Plastic packaging bag material capable of being utilized by means of biodegradation and method for preparing plastic packaging bag material

A biodegradable, packaging bag technology, applied in the field of material engineering, can solve problems such as environmental pollution and resource waste, and achieve the effects of being environmentally friendly, avoiding environmental damage, and having large-scale industrial application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

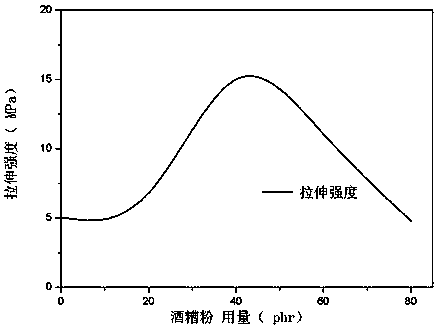

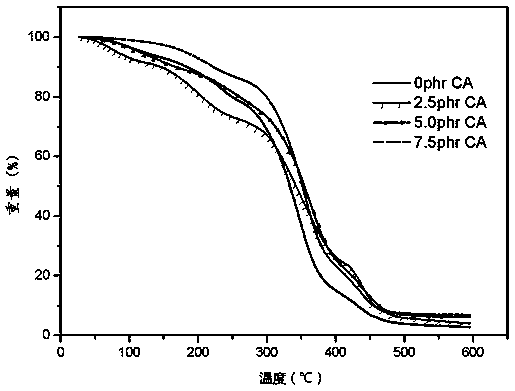

[0036] A biodegradable plastic packaging bag material, in parts by mass, consists of the following components: 100 parts of polyvinyl alcohol, 40 parts of distiller's grains, 7.5 parts of citric acid monohydrate, 30 parts of glycerin, and distilled water accounts for 10% of the total mass .

[0037] Its concrete preparation steps are as follows:

[0038] 1) Dry the distiller's grains at 60°C for 24 hours, then crush them to 50-100 mesh, and then dry them at 60°C for 3 hours to obtain distiller's grains powder;

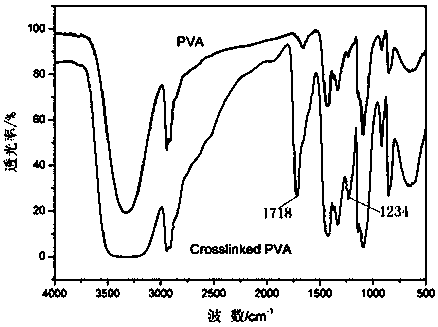

[0039] 2) Dissolve polyvinyl alcohol solids in water, and stir at 80°C at a speed of 400r / min for 1 h to form a polyvinyl alcohol solution; wherein, the mass-volume ratio of polyvinyl alcohol to water is 20 g: 300 mL;

[0040] 3) Heat the above polyvinyl alcohol solution to 90°C, add the above-mentioned citric acid monohydrate and glycerin, stir for 3 hours to make it react fully; then add the above-mentioned distiller’s grain powder to it, and continue stirring for 3...

Embodiment 2 13

[0043] The preparation process and process parameters of Examples 2 to 13 are the same as those of Example 1, the difference being that the ingredient formulations are different, see Table 1 for details:

[0044] Table 1 Ingredient formulations of Examples 2 to 13 (calculated in parts by mass)

[0045] Numbering

Polyvinyl alcohol (parts)

Distiller's grain powder (part)

Citric Acid Monohydrate (parts)

Glycerin (parts)

The ratio of distilled water to the total mass (%)

Embodiment two

100

40

0

30

0

Embodiment three

100

40

2.5

30

0

Embodiment Four

100

40

5

30

0

Embodiment five

100

40

7.5

30

0

Embodiment six

100

40

10

30

0

Embodiment seven

100

40

0

30

10

Embodiment eight

100

40

2.5

30

10

Embodiment nine

100

40

5

30

10

Embodiment ten

100

40

10

30

10

Embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com