Fabric pre-treatment auxiliary

A technology of auxiliaries and fabrics, used in fiber treatment, plant fibers, textiles and papermaking, etc., can solve problems such as holes in the cloth surface, poor cleaning and decontamination ability, and reduced processing effect, and achieve the effect of eliminating air bubbles.

Active Publication Date: 2015-12-16

山东龙港硅业科技有限公司

View PDF7 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, a large amount of caustic soda needs to be used in the one-step deboiling and bleaching method, and the pH value is much higher than the stable decomposition range of hydrogen peroxide. Even if an excessive amount of hydrogen peroxide stabilizer is added, there will be serious problems such as a decrease in whiteness, holes in the fabric surface, and a decrease in fabric strength.

However, when the amount of caustic soda is reduced, the whiteness, gross effect and desizing rate of the fabric will not meet the standard, resulting in a decrease in the pretreatment effect

The surfactants used in conventional pretreatment, such as TX-10, AEO9, JFC, etc., have poor cleaning and decontamination capabilities, are not resistant to strong alkalis, affect the pretreatment effect, and also have the disadvantages of being difficult to degrade and not environmentally friendly

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

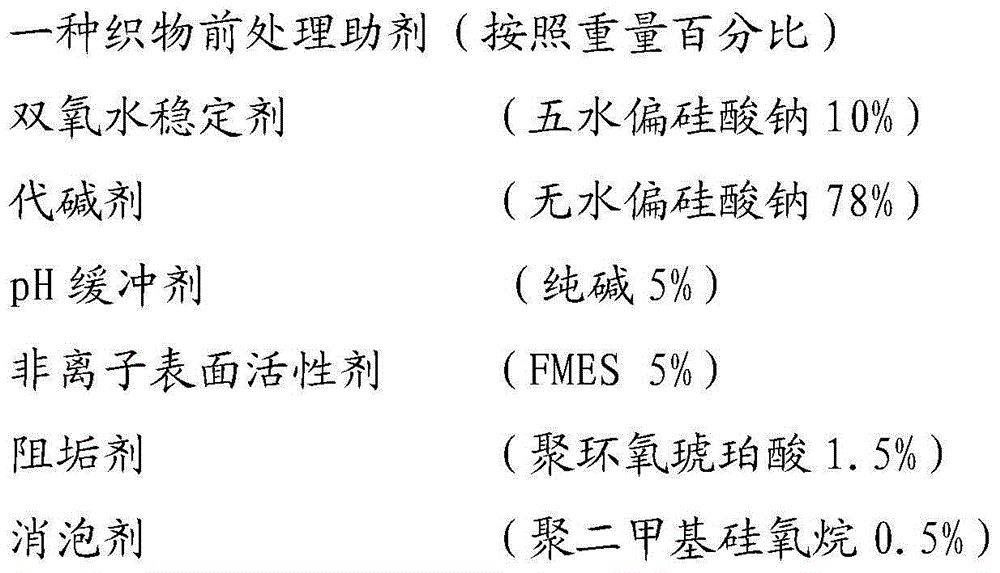

Embodiment 1

[0031]

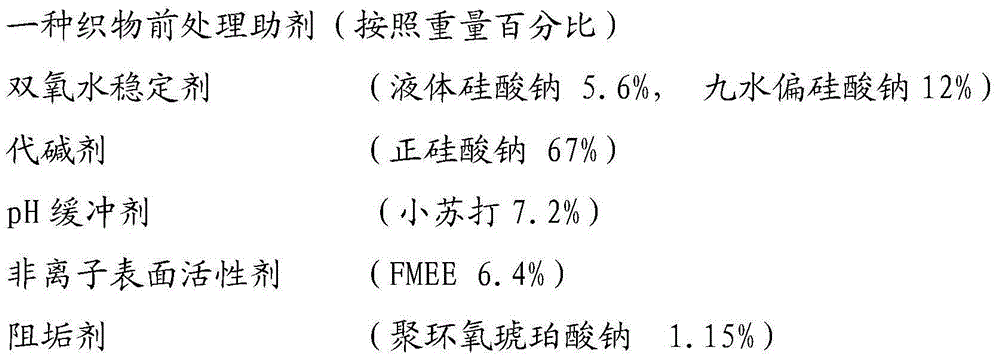

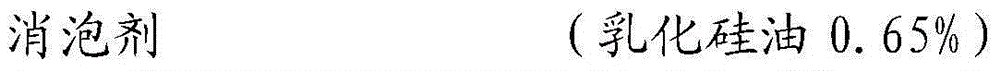

Embodiment 2

[0033]

[0034]

Embodiment 3

[0036]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Login to View More

Abstract

The invention belongs to the technical field of textile chemicals and relates to a fabric pre-treatment auxiliary. The fabric pre-treatment auxiliary is prepared from, by weight, 10-30% of hydrogen peroxide stabilizer, 50-78% of metabolic alcaldosis agent, 5-10% of pH buffering agent, 5-10% of nonionic surfactant, 1-2% of scale inhibitor and 0.5-1% of defoamer. The fabric pre-treatment auxiliary can be free from caustic soda flakes, provides an alkaline environment for stable hydrogen peroxide decomposition, is capable of descaling, environmentally friendly and nontoxic and guarantees that the whiteness, capillary effect and desizing rate of treated fabric meet the standards.

Description

technical field [0001] The invention belongs to the technical field of textile chemical industry, and in particular relates to a fabric pretreatment auxiliary agent. Background technique [0002] In the pretreatment process of cotton fabric, the decomposition reaction of hydrogen peroxide under high temperature and strong alkali conditions is used to desize the fabric, remove impurities in the cotton fiber, and complete the bleaching effect on the fabric at the same time. However, with the rapid development of high-efficiency, low-energy, and short-process pre-treatment processes, the conventional three-step descouring and bleaching process has been combined into a one-step short-process pre-treatment process to remove impurities such as pulp, wax, and pectin. [0003] At present, a large amount of caustic soda is used in the one-step deboiling and bleaching method, and the pH value is far beyond the stable decomposition range of hydrogen peroxide. Even if an excessive amoun...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D06L3/02D06L1/14D06M11/79D06M11/76D06M15/643D06M101/06D06L4/12D06L4/13

Inventor 王敬伟赵贝贝

Owner 山东龙港硅业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com