Gushing type circulating grain dust removing device

A dust removal device and grain technology, applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., can solve the problems of high pressure of hot air, inability to discharge, no dust removal, impurity removal, etc., to achieve Enhanced effect, easy to popularize and apply, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

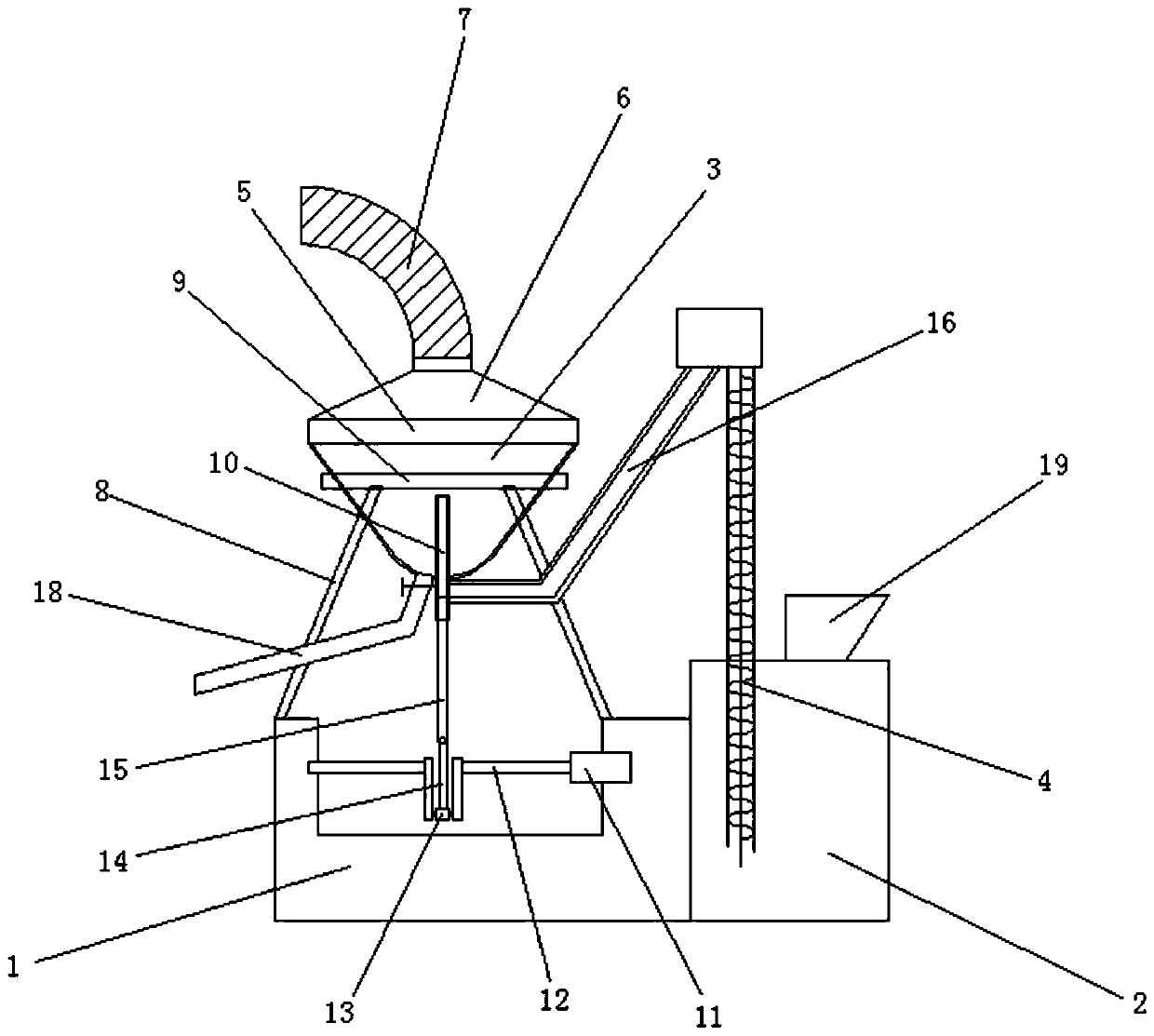

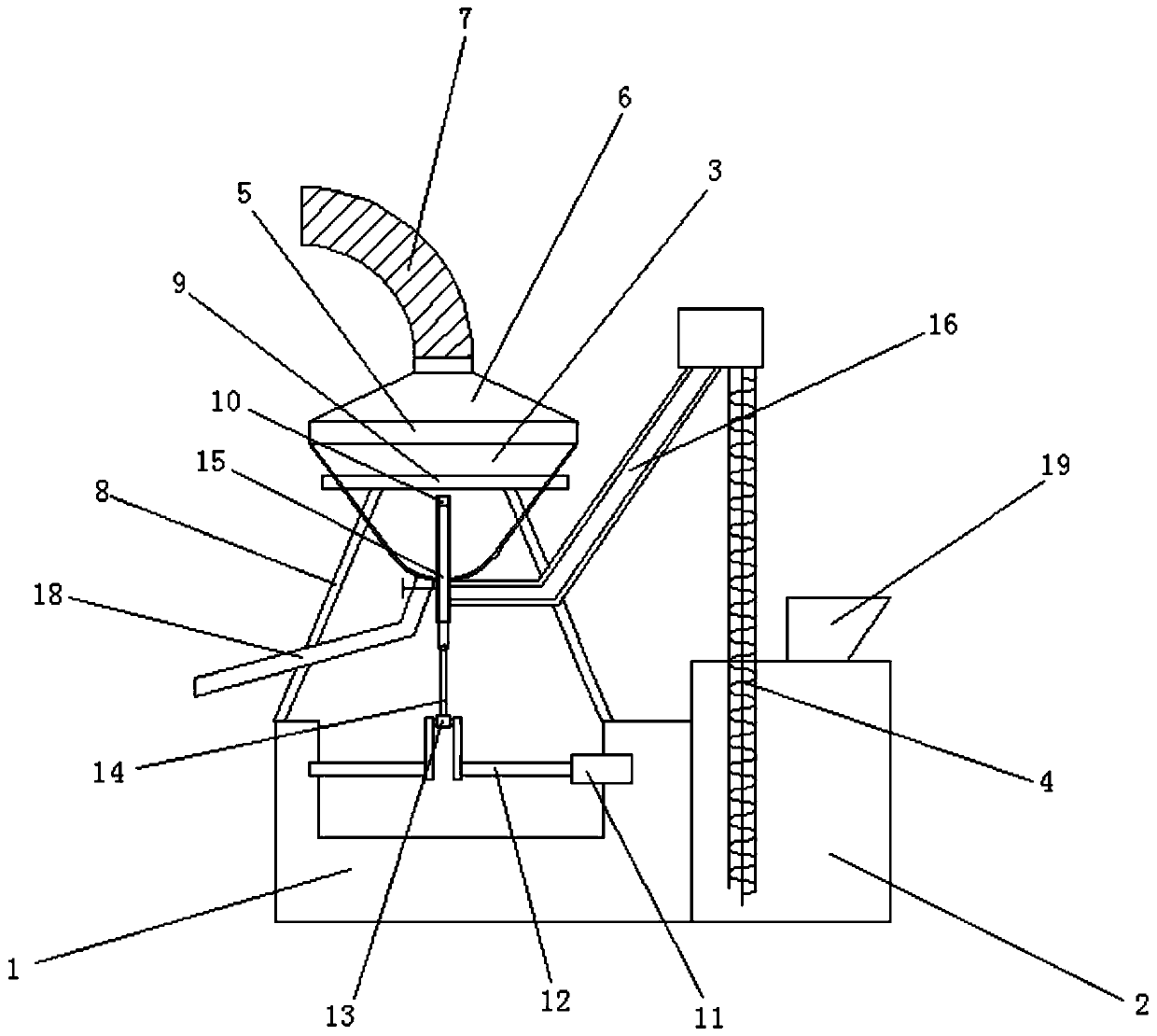

[0032] Embodiment 1: as Figure 1-4 Shown, a kind of gushing type circulation grain dedusting device comprises:

[0033] A base 1, the base 1 is set in a concave shape, a motor 11 is fixedly installed in the middle part of the inner wall on the right side of the base 1, and a crankshaft 12 is fixedly connected to the left end of the motor 11, and the left end of the crankshaft 12 is connected to the base The inner wall on the left side of the seat 1 is rotatably connected, the crankshaft 12 is rotatably sleeved with a sleeve 13, the side wall of the sleeve 13 is fixedly connected with a connecting rod 14, and the top of the connecting rod 14 is rotatably connected with a push rod 15 , the motor drives the crankshaft to rotate and drives the ejector rod to reciprocate up and down through the drum and connecting rod;

[0034] Storage bin 2, the top left side of the storage bin 2 is fixedly equipped with a hoist 4, the bottom of the hoist 4 is located at the bottom of the inner ...

Embodiment 2

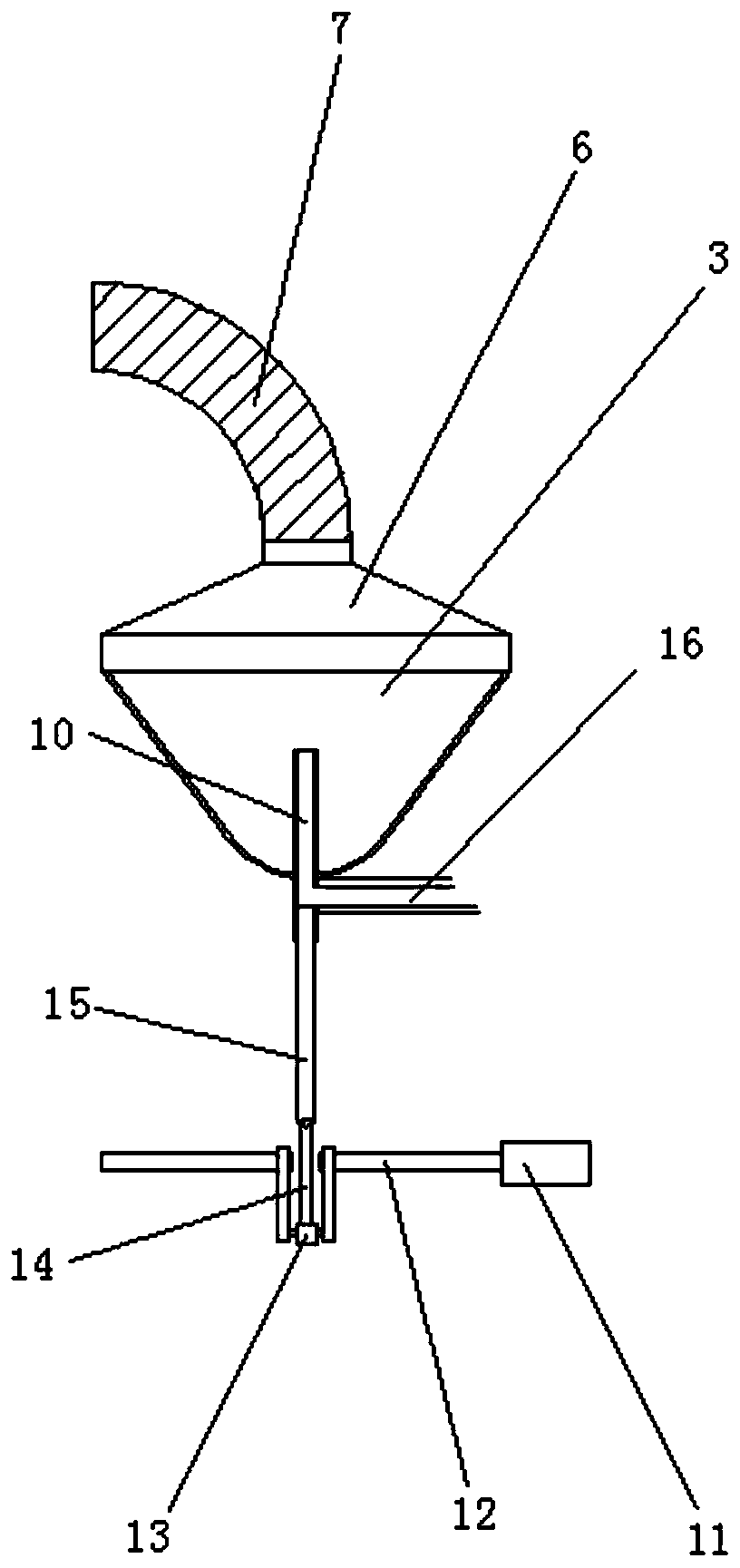

[0040] Embodiment 2: as Figure 5-7 Shown, a kind of gushing type circulation grain dedusting device comprises:

[0041] A base 1, the base 1 is set in a concave shape, a motor 11 is fixedly installed in the middle part of the inner wall on the right side of the base 1, and a crankshaft 12 is fixedly connected to the left end of the motor 11, and the left end of the crankshaft 12 is connected to the base The inner wall on the left side of the seat 1 is rotatably connected, the crankshaft 12 is rotatably sleeved with a sleeve 13, the side wall of the sleeve 13 is fixedly connected with a connecting rod 14, and the top of the connecting rod 14 is rotatably connected with a push rod 15 , the motor drives the crankshaft to rotate and drives the ejector rod to reciprocate up and down through the drum and connecting rod;

[0042]Storage bin 2, the top left side of the storage bin 2 is fixedly equipped with a hoist 4, the bottom of the hoist 4 is located at the bottom of the inner c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com