Particle combustor with dynamically-sealed combustion chambers and automatic feeding, slag disintegrating and ash discharging functions

A technology of automatic feeding and combustion chamber, which is applied in the combustion of solid fuel, combustion method, combustion equipment, etc., can solve the problems of affecting indoor air and human health, waste of fuel, and excessive emission of unburned gas, and ensure the logistics of ash discharge. Unobstructed, avoiding interruption of ash discharge flow, overcoming the effect of uncontrollable discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the technical solution, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

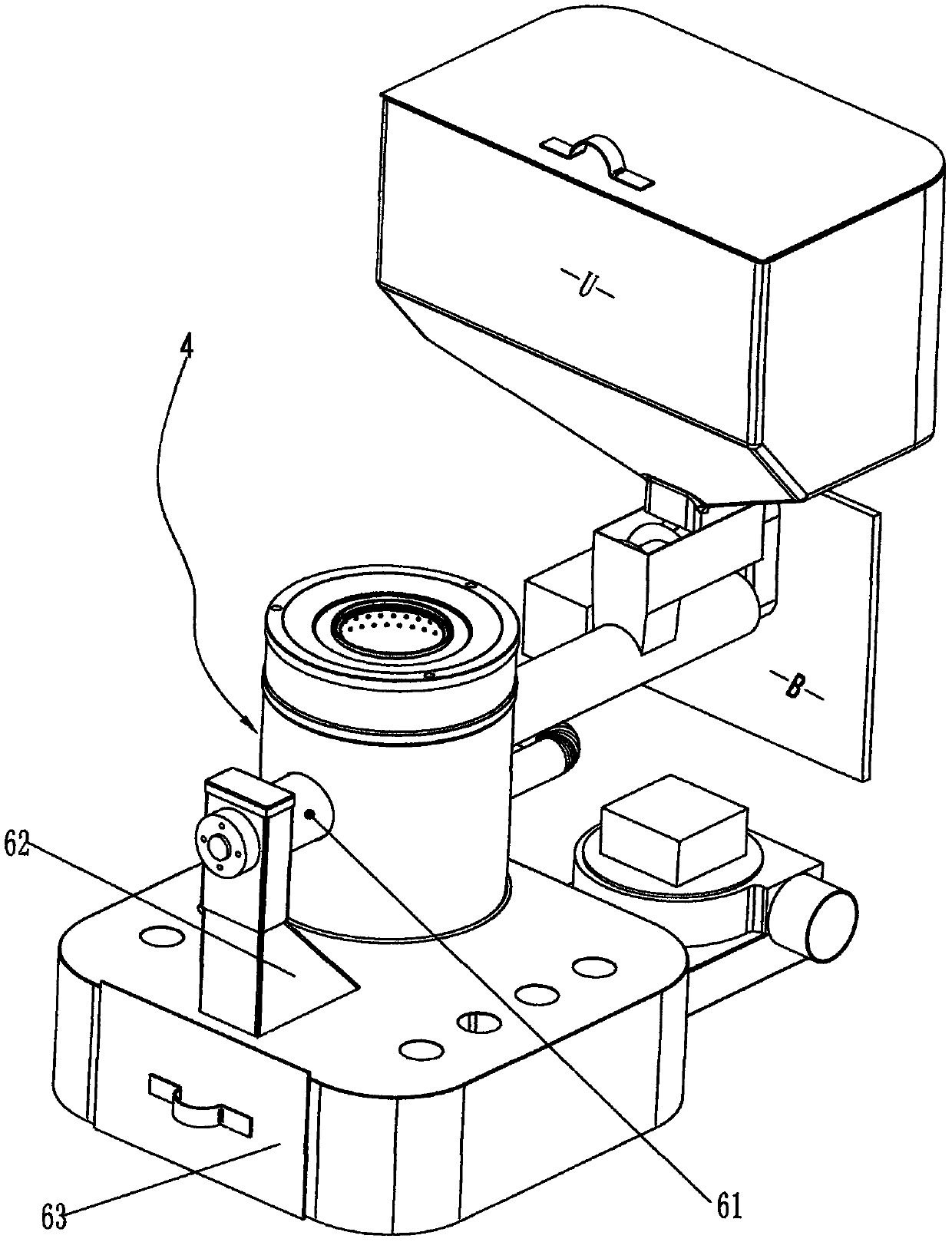

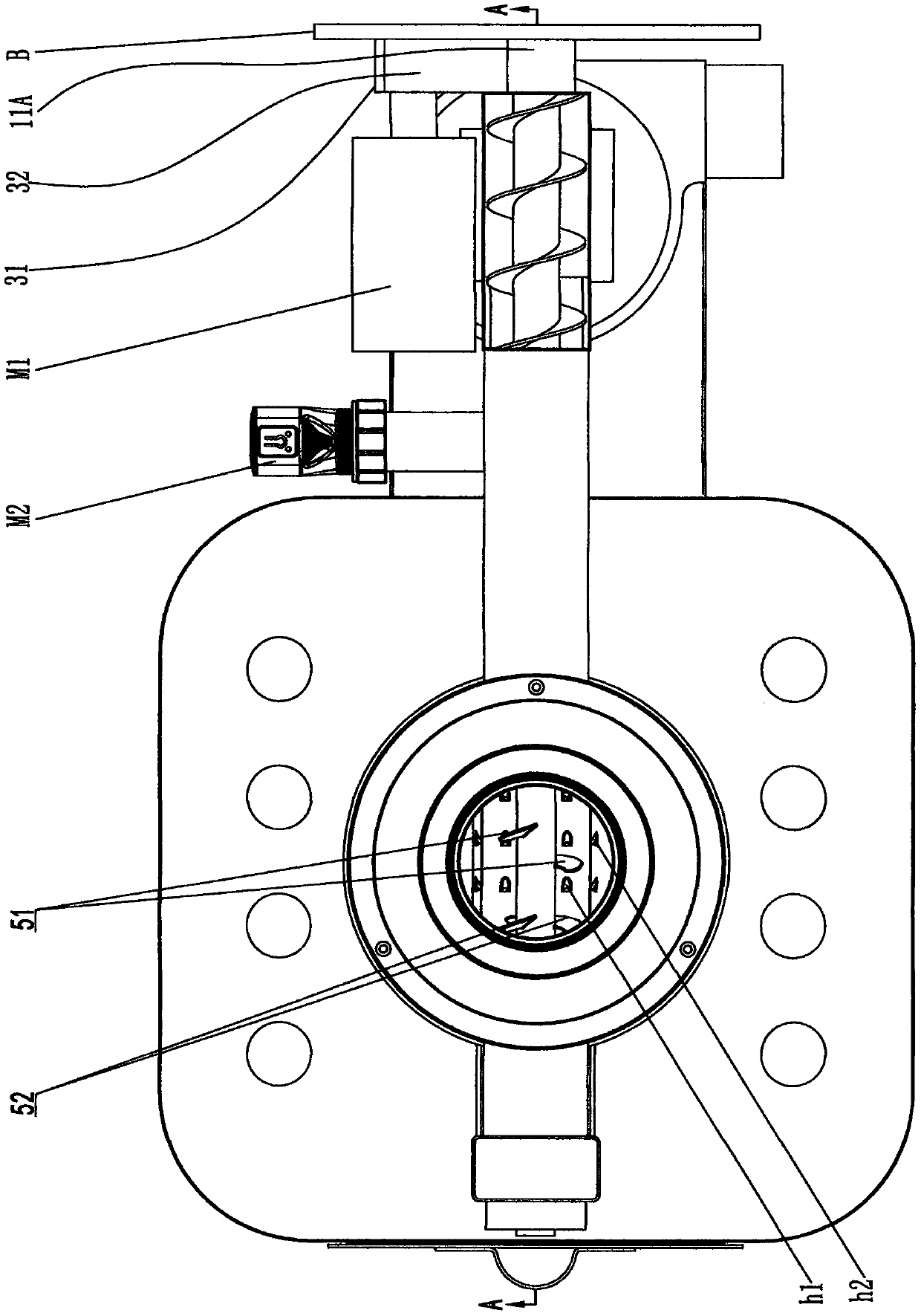

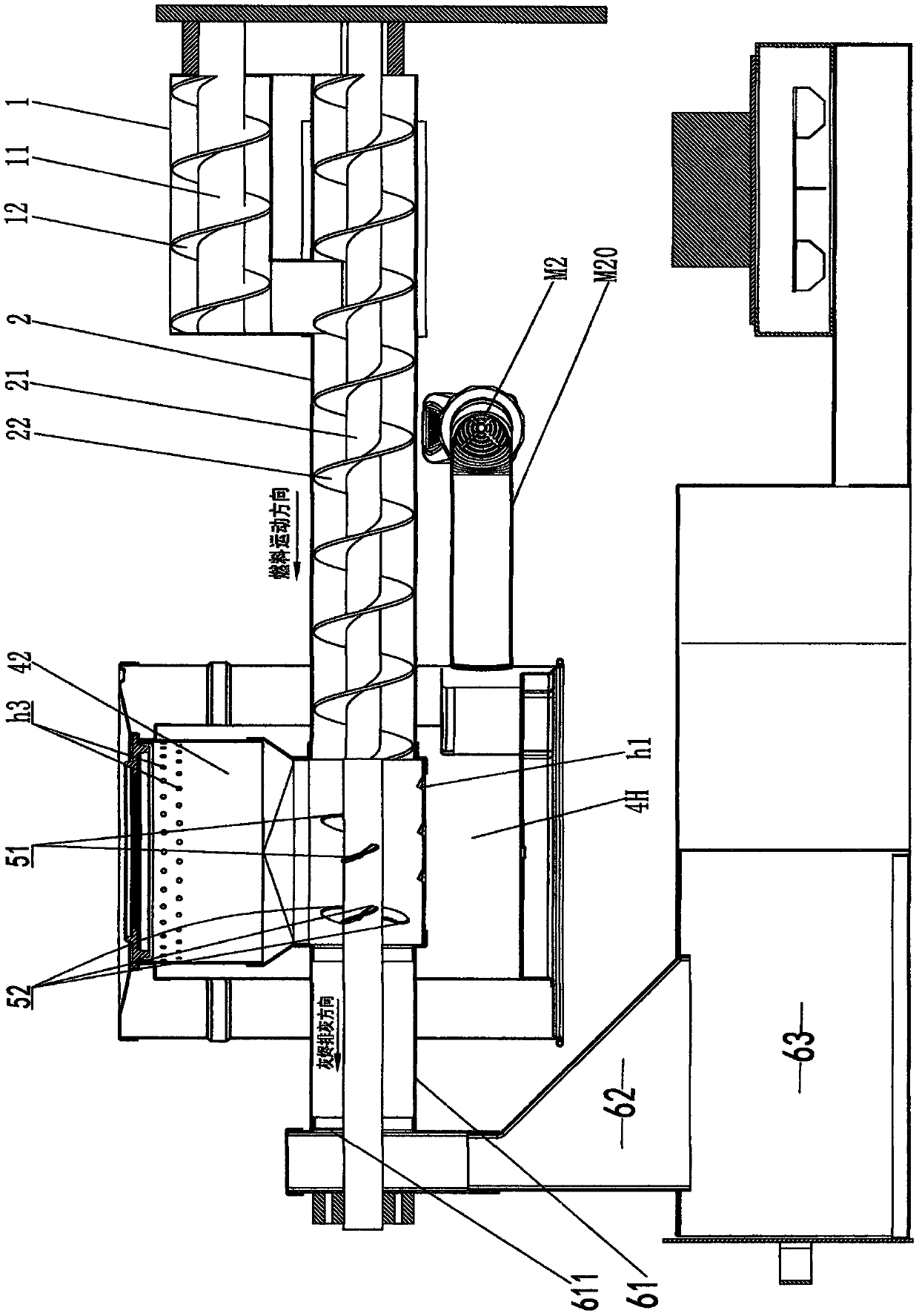

[0038] see Figure 1~6 As shown, the combustion chamber dynamic sealed particle burner with automatic feeding and slag discharge includes an automatic feeding mechanism, a stove 4, a stirring slag component and an ash discharge device located downstream of the stirring slag component. The stove 4 includes The furnace shell 4a, the liner 4b located in the furnace shell, the upper combustion chamber 42 located in the liner, and the lower combustion chamber 41 for containing the granular fuel. The stirring slag component is arranged in the lower combustion chamber. 1. The upper shaft 11 with the upper auger 12 extending into the upper feeding pipe, the lower feeding pipe 2, the lower shaft 21 with the lower auger 22 extending into the lower feeding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com