New method for removing impurities in tellurium electrolyte

An electrolyte and filtrate technology, applied in the field of metallurgy, can solve the problems of low tellurium recovery rate, high production load, long process flow, etc., and achieve the effects of high recovery rate, low energy consumption, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

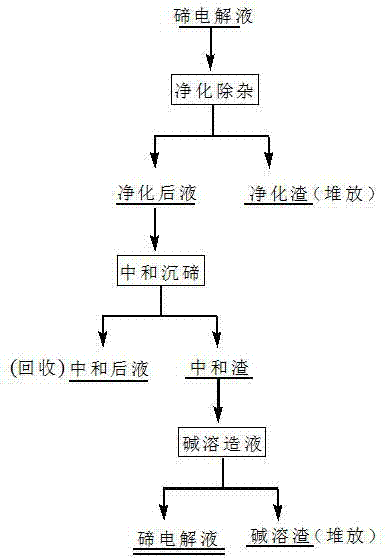

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

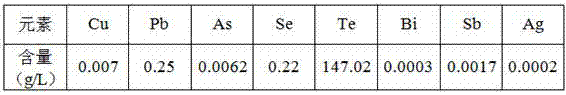

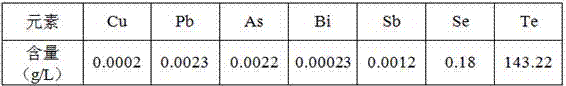

[0023] The component element analysis and content of raw material tellurium electrolyte are as shown in table 1 in this method:

[0024] Table 1

[0025]

[0026] A method for purifying tellurium electrolyte containing high lead and selenium, which comprises the following steps:

[0027] a. Purify and remove lead

[0028] Add sodium sulfide of 1.1 times the mass of lead in the solution to the tellurium electrolyte with higher lead and selenium content, stir and react at room temperature for 1 hour and then let it stand for 4 hours, filter the reacted solution to separate the solid and liquid, and the lead is mixed with lead sulfate The form precipitates in the filter residue, and tellurium and selenium exist in the filtrate in the form of sodium tellurite and sodium selenite respectively, reclaim the filter residue, and collect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com