Modified biofilm carrier as well as preparation method and application thereof

A biofilm carrier and modification technology, applied in sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve problems such as easy pollution, increased modification cost, and limited application of modified carbon fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a preparation method of a modified biological carrier, comprising the following steps:

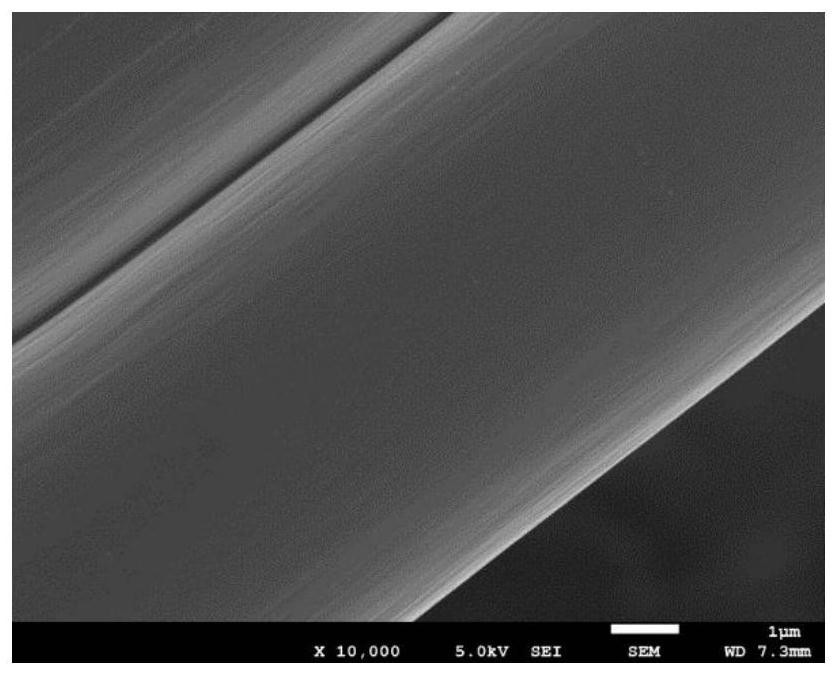

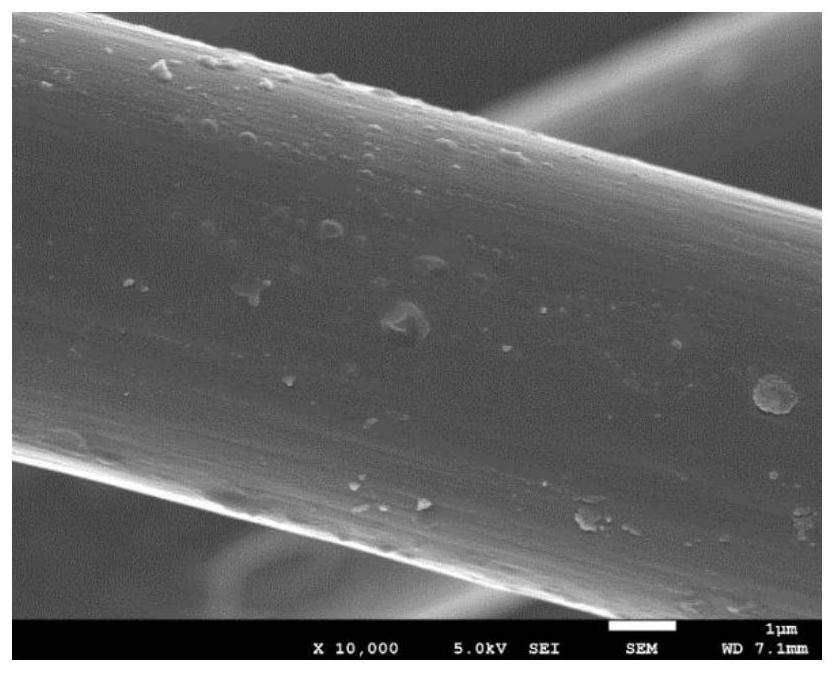

[0027] The carbon fiber is subjected to the first heat preservation and the second heat preservation in sequence to obtain the modified biofilm carrier; the temperature of the first heat preservation is 150-250°C; the temperature of the second heat preservation is 250-650°C.

[0028] In the present invention, the carbon fiber is subjected to the first heat preservation to obtain the desizing carbon fiber.

[0029] In the present invention, the carbon fibers preferably include one or more of polyacrylonitrile-based carbon fibers, pitch-based carbon fibers, viscose-based carbon fibers and lignin-based carbon fibers. In the present invention, there is no special limitation on the source of the carbon fiber, and sources well-known to those skilled in the art can be used, specifically commercially available. In the present invention, the carbon fibers are preferab...

Embodiment 1

[0046] The raw material carbon fibers used in this example were purchased from Jiangsu, and were polyacrylonitrile-based carbon fibers.

[0047] Put the carbon fiber in a high-temperature furnace, raise the temperature to 200°C at a heating rate of 10°C / min, and keep it at 200°C for 10 minutes to obtain desizing carbon fiber; without converting equipment, heat the obtained desizing carbon fiber at a heating rate of 8°C / min The temperature was raised to 350° C. and kept at 350° C. for 3 hours, followed by cooling down in the furnace to obtain a modified biofilm carrier.

Embodiment 2

[0061] The raw material carbon fibers used in this example were purchased from Zhejiang Province and were polyacrylonitrile-based carbon fibers.

[0062] Put the carbon fiber in a high-temperature furnace, raise the temperature to 150°C at a heating rate of 12°C / min and keep it warm at 150°C for 15 minutes to obtain desizing carbon fiber; no need to convert equipment, heat the obtained desizing carbon fiber at a heating rate of 10°C / min The temperature was raised to 400° C. and kept at 400° C. for 2.5 hours, followed by cooling down in the furnace to obtain a modified biofilm carrier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com