Composite tea saponin, preparation method thereof and use thereof

A technology for tea saponin and uses, which is applied in the field of compound tea saponin and its preparation, can solve the problems of not being able to guarantee environmental protection and safe production, and has not been widely used, and achieves the improvement of equipment utilization rate, reduction of production cost and output quality. Uniform and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

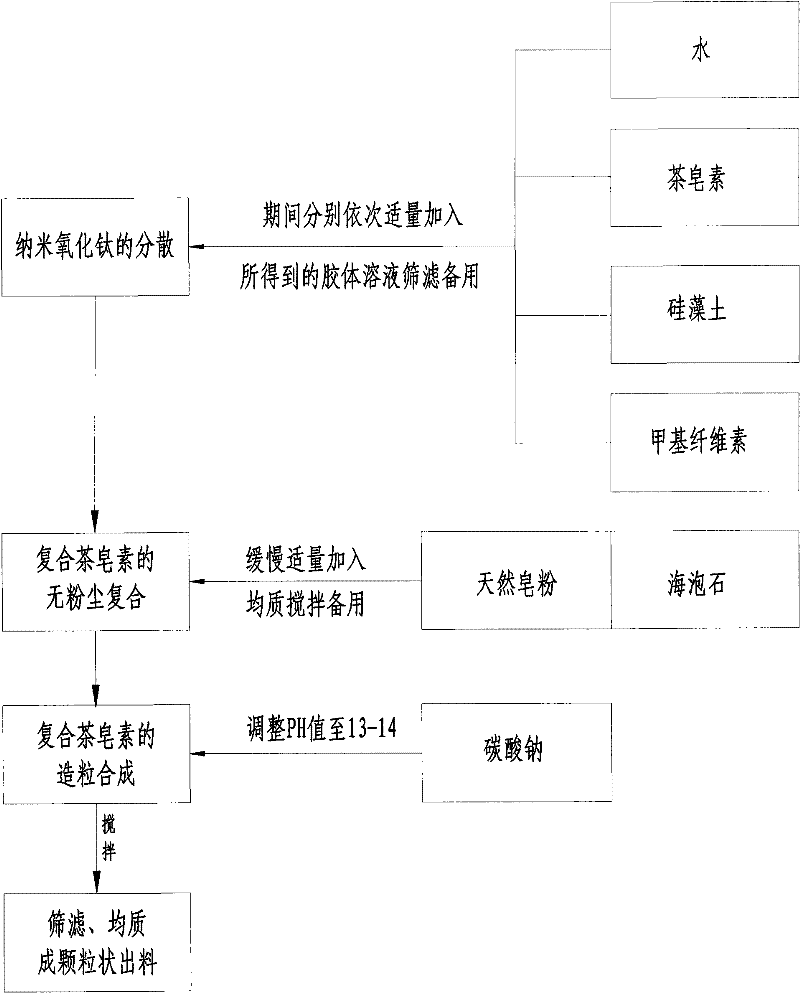

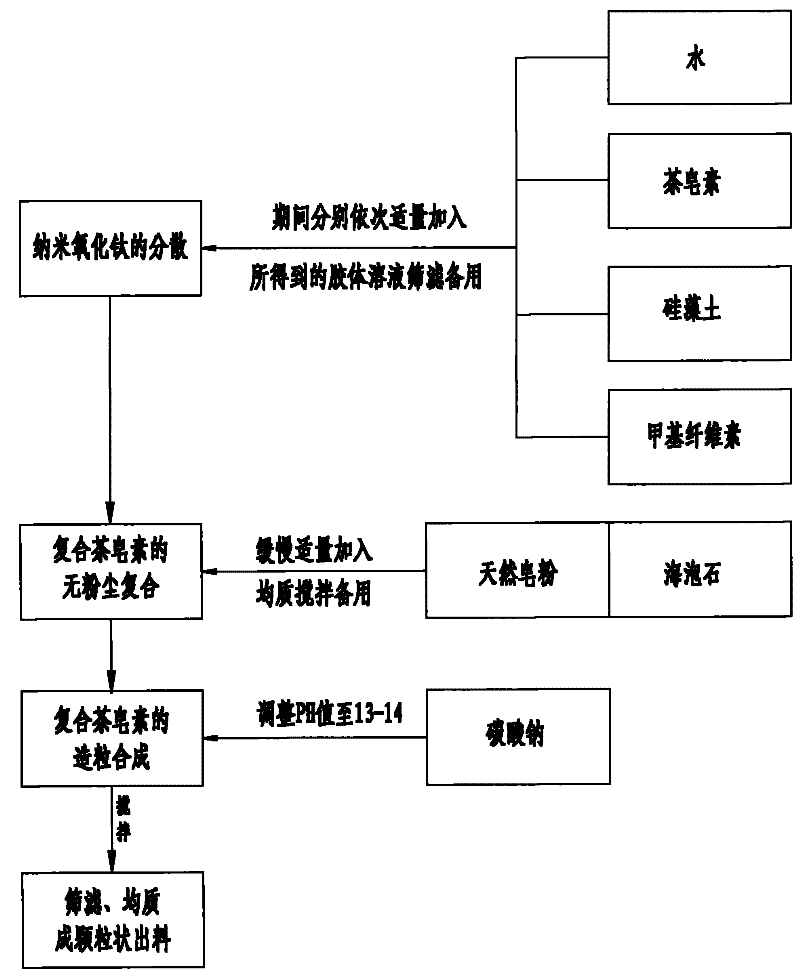

[0041] see figure 1 , the preparation method of the above-mentioned compound tea saponin that the present invention relates to mainly comprises the following steps:

[0042] a) Dispersion of nano-titanium oxide:

[0043] Take an appropriate amount of nano-titanium oxide, use a high-shear disperser dedicated to nano-materials, add an appropriate amount of water under the condition of 10,000-35,000 rpm, and disperse for 5-30 minutes; then move to a homogeneous stirring device, add an appropriate amount of tea Saponin and stir homogeneously for 5-30 minutes at 10-60°C; then add appropriate amount of diatomaceous earth and rotate forward for 10-60 minutes at 100-500 rpm, then reverse for 10-60 minutes minute; then slowly reduce the number of rotations to 50-100 rpm, add an appropriate amount of methyl cellulose and continue to stir evenly, and the obtained colloidal solution passes through a sieve for later use;

[0044] b) Dust-free compounding:

[0045] Slowly add an appropri...

Embodiment 1

[0050] a) Dispersion of nano-titanium oxide:

[0051] Take 1% nano-titanium oxide with a particle size of 10nm, use a high-shear disperser dedicated to nano-materials, add 21% water under the condition of 10,000 rpm and disperse for 5 minutes; then move to a homogeneous stirring device, add 12% tea saponin and stir homogeneously at 10°C for 5 minutes; then add 5% diatomaceous earth and rotate forward at 100 rpm for 10 minutes, then reverse for 60 minutes; then slowly lower Turn the number to 100 rpm, add 5% methylcellulose and continue to stir evenly, and the resulting colloidal solution is passed through a sieve for subsequent use;

[0052] b) Dust-free compounding:

[0053] Slowly add 45% natural soap powder and 6% sepiolite under the condition of 100 rpm and stir for 30 minutes, then slowly pour in the above colloidal solution, homogeneously stir for later use;

[0054] c) Granulation synthesis:

[0055] Start the powder granulator, adjust to the homogeneous granulation st...

Embodiment 2

[0057] a) Dispersion of nano-titanium oxide:

[0058] Take 3% nano-titanium oxide with a particle size of 45nm, use a high-shear disperser dedicated to nano-materials, add 30% water under the condition of 35000 rpm and disperse for 30 minutes; then move to a homogeneous stirring device, add 18% tea saponin and stir homogeneously at 60°C for 30 minutes; then add 3% diatomaceous earth and rotate forward at 500 rpm for 60 minutes, then reverse for 10 minutes; then slowly lower Turn the number of revolutions to 50 rpm, add 1% methylcellulose and continue to stir evenly, and the resulting colloidal solution is passed through a sieve for subsequent use;

[0059] b) Dust-free compounding:

[0060] Slowly add 23% natural soap powder and 12% sepiolite under the condition of 50 rpm and stir for 5 minutes, then slowly pour in the above colloidal solution, stir homogeneously and set aside;

[0061] c) Granulation synthesis:

[0062] Start the powder granulator, adjust to the homogeneou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com