Needle-like petroleum coke and processing process thereof

A processing technology, petroleum coke technology, applied in the field of needle coke preparation, can solve the problems of complex hydrogenation technology, high use cost, inconvenient operation, etc., and achieve the effect of wide application range, high practicability, and reasonable ratio design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

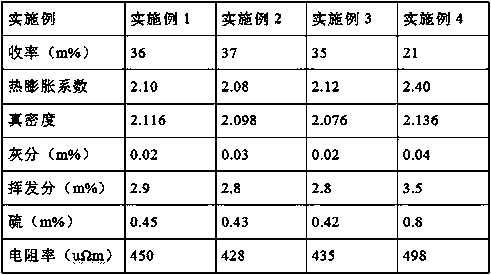

Examples

Embodiment 1

[0049] First prepare raw materials, weigh catalytic cracking clarified oil, coking heavy wax oil and cellulose in proportion, and set aside; then prepare pretreatment agent: weigh formic acid, hydrogen peroxide, ferrous sulfate heptahydrate, extractant, catalyst, Acrylic acid, initiator, crosslinking agent, carboxymethyl chitosan, sodium hydroxide, spare;

[0050] Then take the prepared pretreatment agent to pretreat the catalytic cracking clarified oil; put the catalytic cracking clarified oil into a four-necked flask, stir evenly, and heat to 80°C; then dissolve ferrous sulfate heptahydrate in deionized water, And put it into a four-necked flask, continue to heat up to 80 ° C; then add formic acid and hydrogen peroxide, react for 20 minutes, cool down to 20 ° C in a cold water bath, and separate oil and water; then at 20 ° C, use an extractant to extract 3 times to obtain the material A; then add carboxymethyl chitosan to the prepared material A, stir evenly, place it in a c...

Embodiment 2

[0057] First prepare raw materials, weigh catalytic cracking clarified oil, coking heavy wax oil and cellulose in proportion, and set aside; then prepare pretreatment agent: weigh formic acid, hydrogen peroxide, ferrous sulfate heptahydrate, extractant, catalyst, Acrylic acid, initiator, crosslinking agent, carboxymethyl chitosan, sodium hydroxide, spare;

[0058] Then take the prepared pretreatment agent to pretreat the catalytic cracking clarified oil; put the catalytic cracking clarified oil into a four-necked flask, stir evenly, and heat to 85°C; then dissolve ferrous sulfate heptahydrate in deionized water, And put it into a four-necked flask, continue to heat up to 85 ° C; then add formic acid and hydrogen peroxide, react for 30 minutes, cool down to 25 ° C in a cold water bath, and separate oil and water; then at 25 ° C, use an extractant to extract 3 times to obtain the material A; then add carboxymethyl chitosan to the prepared material A, stir evenly, place it in a c...

Embodiment 3

[0065] First prepare raw materials, weigh catalytic cracking clarified oil, coking heavy wax oil and cellulose in proportion, and set aside; then prepare pretreatment agent: weigh formic acid, hydrogen peroxide, ferrous sulfate heptahydrate, extractant, catalyst, Acrylic acid, initiator, crosslinking agent, carboxymethyl chitosan, sodium hydroxide, spare;

[0066] Then take the prepared pretreatment agent to pretreat the catalytic cracking clarified oil; put the catalytic cracking clarified oil into a four-necked flask, stir evenly, and heat to 90°C; then dissolve ferrous sulfate heptahydrate in deionized water, And put it into a four-neck flask, continue to heat up to 90°C; then put in formic acid and hydrogen peroxide, react for 40min, cool down to 30°C in a cold water bath, and separate oil and water; then at 30°C, use an extractant to extract 3 times to obtain the material A; then add carboxymethyl chitosan to the prepared material A, stir evenly, place it in a constant te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com