Large-stroke high-sensitivity turning tool nose height precision adjustment device

A high-sensitivity, precise adjustment technology, applied in the direction of auxiliary devices, turning equipment, toolholder accessories, etc., can solve the problems of not being able to adjust micron-level precision, adding spring adjustment sleeves, and affecting the rigidity of turning tools, so as to achieve good rigidity and easy replacement. Easy installation and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

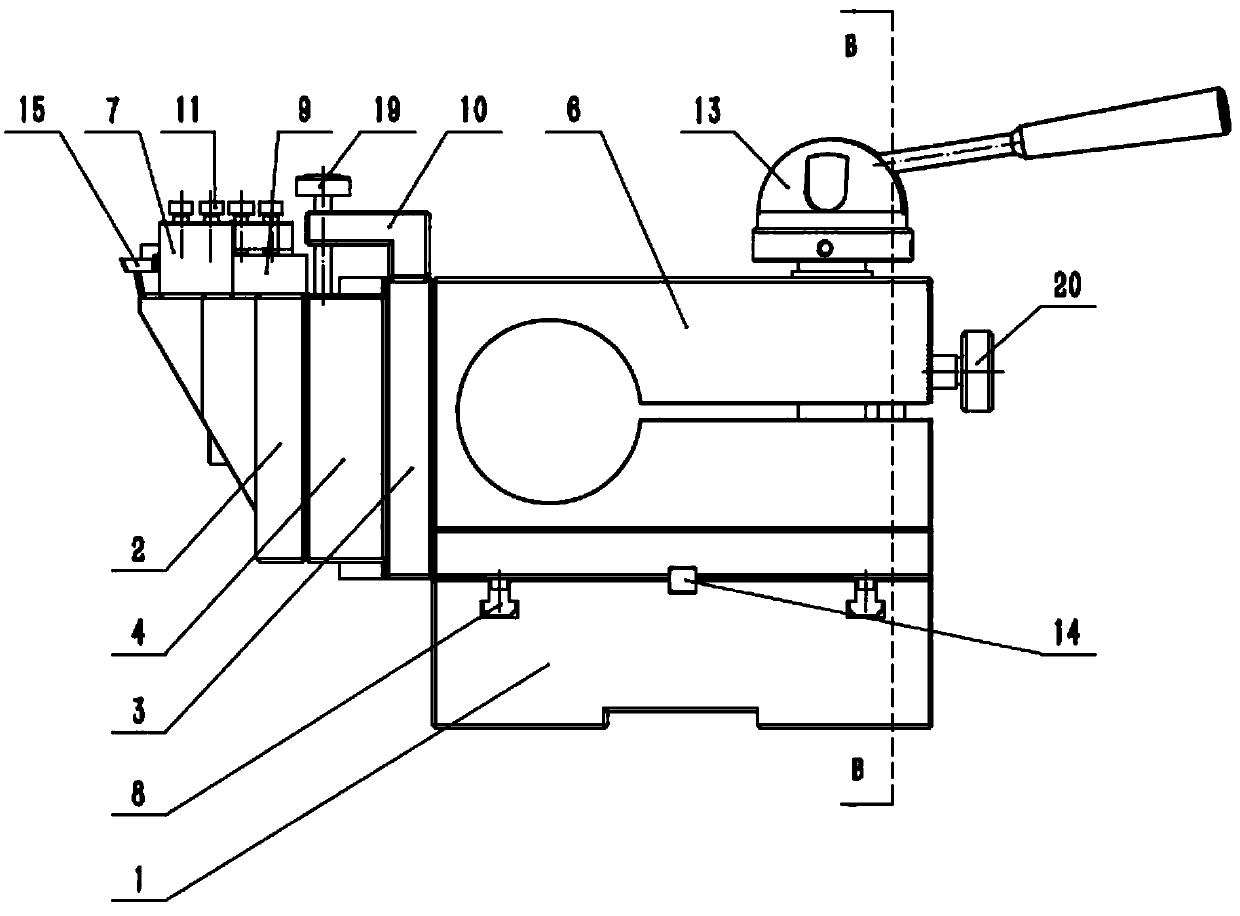

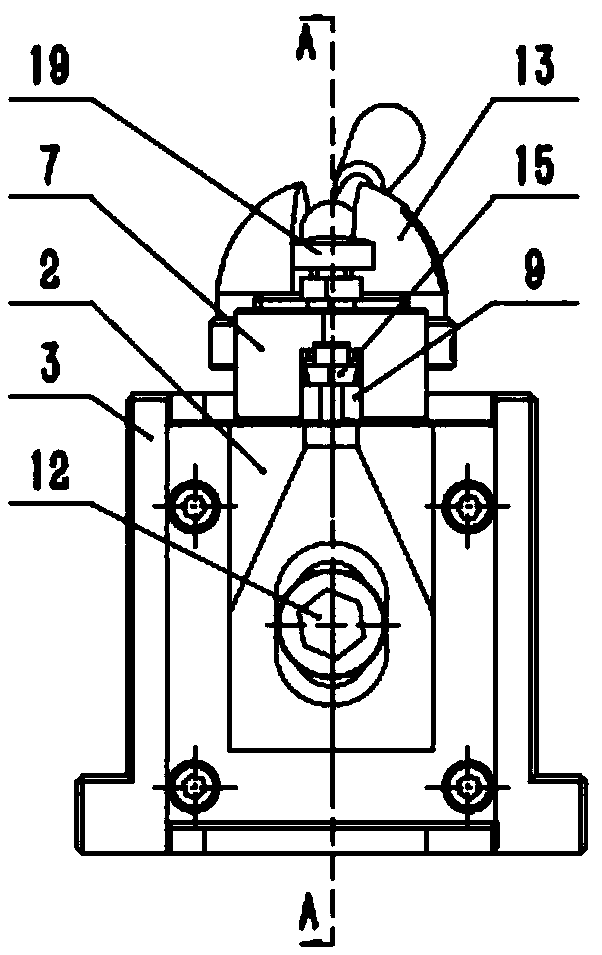

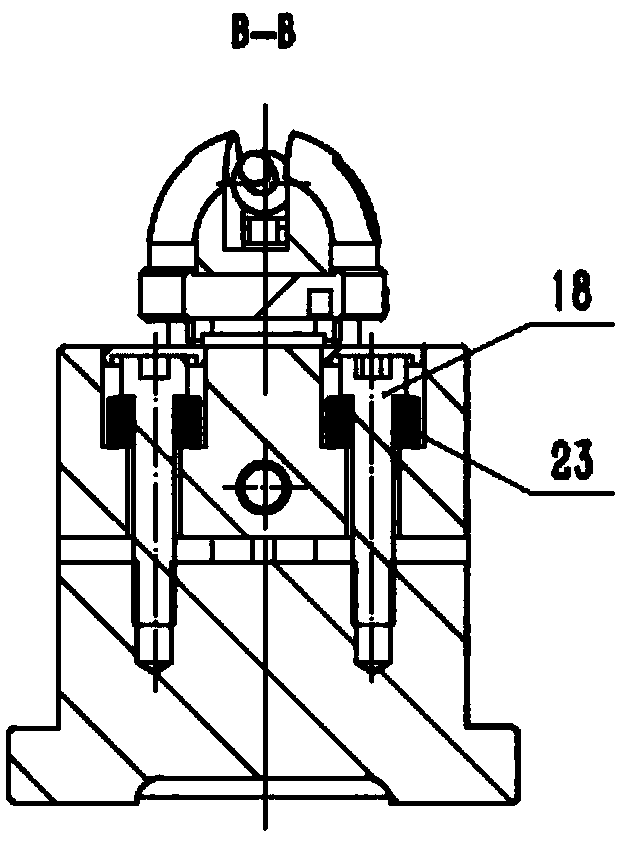

[0032] Such as figure 1 , 2 , As shown in 3 and 4, a large-stroke high-sensitivity turning tool tip height precision adjustment device, including a base 1, a linear-guided moving mechanism (such as a dovetail guide rail) with a locking mechanism fixed on it, installed on a linear The movable knife seat 2 on the moving mechanism (dovetail guide rail), the fixed knife seat 6, the locking screw 12, the coarse adjustment screw 19, the fine adjustment screw 5, the pre-tightening screw 18 and the fine adjustment handle 13, the fixed knife seat 6 is one Rectangular cube, the left side of described fixed knife seat 6 is fixed with fixed block 3, and the left side position of described fixed knife seat 6 is provided with a through hole of large caliber along the vertical direction, and is arranged on the right side wall of through hole There is an open gap, which divides the right side of the fixed knife seat 6 into two parts, the upper knife seat and the lower knife seat, and the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com