Sandwich type round plate stator and ultrasonic motor using the same

An ultrasonic motor, sandwich technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve problems such as mechanical output capacity constraints, achieve simplified structure, improve controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

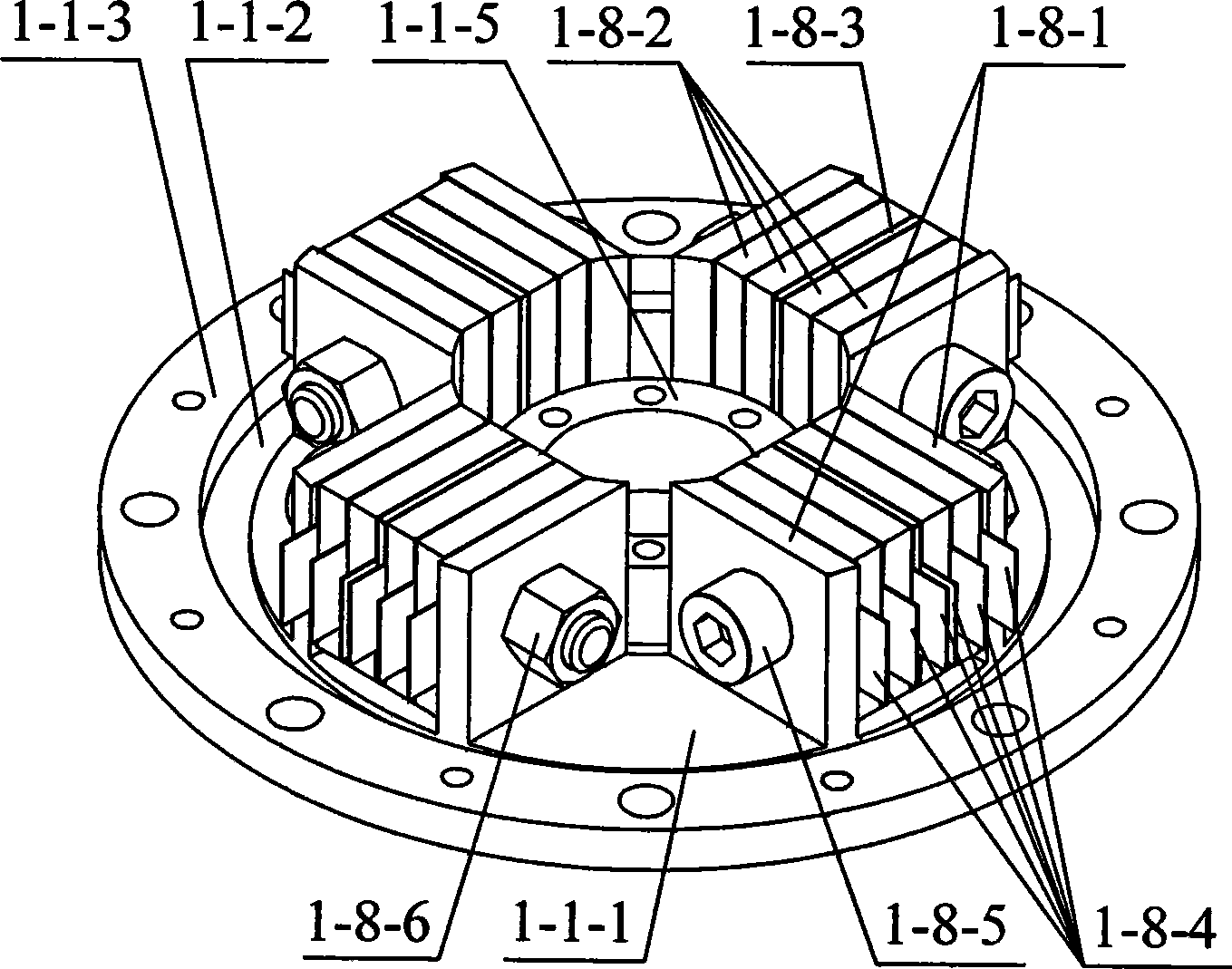

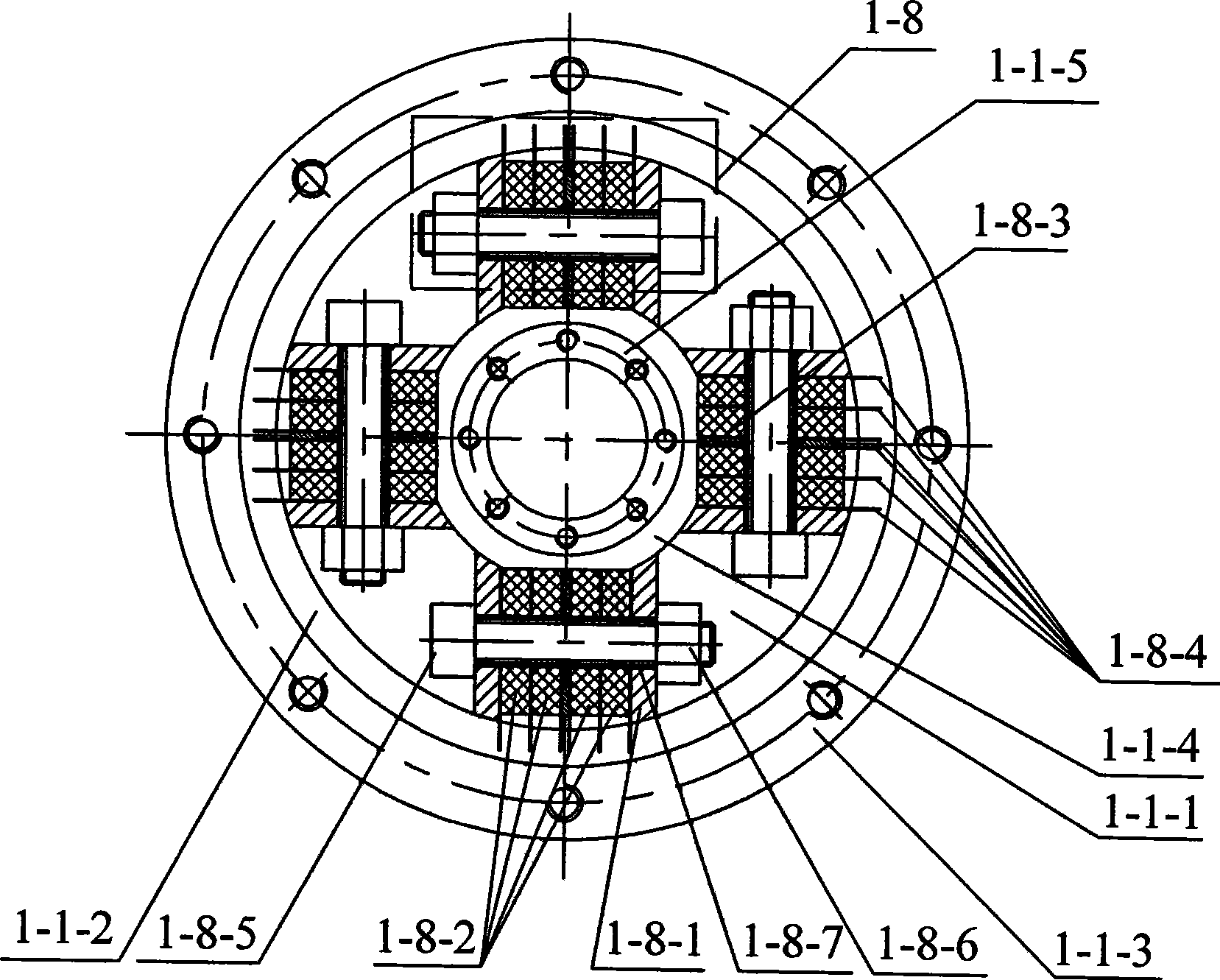

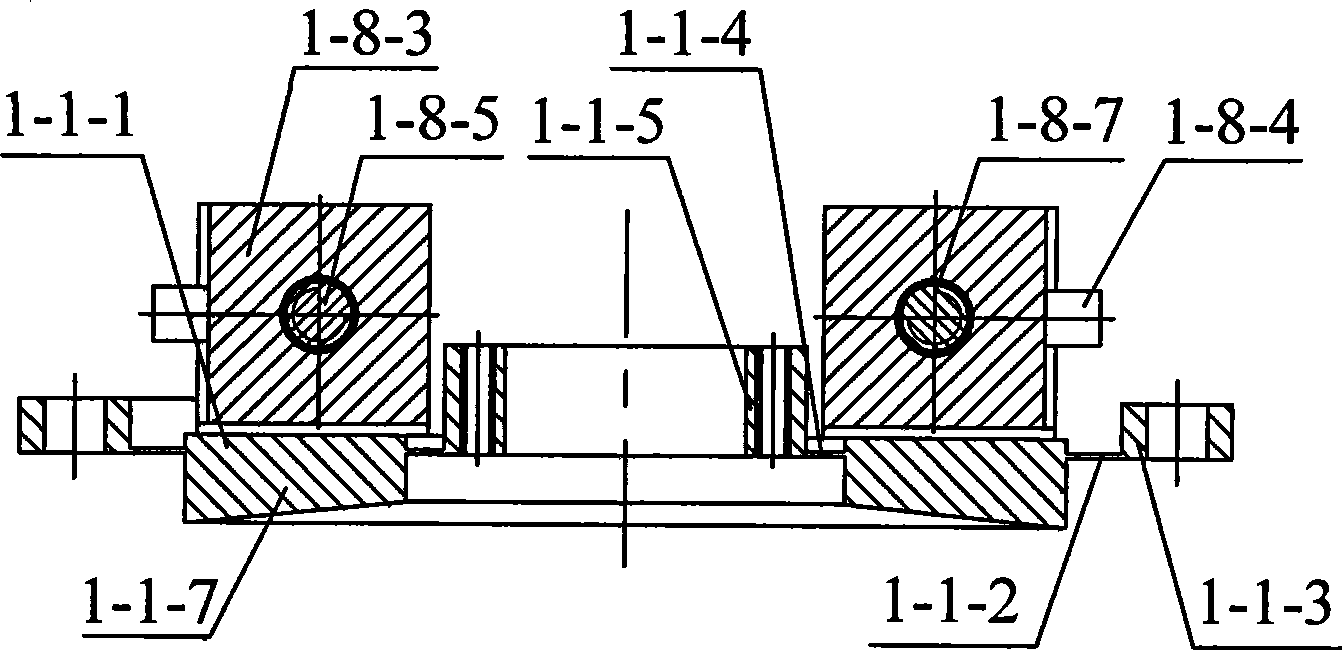

[0010] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment, this embodiment is made up of driving disc 1-1 and even number of driving assemblies 1-8; Said driving disc 1-1 is composed of disc 1-1-1, outer thin-walled ring 1-1-2, The flange 1-1-3, the inner thin-walled ring 1-1-4 and the bearing seat 1-1-5; the outer thin-walled ring 1-1-2 is arranged on the disc 1-1-1 and the flange 1-1- 3; the inner thin-walled ring 1-1-4 is arranged between the disc 1-1-1 and the bearing seat 1-1-5; the central axis of the disc 1-1-1, the outer thin-walled ring 1- The central axis of 1-2, the central axis of flange 1-1-3, the central axis of inner thin-walled ring 1-1-4 and the central axis of bearing seat 1-1-5 are located on the same axis; the drive assembly 1- 8 consists of two cantilever beams 1-8-1, four piezoelectric ceramic sheets 1-8-2, adjusting gaskets 1-8-3, copper electrodes 1-8-4, and pre-tightening screws 1-8-5 , pre-tightening nut 1-8-6 a...

specific Embodiment approach 2

[0012] Embodiment 2: This embodiment differs from Embodiment 1 in that the disk 1-1-1, the outer thin-walled ring 1-1-2, the flange 1-1-3, the inner thin-walled ring 1-1-4, The bearing seat 1-1-5 and the cantilever beam 1-8-1 are processed into an integral piece using a single piece of metal material. Other compositions and connection methods are the same as those in Embodiment 1. Adopting this structure can achieve the purpose of reducing energy loss, and is beneficial to improving the controllability of the particle vibration track on the surface of the driving tooth.

specific Embodiment approach 3

[0013] Embodiment 3: This embodiment differs from Embodiment 1 in that the distance between the two center planes of the two cantilever beams 1-8-1 is half the wavelength of the bending vibration of the disc. Other compositions and connection methods are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com