Recycled concrete aggregate machining device

A technology of recycled concrete and processing device, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of a large amount of dust, environmental pollution, affecting the strength of recycled concrete, etc., to achieve the effect of less environmental pollution and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

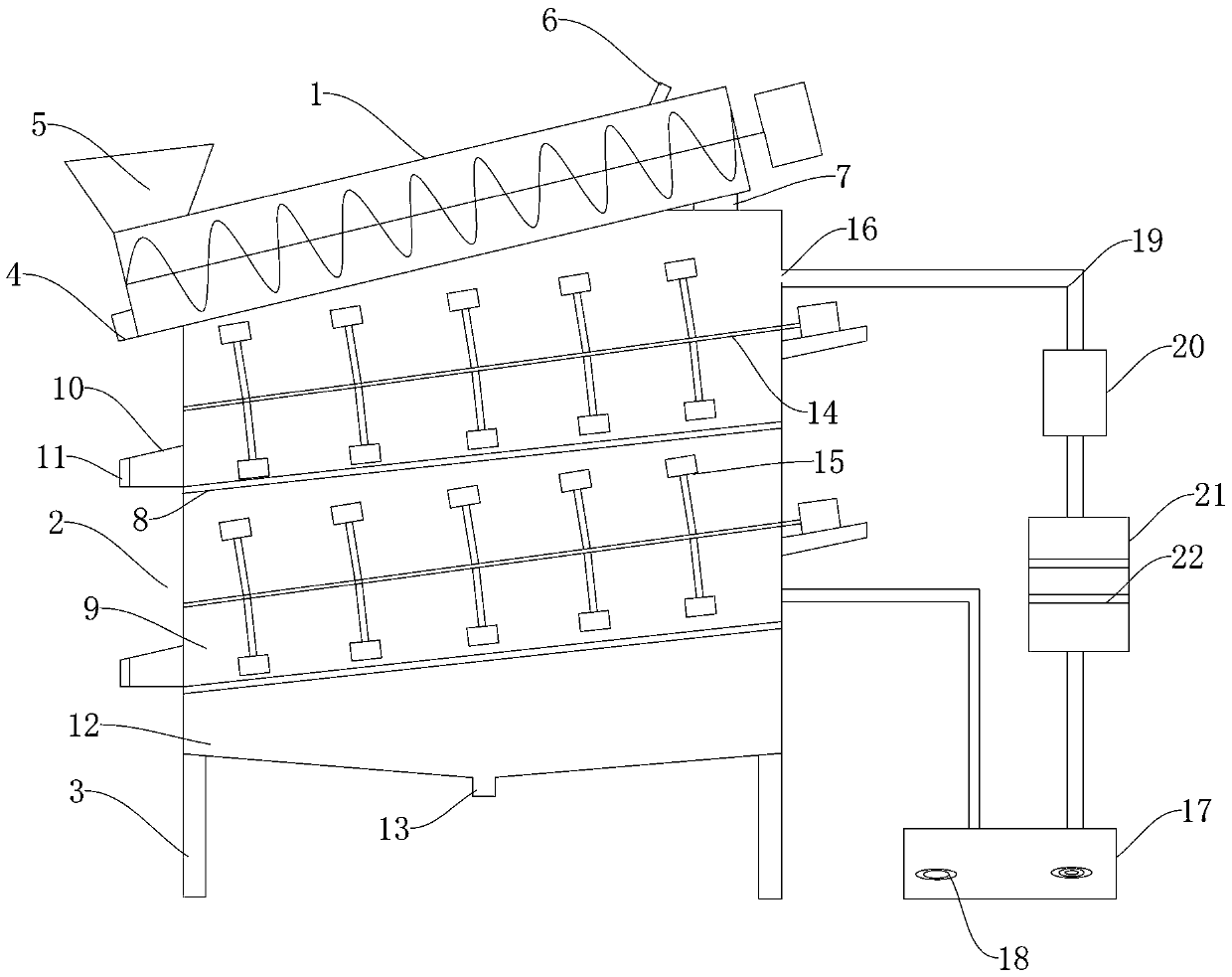

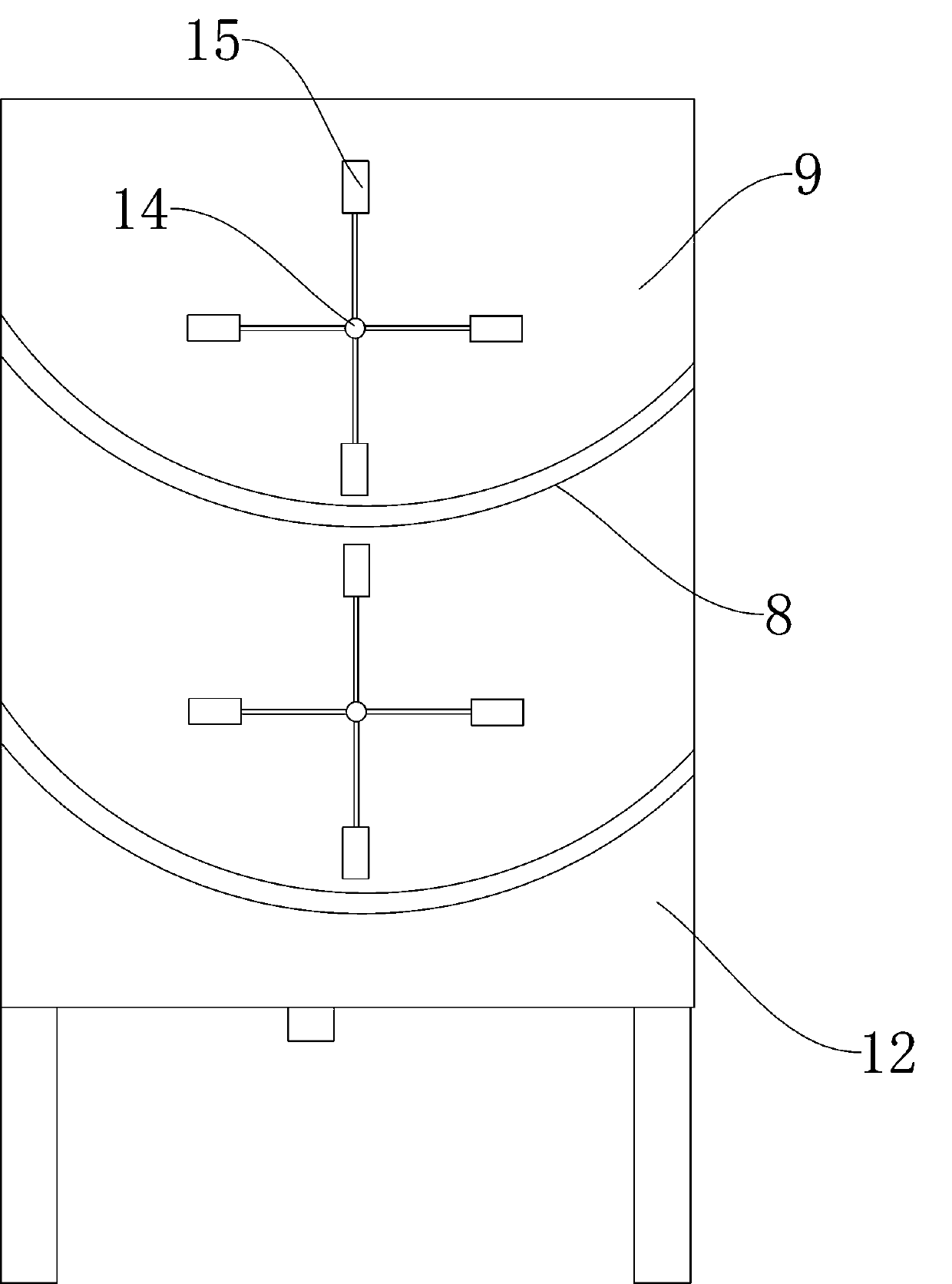

[0018] Such as figure 1 As shown, a recycled concrete aggregate processing device includes an inclined screw conveyor 1 and a screening box 2 arranged below the screw conveyor 1. A support frame 3 is provided at the lower end of the screening box 2. The screw conveyor 1 The lower end is provided with a material leakage port 4, and the upper end is provided with a feed port 5, and the higher end of the screw conveyor 1 is provided with a water inlet 6, and the lower end of the screw conveyor 1 is provided with a discharge port 7, and the discharge port 7 communicates with the screening box 2, the screening box 2 is provided with a multi-layer screen 8 from top to bottom, the aperture of the screen 8 becomes smaller from top to bottom, and the screen 8 divides the screening box 2 into multiple Stirring chamber 9, each stirring chamber 9 is provided with a discharge port 10, the discharge port 10 is provided with a sealing plate 11, the lowermost screen 8 is a water collection ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com