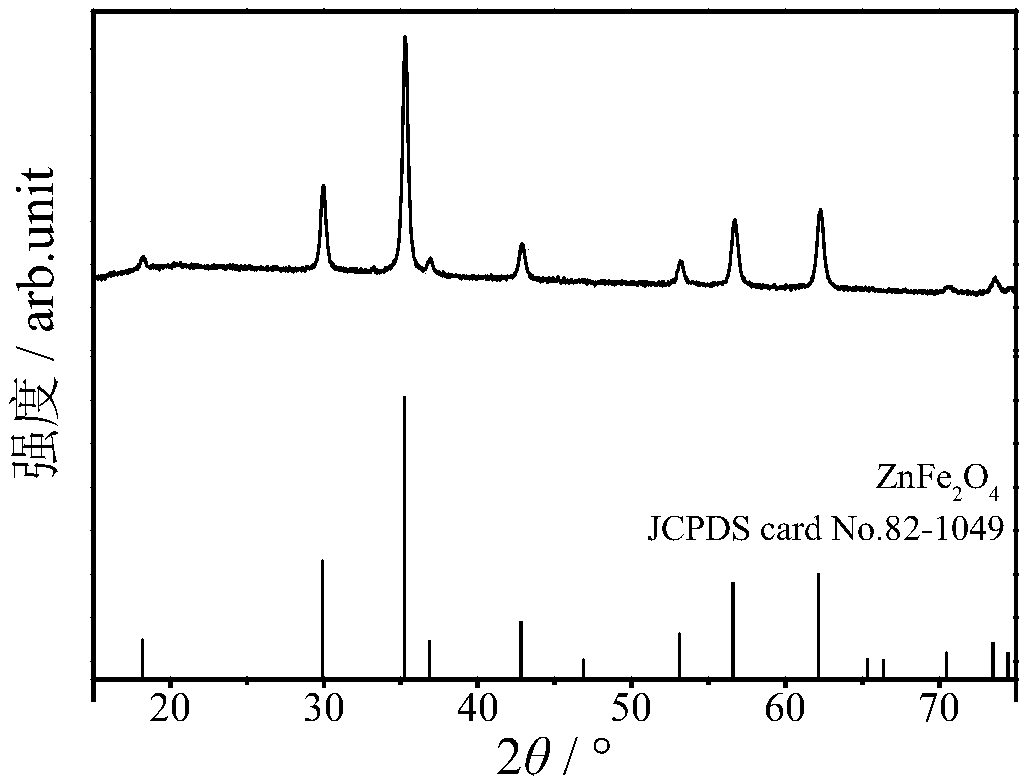

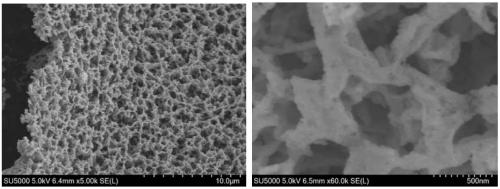

Method for preparing high-performance flaky porous structured zinc ferrite anode material by using jarosite residue sulfate leaching solution and application thereof

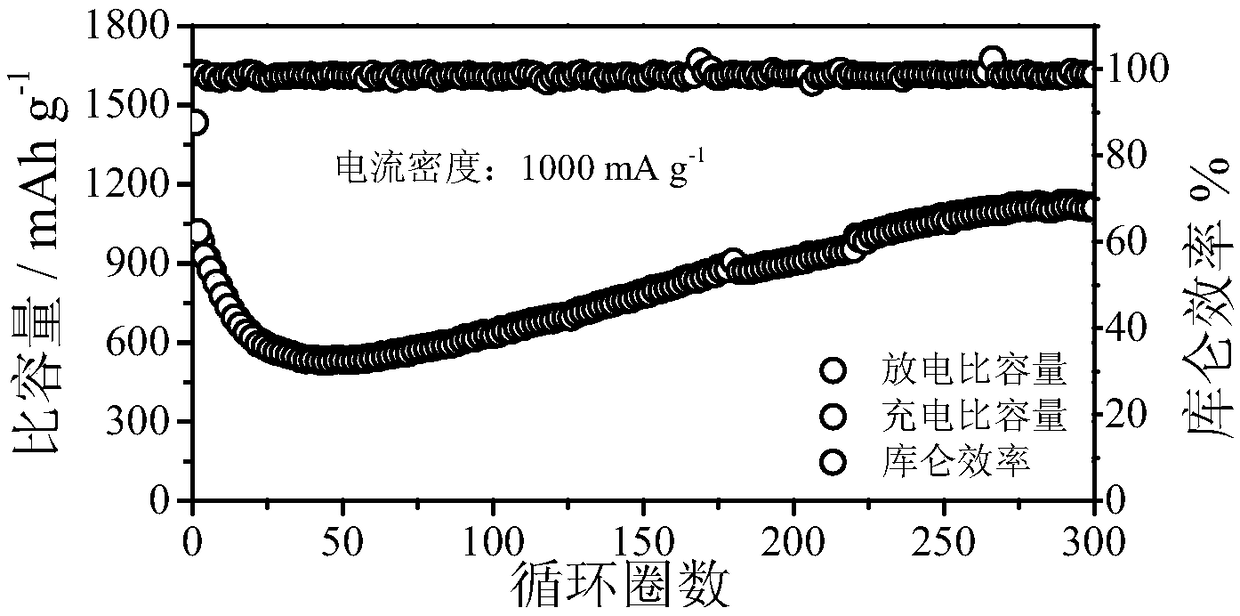

A negative electrode material and porous structure technology, applied in the field of lithium ion battery negative electrode materials, can solve the problems of occupying land resources, untimely recycling of alum slag, waste of resources, etc., to achieve waste reduction, good cycle stability and rate performance, and preparation The effect of easily controlled conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] (1) Determination of Zn in sulfuric acid leaching solution of ferosite slag 2+ and Fe 总 The amount concentration of the substance, where Zn 2+ The concentration of the substance is 0.045mol / L, Fe 总 The concentration of the substance is 0.12mol / L.

[0020] (2) Add 100mL distilled water to 100mL step (1) gained jarosite slag sulfuric acid leaching liquid, adjust the Fe in the solution 总 The concentration of the substance is 0.06mol / L, then add 0.4635g of zinc sulfate heptahydrate, ultrasonically dissolve, so that Zn in the solution 2+ with Fe 总 The molar ratio is 1:2.

[0021] (3) Weigh 12.00g of anhydrous sodium carbonate, measure 120mL of distilled water, mix and dissolve to prepare a sodium carbonate solution, and transfer the prepared solution to a 250mL constant pressure separatory funnel for use.

[0022] (4) Put 200mL of the solution obtained in step (2) into a 500mL flask, and slowly add 120mL of the solution obtained in step (3) dropwise to the beaker throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com