applied in the direction of packaging, etc., can solve the problems of low material extrusion rate, unguaranteed material uniformity, and small space for extrusion chute.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

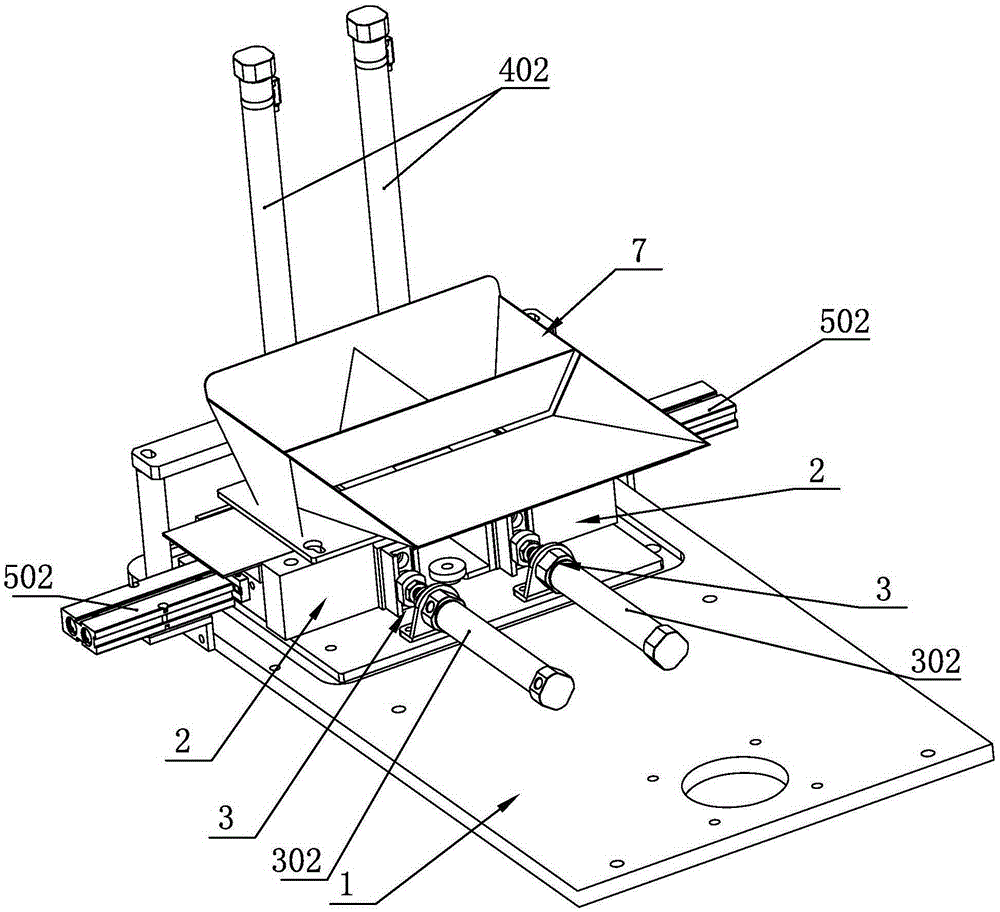

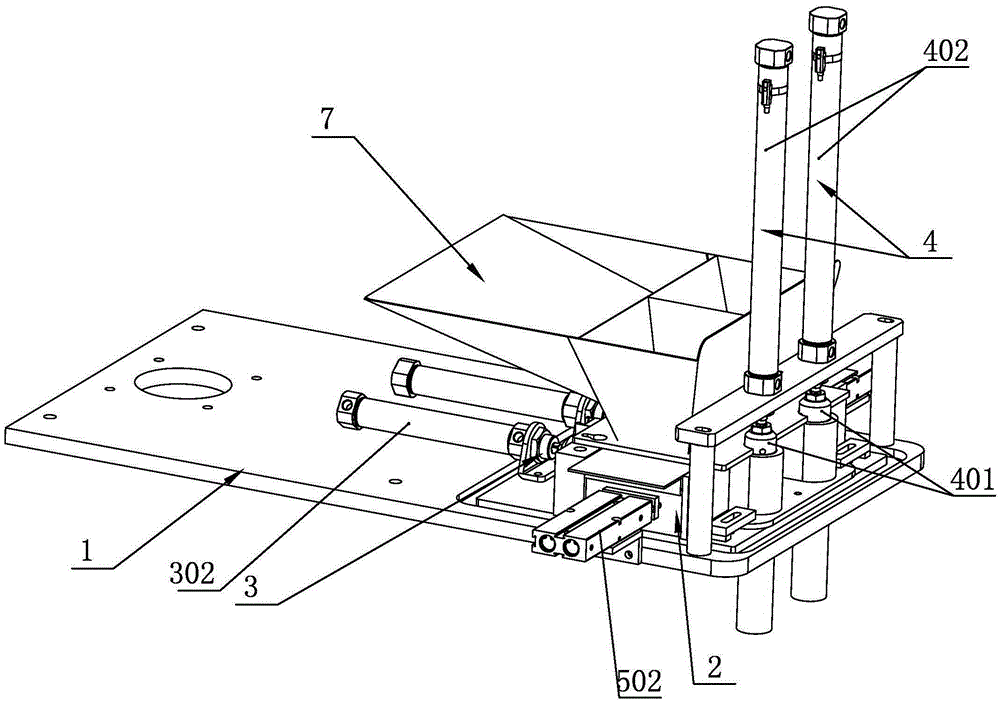

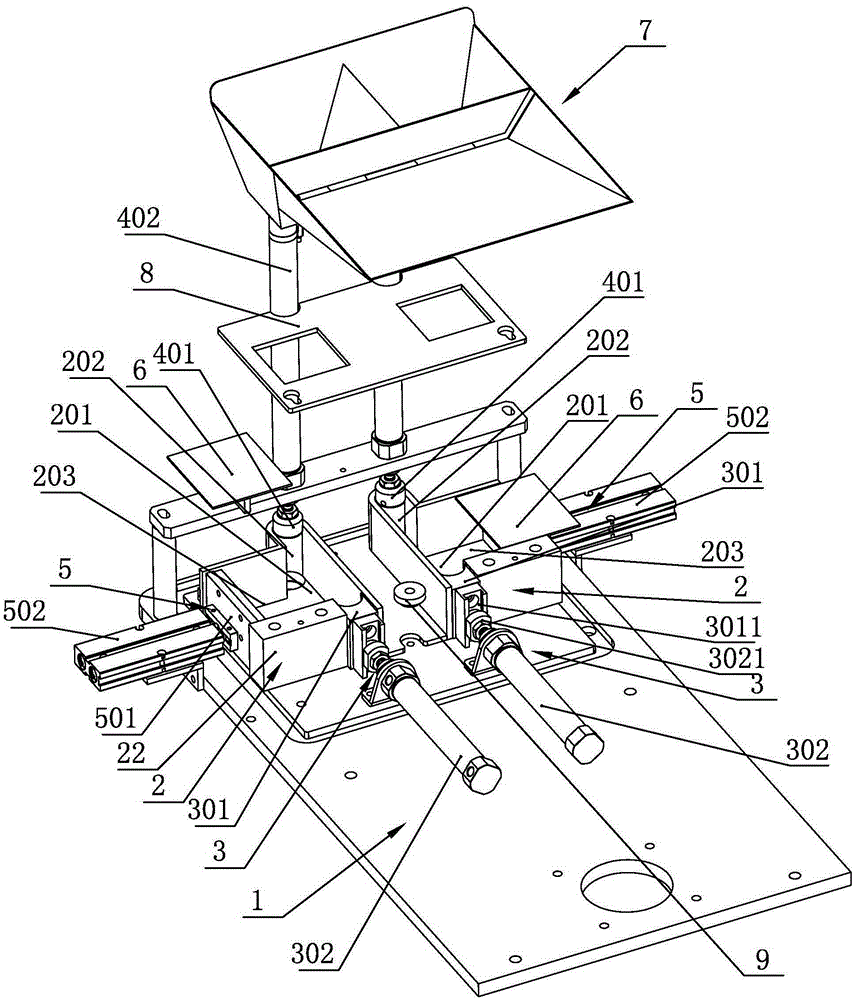

[0022] See attached figure 1 to attach Figure 4 , the multi-station feeding equipment of the packaging machine disclosed in the present invention includes a bottom plate 1 and at least two groups of feeding devices arranged on the bottom plate 1, and the feeding devices each include a housing 2 provided with a material accommodating cavity, The first extruding mechanism 3 and the blanking mechanism 4, the top of the housing 2 is provided with an opening, the first extruding groove 201 is arranged in the material accommodating cavity, and one end of the first extruding groove 201 is provided with The blanking channel 202, the first extrusion mechanism 3 includes a first extrusion push block 301 and a first extrusion drive unit 302 that drives the first extrusion push block 301 to move along the first extrusion groove 201 , the blanking mechanism 4 includes a blanking push block 401 and a blanking drive unit 402 that drives the blanking push block 401 to move along the blankin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com