Soot blower structure of coal burning organic heating medium furnace

A heat carrier furnace and soot blower technology, which is applied to heat storage heaters, fluid heaters, combustion methods, etc., can solve the problems of short working life, large ash amount, and easy burnout of fixed soot blowers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

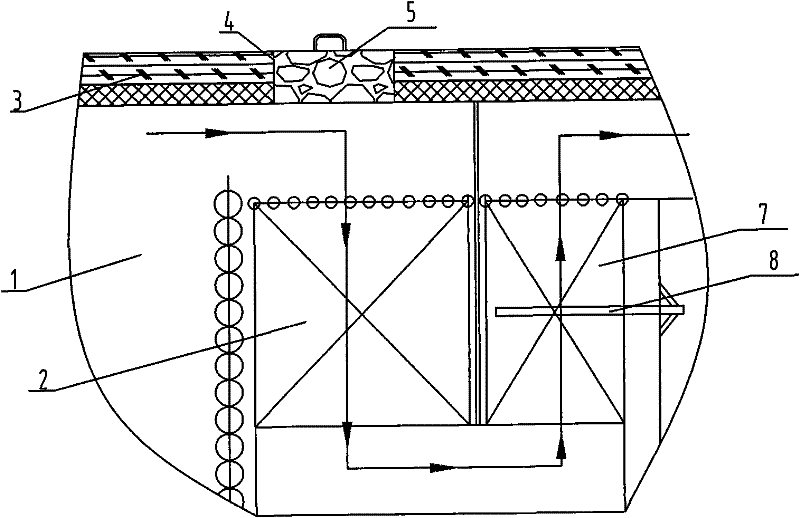

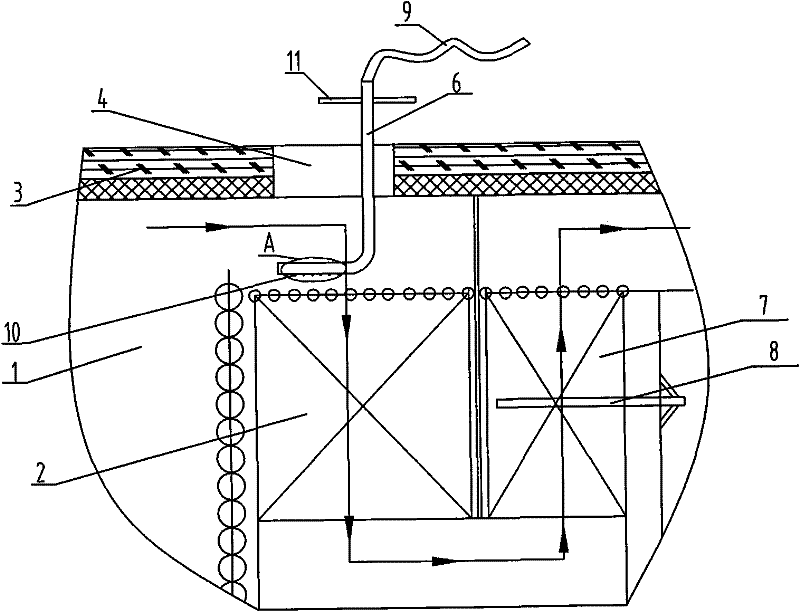

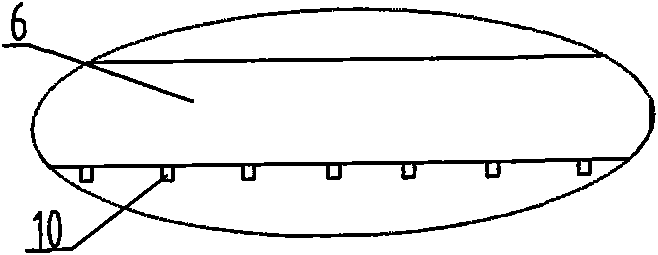

[0012] See figure 1 , figure 2 , image 3 , which includes a furnace 1, a high-temperature convection section 2, a furnace roof 3, a low-temperature convection section 7, and a fixed soot blower 8. The fixed soot blower 8 is installed in the low-temperature convection section 7, and the flue gas from the furnace 1 enters the space of the high-temperature convection section 2. Furnace top 3 has movable groove 4, movable groove 4 is nested with removable cover plate 5, and the junction of high temperature convection section 2 and furnace 1 is equipped with movable soot blowing device; the movable soot blowing device runs through and can be removed The movable groove 4 behind the cover plate 5, the soot blowing side of the movable soot blowing device is facing the junction of the high temperature convection section 2 and the furnace 1, and the intake side of the movable soot blowing device is connected to the external compressed air; the movable soot blowing device Specificall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com