Patents

Literature

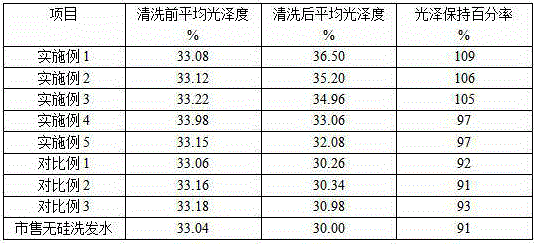

811 results about "Ethylene diamine tetra acetic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethylene diamine tetra acetic acid, widely abbreviated as EDTA is an aminopolycarboxylic acid and a colourless, water-soluble solid. Its conjugate base is named ethylene diamine tetra acetate. It is widely used to dissolve limescale.

Hair-blackening and hair-growing liquid shampoo and preparation method thereof

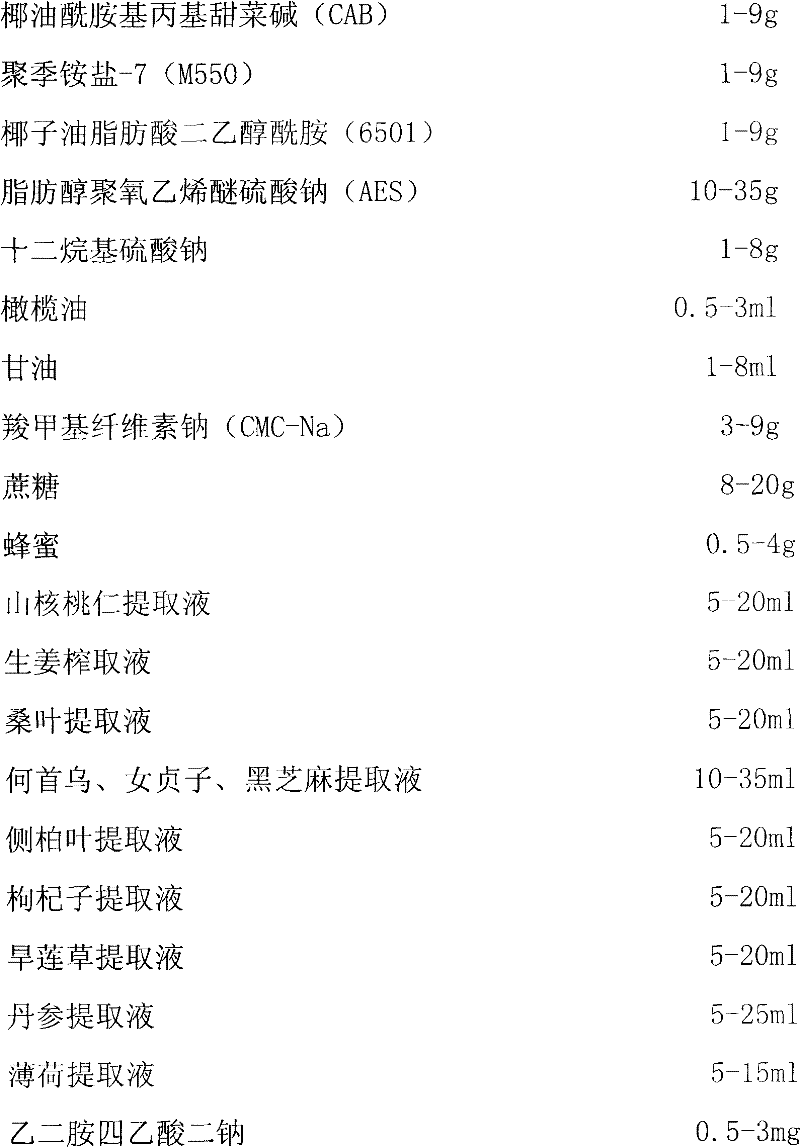

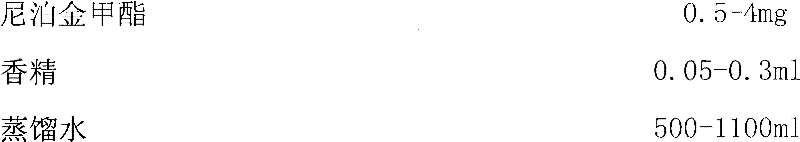

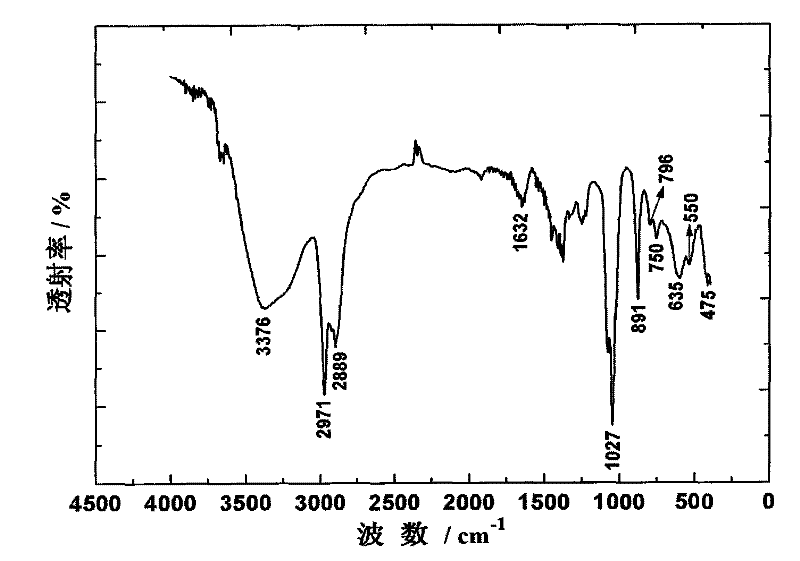

The invention discloses a hair-blackening and hair-growing liquid shampoo and a preparation method thereof. Every 770g of the liquid shampoo comprises the following substances by weight: 1-9g of cocoamidopropyl betaine (CAB), 1-9g of polyquaternium-7 (M550), 1-9g of coconut fatty acid diethanolamide (6501), 10-35g of fatty alcohol-polyoxyethylene ether sodium sulfate (AES), 1-8g of lauryl sodium sulfate, 0.5-3ml of olive oil, 1-8ml of glycerol, 3-9g of sodium carboxymethylcellulose (CMC-Na), 8-20g of cane sugar, 0.5-4g of honey, 5-20ml of a pecan nut extracting solution, 5-20ml of a ginger extracting solution, 5-20ml of a mulberry leaf extracting solution, 10-35ml of a polygonum multiflorum, glossy privet fruit and black sesame extracting solution, 5-20ml of a cacumen biotae extracting solution, 5-20ml of a barbary wolfberry fruit extracting solution, 5-20ml of a yerbadetajo herb extracting solution, 5-25ml of a red-rooted salvia root extracting solution, 5-15ml of a mint extracting solution, 0.5-3mg of ethylene diamine tetraacetic acid, 0.5-4mg of methyl-p-hydroxy benzoate, 0.05-0.3ml of essences and 500-1,100ml of distilled water. The hair-blackening and hair-growing liquid shampoo prepared with the method has the advantages of light yellow color, transparency, glittering, proper viscosity and consistency, high stability, aromatic smell, and capabilities of supplying nutrients to scalp, nourishing deep scalp, and making hairs become black, smooth and elastic.

Owner:广州市昌盛化妆品技术有限公司

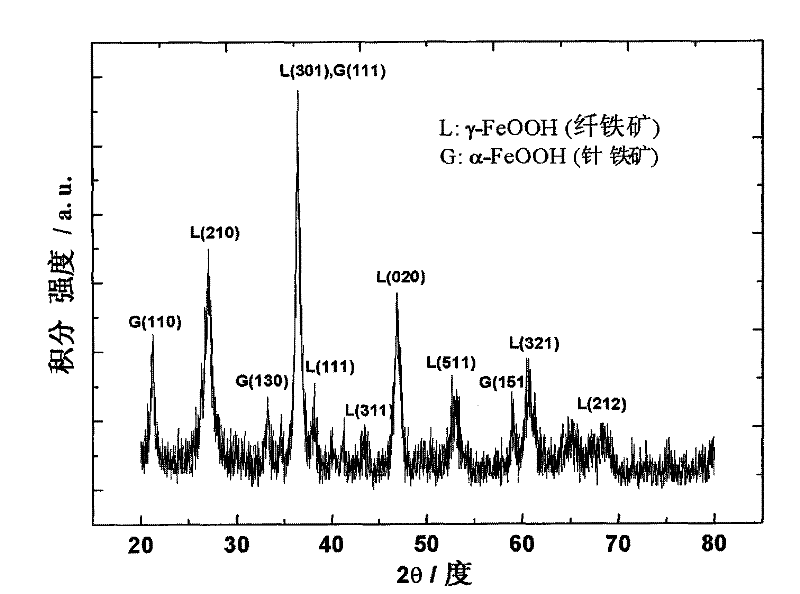

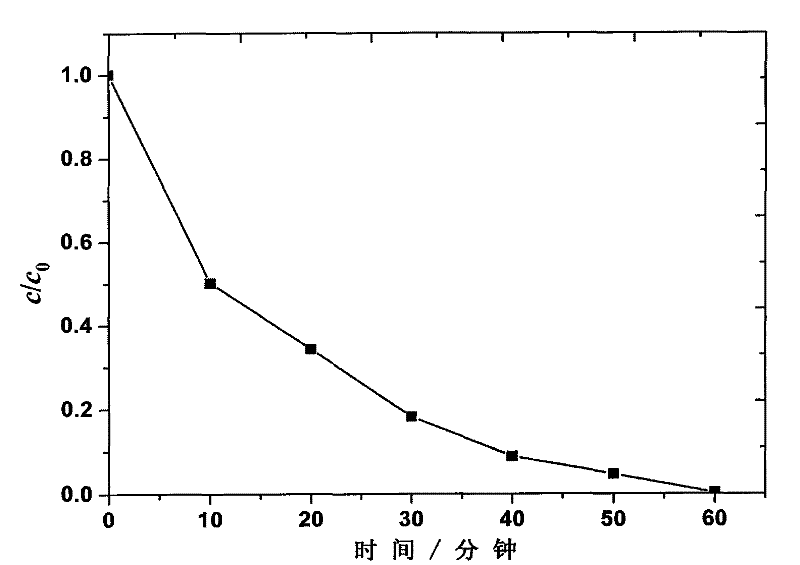

Preparation method of supported FeOOH catalyst, and electro-Fenton waste water treatment system

ActiveCN102218319AEasy to separateNothing producedMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationSludgeWater processing

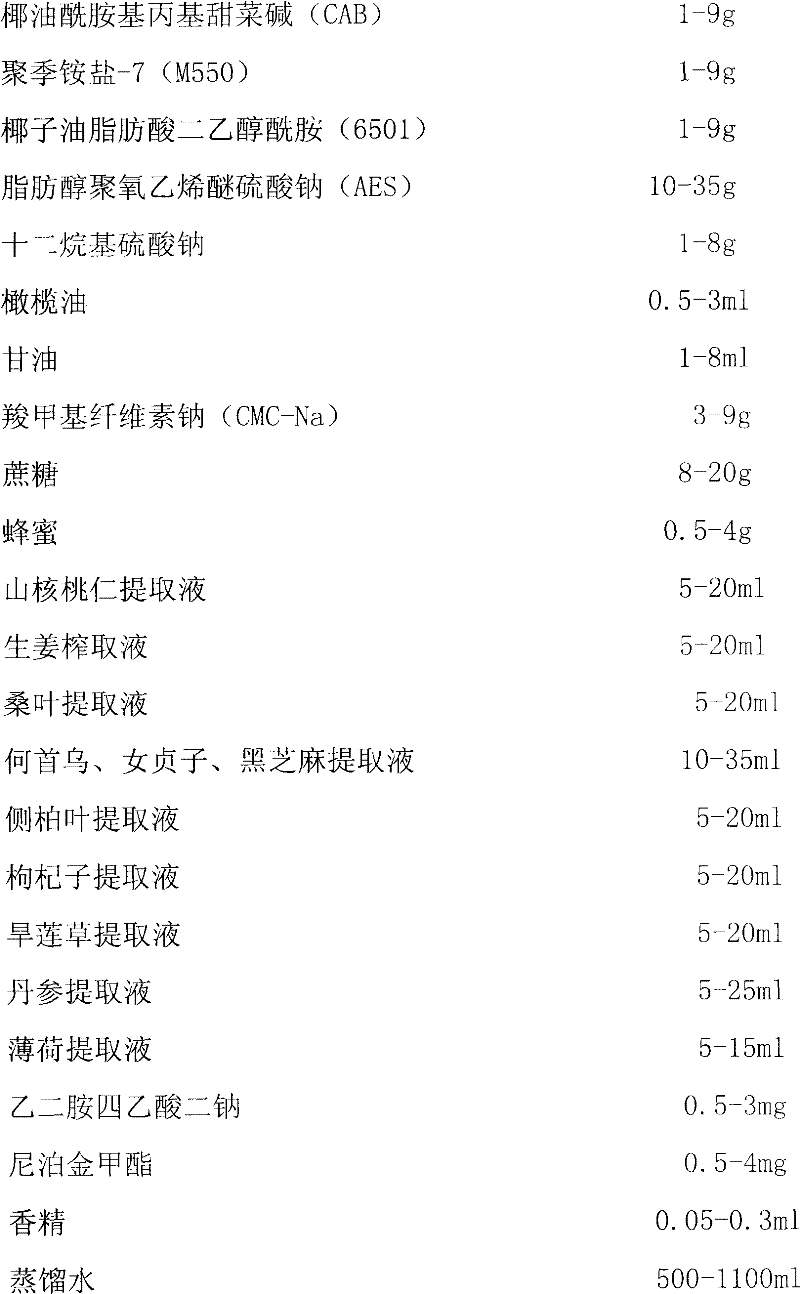

The invention discloses a preparation method of a supported FeOOH catalyst, and an electro-Fenton waste water treatment system. The invention belongs to the technical field of waste water processing. The invention is characterized in that active carbon is utilized as a carrier and ferrous sulphate is utilized as a precursor; through dipping, ethylene diamine tetraacetic acid and ammoniacal undergo an oxidation reduction reaction with active carbon and ferrous sulphate in the presence of oxygen to produce active carbon supported objects and then the active carbon supported objects are washed by deionized water and then are placed in a vacuum oven to be dried at a temperature of 40 to 50 DEG C for 10 to 12 hours to form a supported FeOOH catalyst; active components of the supported FeOOH catalyst comprise alpha-FeOOH and gamma-FeOOH; and under an applied electric field, an out-phase electro-Fenton oxidation system is composed of the supported FeOOH catalyst and hydrogen peroxide and canremove efficiently organic pollutants in waste water. The invention has effects and advantages that an out-phase catalyst can be separated from waste water easily and recycled, and an out-phase electro-Fenton oxidation system can operate in a neutral medium without need of PH adjustment and generation of chemical sludge.

Owner:DALIAN UNIV OF TECH

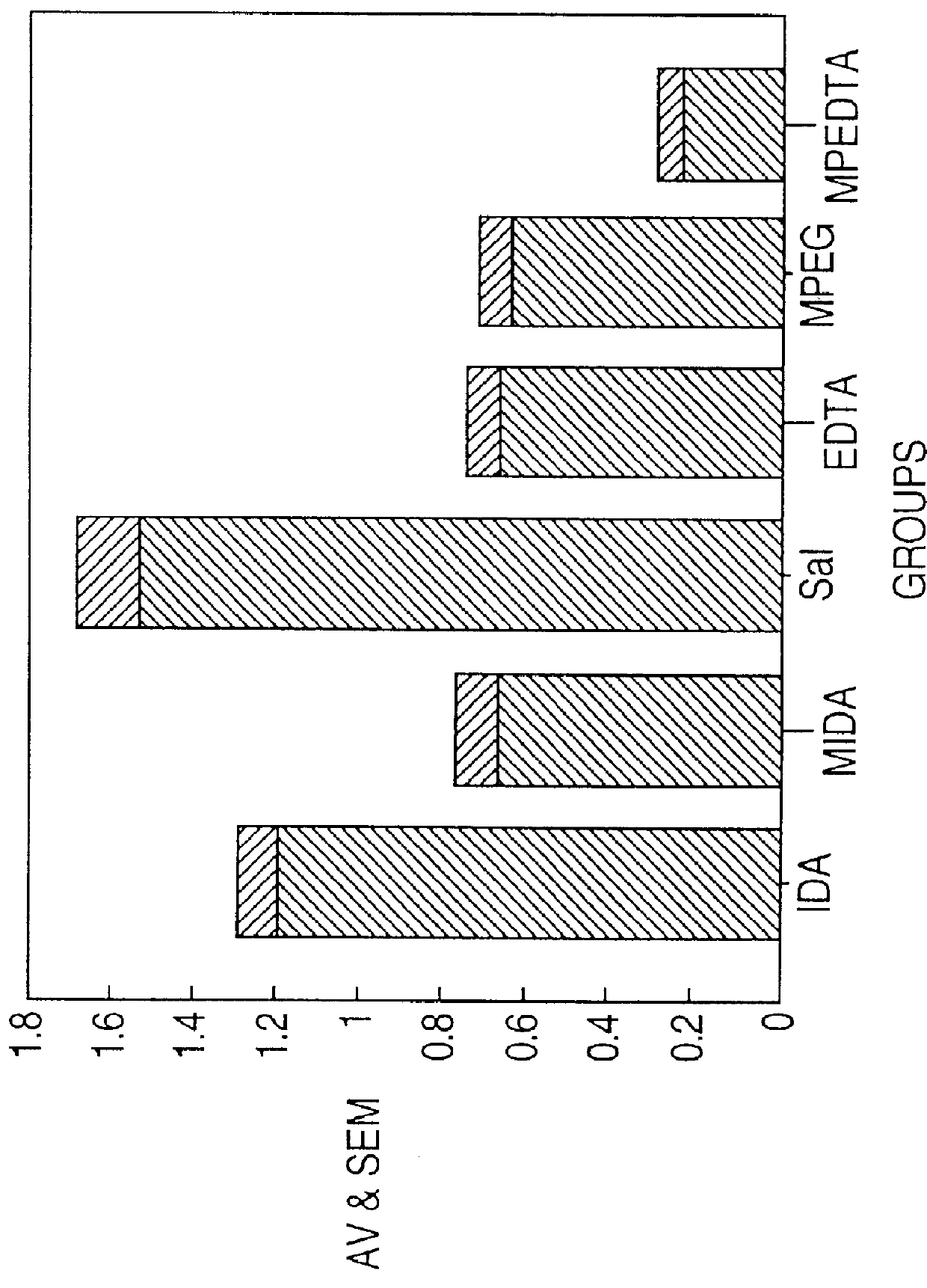

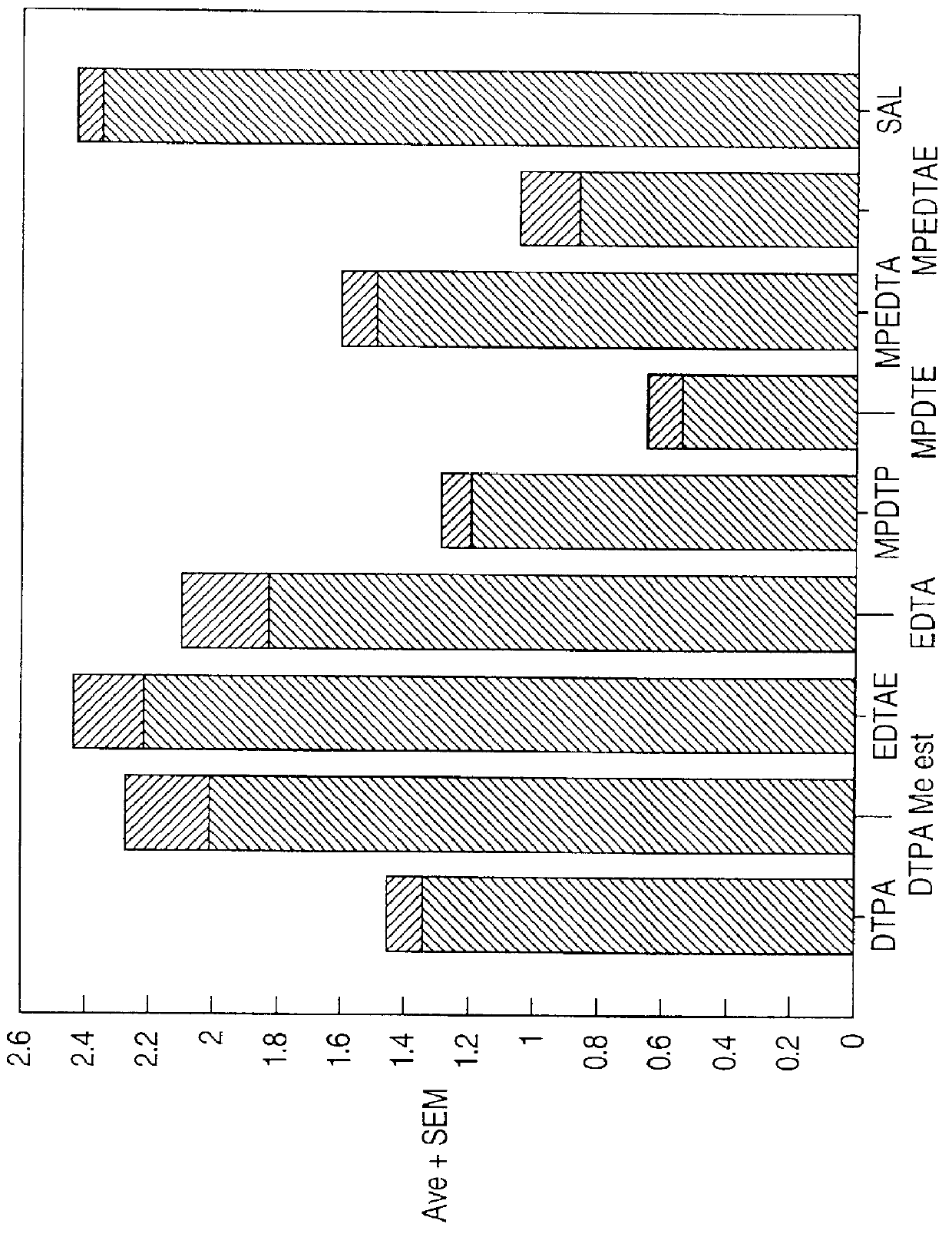

Chelate derivatives as protectors against tissue injury

Derivatives useful in the protection of living organisms against damage due to free radical reactions derived from methoxypolyethylene glycols (MPEG), which are modified by chemically attaching chelating groups in an amide or amine linkage to the nonmethyl end of the polymer. Such chelating groups include ethylene-diamine tetraacetic acid (EDTA), diethylene triamine pentaacetic acid (DTPA), and ethylene glycol aminoethyl ether tetraacetic acid (EGTA), and pharmacologically acceptable salts or esters thereof.

Owner:EASTERN VIRGINIA MEDICAL SCHOOL

Water-soluble organic liquid fertilizer and preparation method thereof

InactiveCN101723735APromote absorptionPromote vegetative growthClimate change adaptationBioloigcal waste fertilisersInsect pestPlant disease

The invention discloses a water-soluble organic liquid fertilizer and a preparation method thereof. The fertilizer is prepared from the following raw materials in percentage by weight: 40 to 80 percent of molasses fermentation liquid, 10 to 50 percent of biochemical potassium fulvate, 3 to 10 percent of boric acid, 2 to 8 percent of ethylene diamine tetra-acetic acid, 1 to 5 percent of heptahydrate zinc sulphate, 2 to 6 percent of manganese sulfate monohydrate, 0 to 5 percent of ferrous sulphate heptahydrate and the balance of water, wherein the sum of the raw materials is 100 percent. The production method for the fertilizer comprises the following steps: putting the molasses fermentation liquid in an amount which is one third of the formulation amount and the water into a reaction kettle, heating the mixture to 60 DEG C, and adding the ethylene diamine tetra-acetic acid into the mixture; adding the heptahydrate zinc sulphate, the manganese sulfate monohydrate and the ferrous sulphate heptahydrate into the mixture, and stirring the mixture for 30 minutes; and adding the boric acid, the residual molasses fermentation liquid and the biochemical potassium fulvate into the mixture, stirring the mixture for 30 minutes and cooling the mixture. The fertilizer is brown liquid, has multiple fertilization modes, can prevent multiple plant diseases and insect pests, increase the yield of crops, improve the quality and increase the yield by 10 to 20 percent, and makes a contribution to the development of organic agriculture.

Owner:SHAANXI HUAXIA AGRI TECH DEV

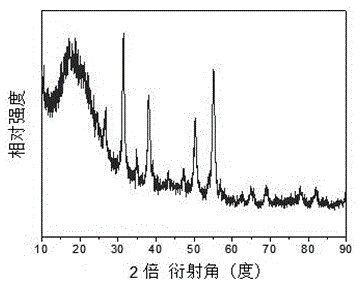

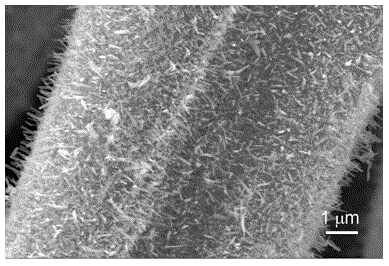

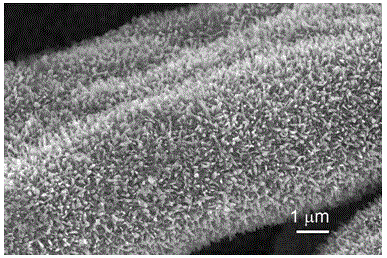

One-dimensional NiCo2S4 crystal array on surface of activated carbon fiber and preparation method of one-dimensional NiCo2S4 crystal array

ActiveCN104088016ALarge specific surface areaFacilitates directional transferPolycrystalline material growthFrom normal temperature solutionsFiberNickel salt

The invention discloses a one-dimensional NiCo2S4 crystal array on the surface of an activated carbon fiber and a preparation method of the one-dimensional NiCo2S4 crystal array. The preparation method comprises the following steps: dissolving soluble nickel salt and soluble cobalt salt in water, wherein the mole number ratio of nickel ions to cobalt ions is 1:2; adding ethylene diamine tetraacetic acid of which the mole number is equal to one half of the total mole number of nickel and cobalt ions and thiourea of which the mole number is equal to 5-10 times of the total mole number of nickel and cobalt ions; immersing an activated carbon fiber in the solution and soaking; then carrying out hydrothermal treatment at the temperature range of 150-260 DEG C; washing hydrothermally treated activated carbon fiber and drying to obtain the one-dimensional NiCo2S4 crystal array growing on the surface of activated carbon fiber. Since the one-dimensional NiCo2S4 crystal array on the surface of the activated carbon fiber obtained by the invention has the directional growth structure, the specific surface area of the activated carbon fiber can be improved, and the one-dimensional NiCo2S4 crystal array is conducive to electronic transport and is an ideal catalyst material and electrode material.

Owner:INNER MONGOLIA PURUIFEN ENVIRONMENTAL SCI ANDTECH

Cleaning agent for ceramic film and its preparation method

InactiveCN1837341AReduce concentration polarizationReduce cleaning frequencySemi-permeable membranesSurface-active detergent compositionsCelluloseCleansing Agents

The invention discloses a ceramic film abluent and preparing method, which comprises the following parts: 50-75 percent NaOH, 3-15 percent sodium polyphosphate, 5-15 percent sodium alkyl benzene sulphonate, 2-8 percent diatomite, 1-8 percent liquid glass, 0-5 percent sodium sulfate, 0-20 percent sodium carbonate, 0-5 percent methylol cellulose and 0-5 percent ethylene diamine tetraacetic acid tetrasodium salt. These components are added int the stirring and grinding corrosion-proof reactor sequently, which is stirred and grinded evenly at room temperature at 4-8 h to obtain the product. The invention shortens the system cleaning time and reduces the system consumption, which doesn't damage ceramic film.

Owner:JIANGSU JIUWU HITECH

Antibacterial soap-based shower gel and preparation method thereof

ActiveCN104800123AImprove antibacterial propertiesGood moisturizing effectCosmetic preparationsToilet preparationsShower gelGlycerol

The invention discloses an antibacterial soap-based shower gel and a preparation method thereof. The shower gel comprises the following ingredients: thymol, salicylic acid, plants extracts, ethyl alcohol, propylene glycol, erythritol, lauric acid, myristic acid, palmitic acid, potassium hydroxide, glycol distearate, dihexyl sodium sulfosuccinate, cocamidopropyl betaine, sodium cocoyl glycinate, polyquaternium-7, polyglyceryl fatty acid ester composition, ethylene diamine tetraacetic acid tetrasodium, sodium chloride, citric acid, essence, a preservative and water. The antibacterial soap-based shower gel is soft and friendly to skin, can effectively resist bacteria and moisturize skin and is particularly applicable to people with thicker cuticle, high grease secretion, skin pruritus and tinea corporis.

Owner:WALCH GUANGZHOU COMMODITY

Heavy metal sewage treatment agent

InactiveCN104118921ARemove reachEasy to remove by filtrationWater/sewage treatment by ion-exchangeWater/sewage treatment by flocculation/precipitationCelluloseCarbamate

The invention relates to a heavy metal sewage treatment agent which is prepared from dodecyl diethylene triamine, dimethyl diallyl ammonium chloride, acrylamide, dibenzoyl peroxide, powdered activated carbon, ethylene diamine tetraacetic acid, tert-butylamine, carbamate, dithiocar-bamate, thiocarbamic acid ester, starch, cellulose, water soluble starch xanthate ester, sodium silicate, potassium peroxodisulfate, sodium hydrosulfite, strong base and water. The heavy metal sewage treatment agent disclosed by the invention is formed by being modified with a high-molecular compound; the mixture contains a plurality of active groups which can be complexed, chelated, absorbed and exchanged with heavy metal, so that heavy metal ions in the aqueous solution can be removed; the heavy metal sewage treatment agent has good removal effect on heavy metal ions, the removal rate is above 97%, and furthermore, the heavy metal sewage treatment agent has stronger Ca2+ and Mg2+ resistant capability; the removal rate of cadmium-containing sewage is 99.8%, which meets the national emission standard; and the removal rate of chromium-containing sewage is above 99.6%.

Owner:江西省恩皓环保有限公司

Stable injectable compositions

This invention relates to a stable parenteral aqueous solutions comprising either (a) diclofenac or a pharmaceutically acceptable diclofenac salt and a cyclodextrin, or (b) an inclusion complex of diclofenac or a pharmaceutically acceptable diclofenac salt and a cyclodextrin, or a mixture of (a) and (b), which are suitable for intramuscular and intravenous administration. The solutions contain diclofenac or diclofenac salt, cyclodextrin, and an antioxidant selected from monothioglycerol, or a combination of ethylene diamine tetra-acetic acid and N-acetyl-cysteine.

Owner:SHIMODA BIOTECH PTY LTD

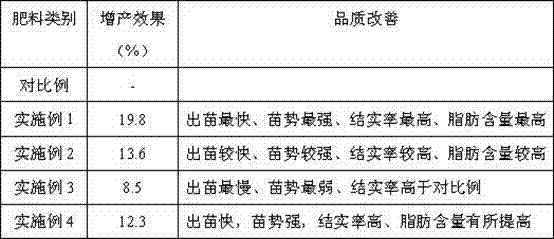

Humic acid full-nutrition type fertilizer special for peanuts and preparing method thereof

ActiveCN102503724ASimple structureImprove stress resistanceFertilizer mixturesBiotechnologyEthylene diamine tetra acetic

The invention discloses a humic acid full-nutrition type fertilizer special for peanuts and a preparing method thereof, which relate to the technical field of fertilizers special for crops. Raw materials of the humic acid full-nutrient type fertilizer, such as urea, potassium sulfate or potassium chloride, calcium magnesium phosphate, monoammonium phosphate, humic acid, ferrous sulfate, zinc sulfate, ethylene diamine tetra acetic acid (EDTA) chelating manganese, sodium borate and ammonium molybdate are dosed according to a specified ratio, and a finished product of the humic acid full-nutrition type fertilizer is obtained through stirring, granulating, secondary drying and cooling, sieving, film enveloping, measuring and packing. Compared with the prior art, the humic acid full-nutrient type fertilizer special for peanuts has the advantages of being complete in nutrition and improving the yield and the quality of the peanuts.

Owner:STANLEY AGRI GRP CO LTD

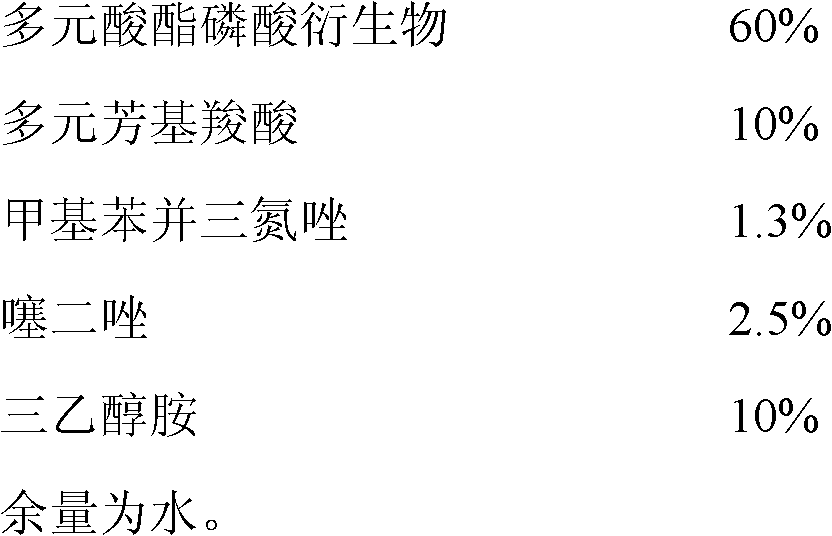

Ferrous sulfide dirt neutral complexing cleaning agent and preparation method thereof

ActiveCN103194325ATo achieve the purpose of safe productionImprove anti-corrosion performanceNon-ionic surface-active compoundsOrganic detergent compounding agentsChemical industrySodium acetate

The invention relates to an equipment cleaning agent which is used in the field of petroleum and chemical industry, in particular to a ferrous sulfide dirt neutral complexing cleaning agent which is used for washing a synthesized ammonia low-temperature methanol washing unit system in the petroleum chemical industry and the coal chemical industry. The ferrous sulfide dirt neutral complexing cleaning agent is prepared from the following raw materials in parts by weight: 5 to 8 parts of sodium gluconate, 7 to 11 parts of sodium salicylate, 20 to 26 parts of gadoliniam diethylene triamine pentaacetic acid, 20 to 26 parts of sodium ethylene diamine tetracetate, 40 to 46 parts of propenoic acid-itaconic acid copolymer, 25 to 32 parts of disodium polyepoxysuccinicate, 12 to 15 parts of sodium hydroxyphenylace, 3 to 7 parts of triethanolamine, 3 to 7 parts of hydrogen peroxide, 0.1 to 0.3 part of lauryl sodium sulfate, 0.1 to 0.3 part of polydimethyl siloxane fluid and 40 to 45 parts of water. The ferrous sulfide dirt neutral complexing cleaning agent is free from generating hydrogen sulfide when cleaning the ferrous sulfide dirt and corroding the equipment and has strong capacity for complexing the iron ions, the removal speed is fast, the decontamination rate is more than 98 percent, the neutralization and passivation are unnecessary to carry out after the chemical washing, and the equipment can be put into operation immediately.

Owner:GANSU HEIMA PETROCHEM ENG

Formula for coal-fired flue gas denitrification catalyst activity regeneration

InactiveCN102764675ADispersed particle separationCatalyst regeneration/reactivationPtru catalystAmmonium paratungstate

Provided is a formula for coal-fired flue gas denitrification catalyst activity regeneration, belonging to the technical field of air pollution control. The formula of the invention mainly makes use of a composite regeneration solution mainly including (NH4)2SO4, ethylene diamine tetraacetic acid (EDTA), alkylphenol ethoxylates (OP-(n), n=10), high-carbon fatty alcohol polyoxyethylene ether (penetrantfor JFC and nylon leveling agent O), ammonium metavanadate and ammonium paratungstate to recover the activity of a deactivated catalyst. The formula of the invention selects the inexpensive and operationally safe (NH4)2SO4 as the main ingredient of a regenerant, adds the EDTA component, and effectively removes heavy metal elements on the surface of the catalyst. The formula can maximally recover the catalyst activity on the basis of no influence on the mechanical properties of the catalyst.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

Treatment and composition for achieving skin anti-aging benefits by corneum protease activation

Novel methods and compositions for treating aged and environmentally damaged skin are disclosed which provide improvements in the skin's visual appearance, function and clinical / biophysical properties by activating at least one proteolytic enzyme in the skin's stratum corneum. The disclosed treatment methods involve topical application of a novel cosmetic composition containing a combination of a cationic surfactant such as N,N,-dimethyldodecyl amine oxide (DMDAO), an anionic surfactant such as sodium dodecyl sulfate (SDS), or monoalkyl phosphate (MAP) and a chelating agent such as ethylene diamine tetraacetate (EDTA) to stimulate a chronic increase in the replacement rate of the skin's stratum corneum by means of corneum protease activation. This chronic, low level stimulation is effective to induce repair and replacement of the stratum corneum, epidermis, and dermis of the skin and improvements in the appearance, function, and anti-aging properties of the skin.

Owner:ALLUSTRA TECH LLC

Hydrogel dressing capable of promoting wound healing and preparation method thereof

The invention discloses a hydrogel dressing capable of promoting wound healing and a preparation method thereof. The hydrogel dressing consists of: by mass, 25-35% of glycerin, 0.1-0.5% of sodium hyaluronate, 5-10% of a skeletal material, 0.1-0.2% of tartrate, 0.01-0.2% of disodium ethylene diamine tetraacetate, 0.1-0.2% of ethylparaben, 0.1-0.4% of a cross-linking agent, 0.5-1.5% of a filler, 0.01-0.1% of an essential component and 60-65% of deionized water. Due to the interaction between an oil phase and a water phase, a compact net structure is formed and water and the essential component are held in a gel, and after solidification and sterilization, the hydrogel dressing capable of promoting wound healing is prepared. The dressing is applicable to postoperative wound nursing of surgery and gynaecology and obstetrics, and helps to make the surface of the wound keep moist, effectively promote wound healing and inhibit scar hyperplasia.

Owner:JIANGSU CHANGJIYONG BIOTECH CO LTD

Foaming agent for shield

The invention discloses a foaming agent for a shield. The foaming agent contains the components in percentage by weight: 1.0-10.0% of alpha-olefin sulfonate (AOS), 1.0-8.0% of sodium fatty alcohol -polyoxyethyleneether sulfate (AES), 1.0-6.0% of ammonium lauryl sulfate (K12 ammonium), 1.0-6.0% of cocoanut fatty acid diethanolamide (6501), 1.0-5.0% of dodecyl dimethyl betaine (BS-12), 0.005-0.1% of fluorocarbon surfactant (FS), 0.2-5.0% of sodium nitrilo triacetate (A92R), 0.2-5.0% of ethylene diamine tetraacetic acid disodium salt (EDTA) and the balance of water. The foaming agent for the shield provided by the invention realizes high multiple foaming rate, long foam stabilizing time, nontoxicity and innocuity and is an environment friendly biodegradable product which does not contain phosphorus.

Owner:GUANGZHOU TAISHENG BIOTECH

Agrochemical formulation aid composition and uses thereof

InactiveUS6936572B2Improve biological activityEasy to storeBiocideDead animal preservationWaxChemistry

There is provided an agrochemical formulation aid composition for preparing bioactive and sprayable agrochemicals, wherein various components for the composition were selected from mineral oil paraffinic distillate and / or aromatic hydrocarbon distillate; 2N-octanol; oleyl-cetyl; alcohol polyoxyethylene (2) oleylether; polyoxyethylene (8) nonylphenolethin and / or ethoxylated tallow amine blend; lauryl sulphate; fatty alcohol alkoxylate; terpenes, diammonium phosphate; tetrasodium ethylene diamine tetracetate; cab-o-sil; fatty acid methyl ester; (C18) free fatty acid blend; N-butanol; and methyl alcohol. Also provided are methods of preparing the formulation aid composition on site by mixing various components and methods of preparing sprayable and bioactive agrochemical systems using the formulation aid and non-formulated or formulated agrochemicals. Also provided are uses of the formulation aid in preparing sprayable and bioactive agrochemical systems for controlling pests.

Owner:ADJUVANTS PLUS INC

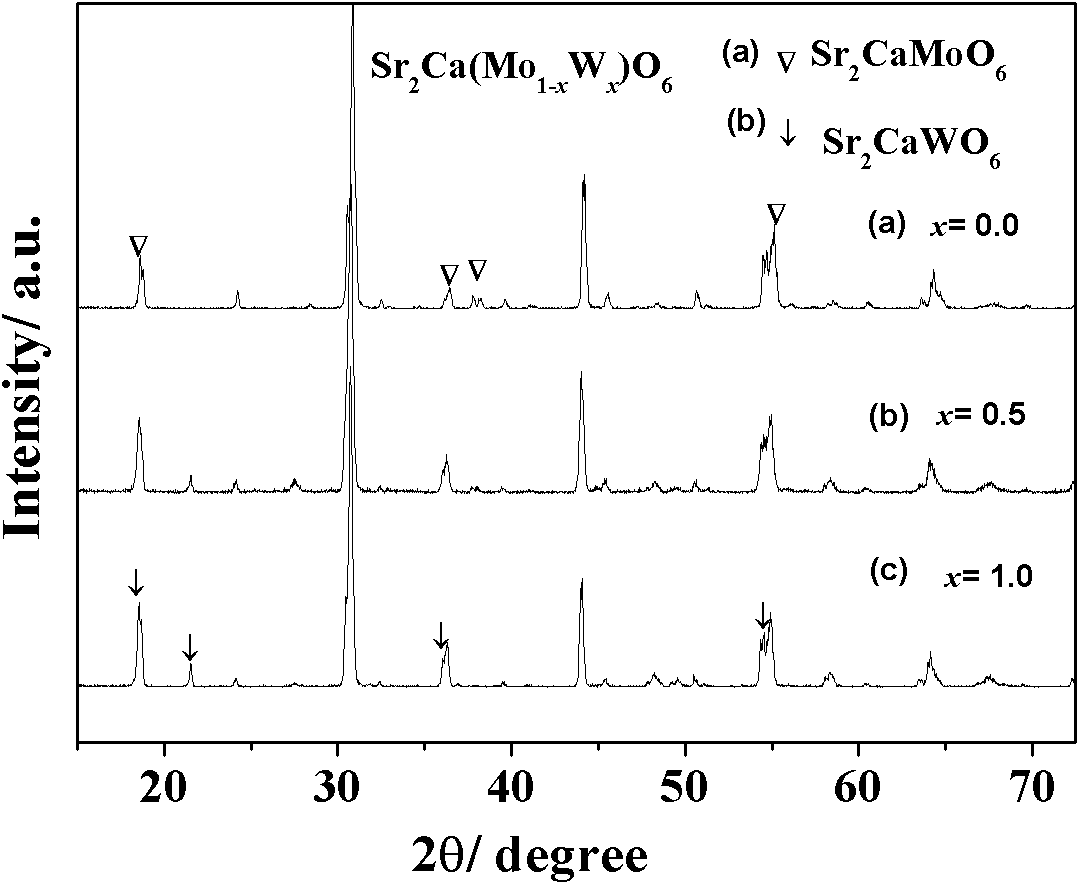

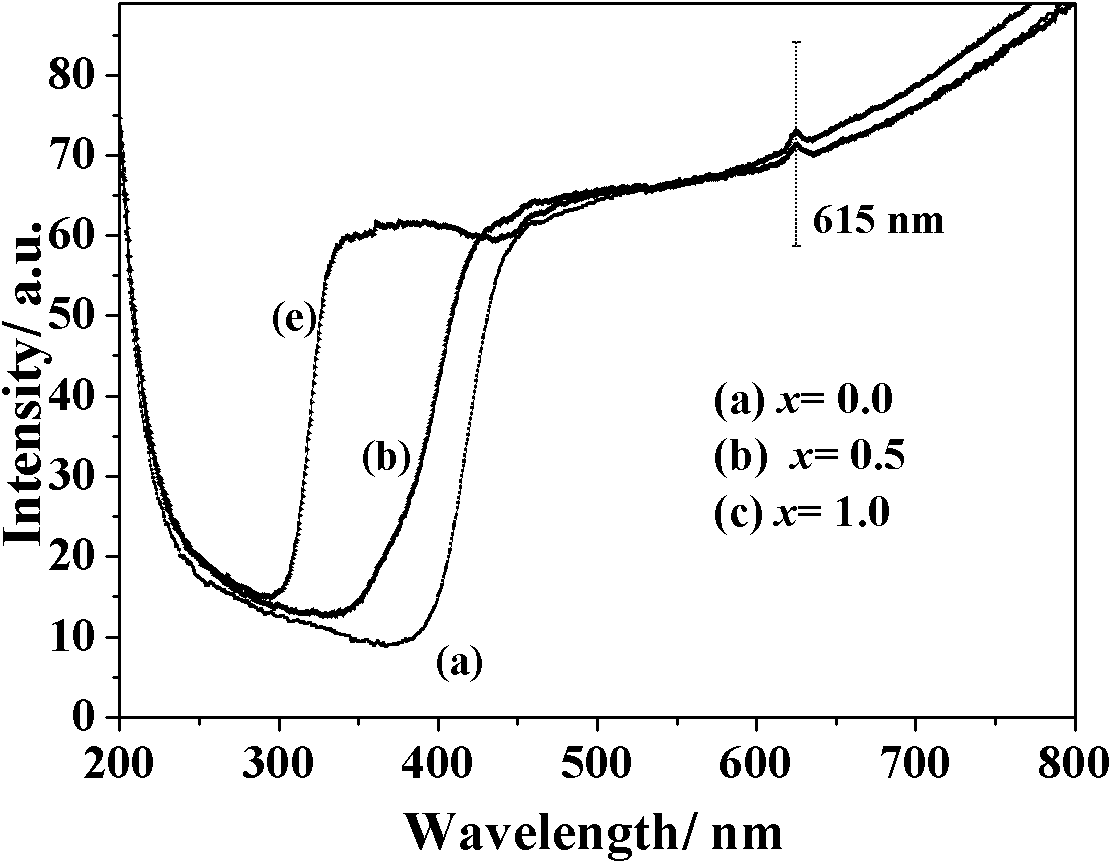

Preparation method of ion-doped double perovskite structure tungsten molybdate oxide powder

The invention relates to a preparation method of ion-doped double perovskite structure tungsten molybdate oxide powder. The preparation method is implemented through gelatinization and redox reaction of metal nitrate, tungsten ammonium molybdate, citric acid and ethylene diamine tetraacetic acid (EDTA) by a sol gel combustion synthesis method, wherein the citric acid and the EDTA serve as complexing agents. The prepared powder is a double perovskite component shown in the following formula: (A1-xMex)2B(Mo1-yWy)O6 or A2(B1-xMex)(Mo1-yWy)O6, wherein A is at least one of Ba, Sr or Ca; B is one of Ca, Mg, Ni, Fe, Co or Zn; A and B are not Ca at the same time; Me is one or two of rare elements or transition metal elements; x is more than or equal to 0.0 and less than or equal to 0.5; and y is more than or equal to 0 and less than or equal to 1. According to the prepared powder, single-phase ion-doped tungsten molybdenum substituted double perovskite oxide powder can be obtained under the conditions of low temperature and short heat-preserving time; test period is greatly shortened; cost is greatly reduced; and the method is particularly suitable for preparing rare earth-doped luminescent materials, magnetic resistance materials and the like with the structure type.

Owner:NANJING UNIV OF TECH

Skin base solution and preparation method thereof

ActiveCN102670444AEasy to synthesizeDelicate and smooth to the touchCosmetic preparationsToilet preparationsBenzoic acidAlpine rose

The invention discloses a skin base solution and a preparation method thereof, belonging to the field of cosmetics. The skin base solution comprises deionized water, xanthan gum, 1,3-propanediol, 1,3-butanediol, sodium pyrrolidonecarboxylate, sodium hyaluronate, ethylene diamine tetraacetic acid, allantoin, methyl-p-hydroxybenzoate, polyoxyethylene (40) hydrogenated castor oil, phenylpropanol, apple stem cell essence, alpine rose stem cells, platinum matrix-EM, lipidure pmb, cactus stoste and rose damascus essential oil.. Active substance essences in the formulation can excite activity of a specific gene again, thereby promoting synthesis of repairing protein. After the skin base solution is used, people's skin becomes fine and smooth and is more uniform and is remarkably improved.

Owner:成都鹏翔生物科技有限公司

Method for removing metal ions of paper pulp and bleaching

The invention relates to a method for removing metal ions of paper pulp and bleaching and relates to a technique for removing metal ions of paper pulp and applications thereof in bleaching, belonging to the technical field of paper making. The method comprises the following steps of: (1) carrying out pretreatment for removing metal ions of the paper pulp, namely under the existence of Mg(CH(3)COO)2, Ca(CH(3)COO)2 and EDTA (disodium ethylene diamine tetraacetate), carrying out bleaching pretreatment to deoxidizing sulfate pulp; and (2) carrying out following no-pollution bleaching, carrying out following secondary bleaching treatment consisting of a peroxyacetic acid bleaching stage and a hydrogen peroxide bleaching stage on the paper pulp after the pretreatment for removing metal ions. The invention is simple and easy to operate and has obvious effect; the removal rate of the metal ions is high, and the removal rate of Mn is 80.5 percent. Compared with the conventional EDTA chelation treatment, the strength performance of the paper pulp can be improved; the Mg(CH3COO)2 and the Ca(CH3COO)2 can replace 60 percent of EDTA, consequently, the accumulative effect toxicity of the conventional chelating agent can be obviously reduced.

Owner:KUNMING UNIV OF SCI & TECH

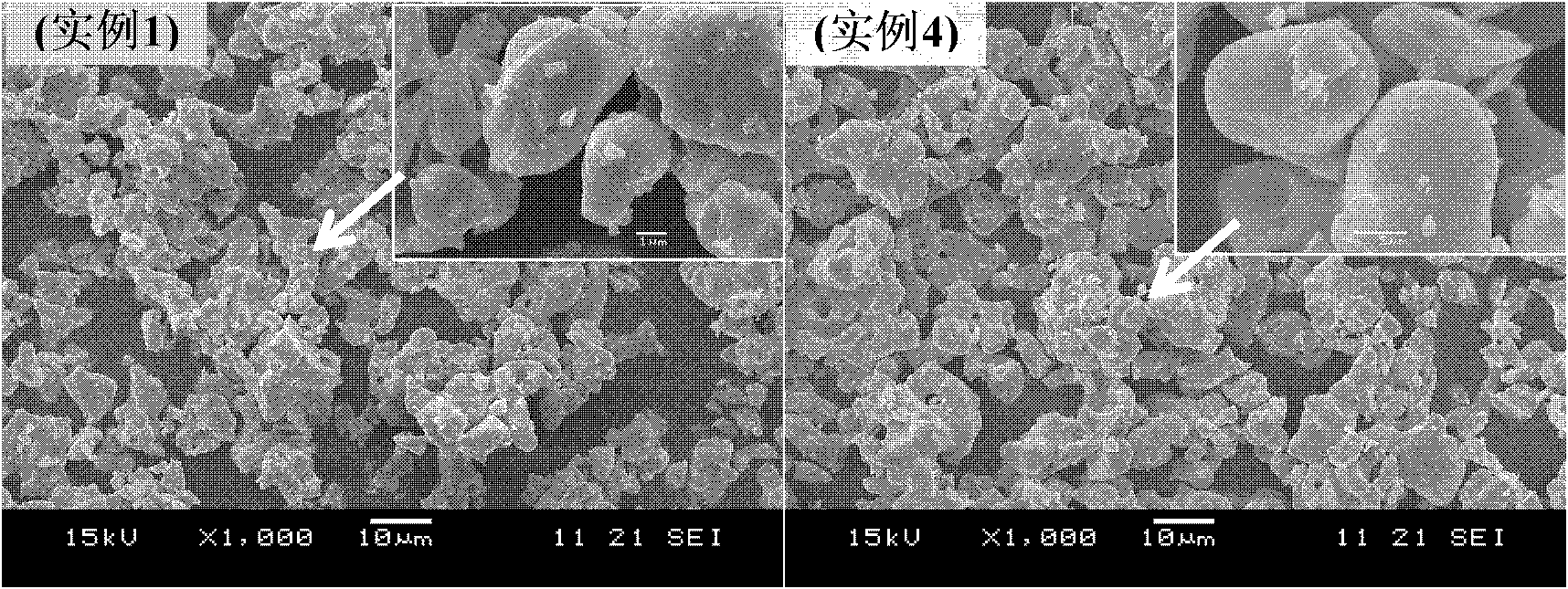

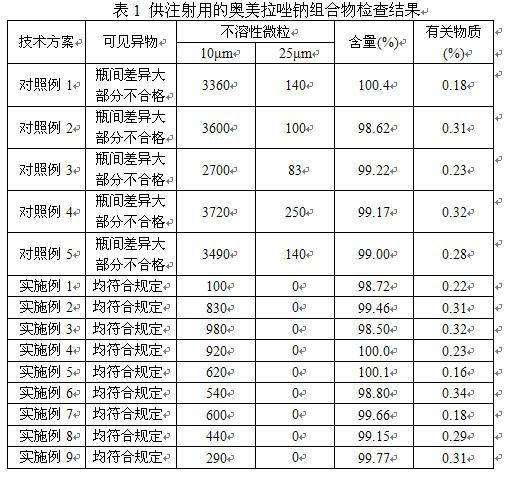

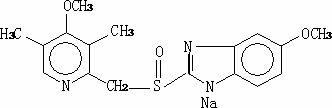

Omeprazole sodium composition for injection

ActiveCN102151264AWon't releaseAvoid reactionPowder deliveryOrganic active ingredientsEthylene diamine tetra aceticEthylene diamine

The invention provides an omeprazole sodium composition for injection. The omeprazole sodium composition for injection contains omeprazole sodium and ethylene diamine tetraacetic acid; and the weight ratio of the omeprazole sodium to the ethylene diamine tetraacetic acid is 1: (0.02-0.1). The composition is prepared by the following method: 1) preparing a liquid medicine: placing the omeprazole sodium and the ethylene diamine tetraacetic acid into a mixing pot, adding water for injection, stirring to dissolve the omeprazole sodium and the ethylene diamine tetraacetic acid and mixing uniformly, and adjusting the pH value to 11.0 to 12.0 by using sodium hydroxide; 2) processing by a rubber stopper; 3) performing aseptic filtering and packing; and 4) freezing and drying in vacuum so as to obtain the omeprazole sodium composition for injection. For medicaments, such as the omeprazole sodium which is easily reacted with an effusion from a capsule, the omeprazole sodium composition for injection can effectively guarantee that visible foreign matters and insoluble particles of the product meet the requirement of injection at the same time. By the omeprazole sodium composition for injection, the quality level is enhanced obviously, and potential hazards in clinical safe medication use of patients due to unqualified visible foreign matters and insoluble particles can be avoided; and the omeprazole sodium composition for injection has better curative effect and lower clinical side reaction.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

Special underwear laundry detergent and preparation method for same

InactiveCN102382728AEffectiveImprove the bactericidal effectAmpholytes/electroneutral surface-active compoundsDetergent compounding agentsBetaineFatty acid

The invention discloses special underwear laundry detergent and a preparation method for the same, which belong to the field of daily chemical engineering. According to the ratio of parts by weight, raw materials include 5-25% of sodium dodecyl benzene sulfonate, 5-10% of coconut oil fatty acid diethanol amide, 2-5% of alkyl phenol polyoxyethylene (OP-10), 2-4% of dodecyl dimethyl betaine (BS-12), 0.1-1% of carboxymethylcellulose, 0.05-1.20% of ethylene diamine tetraacetic acid, 0.1-5.45% of polyhexamethyl biguanide, 0.3-10% of dodecyl dimethyl benzyl ammonium chloride, 1-3% of salt, 0.1-0.3% of essence and 50-80% of deionized water. The preparation method includes that the deionized water and the raw materials are added into a material dissolving kettle for dissolving the materials, and then the special underwear laundry detergent is obtained. The special underwear laundry detergent and the preparation method have the advantages that biguanides and bis-quaternary ammonium are adopted for sub-composition and can effectively act on germs under the effect of special penetration enhancers, germicidal power is improved, and the special underwear laundry detergent can be stored stably and is less in consumption and high in cost performance.

Owner:周强

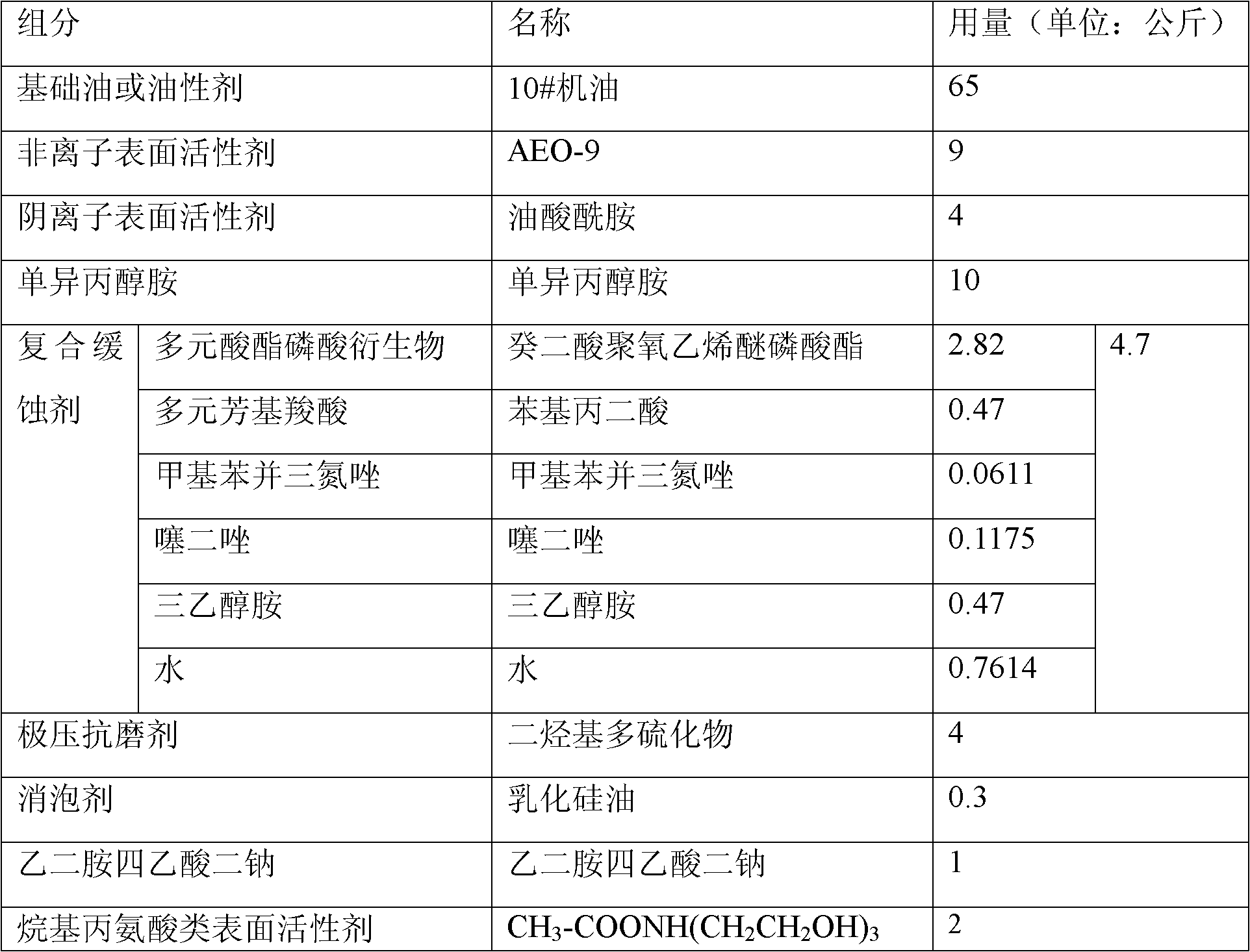

Silicon-free liquid shampoo and preparation method thereof

ActiveCN104856895AWon't gatherWill not adsorbCosmetic preparationsHair cosmeticsOLEAMIDOPROPYL BETAINECocamidopropyl betaine

The invention discloses a silicon-free liquid shampoo and a preparation method thereof. The silicon-free liquid shampoo comprises 0.5-5% of inulin, 0.2-5% of vegetable fat, 0.2-2% of a solubilizing agent, 0.2-2% of a thickening agent, 3-8% of sodium laureth sulfate, 3-8% of cocamidopropyl betaine, 1-5% of alkyl glycoside, 1-5% of sodium cocoyl glycinate, 0.05-0.5% of ethylene diamine tetraacetic acid tetrasodium, 0.05-0.5% of citric acid, 0.2-1% of preservative, 0.2-1% of essence and 58-90% of water. The silicon-free liquid shampoo is mild and non-stimulating, and can nurse hairs efficiently while being used for cleaning hairs; the cleaned hairs are glossy, soft and smooth.

Owner:壹田(广州)生活健康用品有限公司

Special high-performance compound fertilizer for woody flowers and plants

InactiveCN104355945AIncrease profitPromote growthAlkali orthophosphate fertiliserExcrement fertilisersSucroseMyriophyllum

The invention discloses a special high-performance compound fertilizer for woody flowers and plants. The high-performance compound fertilizer is prepared from the following raw materials: poultry manure, roots and stems of leguminous plants, bentonite, steel slag, coal ash, ammonium polyphosphate, ammonium hydrogen phosphate, urea, potassium chloride, calcium nitrate, rare earth salts, zinc sulfate, ferrous sulfate, borax, humic acid, lignin, sodium potassium tartrate, amino acid, sucrose, glucose, ethylene diamine tetra-acetic acid, acrylic resin and a microbial agent. The special high-performance compound fertilizer for woody flowers and plants disclosed by the invention has the advantages of high utilization rate, small amount and balanced nutrients; after the compound fertilizer is applied to the woody flowers and plants, the flowers and plants are healthy and strong and has green leaves, bright-colored flowers and long flowering period and the properties of soil can be improved so that the soil has healthy development.

Owner:WUWEI XINYUEHU LIVESTOCK BREEDING CO LTD

Green antibacterial efficient cleanser essence and preparation method thereof

InactiveCN103484265AStrong decontaminationStrong foaming powerNon-ionic surface-active compoundsDetergent compounding agentsChemical industrySodium Lauryl Sarcosinate

The invention relates to green antibacterial efficient cleanser essence and a preparation method thereof, and belongs to the technical field of detergents in daily-use chemical industries. The green antibacterial efficient cleanser essence comprises the following components by weight: 5-10 parts of tea saponin, 0.2-0.5 part of nano-silver, 0.5-1 part of a natural substance extractive, 15-25 parts of lauryl sodium sulfate, 5-10 parts of sodium lauroyl sarcosine, 5-10 parts of ethylene diamine tetraacetic acid, 1.2-1.8 parts of citric acid, 1.2-1.8 parts of sodium citrate, 0.5-1 part of refined salt, 0.5-1 part of sodium benzoate, 0.5-1 part of AES, and 30-40 parts of water. The preparation method comprises the following steps: using lauryl sodium sulfate, sodium lauroyl sarcosine, the ethylene diamine tetraacetic acid and the water according to the proportion and mixing uniformly, putting ethylene diamine tetraacetic acid into the water and stirring uniformly, then adding the citric acid, sodium citrate, the refined salt, and sodium benzoate into the water slowly while stirring at the temperature of 35-40 DEG C until a product is sticky, finally, adding tea saponin, the nano-silver, the natural substance extractive, and the AES and stirring at the temperature of 40-45 DEG C for 8-10 h to obtain a finished product. Compared with conventional cleanser essence, the green antibacterial efficient cleanser essence has high dirt-removing power, little residual, nontoxicity and an antibacterial effect.

Owner:陈理敬

Slow-release water-retaining compound fertilizer composition

ActiveCN103113157AFully meet nutritional needsMeet nutritional needsFertilizer mixturesPhosphateMonopotassium phosphate

The invention relates to a compound fertilizer for field crops planted in arid regions, semiarid regions and desert regions, and particularly relates to a slow-release water-retaining compound fertilizer composition. The slow-release water-retaining compound fertilizer composition is prepared from the following raw materials in parts by weight: 5-6 parts of urea, 5-6 parts of potassium dihydrogen phosphate, 15-16 parts of diammonium phosphate, 2-3 parts of fulvic acid, 13-18 parts of humic acid, 8-10 parts of attapulgite, 1-1.5 parts of ethylene diamine tetraacetic acid, 1-1.5 parts of citric acid, 15-16 parts of ferrous sulfate, 12.5-14 parts of calcium carbonate, 7-8 parts of zinc sulfate, 4.5-6 parts of borax, 1-1.5 parts of iodine ore powder and 1-1.5 parts of molybdenum ore powder. The slow-release water-retaining compound fertilizer composition has the functions of salt tolerance, drought resistance, water saving, water retaining, nutrition, slow release, rootage, soil structure improvement and the like, can enhance the effective utilization rate of the fertilizer and reduce the pollution to soil, and is applicable to forest planting, desert control, field crops, greenhouse vegetables, fruit trees, traditional Chinese medicinal materials, flowers and the like in arid and semiarid regions.

Owner:兰州熙瑞化工科技有限公司

Efficient composite heavy metal chelating agent

ActiveCN103663663AWide range of applicationsStrong adsorption and flocculation abilityWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionHeavy metal chelationTreatment effect

The invention relates to an efficient composite heavy metal chelating agent and a preparation method thereof. The efficient composite heavy metal chelating agent comprises the components in percentage by mass as follows: 35%-40% of nanometer aluminum oxide, 15%-20% of ethylene diamine tetraacetic acid and 40%-60% of sodium carboxymethyl starch. The efficient composite heavy metal chelating agent is non-toxic and has no harm to aquatic lives, pH value is not required to be adjusted when heavy metal wastewater is treated, and the treatment effect is superior to that of a traditional heavy metal treatment method.

Owner:NANJING XINHAO POLYMER MATERIAL

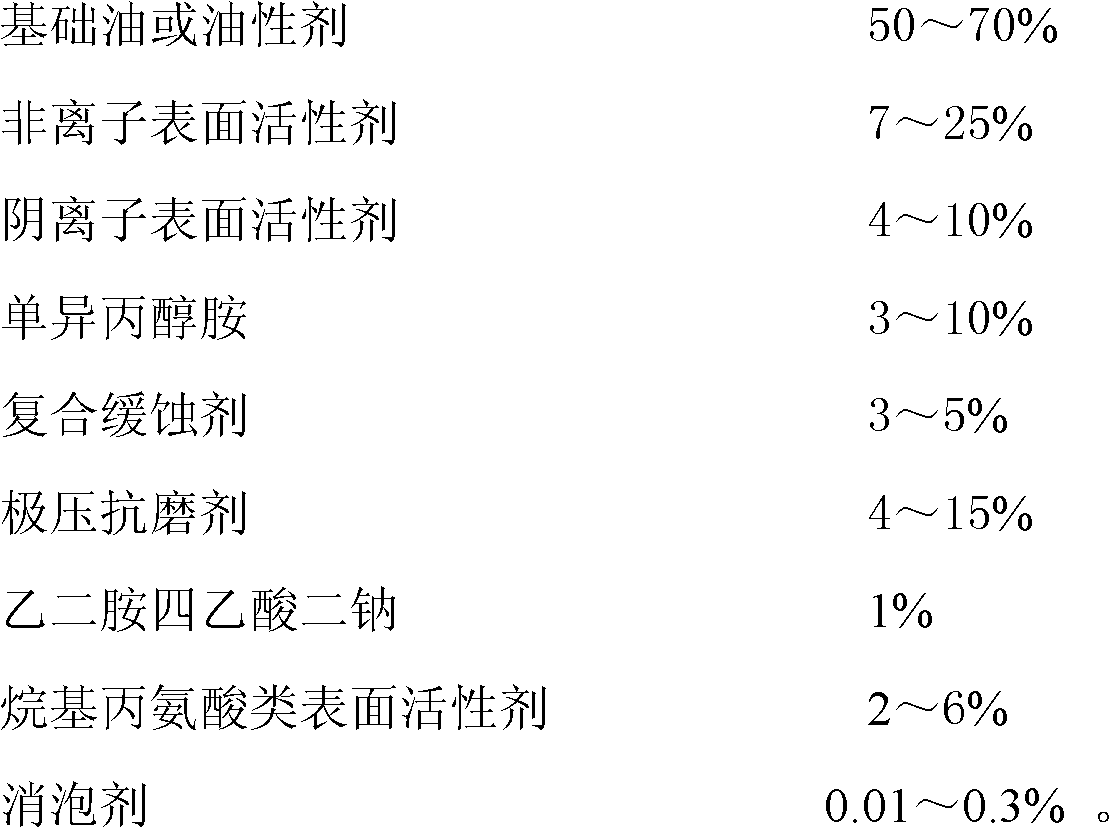

Self-bacteriostasis general emulsion cutting fluid and preparing method thereof

The invention relates to a self-bacteriostasis general emulsion cutting fluid and a preparing method thereof. The components of the emulsion cutting fluid includes, by weight, 50-70 parts of base oils, 7-25 parts of non-ionic surface active agents, 4-10 parts of anion surface active agents, 3-10 parts of monoisopropanolamines, 3-5 parts of compound corrosion inhibitors, 4-15 parts of extreme pressure antiwear agents, 0.01-0.3 parts of defoaming agents, 1 part of ethylene diamine tetraacetic acid, and 2-6 parts of alkyl alanine surface active agents. According to the self-bacteriostasis general emulsion cutting fluid, an organic triethylhexanoin process is adopted, cutting fluids produced has strong cooling characteristics, lubricity and rust protection, and is easy to wash, defects of heavy loading water-soluble cutting fluids in rust protection and odor aspects in use are avoided, simultaneously, bacteriacides are replaced by the alkyl alanine surface active agents, therefore strong bacteriostatic capacity for bacteria, fungi and molds can be achieved without adding special bacteriacides into products, service life of products is prolonged, and cost of products is reduced.

Owner:泰伦特生物工程股份有限公司

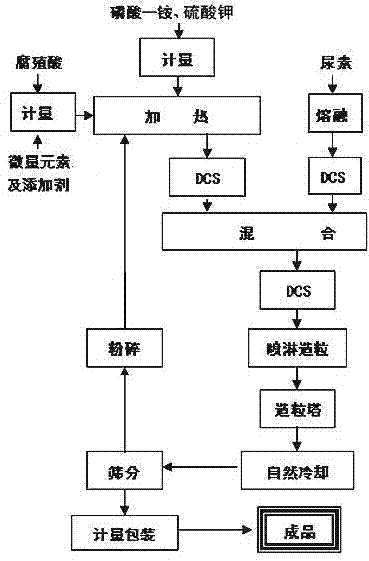

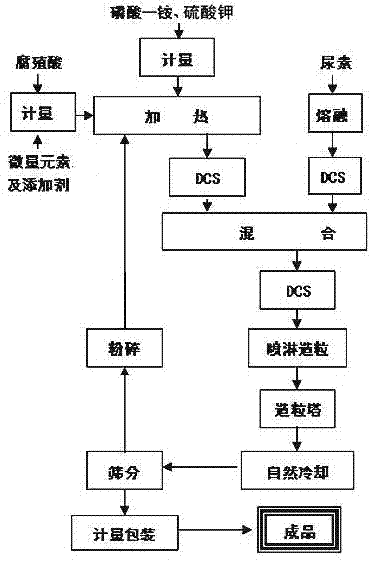

Melt granulation humic acid functional fertilizer special for corns and preparing method thereof

ActiveCN102503639AAdvanced technologyRealize continuous feedingFertiliser formsFertilizer mixturesPhosphateCaking

The invention discloses a melt granulation humic acid functional fertilizer special for corns and a preparing method thereof. The melt granulation humic acid functional fertilizer adopts raw materials of urea, monoammonium phosphate, potassium sulfate, humic acid, calcium magnesium phosphate, ethylene diamine tetra acetic acid (EDTA) chelating zinc, EDTA chelating ferrite, EDTA chelating boron, ammonium molybdate and additives, all the raw materials are dosed according to a specified ratio, and finished products are obtained through mixing, stirring, heating, filtering, granulating, cooling, sieving, anti-caking processing and measurement packaging of the raw materials. The melt granulation humic acid functional fertilizer special for corns has the advantages of being environment-friendly, balanced in nutrition, fast in fertilizer effect, high in crop absorption rate and capable of prolonging valid period of nitrogen nutrient and improving the soil, is a novel fertilizer for agricultural sustainable development and green food production, and has important meaning for promoting development of the ecological agriculture.

Owner:STANLEY AGRI GRP CO LTD

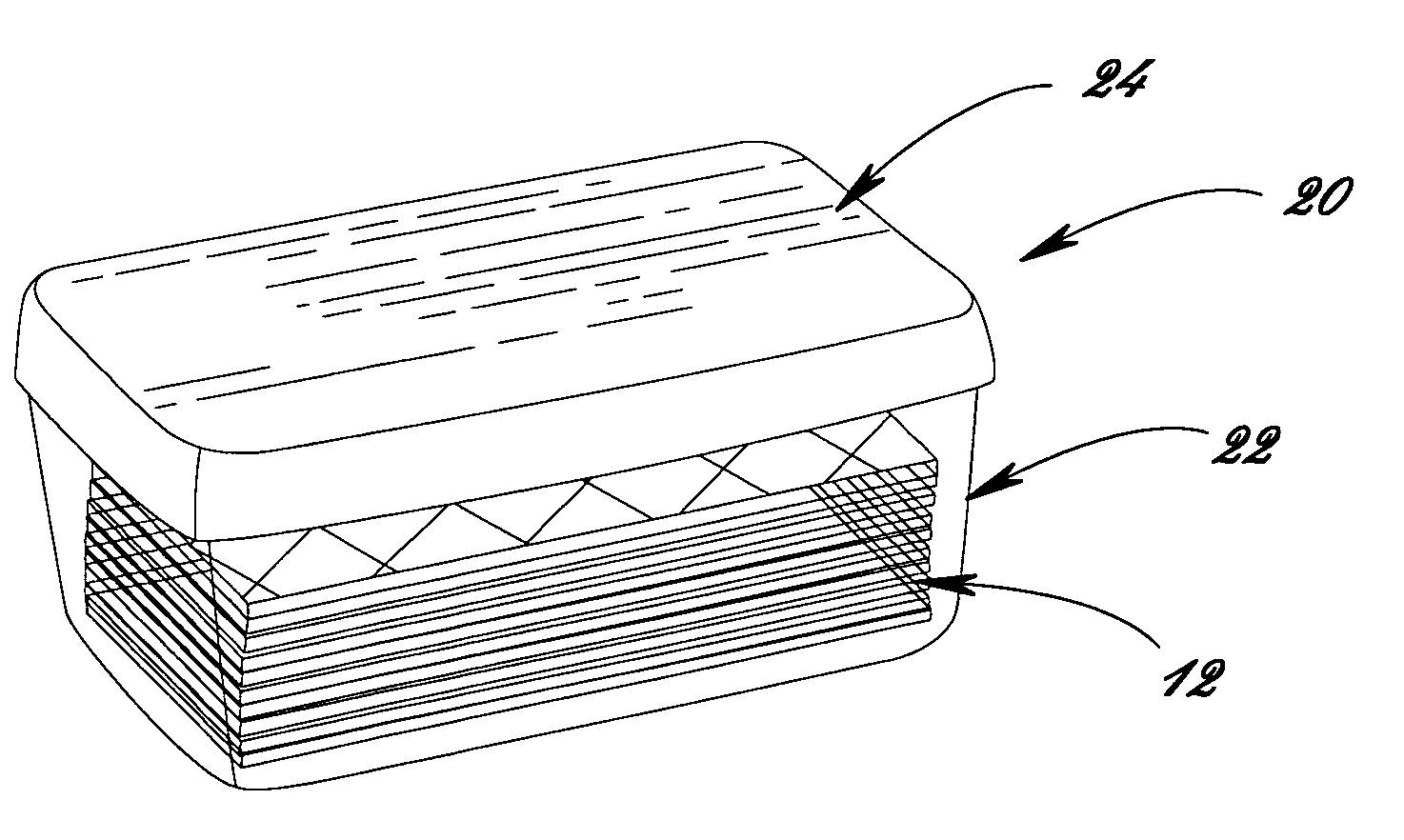

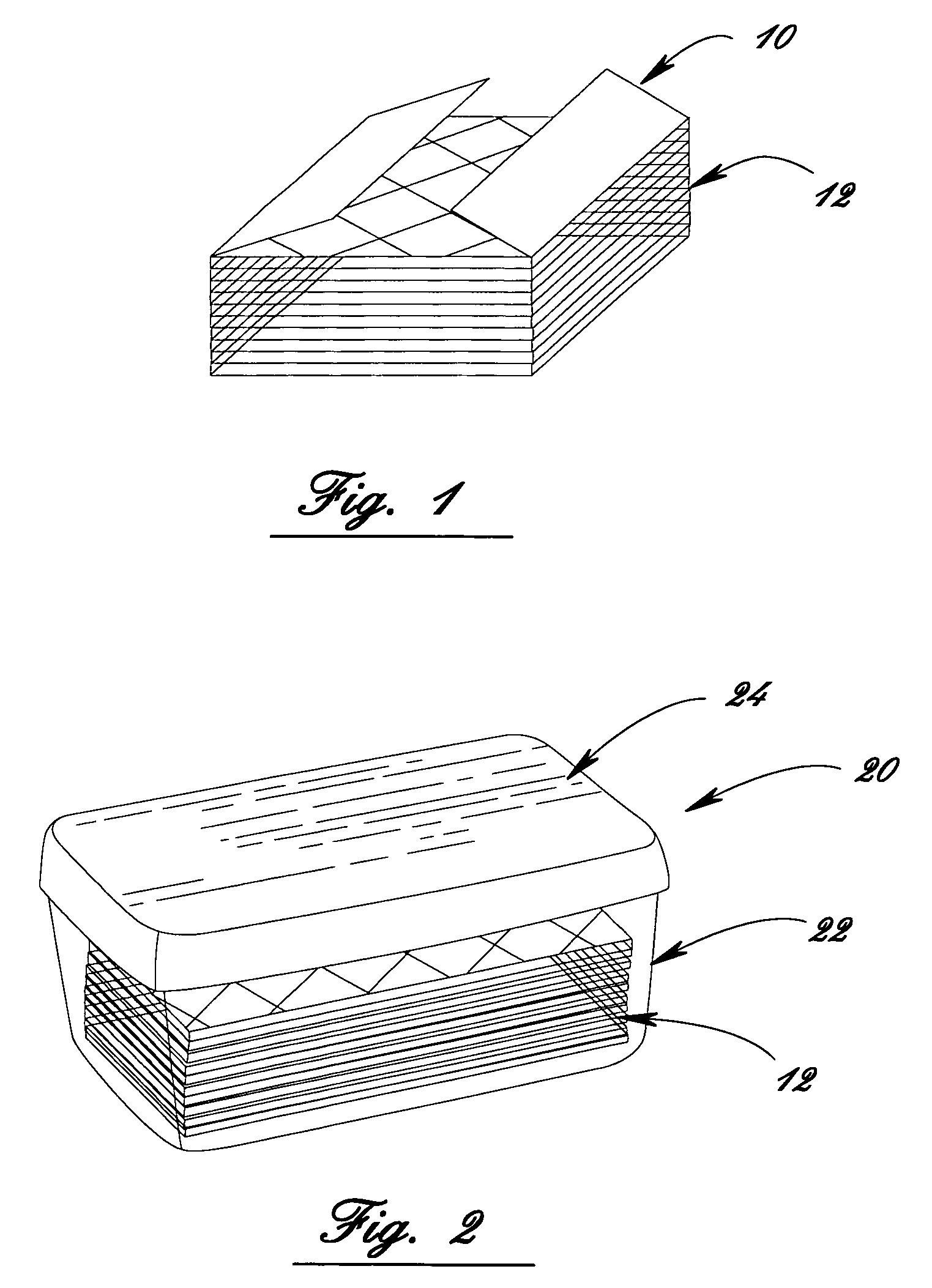

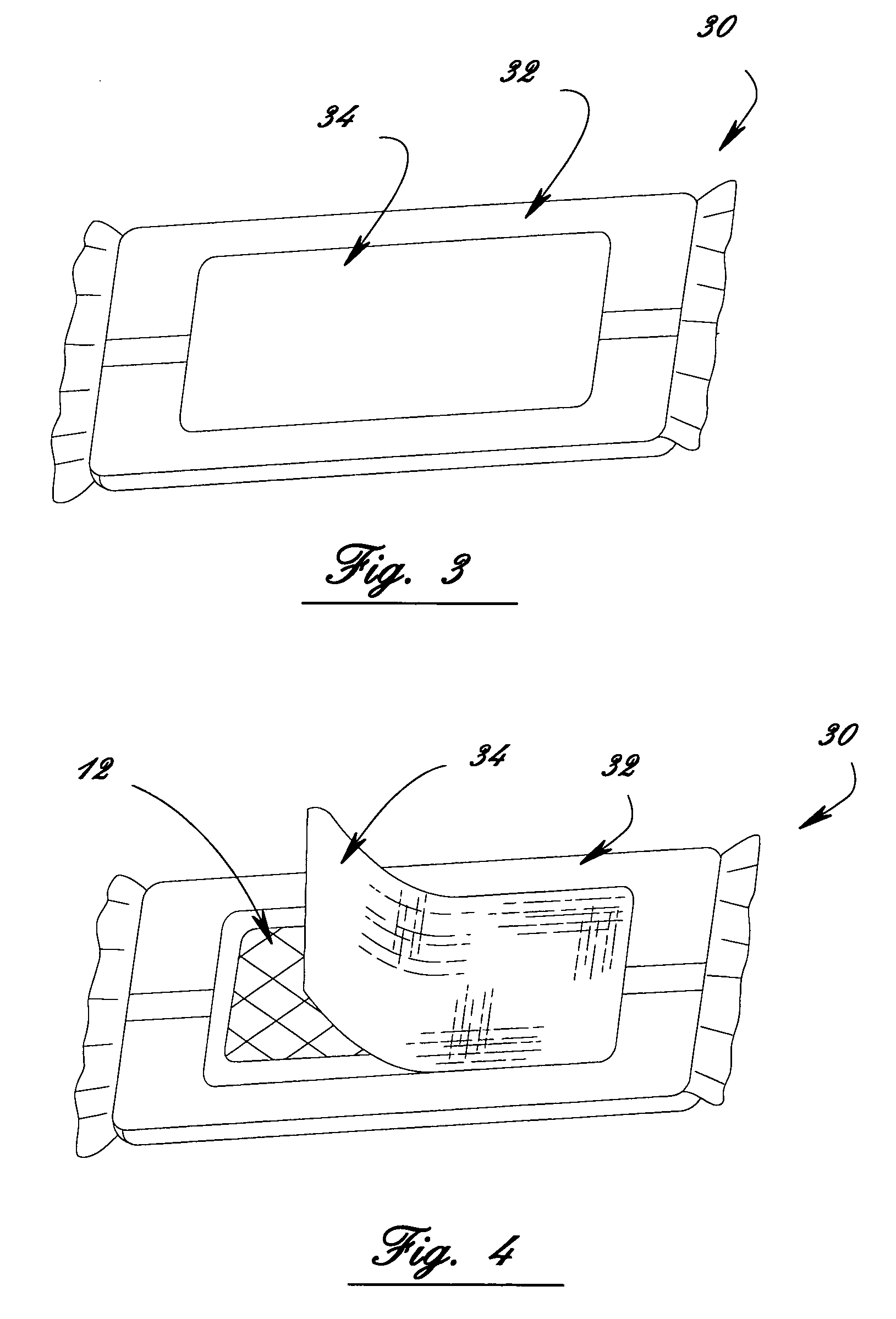

Sheet substrates impregnated with aromatic releasing compositions and a method of delivery of aromatic releasing compositions

An article of manufacture and a method directed to application of aromatic releasing compositions impregnated within substrates such as non-woven paper materials (e.g., wipes, paper towels) and dispensable cloth materials (e.g., gauze or a thin fabric of silk, linen, or cotton materials) for providing relief from cold, allergies, sinus and symptoms associated with respiratory disorders, the aromatic releasing compositions including the following: Menthol; Camphor; Eucalyptus oil; Cedarleaf Oil; Myristica Oil; Peppermint Oil; Lavender oil; Methyl Salicylate; Naproxen; Nutmeg Oil and Thymol; Beclometasone dipropionate; Benzethonium chloride with base solution consisting of Emollients, Emulsifiers and Moisturizer; Deionized Water; Vegetable Oil; Dicaprylyl Carbonate; Glyceryl Oleate; Polyglyceryl-2 Dipolyhydroxystearate; Cetearyl Isononanoate; Ceteareth-20; Cetearyl Alcohol; Glyceryl Stearate; Glycerin; Cetyl Palmitate; Ceteareth-12, Lauryl Glucose Carboxylate; Lauryl Glucoside; Sodium Citrate; Citric Acid; Benzethonium Chloride 0.05%; Ethylene diamine tetra acetic acid; Phenoxyethanol; Methylparaben; Propylparaben; 2-bromo-2-nitropropane-1,3-diol; and subcombinations thereof. In further embodiments, the compositions impregnated within substrate further include one or more topical actives, and are useful for providing relief from cold, allergies, sinus and symptoms associated with respiratory disorders, as well as repelling common virus and bacteria.

Owner:ADELAKUN OLUFEMI

Silvered aluminum powder as well as preparation method and application thereof

ActiveCN101927342ALow densityLight in massPigment treatment with non-polymer organic compoundsOrganic acidAcetic acid

The invention provides silvered aluminum powder as well as a preparation method and application thereof. The method comprises the following steps of: (a) firstly, evenly mixing a copper sulfate solution and an EDTA (Ethylene Diamine Tetraacetic Acid) solution and then adding ammonia to adjust a pH value to 7.5-10; (b) putting aluminum powder in the mixed solution of the step (a), stirring, settling the plating bath and washing to be neutral and obtaining coppered aluminum powder; (c) adding water to silver nitrate to prepare an aqueous silver nitrate solution; (d) arranging the coppered aluminum powder of the step (b) in the aqueous EDTA solution, evenly stirring at 20-80 DEG C, then slowly adding the aqueous silver nitrate solution of the step (c), stirring for 20-150 min, adding a reducing agent to react, cleaning, centrifugating and filtering to obtain silvered aluminum powder; and (e) adding a mixed solution of organic acid esters to the silvered aluminum powder of the step (d), soaking for 0.5-2 h, filtering and drying to obtain a product.

Owner:TIANNUO PHOTOELECTRIC MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com