Novel device capable of washing and removing impurities of PET bottle pieces

A technology for cleaning and removing impurities and bottle flakes. It is applied in the direction of plastic recycling and recycling technology. It can solve the problems of not too large an angle, insufficient material cleanliness, clogging of inclined plates, etc. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

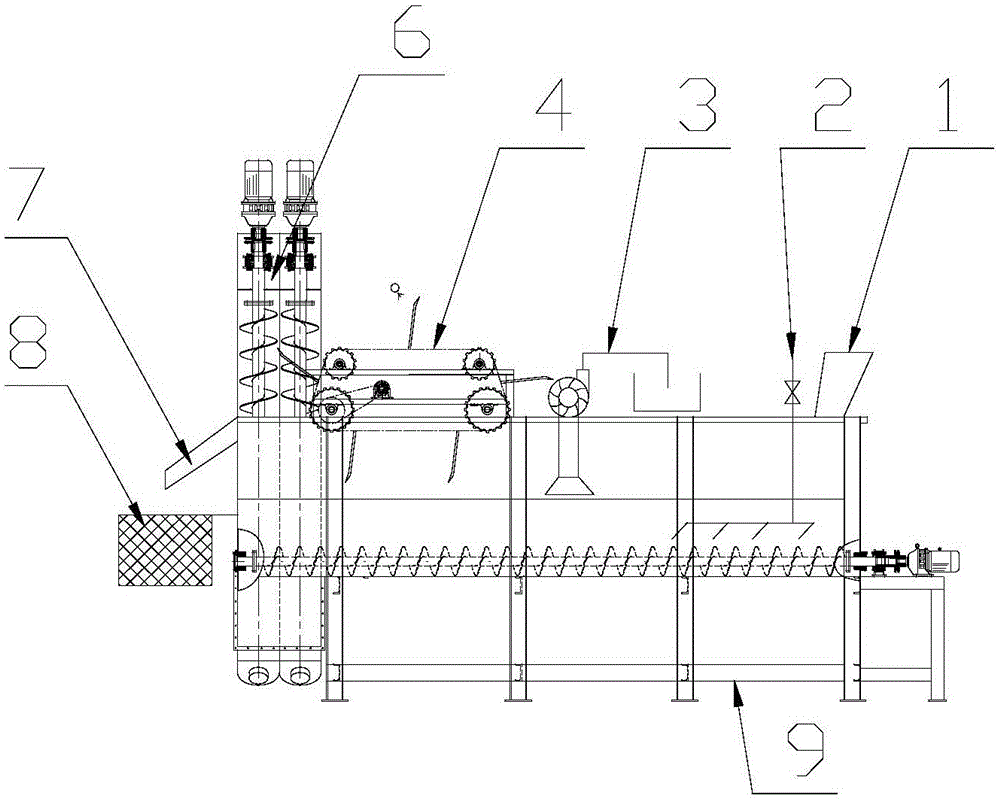

[0023] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

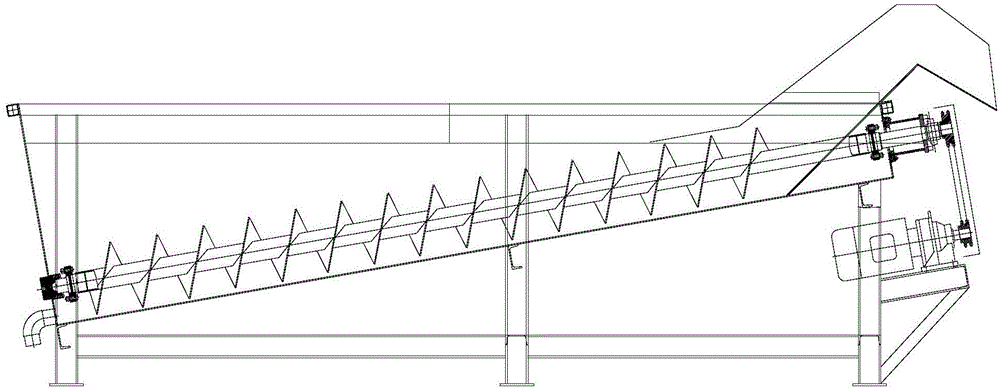

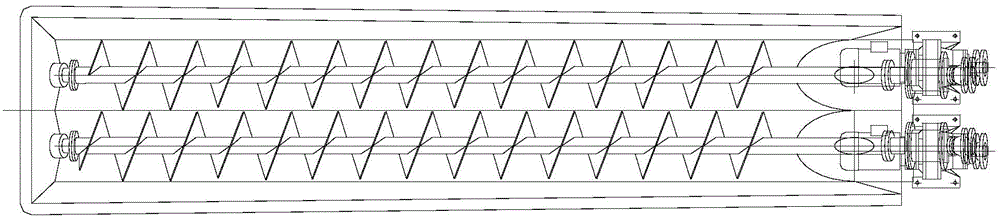

[0024] like image 3 , Figure 4 , Figure 5 Shown is a new type of cleaning and removing device for PET bottle flakes. The conveying mechanism 6, the water outlet 7, the filtering device 8 and the tank body 9 are composed. The upper part of the tank body 9 is square, the lower part is tapered, the feed inlet 1 is arranged on the right side of the tank body 9, and the flat auger conveying mechanism 5 is arranged at the bottom of the lower part of the tank body 9. The tank bottom flushing mechanism 2 is arranged on the left side of the feed inlet 1, the water absorbing and impurity removing mechanism 3 is arranged on the left side of the tank bottom flushing mechanism 2, and the impurity removing mechanism 4 is arranged on the left side of the water absorbing and impurity removing mechanism 3 . The inclined auger conveying me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com