Mucilage glue emission-reduction type one-bath dyeing process

A viscose and process technology, applied in dyeing, biochemical fiber treatment, dry-cleaning fiber products, etc., can solve the problems of high energy consumption, time-consuming and labor-intensive, low efficiency, etc., achieve good mutual solubility, promote dispersion, and improve degradation activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

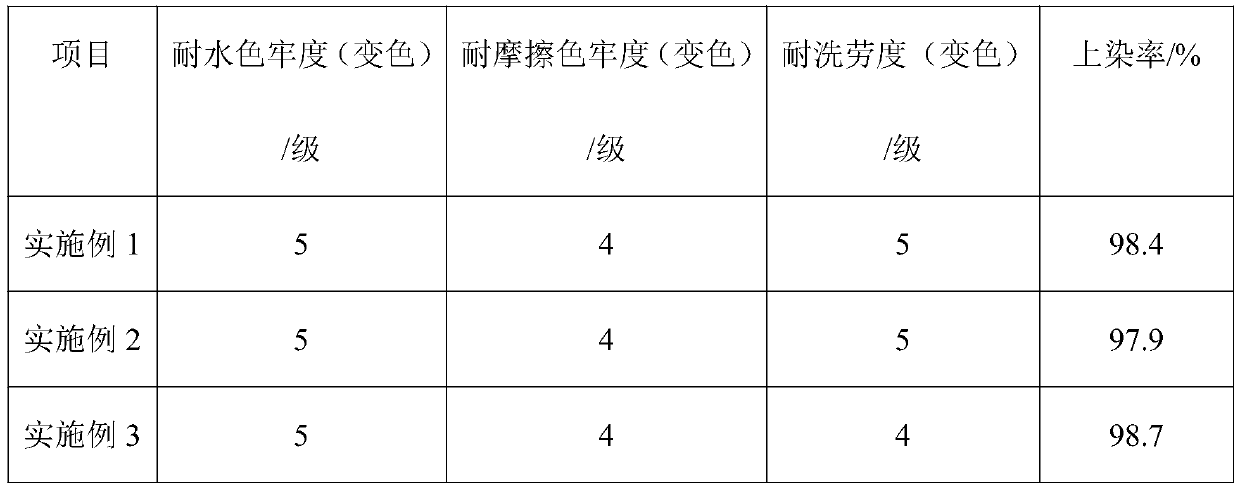

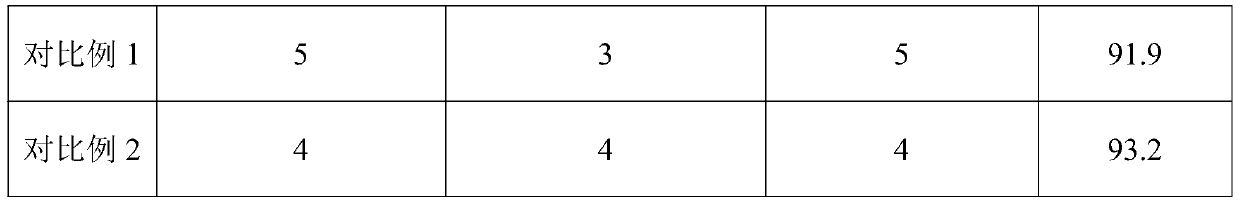

Embodiment 1

[0024] The invention provides a viscose emission reduction one-bath dyeing process, the specific steps are as follows:

[0025] (1) To prepare a composite desizing enzyme, take 10 to 50 parts of deionized water, 5 to 10 parts of sodium silicate, 2 to 5 parts of sodium carboxymethylcellulose, 1 to 3 parts of EDTA, and 5 to 5 parts of desizing enzyme by weight. 8 parts, 5-8 parts of PVA-degrading enzyme, 1-3 parts of sodium citrate, and 1-5 parts of soap oil were sequentially added to the stirring tank, and the rotation speed of the stirring tank was controlled at 15-20r / min, and mixed well at room temperature to obtain Composite desizing enzyme; wherein, parts by weight of high temperature resistant α-amylase:alkaline pectinase=3:1, activity of desizing enzyme 5000-10000U / ml, pH6.0-7.5; PVA degrading enzyme contains parts by weight Number of polyvinyl alcohol oxidase: polyvinyl alcohol dehydrogenase: β-diketone hydrolase = 1:1:1, pH6.0~7.5.

[0026] (2) Prepare the base liquid...

Embodiment 2

[0046] The invention provides a viscose emission reduction one-bath dyeing process, the specific steps are as follows:

[0047] (1) To prepare a compound desizing enzyme, take 10 to 50 parts of deionized water, 5 to 10 parts of sodium silicate, 2 to 5 parts of sodium carboxymethyl cellulose, 1 to 3 parts of EDTA, and 10 to 5 parts of desizing enzyme in parts by weight. Add 15 parts, 10-15 parts of PVA degrading enzyme, 1-3 parts of sodium citrate, and 1-5 parts of soap oil into the stirring tank in turn, control the rotation speed of the stirring tank at 15-20r / min, and mix well at room temperature to obtain Composite desizing enzyme; wherein, parts by weight of high temperature resistant α-amylase:alkaline pectinase=4:1, activity of desizing enzyme 5000-10000U / ml, pH6.0-7.5; PVA degrading enzyme contains parts by weight Number of polyvinyl alcohol oxidase: polyvinyl alcohol dehydrogenase: β-diketone hydrolase = 1:1:1, pH6.0~7.5.

[0048](2) Prepare the base liquid, dissolve ...

Embodiment 3

[0055] The invention provides a viscose emission reduction one-bath dyeing process, the specific steps are as follows:

[0056] (1) To prepare a composite desizing enzyme, take 10 to 50 parts of deionized water, 5 to 10 parts of sodium silicate, 2 to 5 parts of sodium carboxymethyl cellulose, 1 to 3 parts of EDTA, and 16 to 5 parts of desizing enzyme in parts by weight. Add 20 parts, 16-20 parts of PVA degrading enzyme, 1-3 parts of sodium citrate, and 1-5 parts of soap oil into the stirring tank in turn, control the rotation speed of the stirring tank at 15-20r / min, and mix well at room temperature to obtain Composite desizing enzyme; wherein, parts by weight of high temperature resistant α-amylase:alkaline pectinase=5:1, activity of desizing enzyme 5000-10000U / ml, pH6.0-7.5; PVA degrading enzyme contains parts by weight Number of polyvinyl alcohol oxidase: polyvinyl alcohol dehydrogenase: β-diketone hydrolase = 1:1:1, pH6.0~7.5.

[0057] (2) Prepare the base liquid, dissolv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com