Grain drying machine with dust-collecting device

A technology for grain dryers and dust collection devices, which is applied in the direction of dryers, drying gas arrangement, drying, etc., and can solve the problems such as the effect of dust removal effect is not obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

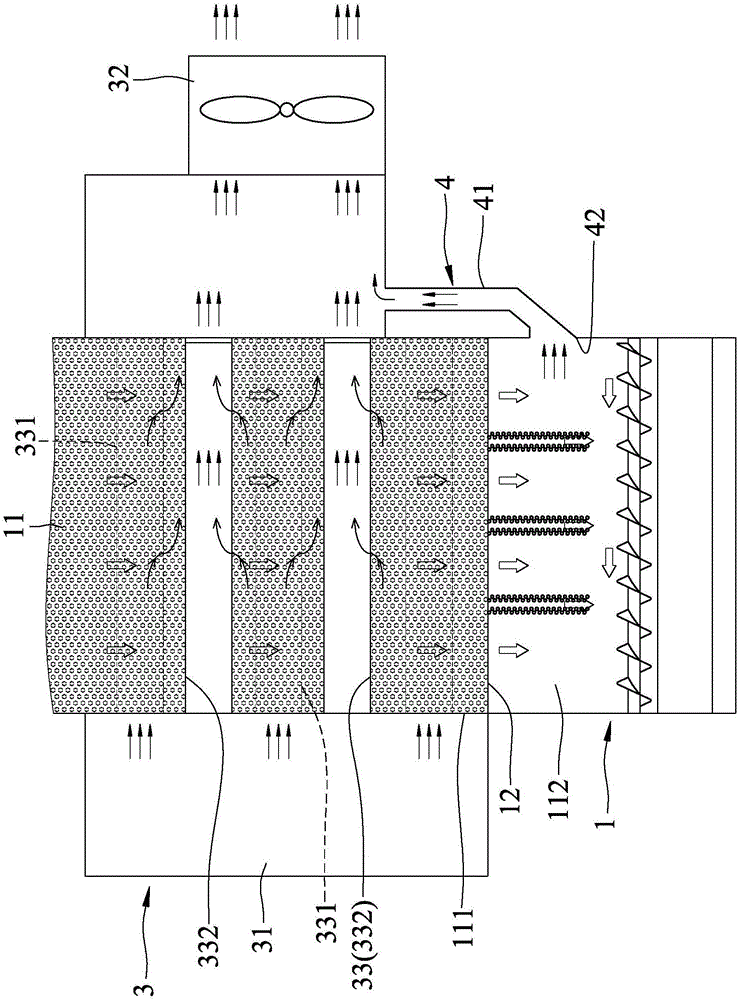

[0011] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

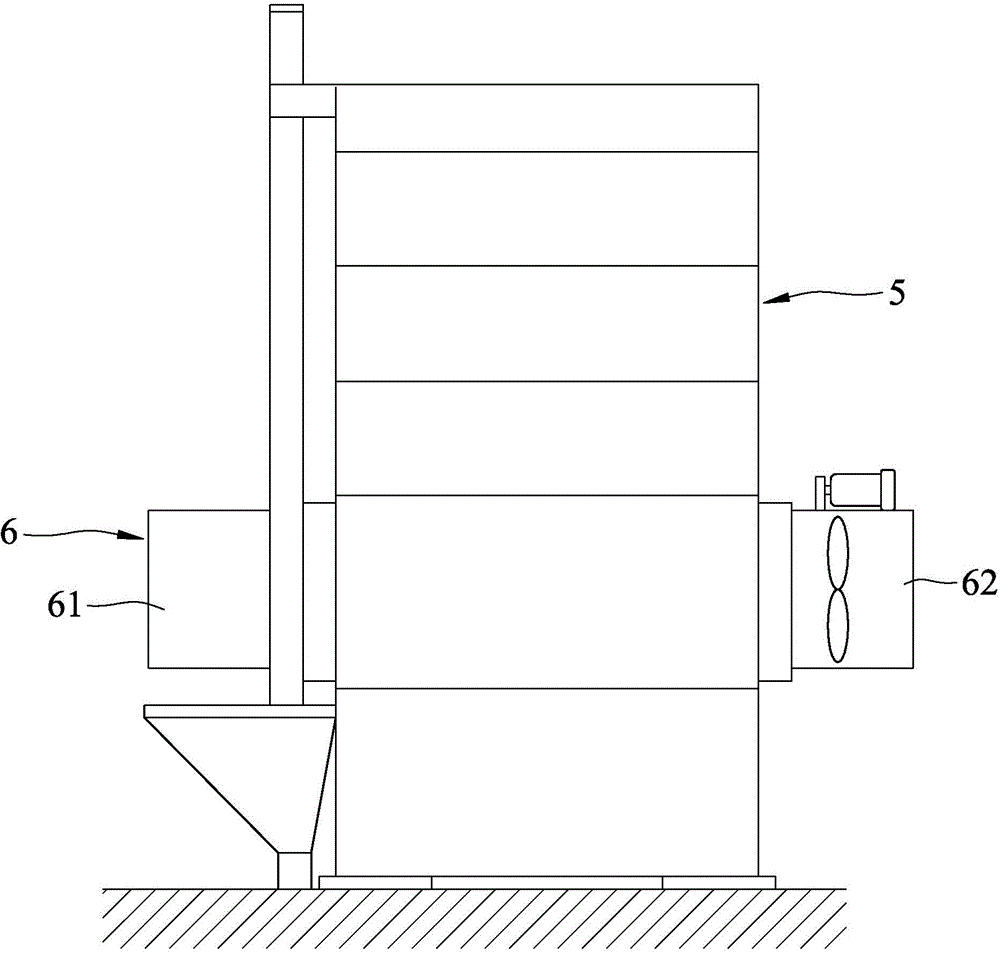

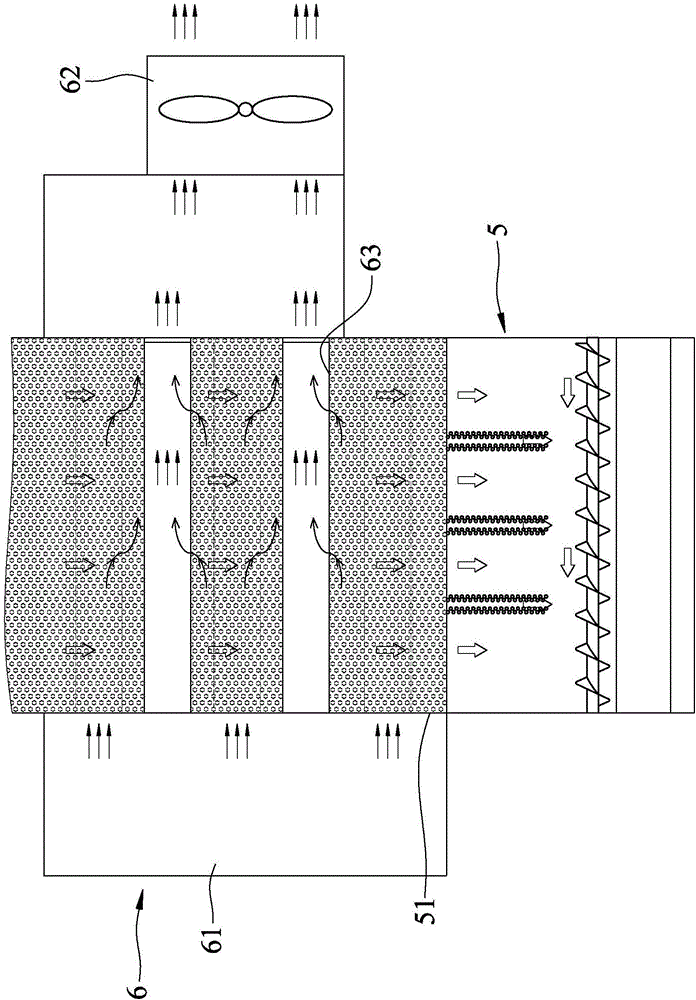

[0012] see image 3 and Figure 4 , The preferred embodiment of the grain dryer with dust collecting device of the present invention includes a casing 1, several claws 2, a hot air dust collecting unit 3, and a main dust collecting unit 4.

[0013] The casing 1 defines a hollow chamber 11 and includes a partition 12 separating the hollow chamber 11 into an upper drying space 111 and a lower grain collecting space 112 . The partition 12 has several openings 121 for the grain to fall from the drying space 111 to the grain collecting space 112 .

[0014] The several claws 2 are rotatably arranged adjacent to the opening 121 and respectively located in the drying space 111 , and can pull the grains located in the drying space 111 and drop them into the grain collecting space 112 . The flow of the grain falling into the grain collecting space 112 from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com