Low-radiation coated glass and processing technology thereof

A low-emission coating and processing technology, applied in the direction of coating, can solve the problems of weak bending resistance, low oxide brittleness, limited application scope, etc., to achieve high practicability, stable chemical properties, and improved corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

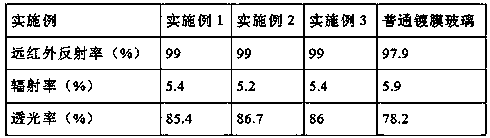

Examples

Embodiment 1

[0049] First clean the glass substrate, put the glass substrate into the concentrated sulfuric acid solution of potassium permanganate and soak it for 18 hours, then wash it with deionized water, then put it into acetone and ethanol for 10 minutes ultrasonic cleaning respectively, and then rinse it with deionized water 5min, nitrogen drying, standby;

[0050] Then sputter the first dielectric layer on the surface of the glass substrate, and first sputter the zinc stannate layer in the argon and oxygen atmosphere: choose zinc-tin alloy as the target material, and the mass ratio of zinc and tin is 54:46; Take the obtained zinc-tin alloy target and glass substrate, and sputter on the glass substrate in the atmosphere of argon and oxygen. -3 Pa, the spacing of the base target is 2mm, the working pressure is 0.2Pa, the sputtering power is 30W, the sputtering time is 0.5h, and the flow rate of oxygen is 60sccm; then coating is carried out to obtain the zinc stannate layer; then heat...

Embodiment 2

[0059] First clean the glass substrate, soak the glass substrate in concentrated sulfuric acid solution of potassium permanganate for 20 hours, then wash it with deionized water, then put it into acetone and ethanol for ultrasonic cleaning for 13 minutes, and then rinse it with deionized water 8min, nitrogen drying, standby;

[0060] Then sputter the first dielectric layer on the surface of the glass substrate, and first sputter the zinc stannate layer in the argon and oxygen atmosphere: choose zinc-tin alloy as the target material, and the mass ratio of zinc and tin is 54:48; Take the obtained zinc-tin alloy target and glass substrate, and sputter on the glass substrate in the atmosphere of argon and oxygen. The process parameters of magnetron sputtering coating are: the degree of vacuum is 3.0×10 -5Pa, the spacing of the base target is 4mm, the working pressure is 1Pa, the sputtering power is 120W, the sputtering time is 1h, and the flow rate of oxygen is 65sccm; The temper...

Embodiment 3

[0069] First clean the glass substrate, put the glass substrate into the concentrated sulfuric acid solution of potassium permanganate and soak for 24 hours, then wash it with deionized water, then put it in acetone and ethanol for ultrasonic cleaning for 15 minutes, and then rinse it with deionized water 10min, nitrogen drying, standby;

[0070] Then sputter the first dielectric layer on the surface of the glass substrate, and first sputter the zinc stannate layer in the atmosphere of argon and oxygen: choose zinc-tin alloy as the target material, and the mass ratio of zinc and tin is 54:50; Take the obtained zinc-tin alloy target and glass substrate, and sputter on the glass substrate in the atmosphere of argon and oxygen. -5 Pa, the spacing of the base target is 6mm, the working pressure is 1.5Pa, the sputtering power is 160W, the sputtering time is 1.5h, and the flow rate of oxygen is 70sccm; then carry out coating, make described zinc stannate layer; Carry out heat treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com