A profiling grain harvesting wheel structure

A technology of grain wheel and grain harvesting piece, which is applied in the field of profiling grain harvesting wheel structure, can solve problems such as grain omission, and achieve the effect of simple structure and novel structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

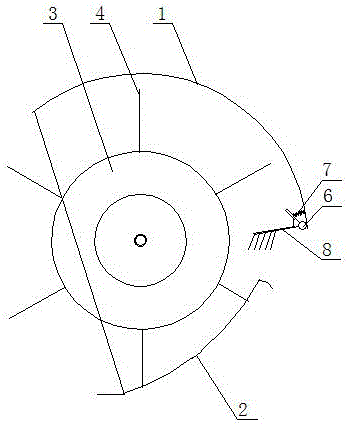

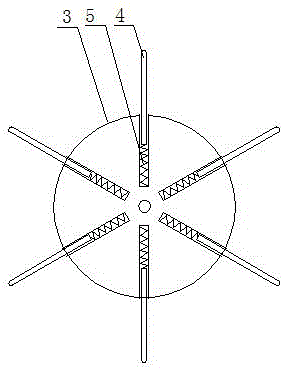

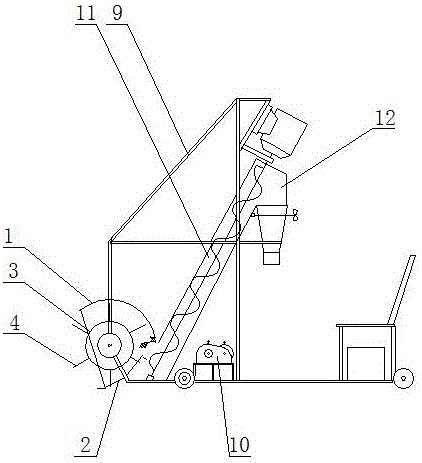

[0013] The grain harvesting wheel structure includes a protective cover 1, a grain shoveling plate 2, a grain harvesting cylinder 3, a grain harvesting sheet 4 and a compression spring 5, and a grain shoveling plate 2 is arranged below the grain harvesting cylinder 3; the upper diameter of the circumference of the grain harvesting cylinder 3 To be provided with a plurality of assembly grooves, in each assembly groove, a grain harvesting sheet 4 is installed by a compression spring 5; the other end of the grain harvesting sheet 4 extends to the outer end of the assembly groove. One end of the compression spring 5 is fixed on the bottom of the assembling groove, and the other end of the compression spring 5 is fixedly connected with the grain collection sheet 4; The grain harvesting cylinder 3 tops are provided with a protective cover 1, and the grain clearing brush 8 is movably installed with a pin shaft 6 and a spring 7 on the protective guard 1; figure 1 -2).

[0014] The gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com