Double-funnel type medium-pressure smoke discharging device for laser engraving (cutting) machine

A technology of laser engraving and smoke exhaust device, which is applied to laser welding equipment, welding equipment, metal processing equipment, etc., to achieve complete smoke exhaust, improve smoke exhaust effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

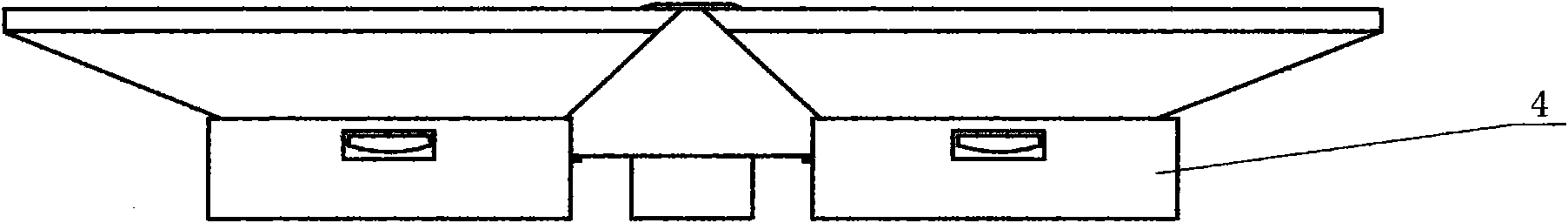

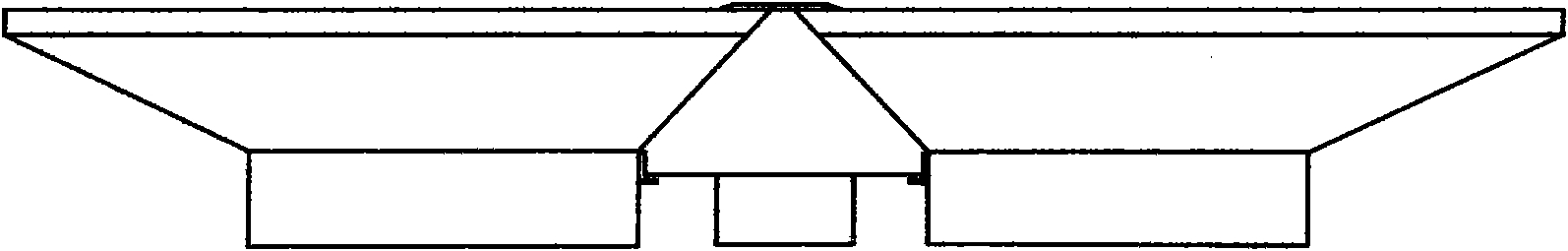

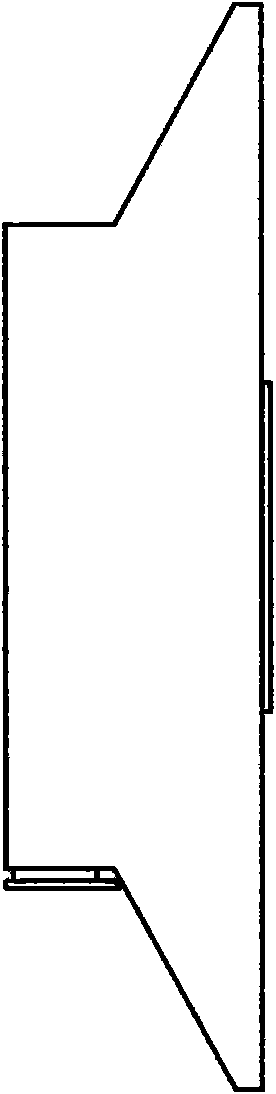

[0014] 1. The smoke exhaust device of the present invention is made of 0.9-1.2MM iron plate. For the specific manufacturing method, please refer to Figure 1 to Figure 7 .

[0015] 2. Place the device on the laminate support 13 under the working surface 8 of the laser engraving (cutting) machine (see Figure eight ). The double bell mouth air suction nozzle 2 is modularized. After taking out the exhaust pipe 6, it is inserted into the bracket 12. The other end of the exhaust pipe 6 is connected to the centrifugal fan 7. A figure-eight movable cover 3 is placed above the suction nozzle to complete the smoke exhaust. System installation (the air nozzle cavity embedded filter 11 is optional).

[0016] 3. When the large-format workpiece 9 is processed, open the air door inserts 5 (A / B) on both sides of the bell mouth, and open the centrifugal fan 7 to work normally. During laser engraving, flue gas mainly concentrates on the workpiece 9 tops, and air inlet holes 13 around the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com