Composite modified rubber asphalt mixture and preparation method thereof

A rubber asphalt, compound modification technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of insufficient adhesion performance, high viscosity of rubber asphalt, poor high temperature performance, etc., to improve the viscosity Adhesive performance and high temperature stability, simple preparation process, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

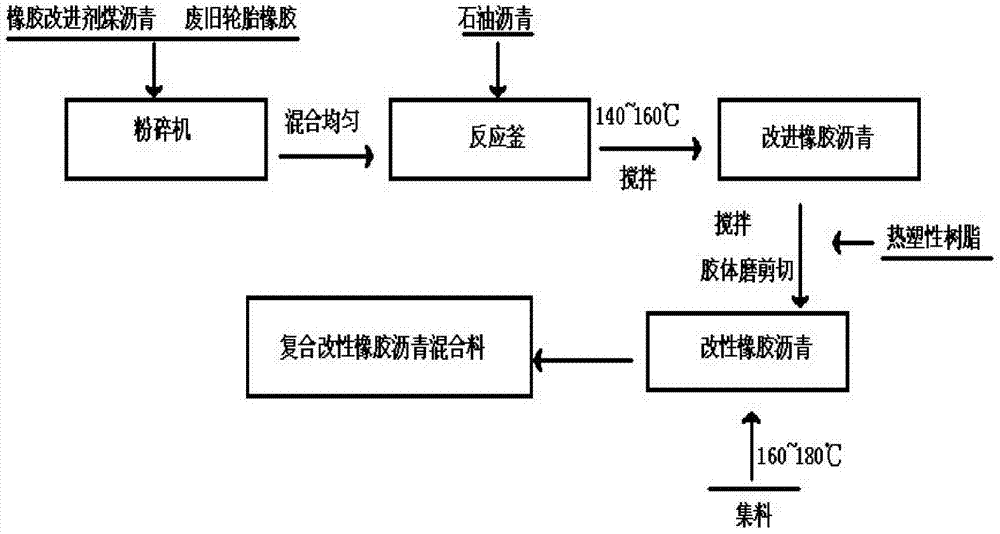

Method used

Image

Examples

Embodiment 1

[0029] (1) Put 5 parts of waste tire rubber and 10 parts of polyethylene wax into the pulverizer according to the mass ratio according to the mass ratio, and then put them into the reaction kettle together with 35 parts of petroleum asphalt, and heat up to 140°C, and stirred for 0.2 h to obtain improved rubber asphalt;

[0030] (2) Add 0.1 part of ethylene-vinyl acetate copolymer to the modified rubber asphalt prepared above according to the ratio of parts by mass, stir for 20 min, and cut for 0.2 h in a colloid mill to prepare modified rubber asphalt;

[0031] (3) Add 45 parts of gravel preheated to 160°C to the prepared modified rubber asphalt according to the ratio of parts by mass and stir evenly to prepare a composite modified rubber asphalt mixture.

[0032] The performance of the product of this embodiment is shown in Table 1.

[0033]

Embodiment 2

[0035] (1) Put 10 parts of waste tire rubber with a particle size of 30 mesh and 15 parts of polyethylene wax into the pulverizer according to the mass ratio to fully pulverize and mix them, and then put them into the reaction kettle together with 35 parts of petroleum asphalt, and heat up Stir for 0.3 h at 150°C to obtain improved rubber asphalt;

[0036] (2) Add 0.02 parts of polyethylene to the modified rubber asphalt prepared above according to the ratio of parts by mass, stir for 25 min, and cut for 0.3 h in a colloid mill to prepare modified rubber asphalt;

[0037] (3) Add 35 parts of sand preheated to 170°C to the prepared modified rubber asphalt according to the ratio of parts by mass and stir evenly to prepare a composite modified rubber asphalt mixture.

[0038] The performance of the product of this embodiment is shown in Table 1.

[0039]

Embodiment 3

[0041] (1) Put 10 parts of waste tire rubber with a particle size of 60 mesh and 15 parts of polyethylene wax into the pulverizer according to the ratio of mass parts to fully pulverize and mix them, then put them into the reaction kettle together with 40 parts of petroleum asphalt, and heat up To 160 ° C, stirring for 0.2 h, the improved rubber asphalt is obtained;

[0042] (2) Add 0.02 parts of polystyrene to the modified rubber asphalt prepared above according to the ratio of parts by mass, stir for 25 min, and shear for 0.4 h in a colloid mill to prepare modified rubber asphalt;

[0043] (3) Add 30 parts of powder preheated to 160°C to the prepared modified rubber asphalt according to the ratio of parts by mass and stir evenly to prepare a composite modified rubber asphalt mixture.

[0044] The performance of the product of this embodiment is shown in Table 1.

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com