Production of crystal jade glass

A production method and glass technology, applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve problems such as low yield, high requirements for glass powder, and difficult control of internal quality, so as to achieve stable internal quality, The effect of eliminating air bubbles and stabilizing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

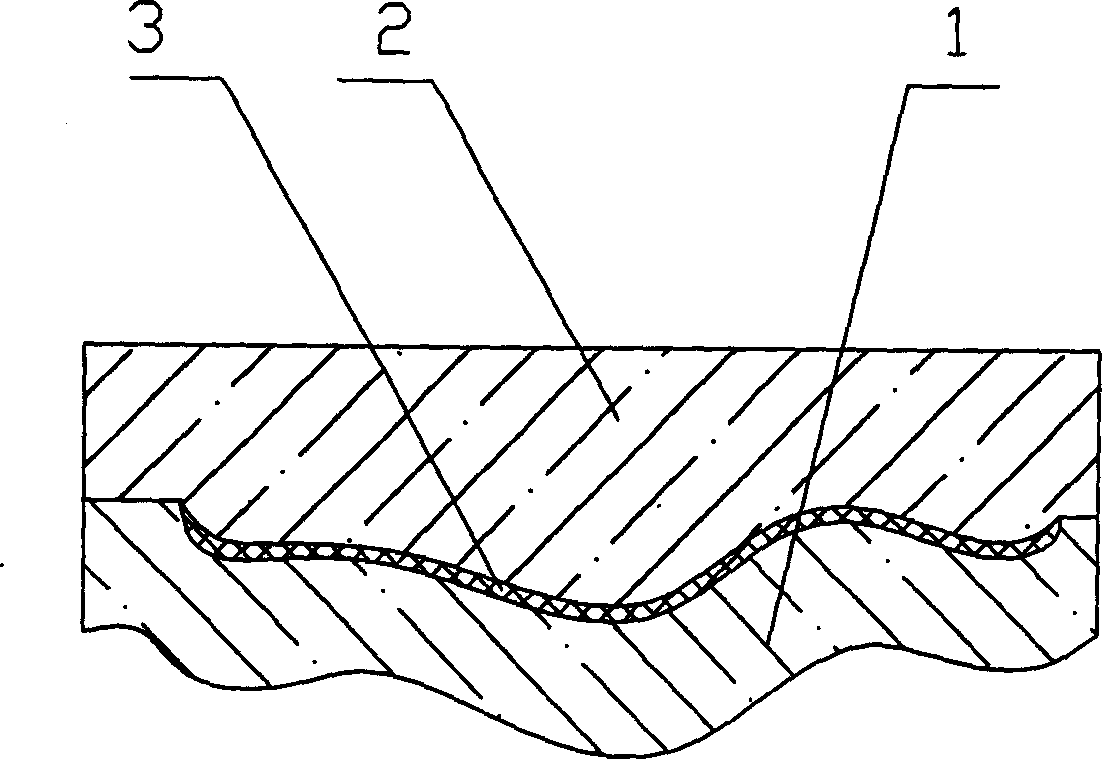

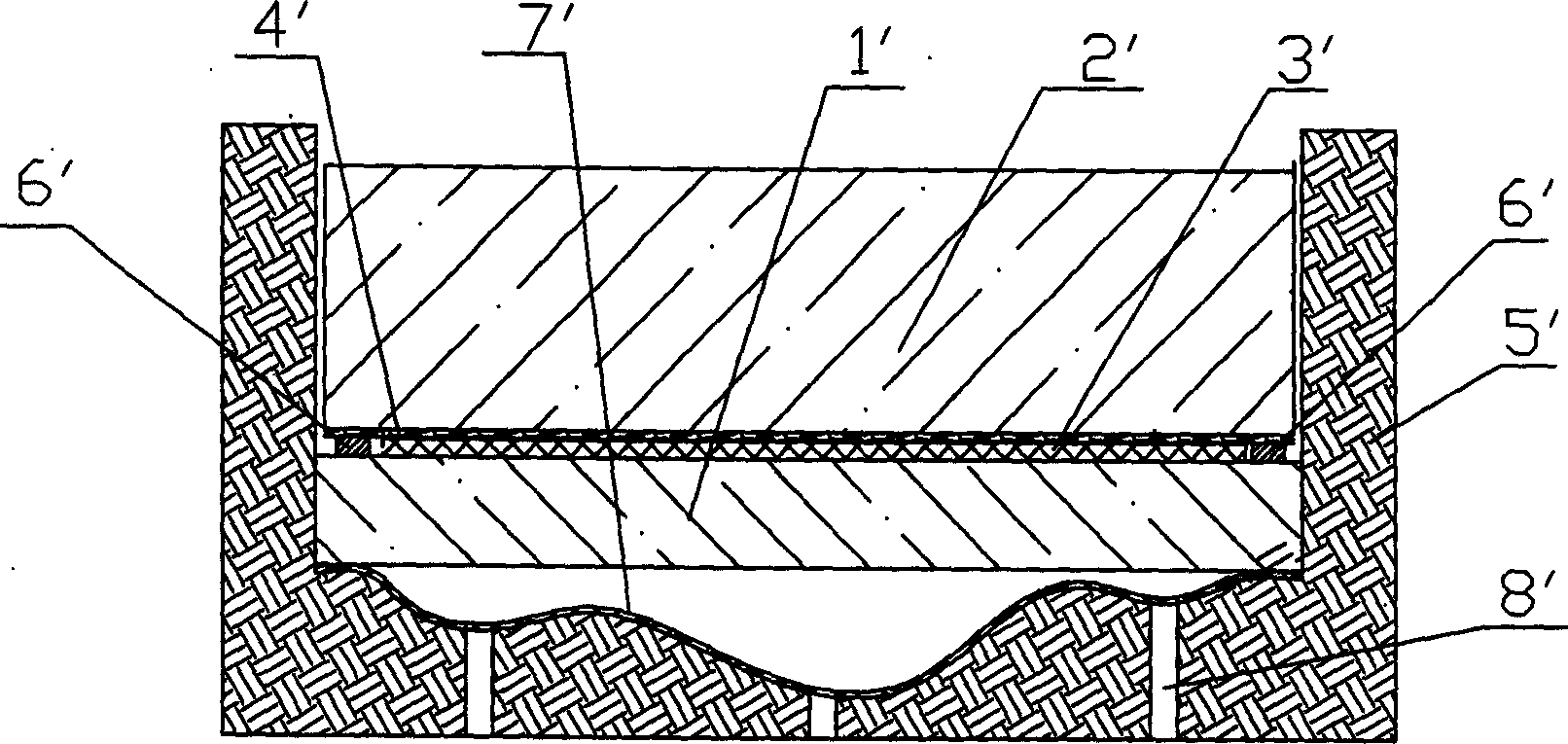

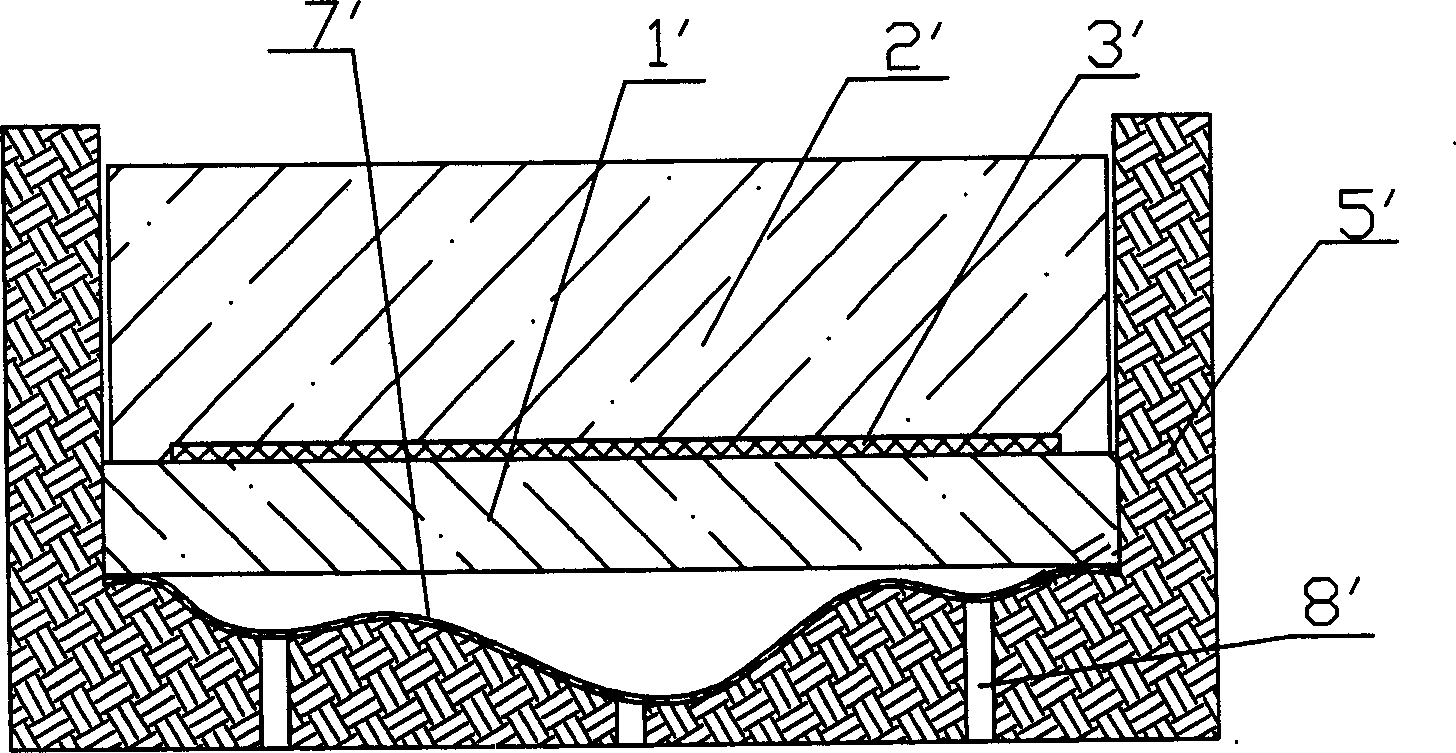

[0018] refer to figure 1 , figure 2 , image 3 , Figure 4 , a preparation method of crystal jade glass, the steps are as follows:

[0019] (a) making the mold 5' with concrete or abstract concave and convex surfaces at the bottom, the mold 5' can be a high-temperature pottery mold or other high-temperature-resistant material mould;

[0020] (b) Put mold release agent 7' on the bottom of mold 5' described in step (a), place flat glass 1' with color layer 3' on one side in mold 5', and place another flat glass 2' It is placed above the flat glass 1' with the color layer 3', and the bottom surface of the above flat glass 2' is coated with a low-temperature flux 4'. Wherein, the flat glass can be an ordinary glass plate with a softening point of about 550-700°C; the low-temperature flux 4' can be a flux whose initial melting temperature is lower than the softening point of the glass plate, such as at 500°C The following flux can advance the softening point of the glass plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com