Preparation method and application of biomass-based porous carbon/sulfur composite

A technology of porous carbon materials and composite materials, applied in the field of preparation of porous carbon/sulfur composite materials, can solve the problems of underutilized value, difficult to meet a large number of needs, complicated and tedious preparation process, etc., and achieves good activation effect, high The effect of carbon yield and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

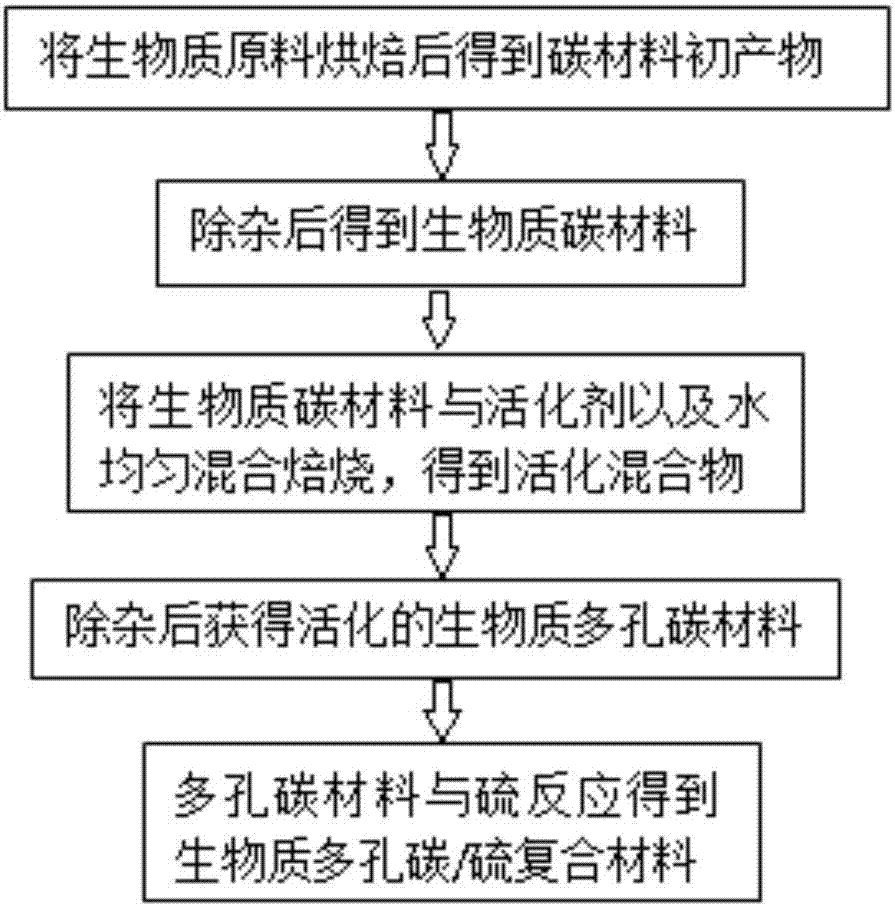

[0046] The invention provides a method for preparing a biomass porous carbon / sulfur composite electrode material, comprising the following steps:

[0047] S1. Wash the prepared biomass raw material with water, and dry it at a temperature of 60°C to 150°C for 12h to 24h to remove dust and other inorganic impurities on the surface of the biomass material; then dry the biomass raw material in an inert atmosphere Among them, roasting at 400℃~600℃ for 1h~3h can obtain the primary product of biomass carbon material; among them, the temperature and roasting time have an impact on the product, the temperature is too high or the time is too long will lead to excessive carbonization, and the carbon yield If the temperature is too low or the carbonization time is too short, it will lead to insufficient carbonization of the material, which is not conducive to the subsequent activation process.

[0048] S2. After naturally cooling the initial product of the carbon material in step S1, firs...

Embodiment 1

[0059] (1) Wash 5 g of waste sawdust with water and dry at 60°C for 24 hours to obtain 4.9 g of dry matter;

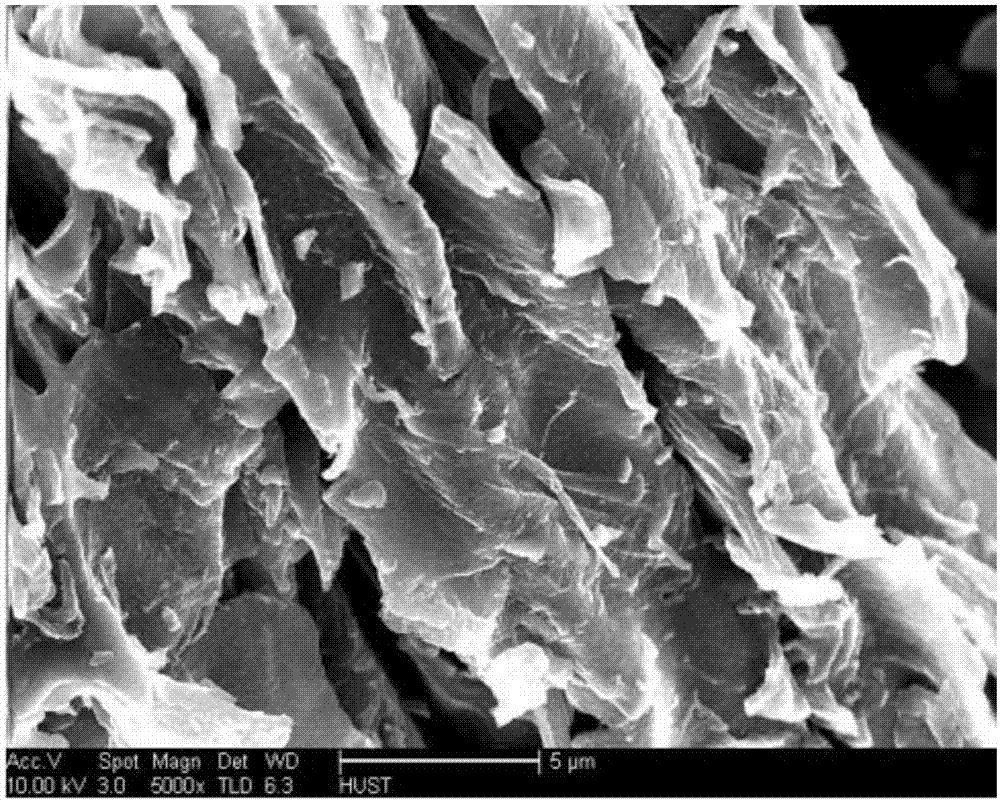

[0060] (2) Heating the dried product to 500°C at 5°C / min in a nitrogen atmosphere, keeping the temperature at a constant temperature for 1.5h, and cooling naturally to obtain the primary product of carbon material;

[0061] (3) Then, it was treated with dilute hydrochloric acid (10wt%), and then the initial product of the carbon material was washed with deionized water to neutrality, and 3.4 g of the product was obtained after drying;

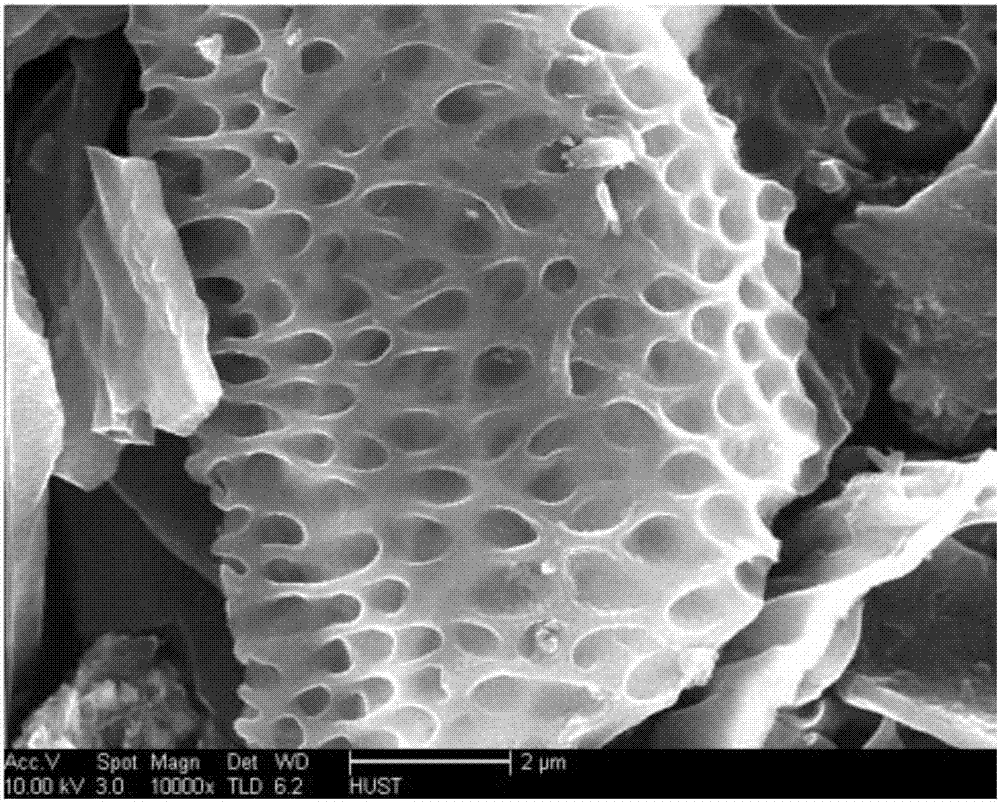

[0062] (4) Evenly mix the dried product with KOH and water at a mass ratio of 1:3:15, and fully dry it, then heat it up to 800°C at 5°C / min for 2h in a nitrogen atmosphere, and then natural cooling;

[0063] (5) The activated product was then washed with dilute hydrochloric acid (10wt%), then washed with deionized water until neutral and dried to obtain 2.1 g of wood chip-based porous carbon material;

[0064] (6) Fully mix the prepar...

Embodiment 2

[0068](1) Wash 6 g of melon seed shells with water and dry at 90°C for 22 hours to obtain 5.8 g of dry matter;

[0069] (2) Heating the dried product to 600°C at a rate of 5°C / min in a nitrogen atmosphere and keeping the temperature constant for 1 hour, then cooling naturally to obtain the primary carbon material product;

[0070] (3) Then, it was treated with dilute hydrochloric acid (12wt%), and then the initial product of the carbon material was washed with deionized water to neutrality, and 4.8 g of the product was obtained after drying;

[0071] (4) Evenly mix the dried product with KOH and water at a mass ratio of 1:1:5, and fully dry it, then heat it up to 600°C at 5°C / min for 5 hours in a nitrogen atmosphere, and then natural cooling;

[0072] (5) The activated product was then washed with dilute hydrochloric acid (12wt%), then washed with deionized water until neutral and dried to obtain 3.5 g of wood chip-based porous carbon material;

[0073] (6) Fully mix the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com