Profiling vibration-damping crawler type traveling chassis of grain combine harvester

A combine harvester and walking chassis technology, applied in tracked vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of heavy machine weight, long track length, severe bumps, etc., to enhance bearing capacity and avoid vertical vibration , the effect of strengthening the connection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

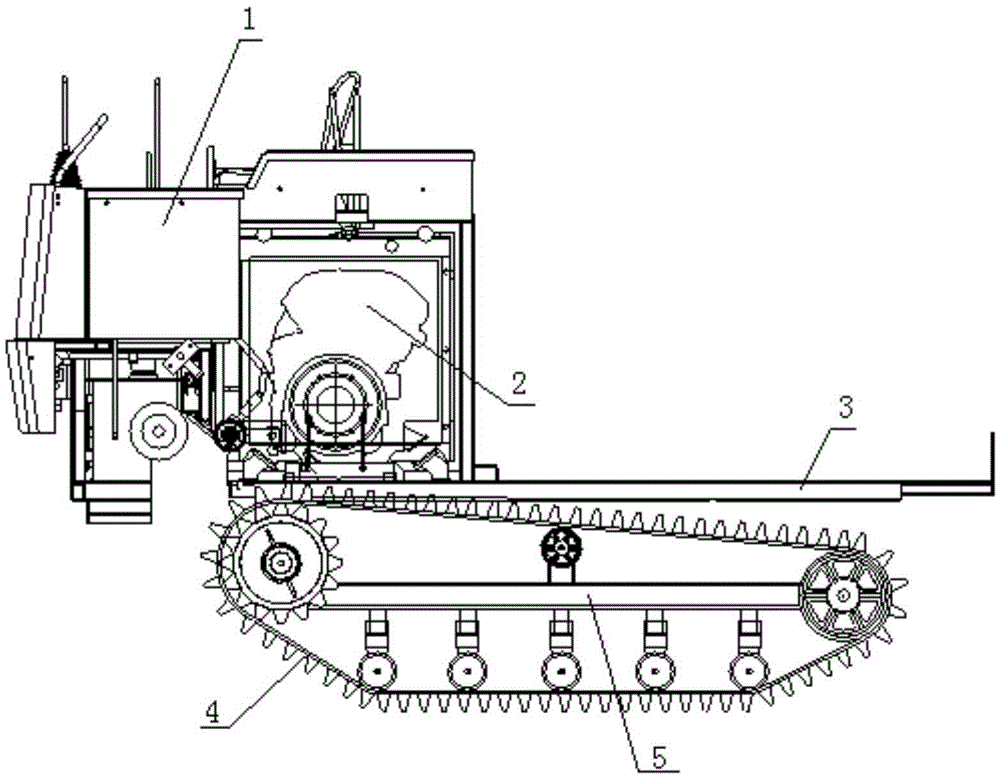

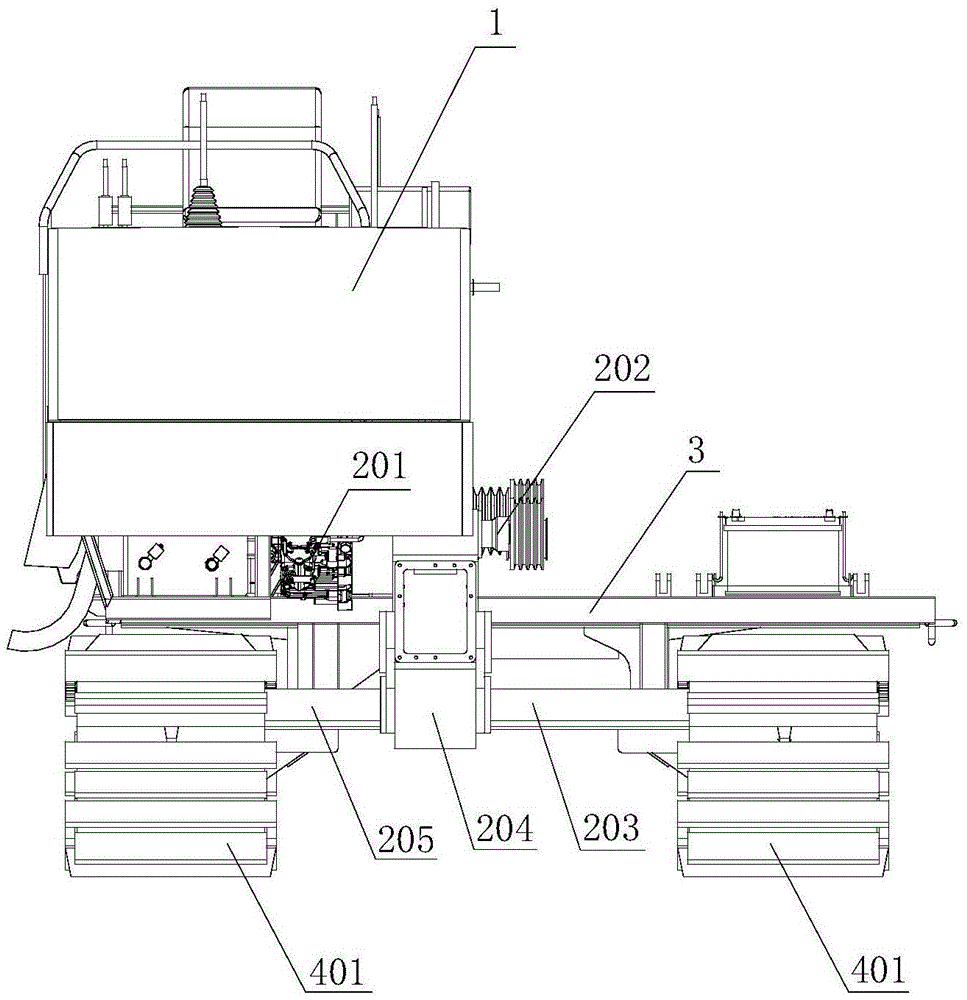

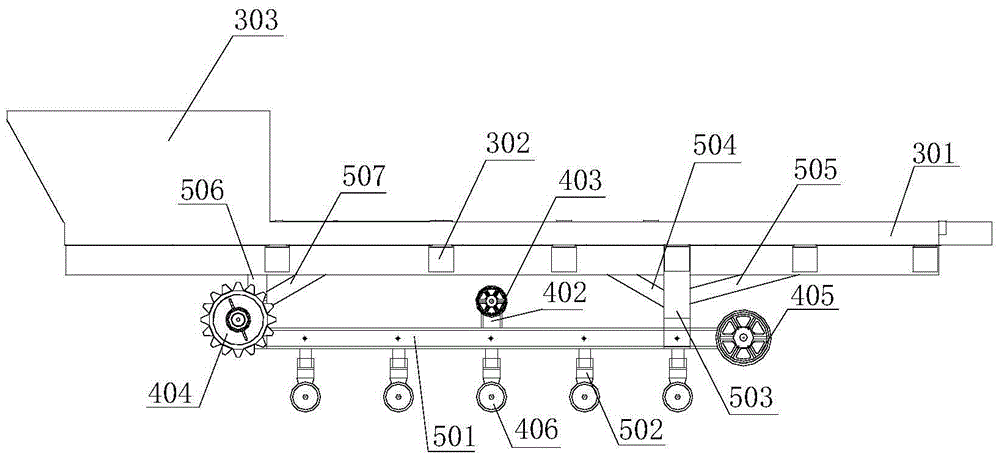

[0031] Such as figure 1 As shown, a profiling vibration-absorbing crawler-type walking chassis of a grain combine harvester includes a driving control system 1, a power transmission system 2, a chassis frame 3 and a crawler mechanism, and the driving control system 1 and the power transmission system 2 are located on the chassis frame. Above 3, the crawler mechanism is located below the chassis frame 3, and two groups of crawler mechanisms are arranged symmetrically about the central axis of the chassis frame 3; each group of crawler mechanisms includes a crawler running mechanism 4 and a crawler support mechanism 5. Such as figure 2 As shown, the power transmission system 2 mainly includes an engine 201, a power output end 202, a gearbox 204, a power transmission right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com