Tuning mass damping device

A technology of vibration damping device and quality tuning, applied in building components, anti-vibration and other directions, can solve the problems of difficult adjustment of spring unit stiffness, reduce the effectiveness of TMD, frequency imbalance, etc., achieve convenient and effective stiffness and quality adjustment, reduce requirements, and use materials easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] While the present invention will be fully described with reference to the accompanying drawings containing preferred embodiments of the invention, it should be understood before proceeding that those skilled in the art may modify the invention described herein while obtaining the technical effects of the present invention. Therefore, it should be understood that the above description is a broad disclosure for those skilled in the art, and its content is not intended to limit the described exemplary embodiments of the present invention.

[0020] Specific examples of the vertically tuned mass damping device are described below.

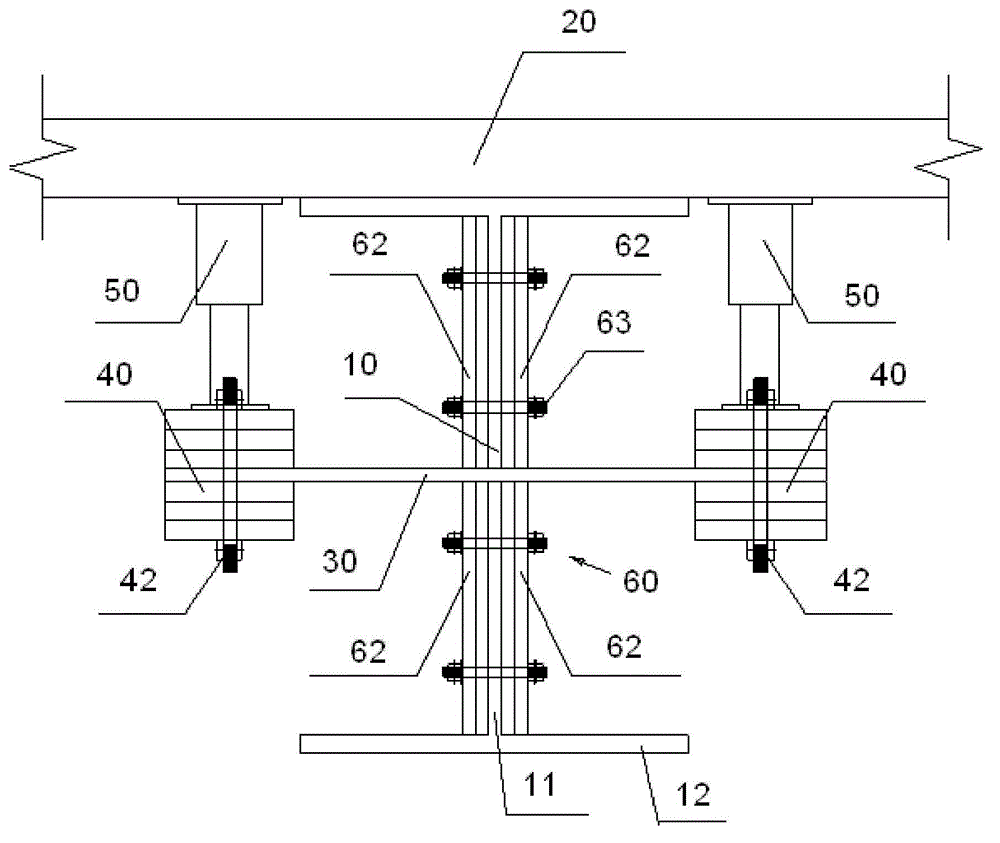

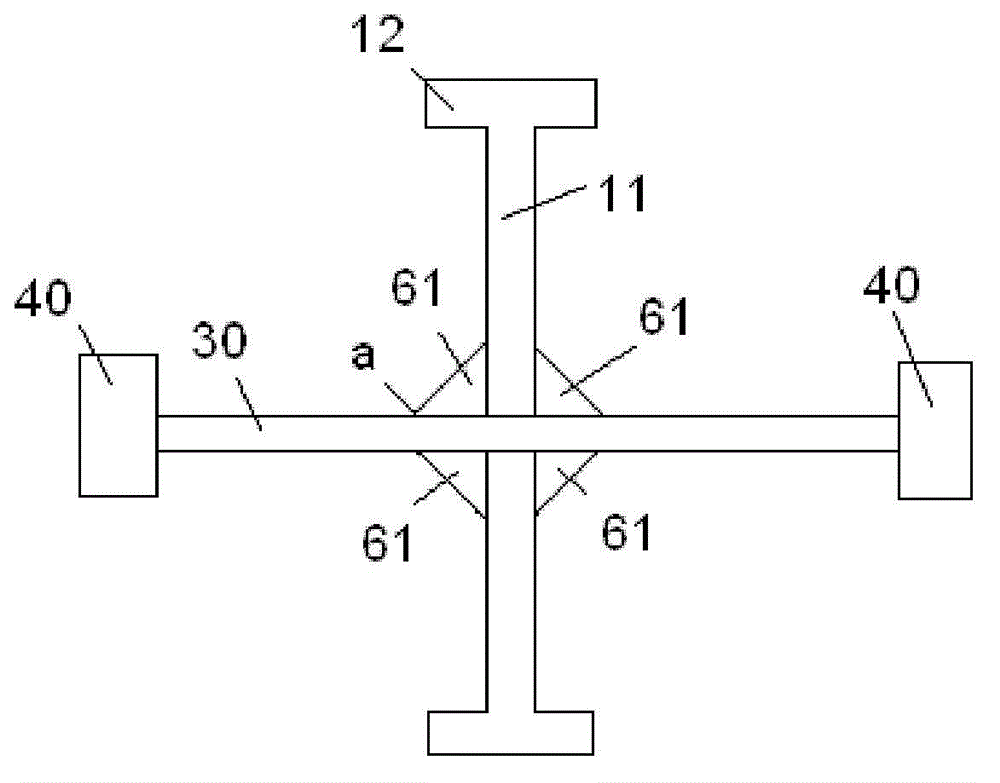

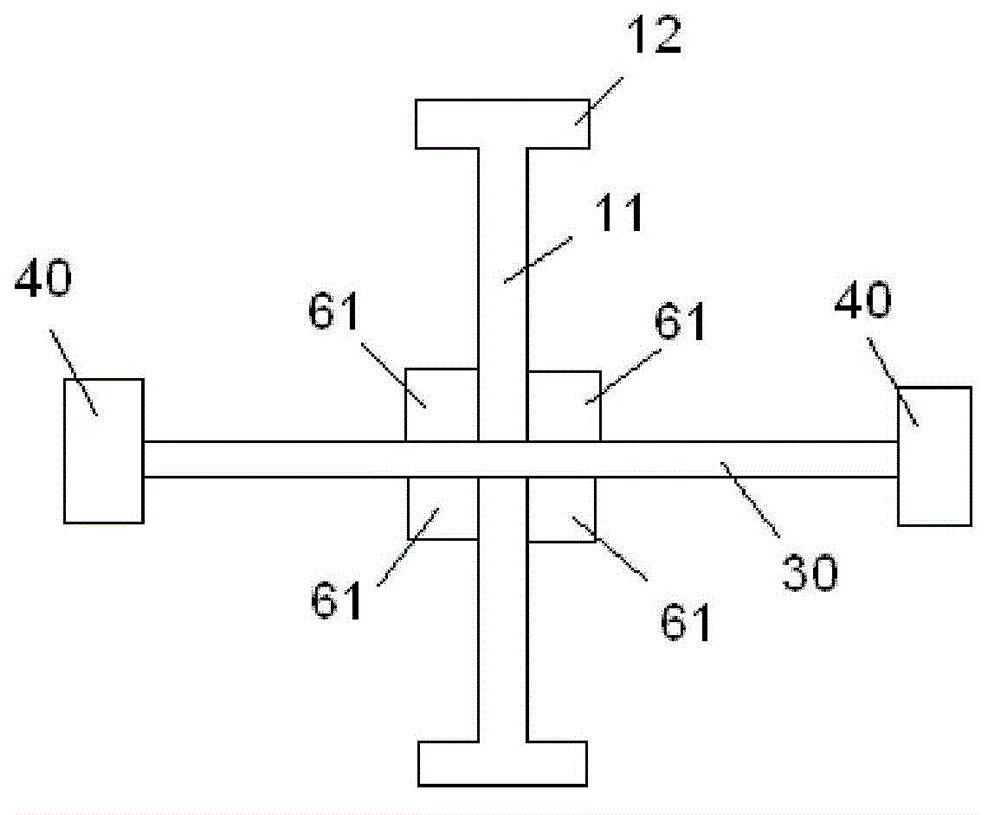

[0021] Such as Figure 1-3 As shown, the vertical tuning mass damping device includes: a profile 10 with a web 11, the profile 10 is fixed on the structural member 20 to be damped; a leaf spring 30 passes through the web of the profile 10 in the horizontal direction plate 11, and arranged symmetrically with respect to the web 11; mass blocks 40 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com