Patents

Literature

96results about How to "Will not adsorb" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

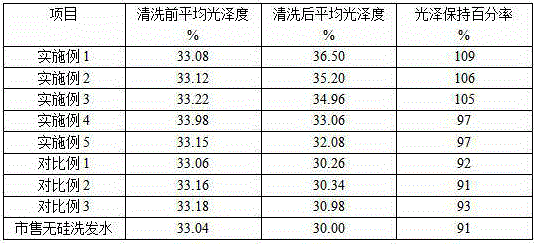

Silicon-free liquid shampoo and preparation method thereof

ActiveCN104856895AWon't gatherWill not adsorbCosmetic preparationsHair cosmeticsOLEAMIDOPROPYL BETAINECocamidopropyl betaine

The invention discloses a silicon-free liquid shampoo and a preparation method thereof. The silicon-free liquid shampoo comprises 0.5-5% of inulin, 0.2-5% of vegetable fat, 0.2-2% of a solubilizing agent, 0.2-2% of a thickening agent, 3-8% of sodium laureth sulfate, 3-8% of cocamidopropyl betaine, 1-5% of alkyl glycoside, 1-5% of sodium cocoyl glycinate, 0.05-0.5% of ethylene diamine tetraacetic acid tetrasodium, 0.05-0.5% of citric acid, 0.2-1% of preservative, 0.2-1% of essence and 58-90% of water. The silicon-free liquid shampoo is mild and non-stimulating, and can nurse hairs efficiently while being used for cleaning hairs; the cleaned hairs are glossy, soft and smooth.

Owner:壹田(广州)生活健康用品有限公司

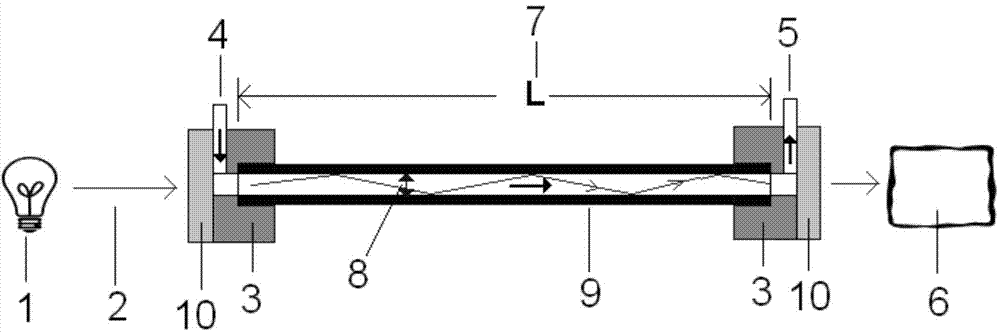

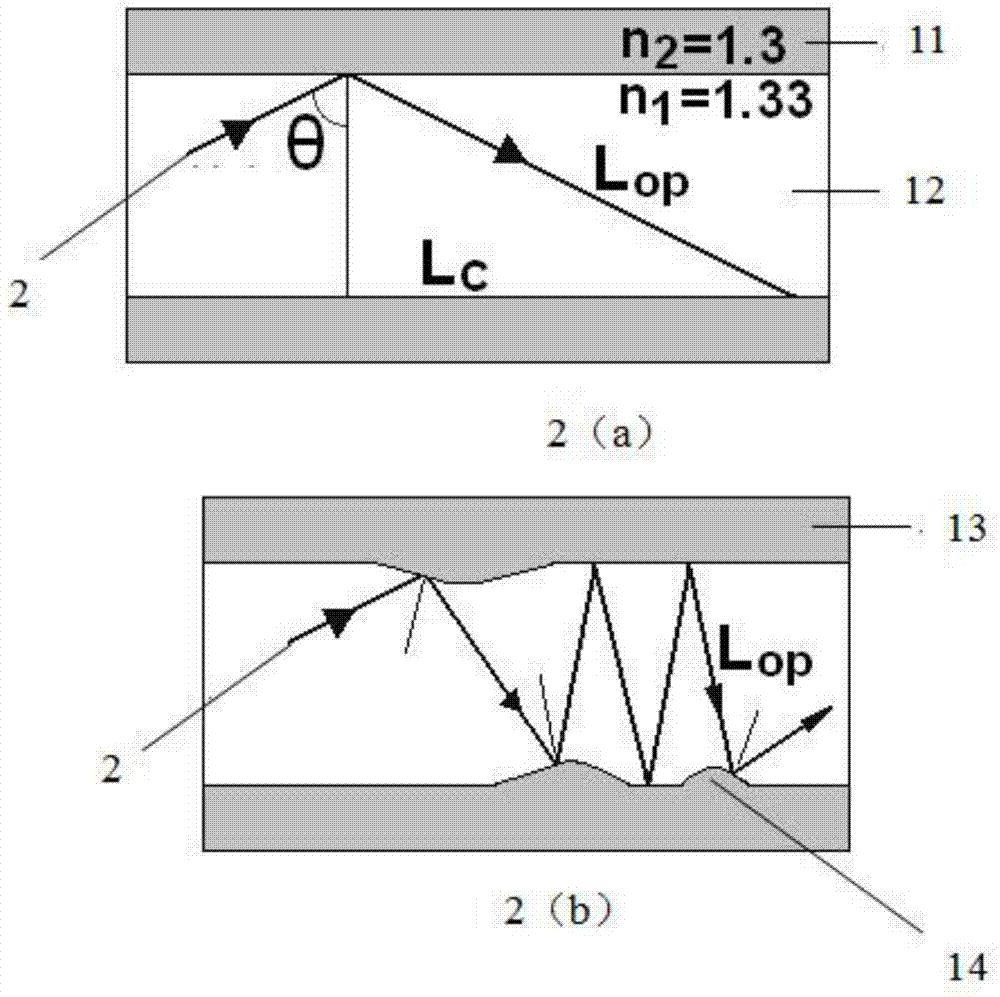

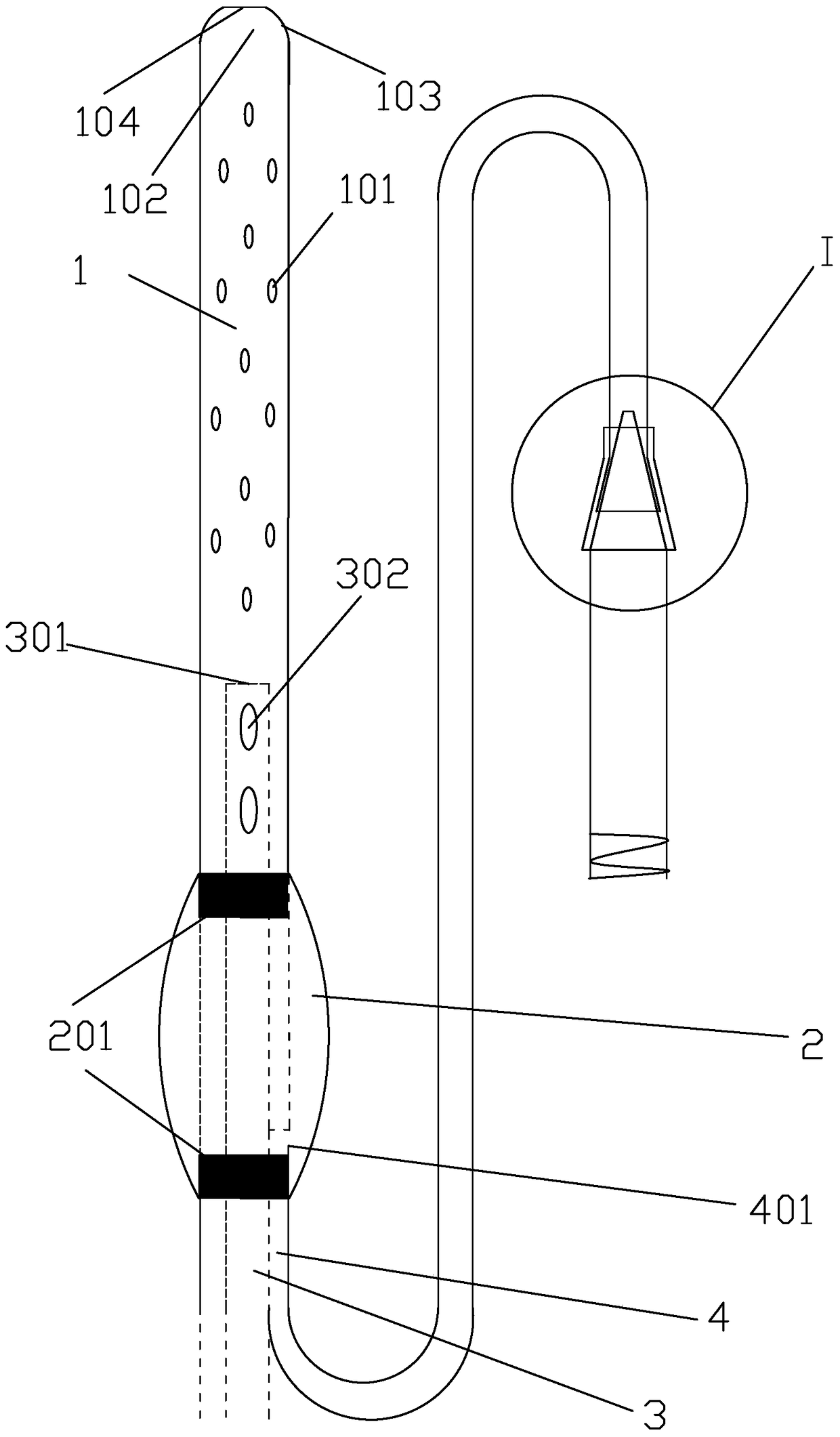

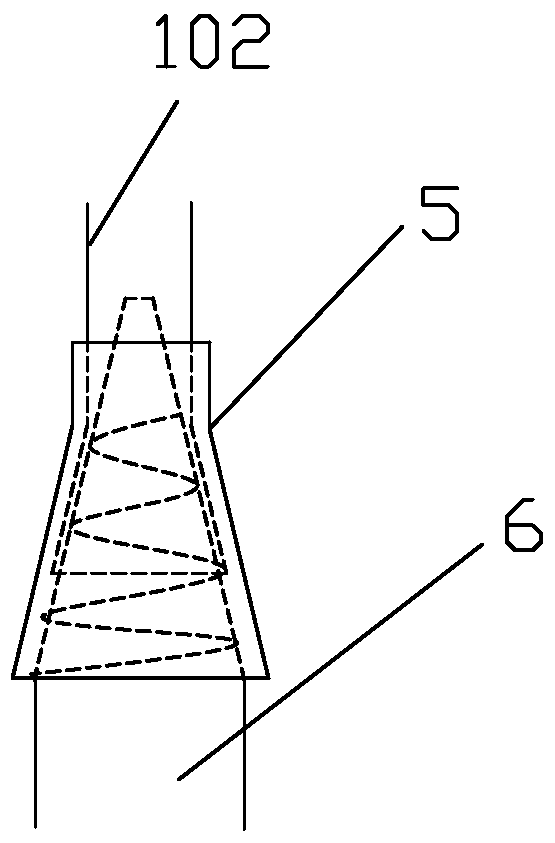

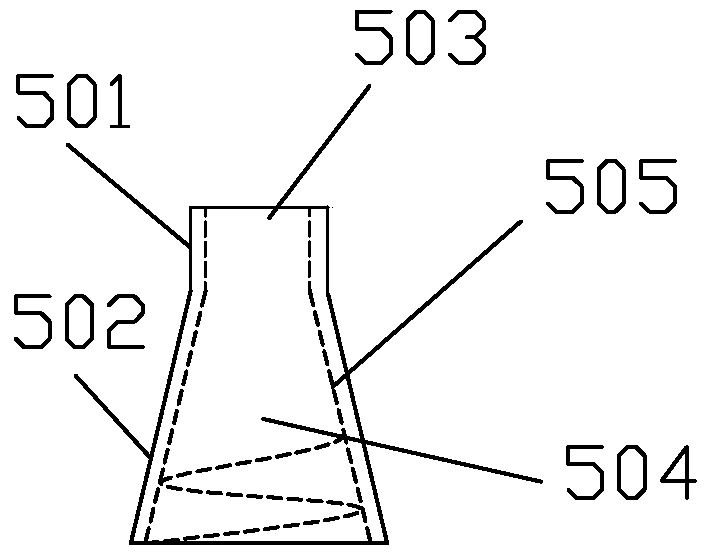

Photometric analyzer based on light guide metal capillary and detection method thereof

ActiveCN104515743AReduce internal volumeIncrease the lengthColor/spectral properties measurementsLight guideLight beam

The invention relates to a photometric analyzer based on a light guide metal capillary and a detection method thereof. The analyzer comprises a light source, a light detector and the light guide metal capillary, and is characterized in that a light wave can be reflected on the side wall of the light guide metal capillary, a detection light beam emitted by the light source is restricted in the light guide metal capillary for transmission through total reflection on the side wall of the light guide metal capillary, and the light detector is used for receiving the detection light beam emitted out from the light guide metal capillary; a sample inlet is formed in one end of the light guide metal capillary, and a sample outlet is formed in the other end of the light guide metal capillary. The analyzer utilizes the light guide metal capillary to guide the transmission of the detection light beam and a sample to be detected; the total reflection for light on a metal surface is not limited by critical angle, and corrugated fluctuation on the inner surface of the metal capillary enables the incident angle of the detection light beam to change, so that the transmission light path of the detection light beam in the sample can be greatly increased, and the detection precision is improved.

Owner:黄辉 +2

Ceramic product fired at medium-low temperature and manufacturing process thereof

ActiveCN107827433AEasy to cleanExtended service lifeCeramic shaping apparatusClaywaresCalcium silicateSilicon oxide

The invention provides a ceramic product fired at a medium-low temperature and a manufacturing process thereof. The ceramic comprises a blank body and a glaze layer applied on the blank body. The ceramic is characterized in that the blank body is prepared from the following raw materials in parts by weight: 50-70 parts of dolomite, 10-20 parts of quartz, 10-25 parts of feldspar, 2-5 parts of cobalt oxide, 15-20 parts of diatomite, 5-20 parts of clay, 8-15 parts of calcium silicate and 4-8 parts of konjac glucomannan; the glaze layer is prepared from the following raw materials in parts by weight: 28-32 parts of quartz, 26-30 parts of feldspar, 14-18 parts of borax, 6-10 parts of dolomite, 8-12 parts of kaolin, 3-7 parts of zinc oxide, 5-10 parts of sodium silicate, 5-10 parts of silicon oxide, 4-6 parts of boron oxide and 5-10 parts of pigment. The ceramic product fired at the medium-low temperature provided by the invention has the advantages that the water absorptivity is lower than1% and the problem of low water absorptivity of the ceramic fired at the medium-low temperature is solved.

Owner:福建省德化县优扬工艺品有限公司

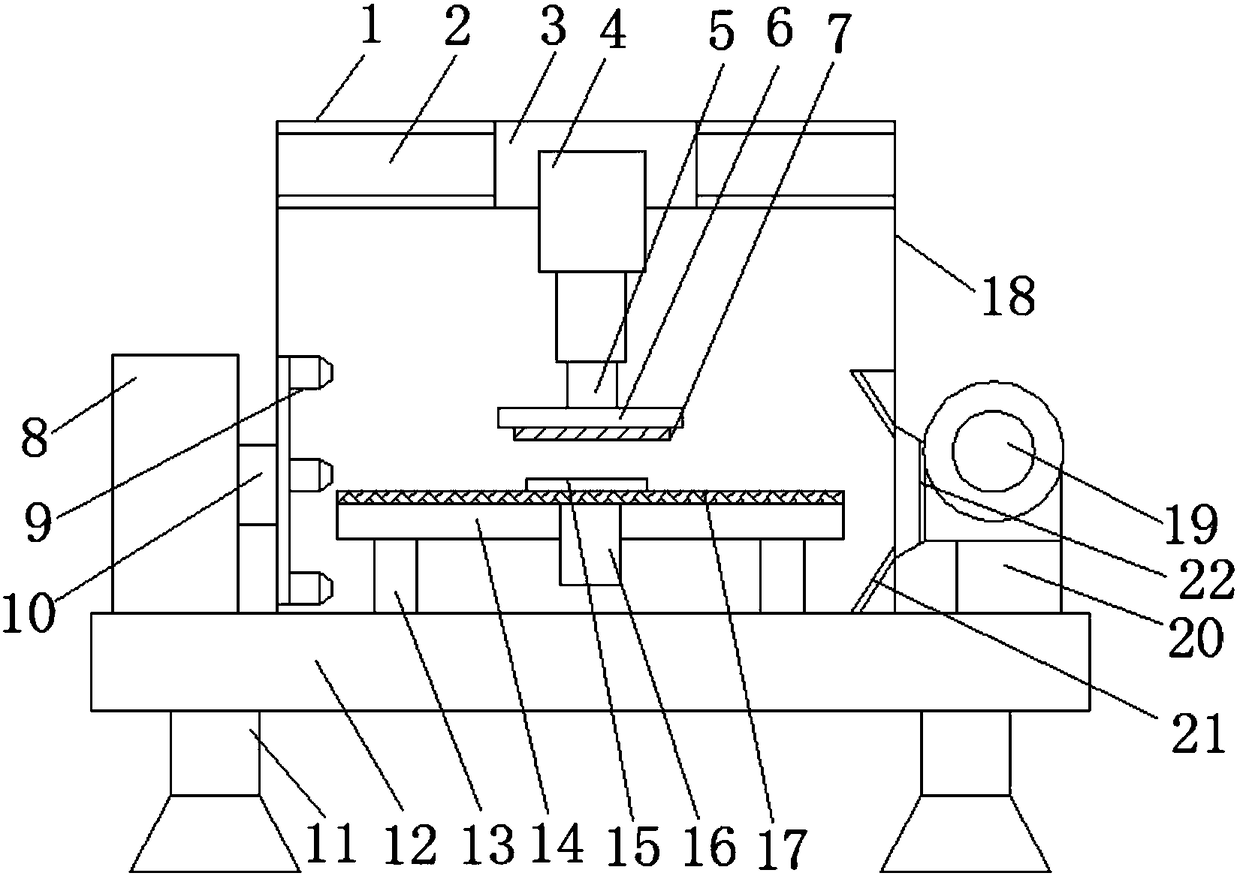

High-efficiency dust removal device for leather production processing

InactiveCN109127502AFully filteredFully adsorbedMechanical cleaningPressure cleaningFiltrationEngineering

The invention discloses a high-efficiency dust removal device for leather production processing. The high-efficiency dust removal device comprises a horizontal rod, the horizontal rod is fixed at thetop end of a dust removal box, and the side face of the horizontal rod is provided with guide rails, a horizontal driving device is installed between the guide rails, the bottom of the horizontal driving device is connected with an air cylinder, the output end of the air cylinder is fixedly connected with a rotating motor, one end of the rotating motor is provided with a rotating disc, and one side of the rotating disc is provided with a hairbrush. According to the high-efficiency dust removal device for the leather production processing, the rotating motor is driven to move horizontally through the horizontal driving device, so that the hairbrush at the bottom of the rotating disc is made to perform cleaning work on the leather surface, retracting and releasing of the hairbrush and the distance of the hairbrush to a placing plate are adjusted utilizing the air cylinder, the hairbrush is flexible to rotate and move, two sides of the dust removal box are provided with an air blower andan air suction machine correspondingly, filtration treatment is sufficiently performed on dust and debris kicked-up inside the dust removal box, a vibrating electric motor prevents the dust from adhering to the leather surface, and the high-efficiency dust removal device for the leather production processing is reasonable in structure, convenient in functional usage and suitable for wide popularization.

Owner:JIANGSU KEMEI NEW MATERIALS

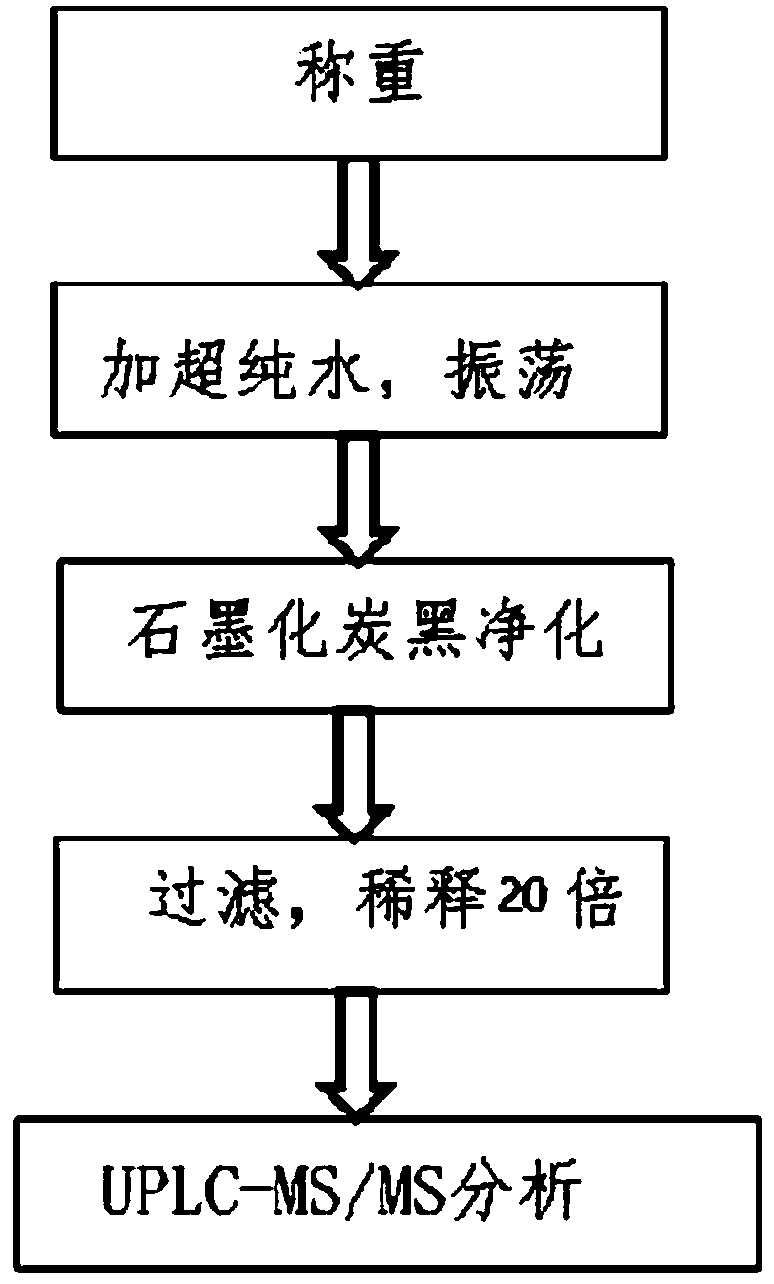

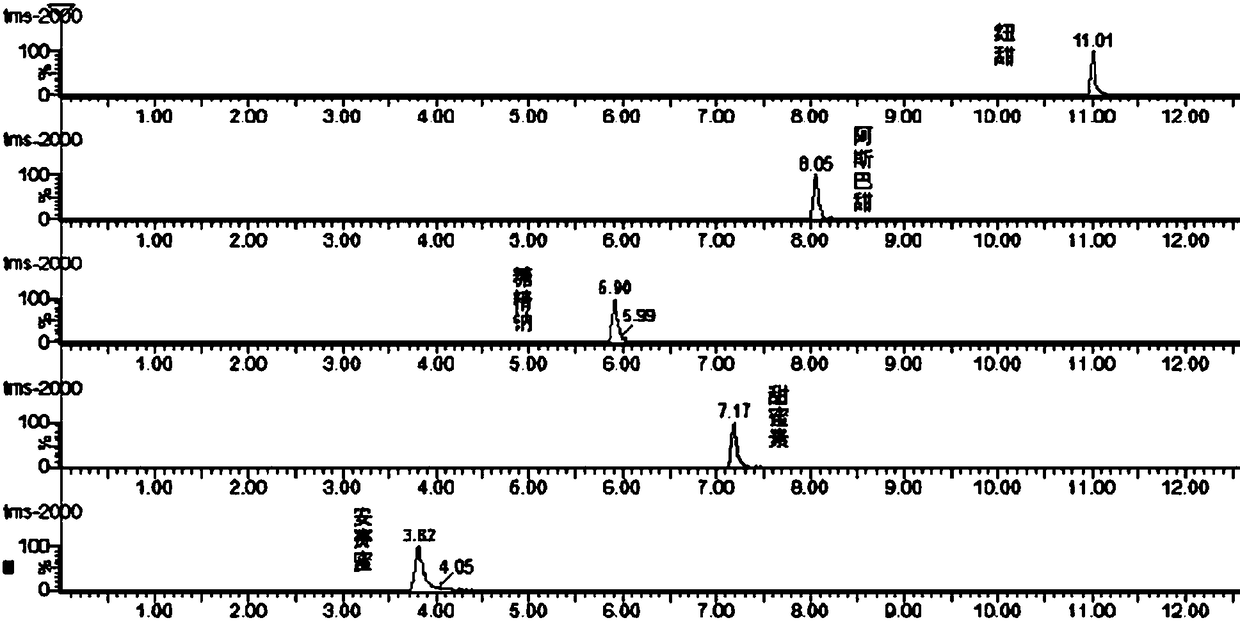

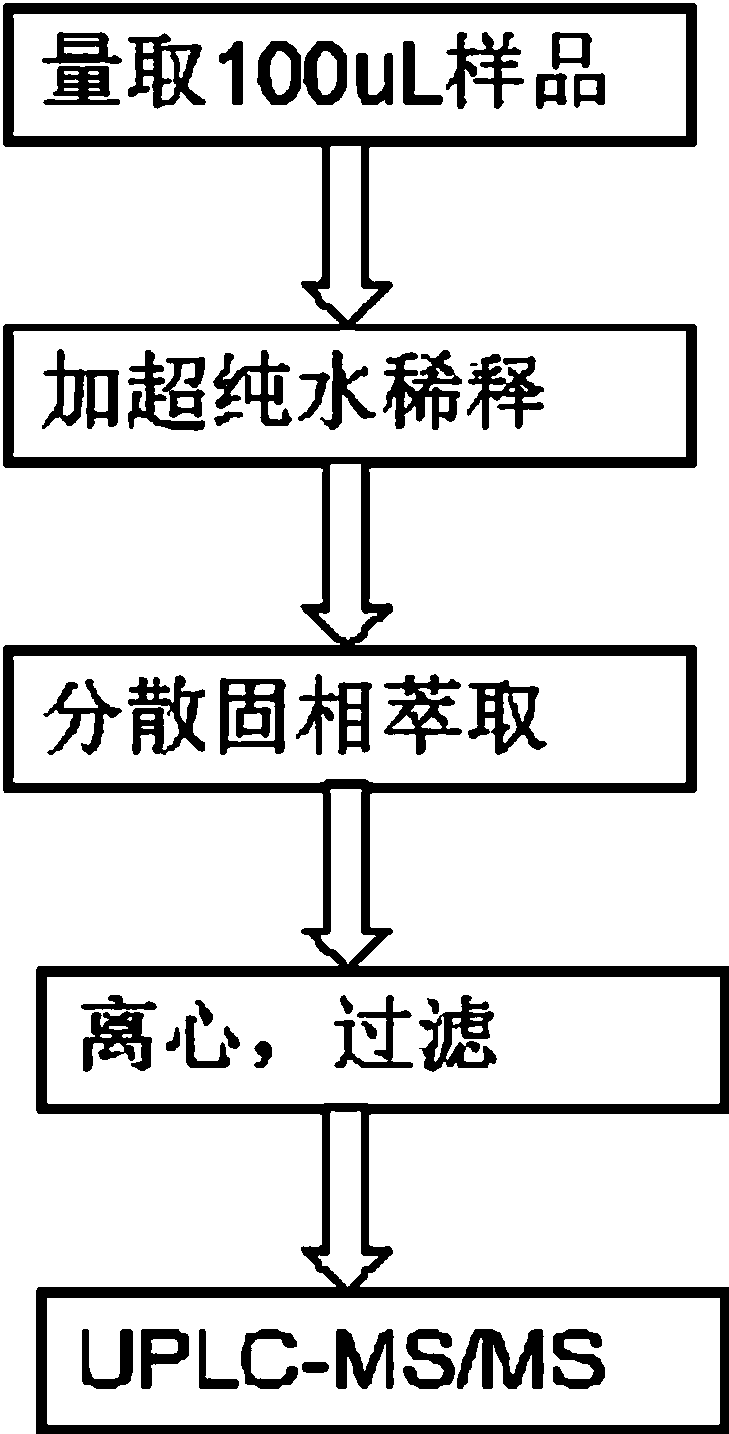

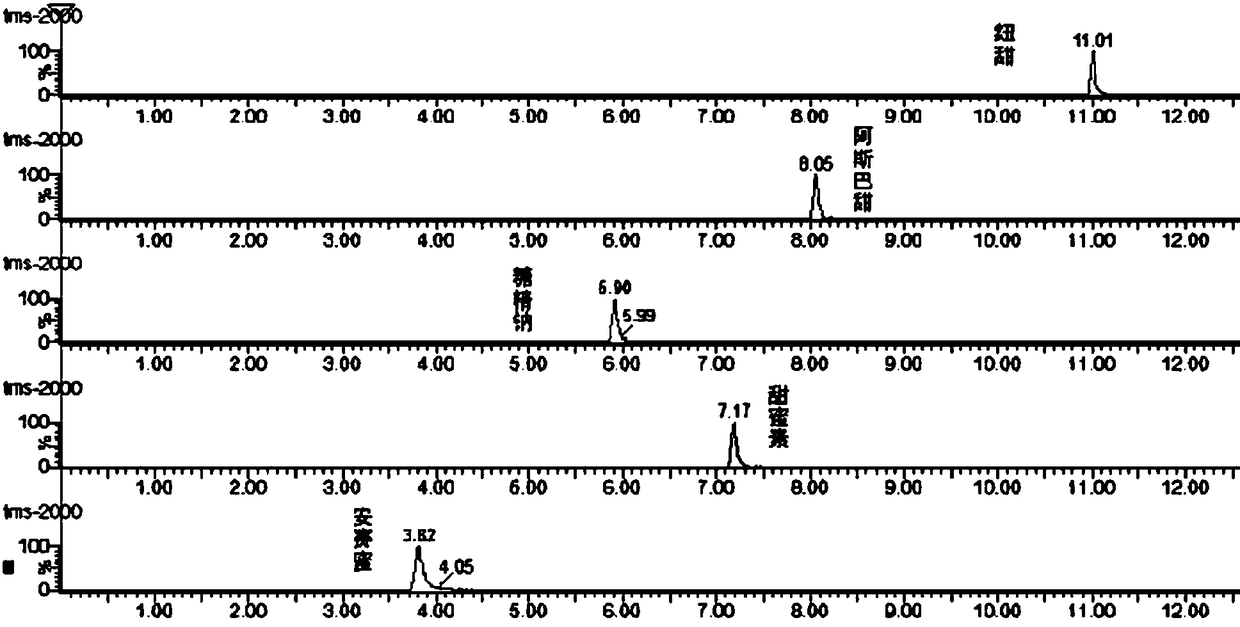

Method for detecting five sweetening agents in tobacco essence through ultra-high performance liquid chromatography-tandem mass spectrometry

ActiveCN108872448AGood effectStrong anti-matrix interference abilityComponent separationFood additiveRepeatability

The invention belongs to the technical field of physical and chemical inspection of food additive residues in tobacco essences, and particularly relates to a method for detecting five sweetening agents in a tobacco essence through the ultra-high performance liquid chromatography-tandem mass spectrometry. The method is characterized by comprising the following steps that the tobacco essence is weighed, then ultrapure water is added, then oscillating extraction is carried out, extract liquid is purified and filtered and is diluted by using the ultra-pure water, and then the sweetening agents inthe tobacco essence are directly detected through the ultra-high performance liquid chromatography-tandem mass spectrometry. The method has the advantages of being capable of rapidly and accurately detecting the residual quantity of the sweetening agents in the tobacco essence, environmentally friendly, accurate in result, less in interference, high in sensitivity and good in repeatability.

Owner:CHINA NAT TOBACCO QUALITY SUPERVISION & TEST CENT

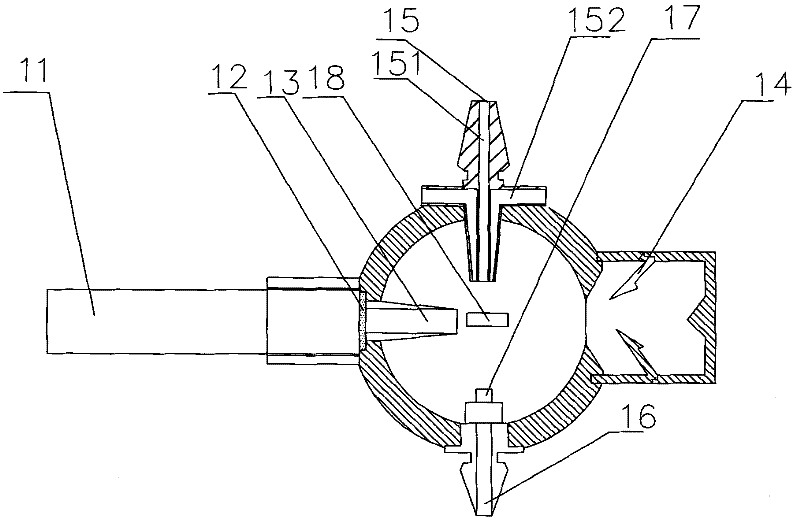

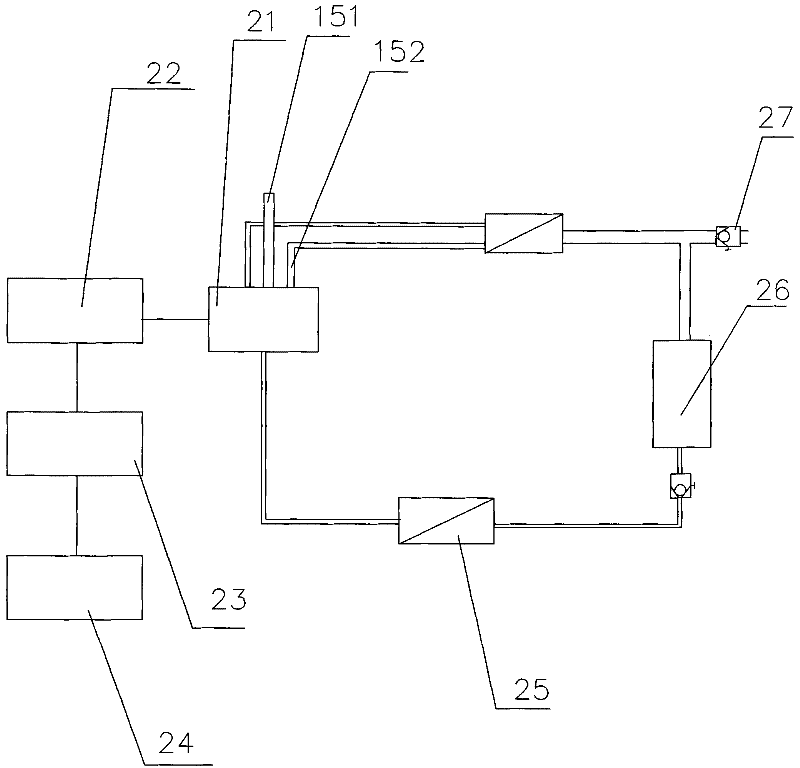

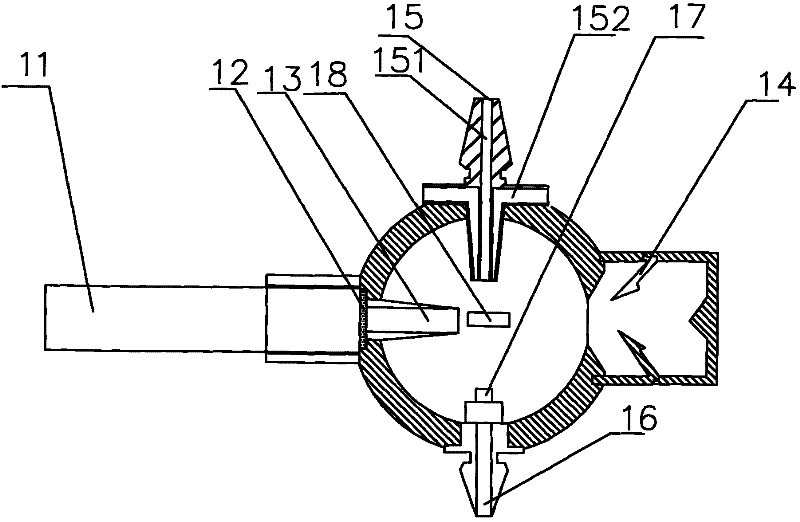

Laser sensor and airborne particle counter with laser sensor

InactiveCN102331395AImprove accuracyWon't settleIndividual particle analysisShielding gasSemiconductor package

The invention discloses a laser sensor and an airborne particle counter with the laser sensor. The laser sensor which comprises a semiconductor laser which is used as a laser light source is characterized in that: a slit diaphragm which is arranged under the irradiation of the laser light source allows the laser light source to form a photosensitive area; a photoelectric receiver is arranged in the photosensitive area at a vertical direction; a suction nozzle and a venting nozzle which is symmetric with the suction nozzle are arranged in the photosensitive area at the vertical direction; and the suction nozzle comprises an internal sampling tube for conveying a sampling gas and an external protection tube which is arranged on the outboard of the internal sampling tube and is used for providing the protection gas. By adopting the airborne particle counter, large granular airborne particles with the diameter of over 10mum in air can be accurately detected.

Owner:SUZHOU INDAL PARK HJCLEAN TECH

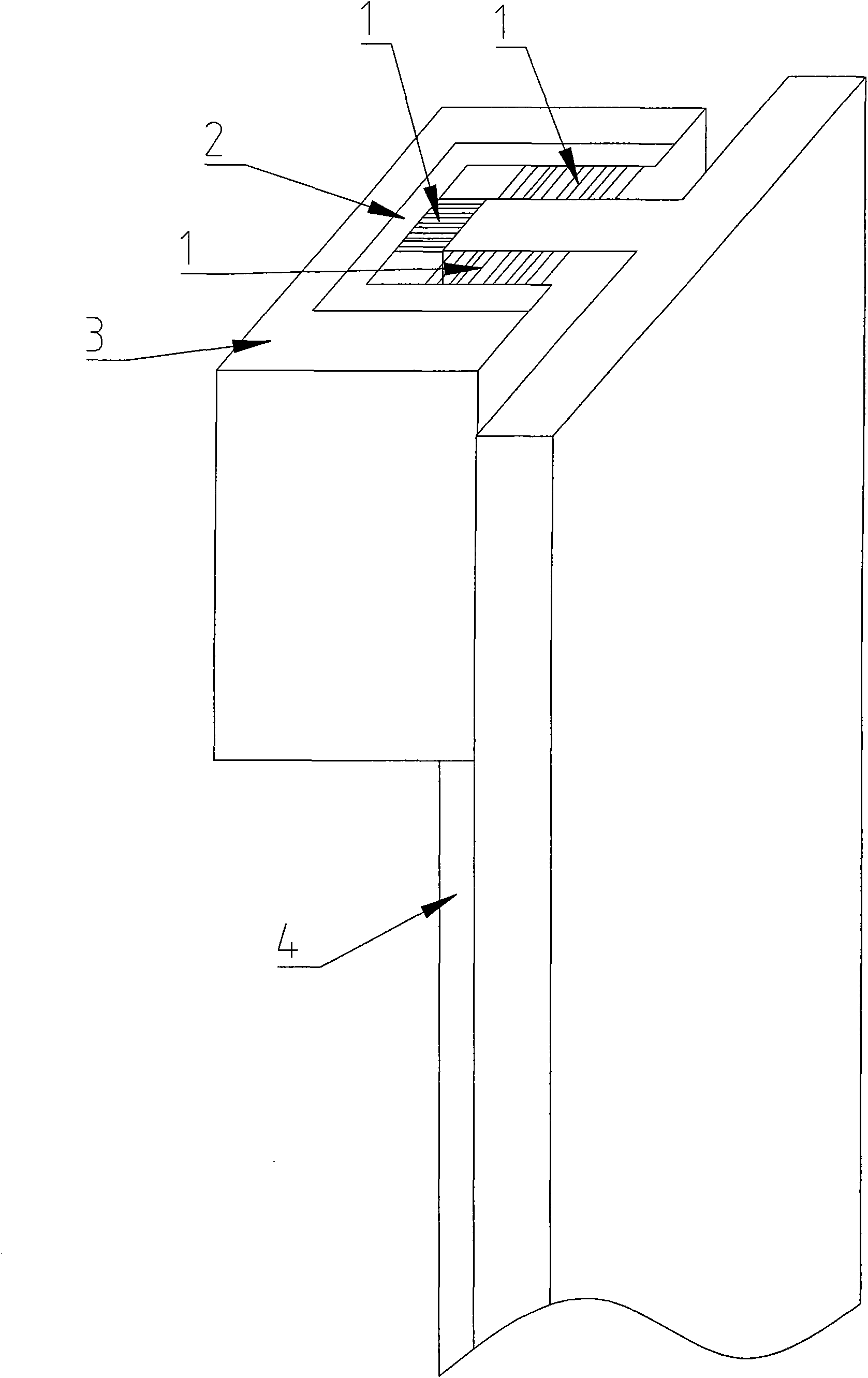

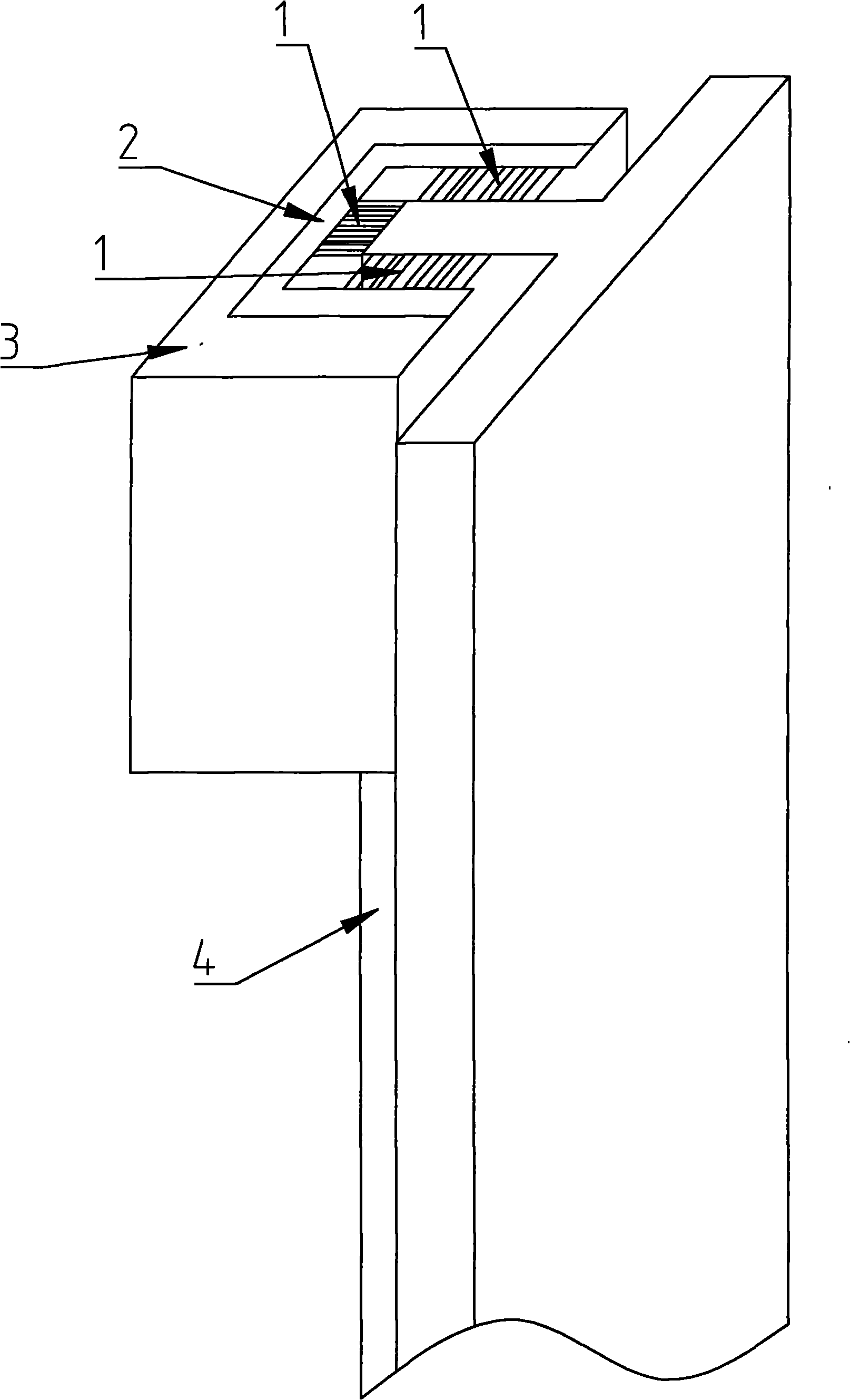

Device for automatically cleaning guide rails of elevator

The invention provides a device for automatically cleaning guide rails of an elevator. The device can remove or absorb the dust and sundries on the guide rails when the elevator runs so that rollers or bushes of guide shoes can not adsorb the dust and sundries on the guide rails so as to improve the service lives of the guide shoes. The device is characterized in that brushes contacted with the surfaces of the guide rails are arranged on the guide shoes.

Owner:JIANGSU FORCITY ELEVATOR

Method for detecting five sweetening agents in electronic cigarette liquor through ultra-high performance liquid chromatography-tandem mass spectrum

ActiveCN108956840AGood effectStrong anti-matrix interference abilityComponent separationFood additiveElectron

The invention belongs to the technical field of physical and chemical inspection for food additive residues in electronic cigarette liquor and specifically relates to a method for detecting five sweetening agents in electronic cigarette liquor through ultra-high performance liquid chromatography-tandem mass spectrum. The method is characterized by comprising the following steps: first, weighting the electronic cigarette liquor, and then adding ultrapure water for diluting, and at last, determining the sweetening agents in the electronic cigarette liquor through ultra-high performance liquid chromatography-tandem mass spectrum. According to the method, the sweetening agent residues in electronic cigarette liquor can be quickly and accurately detected. The invention has the advantages of environment-friendly method, accurate result, little interference, high sensitivity and good repeatability.

Owner:CHINA NAT TOBACCO QUALITY SUPERVISION & TEST CENT

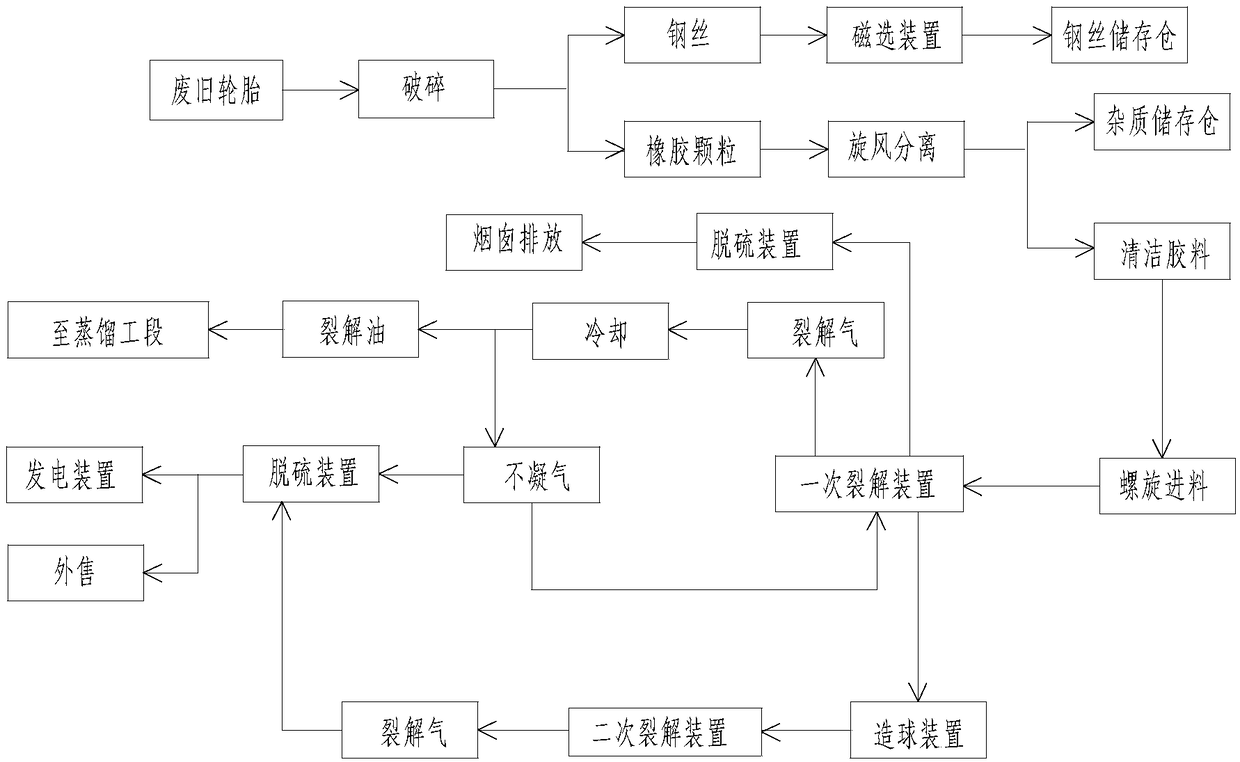

Method for catalytic cracking treatment of waste/used tires

InactiveCN108342215AFast heating rateSolve the problem of poor cracking efficiency aloneLiquid hydrocarbon mixture productionDistillationPre treatment

The invention discloses a method for catalytic cracking treatment of waste / used tires and belongs to the technical field of reutilization of the waste / used tires. The method is used for solving the problems in the prior art that the recovery rate is low, carbon black granules are large in size, and the pollution is heavy. The method for the catalytic cracking treatment of the waste / used tires comprises the procedures of raw material pretreatment, primary catalytic cracking, secondary cracking, distillation and desulfurization, wherein the secondary cracking means adding a solid-state cracked product produced from primary catalytic cracking into a secondary cracker for secondary cracking, subjecting produced cracked gas to dedusting and desulfurizing, and then, storing up the cracked gas. The method can be applied to the catalytic cracking treatment of the waste / used tires.

Owner:山东铂铠环保科技有限公司

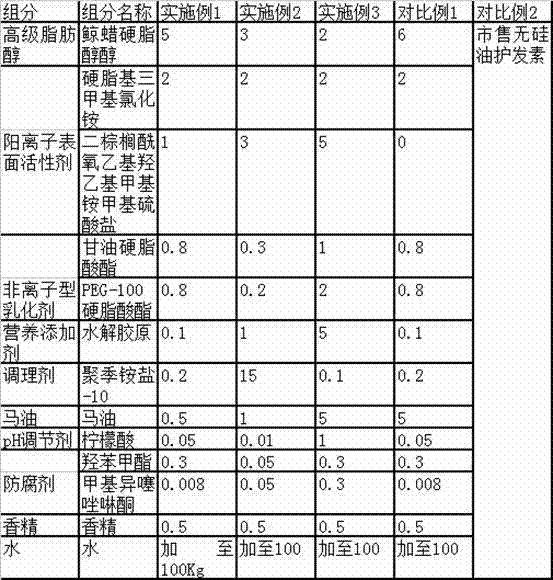

Silicone oil-free hair care composition containing horse oil

InactiveCN107440940ASpeed up penetrationGood adhesionCosmetic preparationsHair cosmeticsSurface-active agentsSilicone oil

The invention discloses a silicone oil-free hair care composition containing horse oil. The silicone oil-free hair care composition is prepared from the following components in percentage by weight: 2.0 to 5.0 percent of higher aliphatic alcohol, 1.0 to 10.0 percent of a cationic surface active agent, 0.5 to 3 percent of a non-ionic emulsifier, 0.5 to 5 percent of horse oil, and the balance of water. The silicone oil-free hair care composition adopts the horse oil instead of silicone oil, and has a good conditioning and care action on hair, can obviously reduce the hair wet-combing resistance, and can maintain and improve the hair luster. After the silicone oil-free hair care composition is used, the scalp is relaxed, the hair is full, lustrous, soft and smooth, and the hair is not knotted.

Owner:OPAL COSMETICS HUIZHOU

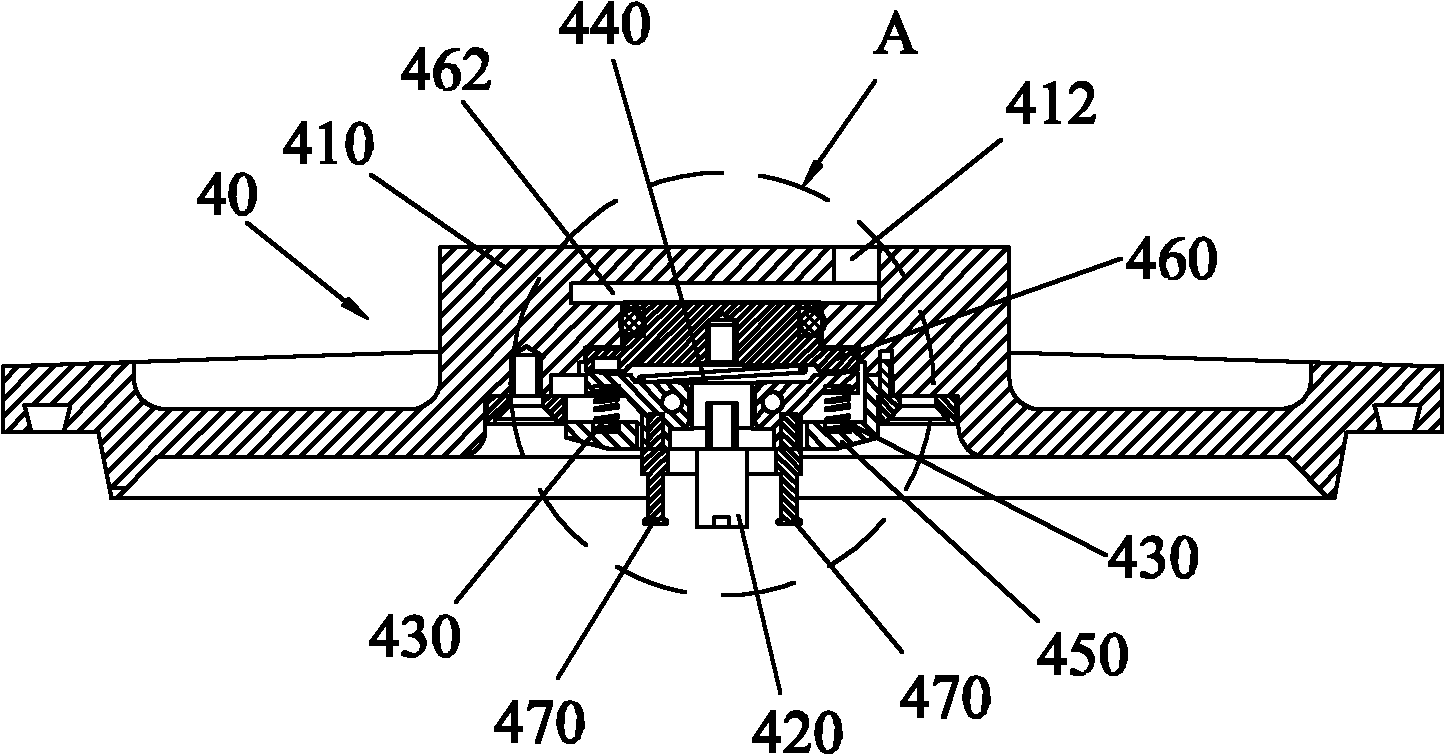

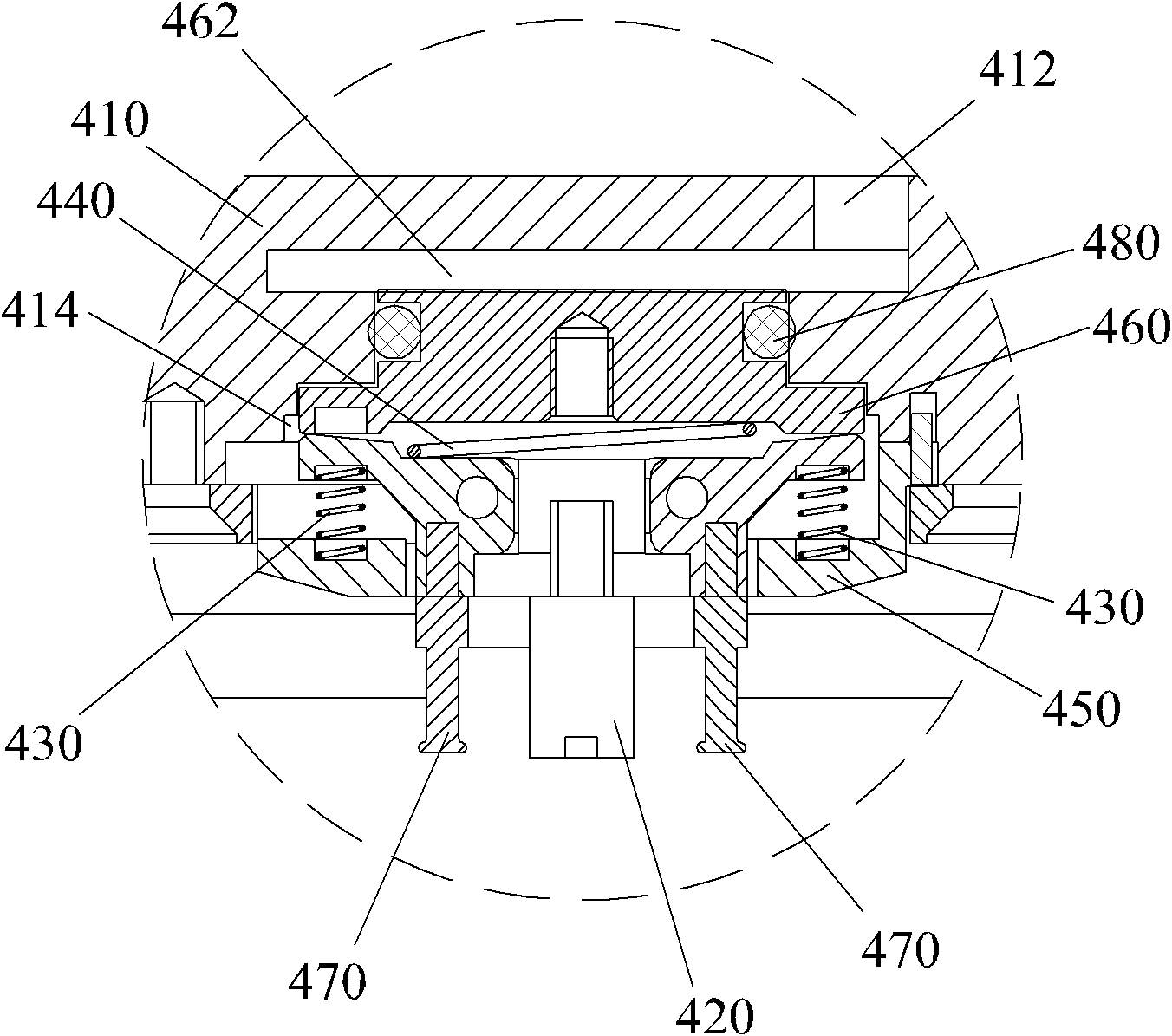

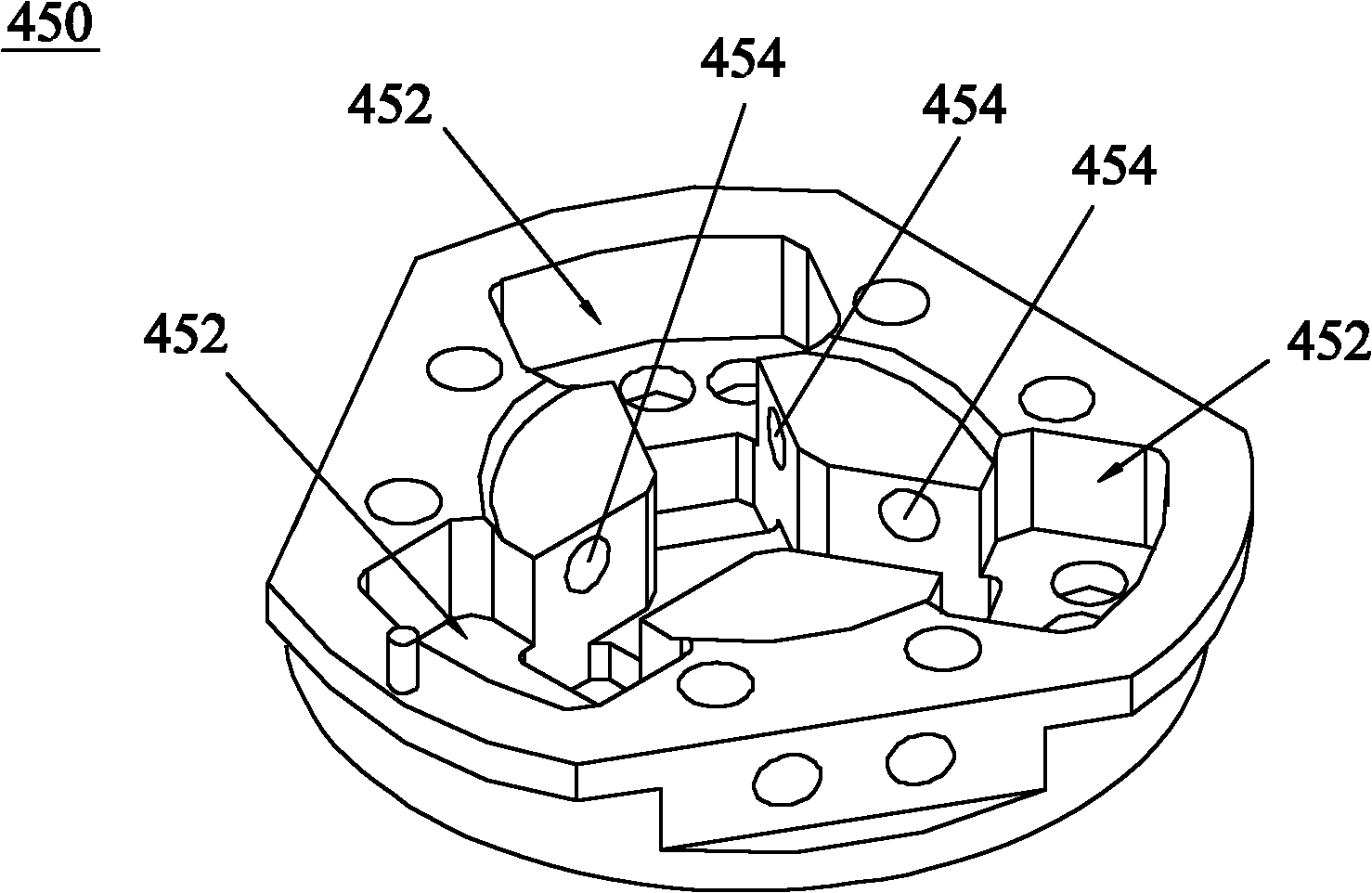

Disk grabbing device

InactiveCN102054502AAchieve crawlingImprove cleanlinessRecord information storageEngineeringAtmospheric pressure

The invention discloses a disk grabbing device which comprises a locating mechanism and a grabbing mechanism that are mutually matched, wherein the grabbing mechanism comprises a foundation support, a thimble, elastic elements, a permanent seat, a piston and three jack catches, the foundation support is arranged right above a tray and provided with an installing groove, the permanent seat is fixed in the installing groove, the piston is accommodated in the installing groove, the jack catches are uniformly distributed at 60 degrees and arranged in the foundation support in a pin-jointed way, each jack catch is provided with a button arm and a claw arm which form a lever, the claw arm is provided with a hook part for grabbing a disk, the bottom of the piston supports against the button arm, an air pressure cavity is formed between the piston and the installing groove, the elastic elements are respectively arranged between the piston and the claw catches and between the permanent seat and the claw catches, when the disk is put down, air pressure is charged, the piston moves downwards, the elastic elements are compressed, the three claw catches are folded up; and when the disk is taken, the air pressure is released, the elastic elements restore and stretch out, the piston moves upwards, and the three claw catches unfold. The disk grabbing device disclosed in the invention has the advantages of higher cleanness and capability of effectively improving the yield and the production efficiency.

Owner:HENAN KAIRUI DIGITAL

Special round UV cured and hot pressed tag for resin grinding wheel

The invention discloses a special round UV cured and hot pressed tag for a resin grinding wheel. The special round UV cured and hot pressed tag comprises a tag body with a circular structure, wherein the tag body is formed by a paper base layer as well as a bottom ink layer and an image-text ink layer which are printed on the paper base layer sequentially. In order to ensure that the hot pressed tag is clear in imprint, is not chalked or cracked and has small color change amplitude at a high temperature, modified ink used in the image-text ink layer is prepared from UV ink, epoxy acrylic resin, polyester acrylic resin, tricarboxymethylolpropane triacrylate, tripropylene glycol diacrylate, benzophenone, 1,2-diphenylethane, methyldiethanolamine, benzenediol, 502 A / B-2 adhesive, pigments and auxiliary additives in proportion. The proper paper base layer is adopted for the hot pressed tag, on the basis of the principle that hot melted chemical molecules are mutually incompatible and with adoption of a UV improved printing technology, the finished tag product is non-toxic, odorless and environment-friendly, and can be compared favorably with a screen plated tag, the cost is reduced by 30% as compared with screen printing cost, and the printing speed is 4-5 times higher than that of screen printing.

Owner:郑州市晶森彩印有限公司

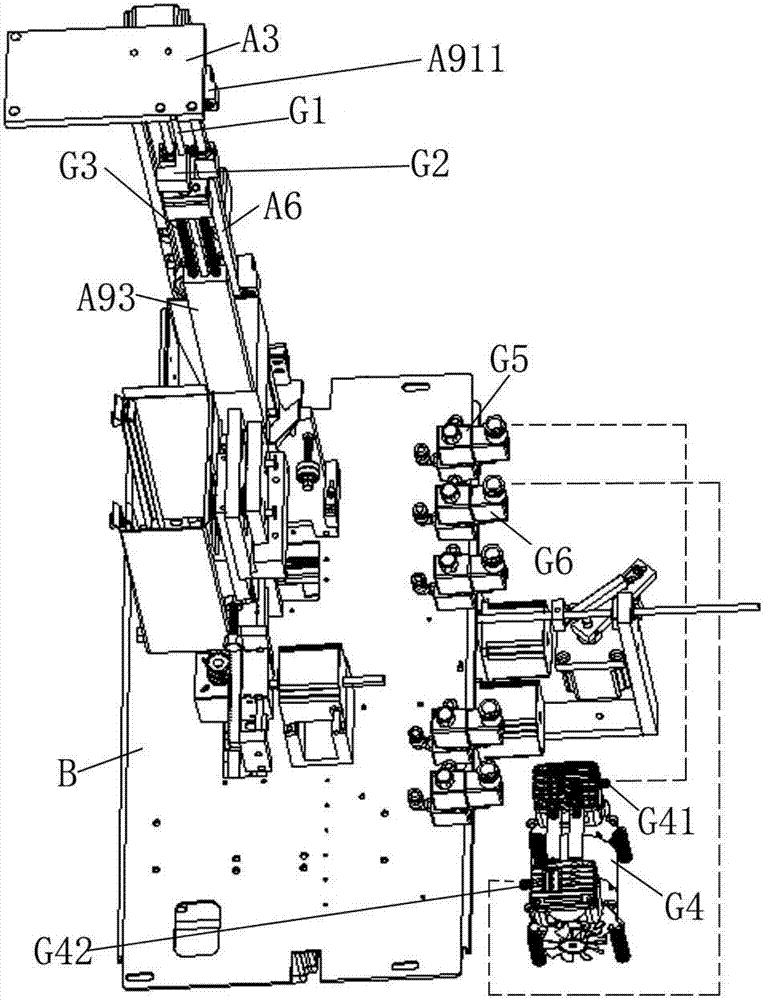

Needle type vacuum pumping and heat seal coding device used for pure electric shaping packaging machine

ActiveCN107512426AHigh speedWill not adsorbPackaging by pressurising/gasifyingWrapper twisting/gatheringVacuum pumpingEngineering

The invention discloses a needle type vacuum pumping and heat seal coding device used for a pure electric shaping packaging machine. A bag body seal coding system is arranged at the lower end of a needle suction type bag body vacuum pumping system, the bottom end of a strip-shaped needle type ventilation pipe in the needle suction type bag body vacuum pumping system can be inserted into a bag body and makes contact with the surface of tea leaves in the bag body, a bag opening of the bag body and the strip-shaped needle type ventilation pipe inserted into the bag body can be clamped by a seal strip mechanism in the bag body seal coding system at the same time, when the vacuum pumping procedure of the bag body is finished, the bottom end of the strip-shaped needle type ventilation pipe in the needle suction type bag body vacuum pumping system is pulled out upwards and enters the tea foam blowing work, and the bag body seal coding system carries out dual-side heat seal and date code coding work on the bag opening of the bag body subject to vacuum pumping work finally. The device has the beneficial effects that the structure is novel, the vacuum pumping speed of the bag body is higher, vacuum pumping is more thorough, the expiration date of filler in the bag body is longer, the tea foam blowing effect is ideal, and the practicability is higher.

Owner:福建省安溪县兴安金属有限公司

Blue titan-alloy microarc oxidation coloring solution and preparation method thereof

InactiveCN102995092ACorrosion resistantHeat resistantSurface reaction electrolytic coatingPlasma electrolytic oxidationUltraviolet lights

The invention belongs to the field of metal coloring and dyeing in surface treatment technology, and particularly relates to a blue titan-alloy microarc oxidation coloring solution and a preparation method thereof, and the blue titan-alloy microarc oxidation coloring solution is used for overcoming the defects of an electrolytic coloring coating. The coloring solution comprises a microarc oxidation spark discharge introducing agent for causing microarc oxidation, a blue microarc oxidation coloring agent, a blue coasting compact accelerator, a blue microarc oxidation coating color homogenizing agent, a blue coating stabilizer and a bath solution stabilizer. The blue titan-alloy microarc oxidation coloring solution provided by the invention is applicable to microarc oxidation coloring, the resulting coating is up to 20 microns in thickness, and the coating with the thickness of 2 to 0 microns is blue as required, and the prepared coating is stable in color and luster and has the characteristic of resistance to touch and wear; the coating is compact and cannot absorb the splotch; and the coating has the excellent characteristics that no organic matter is contained, and the ultraviolet light can be resisted for a long duration. The coating is at temperature below 600 DEG C and is free from discoloring.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

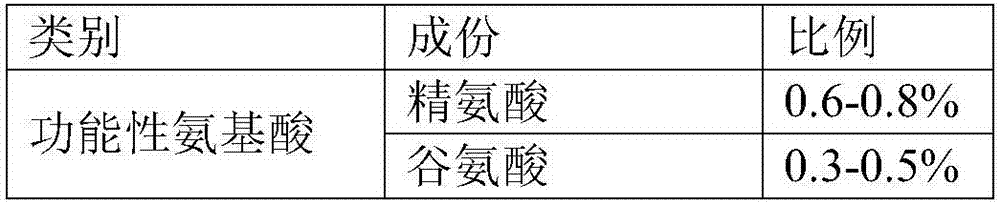

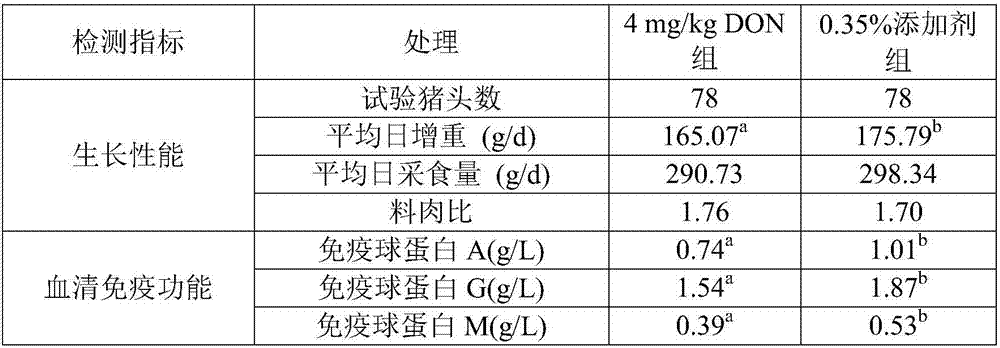

Functional compound feed additive for alleviating vomitoxin poisoning of weaned piglets

ActiveCN107136334AImprove antioxidant capacityImprove immunityAnimal feeding stuffAccessory food factorsChemistryToxin

The invention discloses a functional compound feed additive for alleviating vomitoxin poisoning of weaned piglets. The functional compound feed additive is prepared from the following components: 0.6 to 0.8 percent of arginine, 0.3 to 0.5 percent of glutamic acid, 0.2 to 0.5 percent of methionine, 2.0 to 3.0 percent of baicalin selenium, 0.6 to 1.5 percent of baicalin zinc, 0.5 to 1.0 percent of baicalin copper, 1.5 to 2.0 percent of baicalin, 0.6 to 1.3 percent of grape seed proanthocyanidin, 1.2 to 1.6 percent of globe artichoke extract, 0.4 to 1.0 percent of vitamin A, 0.6 to 1.0 percent of vitamin C, 1.7 to 3.0 percent of vitamin E, 2.8 to 4.0 percent of zymosan, 4.5 to 5.0 percent of astragalus polysaccharide, 2.5 to 3.3 percent of echinacea polysaccharide, 0.2 to 0.5 percent of lactobacillus, 2.7 to 4.0 percent of bacillus subtilis, 0.2 to 0.5 percent of enterococcus faecium, and 65.5 to 76 percent of zeolite powder. The functional compound feed additive has relatively good alleviation effects for oxidization injury of weaned piglet intestinal tracts, reduction of immunity, intestinal flora disturbance and growth suppression.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

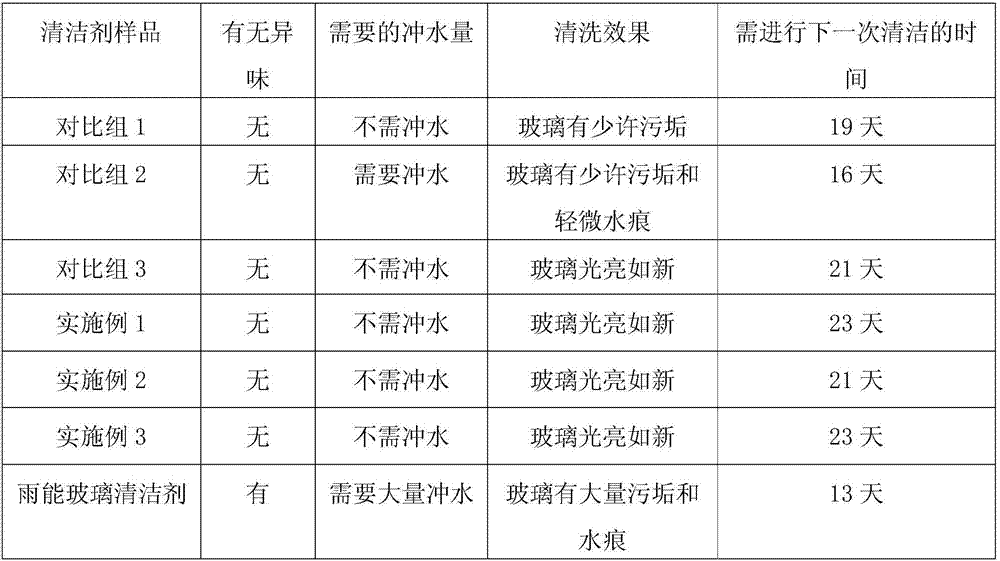

Cleaning agent for window glass of car and preparation method thereof

InactiveCN106967520AImprove performanceExcellent decontaminationInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSODIUM METAPHOSPHATEThiourea

The invention provides a cleaning agent for the window glass of a car and a preparation method thereof. The cleaning agent for the window glass of the car comprises the following raw materials by weight: 11 to 15 parts of fluorosilicone resin, 4 to 8 parts of coconut diethanolamide, 9 to 13 parts of sodium fatty alcohol polyoxyethylene ether sulfate, 16 to 24 parts of sodium acid pyrophosphate, 11 to 17 parts of sodium metaphosphate, 6 to 12 parts of sorbitol, 8 to 12 parts of fluorocarbon emulsion, 6 to 16 parts of edetic acid, 6 to 14 parts of isopropanol, 10 to 14 parts of sodium isopropyl benzenesulfonate, 8 to 16 parts of fatty alcohol polyoxyethylene ether, 6 to 10 parts of alkylphenol polyoxyethylene, 7 to 11 parts of sodium benzoate, 6 to 8 parts of modified thiourea and 22 to 26 parts of deionized water. The cleaning agent provided by the invention is free of peculiar smell, does not need flushing with water during cleaning, has better cleaning effect and reduces cleaning frequency; and the preparation method is simple in process and suitable for application in related fields.

Owner:玉林博飞商贸有限公司

Oil-free antistatic pearl cotton

The invention relates to oil-free antistatic pearl cotton prepared by foaming the following materials by mass: 75%-85% of high pressure polyethylene, 3%-10% of degreased masterbatch and 3%-10% of antistatic masterbatch; in the making process, butane gas with the mass ratio of 8%-12% is introduced for foaming. The oil-free antistatic pearl cotton prepared from the materials does not appear the phenomenon of infiltration of grease in the late use, and may not pollute parts; by the use of the antistatic masterbatch, the prepared oil-free antistatic pearl cotton has good antistatic effect, may not absorb dust and fine particles, and can ensure the parts are not polluted by dust, the oil-free antistatic pearl cotton can be prepared into foam packing bags by post processing, and the foam packing bags are used to package some electronic products such as TV, mobile phones, LCD panels and the like, ensures that the surface of the electronic product may not stick to grease and dust layer, and ensures the normal operation of electrical components of the electronic products.

Owner:ZHANGJIAGANG SANYING NEW TYPEPACKING MATERIAL CO LTD

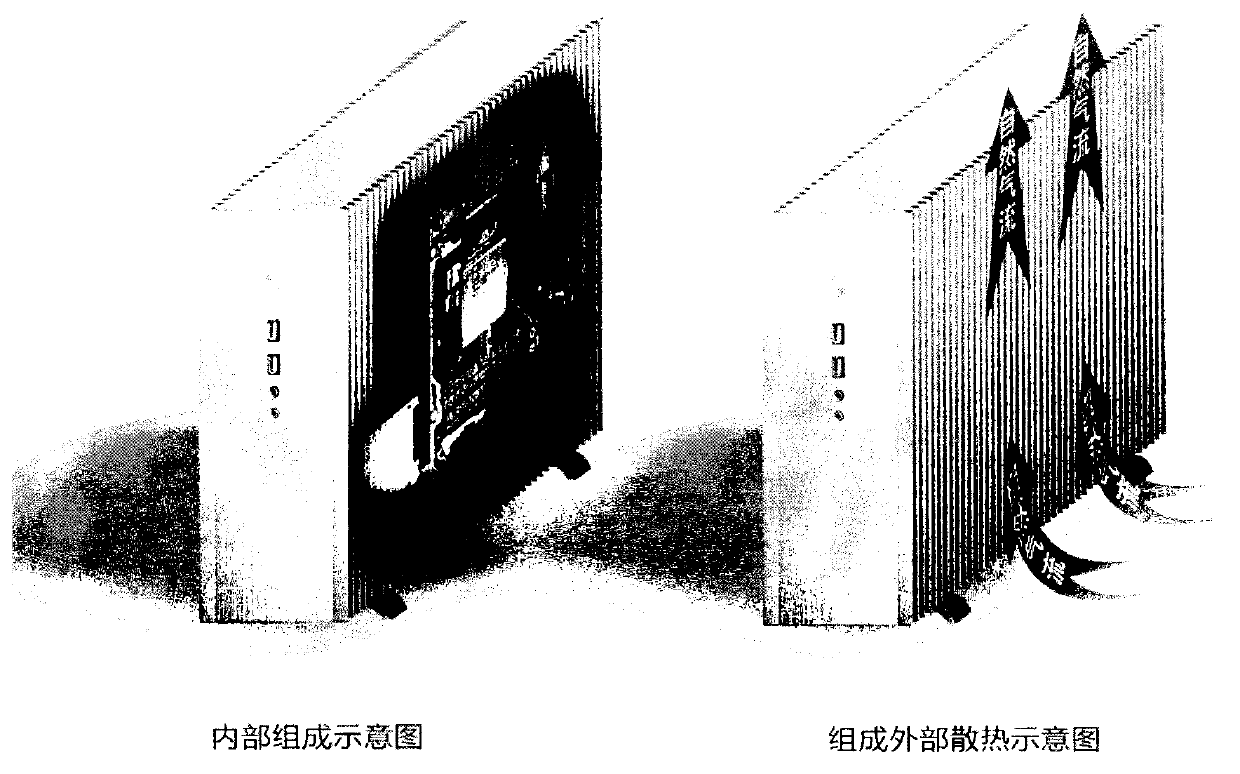

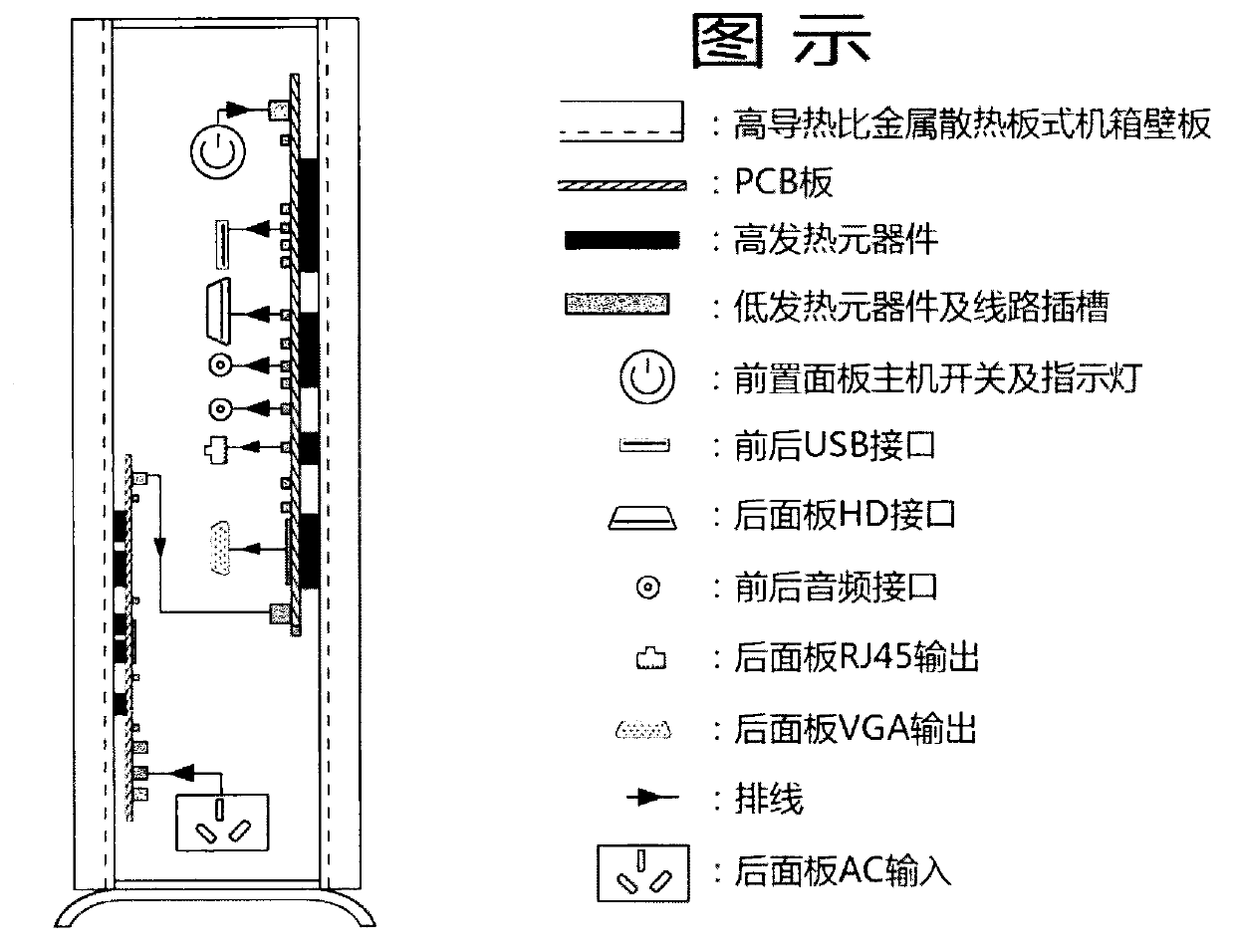

Silent non-power-consumption heat dissipation type computer mainframe

InactiveCN103149991ANo loadNo power consumptionDigital processing power distributionEnergy efficient computingInfrasonic wavesLife time

The invention discloses a silent non-power-consumption heat dissipation type computer mainframe, wherein heating components in the computer mainframe are directly and fixedly arranged on a case wall board with a heat dissipation function; the heat conducted to the outer surface of a case is brought away through external natural air flow to perform physical heat dissipation; and the silent non-power-consumption heat dissipation type computer mainframe is characterized in that no additional power consumption exists in the entire heat dissipation process. The computer case wall board is made of metal with high thermal conduction ratio; and a heat dissipation toothed lattice for increasing the heat dissipation area is arranged on the outer side of the computer case wall board according to a heat dissipation requirement. The heat of the heating components in the mainframe is directly conducted to the exterior of a computer in real time through the heat dissipation wall board, so that infrasonic wave and noise caused by a fan are avoided, meanwhile, the stability performance for operation of the computer is improved, and the service life of the electronic components in the computer is effectively prolonged. Meanwhile, electromagnetic radiation in the computer is effectively obstructed by the metal wall board with high thermal conduction ratio and the heat dissipation toothed lattice of the metal wall board. The silent non-power-consumption heat dissipation type computer mainframe has a good actual measurement effect in the aspects of performance, energy conservation and environmental protection.

Owner:张伟 +1

Method for refining and purifying rice bran oil

InactiveCN108179059ALow impurity contentImprove qualityFatty-oils/fats refiningRice Bran ExtractDeep processing

The invention discloses a method for refining and purifying rice bran oil, and relates to the technical field of deep processing of agricultural and sideline products. The method comprises the following steps: (1) degumming, (2) dewaxing, (3) decolorizing, (4) deacidification, (5) deodorization and (6) freeze degreasing. The method for refining and purifying the rice bran oil has the advantages ofsimplicity in operation, low energy consumption during production, high oil yield, and good decolorizing and impurity-removing effects, and effectively reduces the content of impurities in finished rice bran oil to improve the quality of the finished rice bran oil in order to enhance the market competitiveness.

Owner:福建小薇金匙科技孵化有限公司

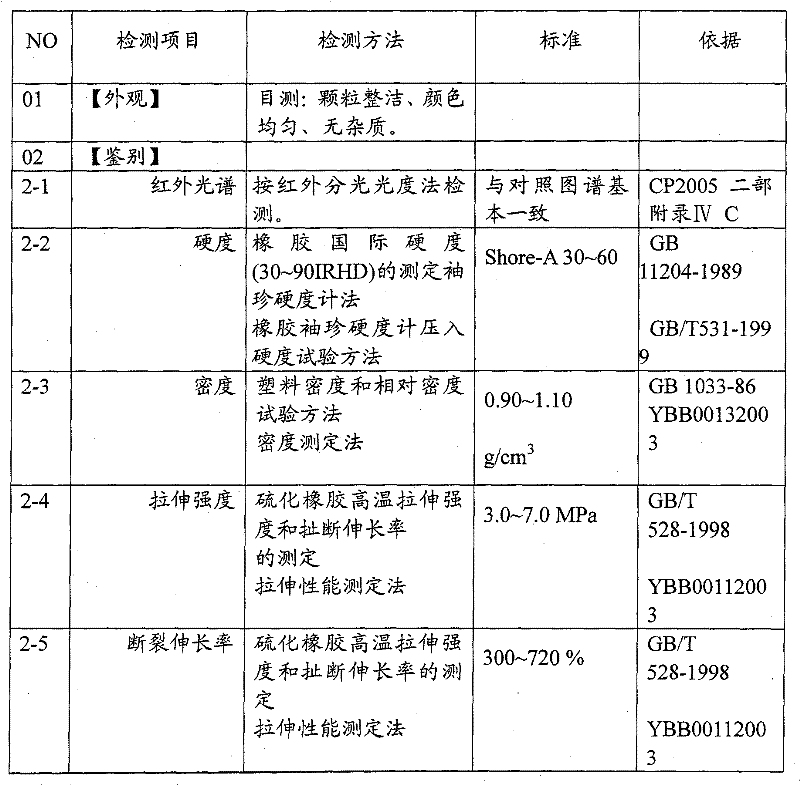

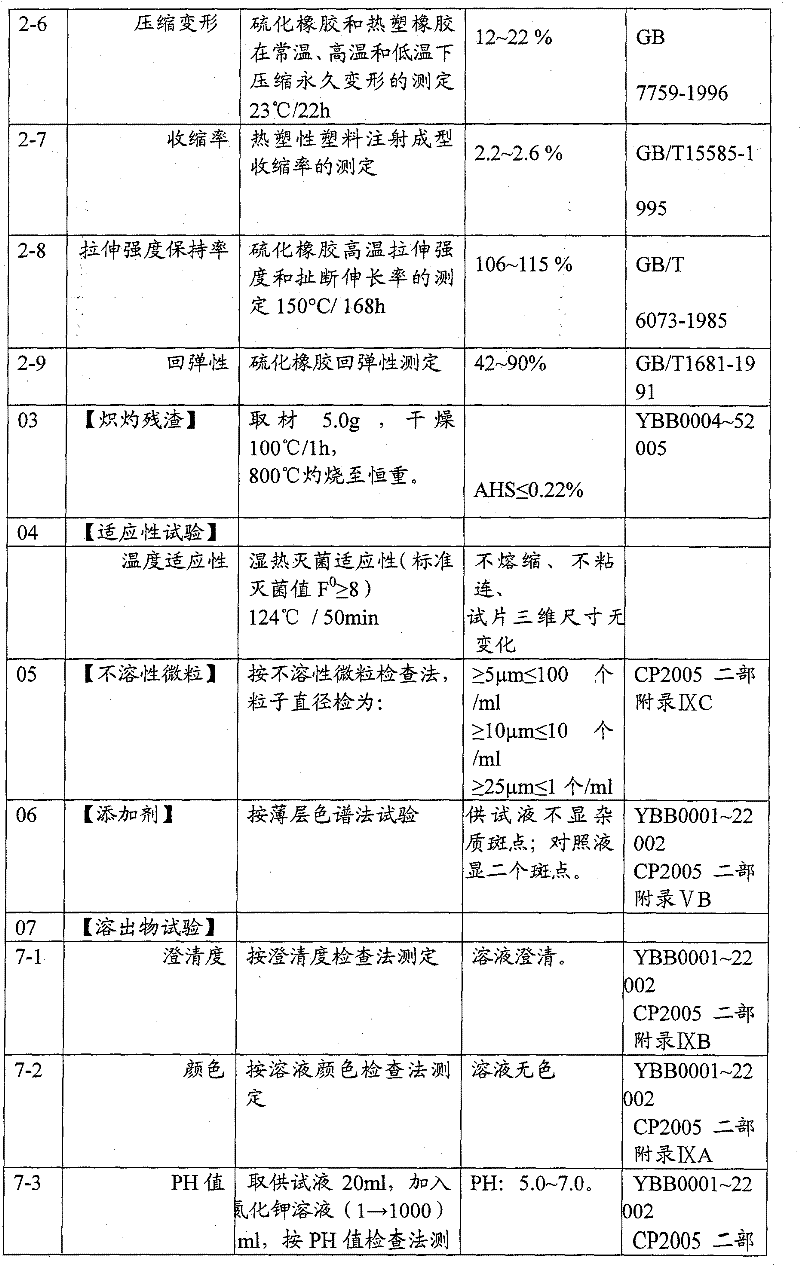

Thermoplastic elastomer material, preparation thereof and method for manufacturing medicinal bottle stopper by using the same

InactiveCN101376730BCreate pollutionWon't releasePharmaceutical containersMedical packagingRubber materialAntistatic agent

The invention provides thermoplastic elastomer materials used for a bottle cork for manufacturing medicines, a preparation method thereof and a method for applying the bottle cork for manufacturing medicines thereof. The materials are prepared by the following components: styrene copolymer or rubber materials as well as polyolefine matters. The styrene copolymer is PP or PE; besides, the materials also contain a plasticizer and a loading agent, contain or do not contain a compatibilizer, contain or do not contain an antioxidant, contain or do not contain an antistatic agent, contain or do notcontain adhesion preventives. The preparation method thereof includes the steps of drying the materials, fusing a reaction kettle, using a plastic extruding machine to extrude the materials, using a cooling water slot to cool and shape the materials, using a hauling machine to haul and cut off the materials, and the like. The thermoplastic elastomer materials provided by the invention have the advantages of stable chemical property, no poison, low polarity and good rebound resilience.

Owner:谷其昌

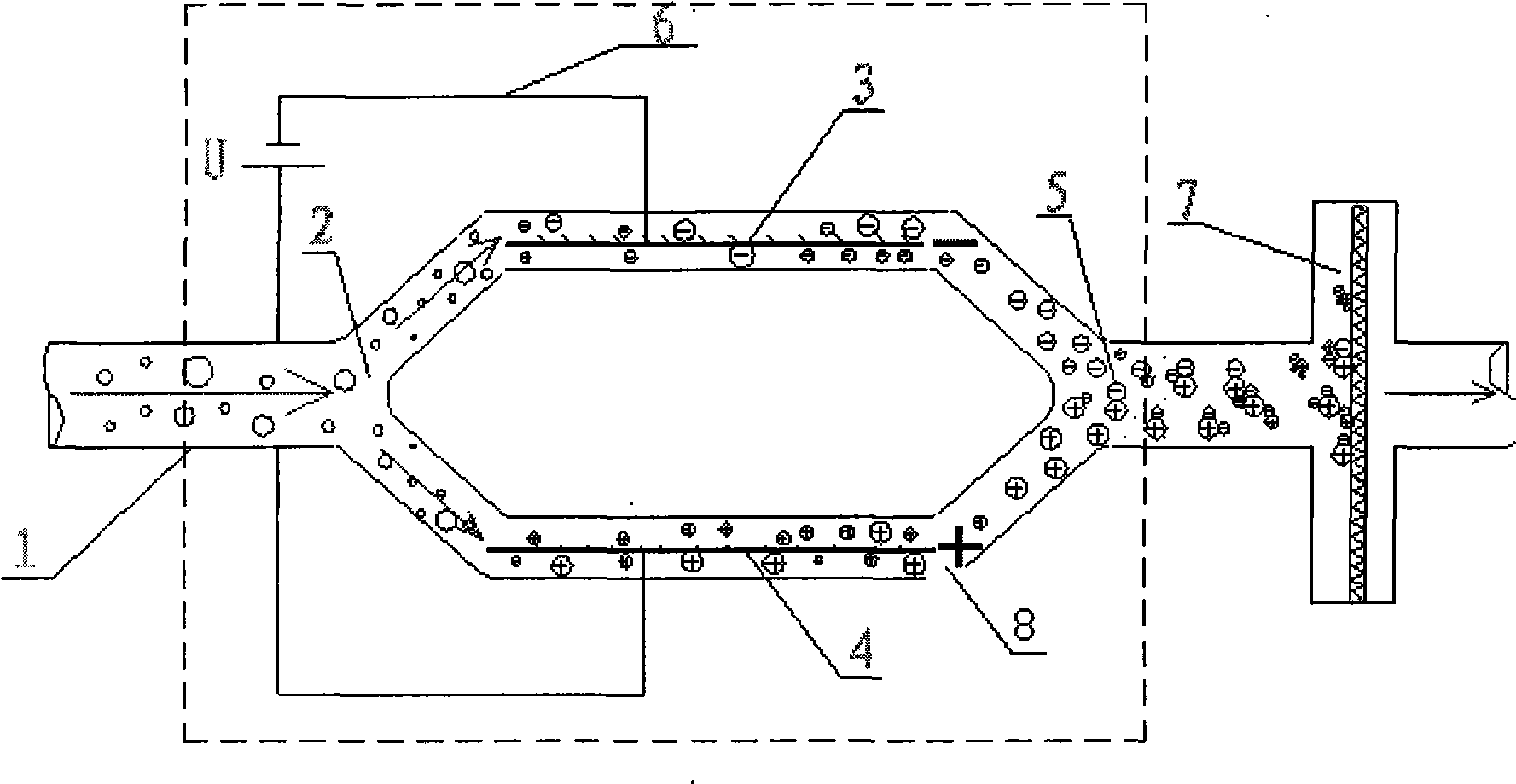

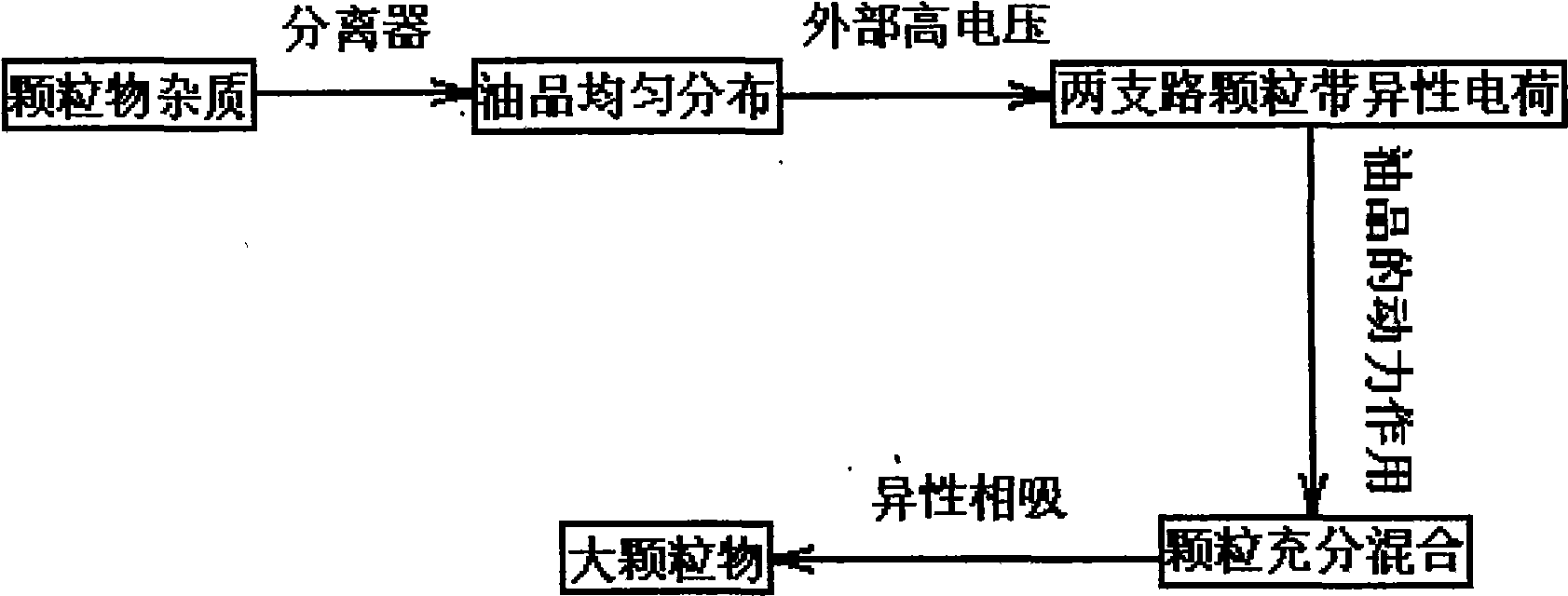

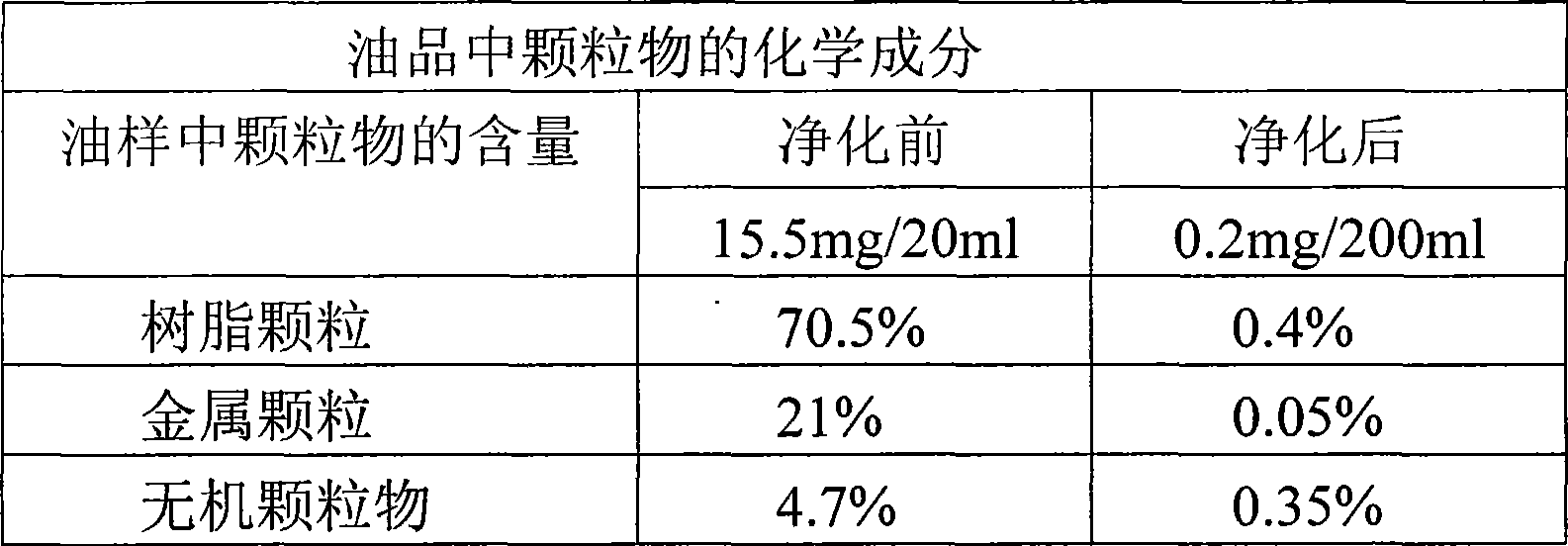

Method for conglomerating particulate matters in oil

InactiveCN101530694AWill not adsorbRestore surface tensionFiltration separationParticulatesSmall particle

The invention relates to a method for conglomerating micro particulate matters in oil, which is characterized by comprising that: firstly, the oil is introduced into an oil inlet pipe and divided into two branches by a branching device, and the oil in each branch flows into two insulating tube cavities respectively; the particulate matters in the oil of the two branches are taken with charges of different polarities respectively under the action of strong voltage outside; the charged particulate matters in the oil enter a mixer and are fully mixed, the particulate matters in the fluid are continuously mutually 'conglomerated to become large' and collected by a filter plant; and ultramicro particulate matters which are not neutralized yet enter an oil piping system with high electrification and are neutralized and conglomerated with the particulate matters with original charges deposited in the whole oil piping system, so that the particulate matters in the oil piping system are gradually neutralized and fall off. The method can purify the particulate matters in the oil to the submicron degree, thereby recovering the surface tension of the oil, improving the quality of the oil, achieving the purification aim truly, and having good protection function on precision equipment with high requirement on the oil.

Owner:西安凯创机电科技有限公司

Preparation method of bamboo weaving handicraft surface spot cleaning agent

ActiveCN106398907AAvoid problems such as moldy interface breakageNo harmInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsDistillationCleansing Agents

The invention provides a preparation method of a bamboo weaving handicraft surface spot cleaning agent. The method mainly comprises the following steps: pueraria root powder is prepared, an organic silane coupling agent is prepared, and nanometer silicon dioxide, zinc stearate, an octadecanol mixture, and 50% of the pueraria root powder are mixed; distillation is carried out, and distilled fluid is collected; auxiliary liquid is prepared in an agitator tank, the auxiliary liquid and distilled fluid are mixed, the rest 50% of the powder is added, and the cleaning agent is obtained. The method has the beneficial effects that the cleaning agent is sprayed on the handicraft, and dust on the handicraft can be cleaned; at the same time, the cleaning agent does not have viscosity and is not attached to the handicraft, the cleaning agent flows rapidly and does not damage the material of the handicraft, and the problems such as mildewing of the handicraft and connector fracture due to wetting and the like are avoided.

Owner:FUNAN COUNTY TIANYI CRAFTS

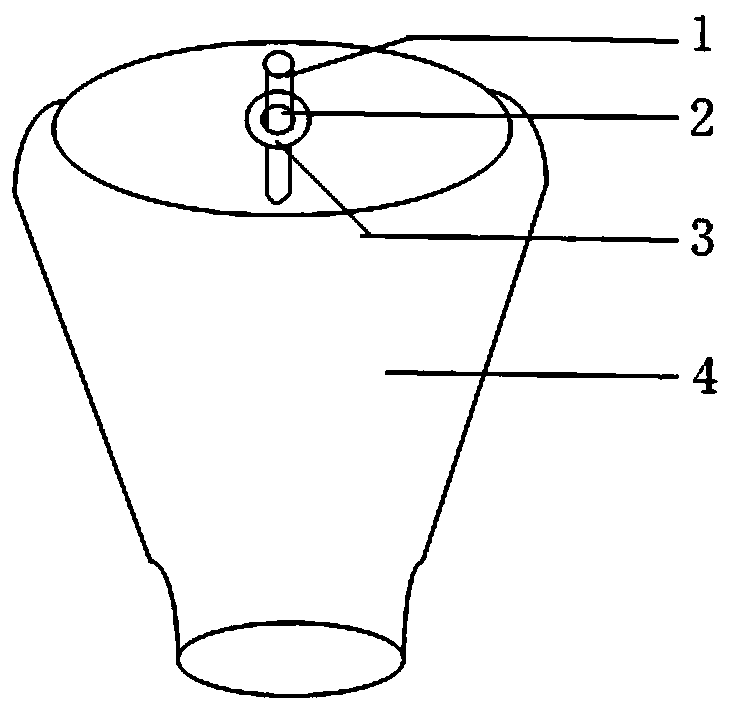

Sampling device and concentration determination method for semi-volatile organic matter in ambient air

ActiveCN109085027AWon't leakOutflow smoothlyComponent separationWithdrawing sample devicesVena contracta diameterInterference fit

The invention discloses a sampling device and a concentration determination method for semi-volatile organic matters in ambient air, comprising a housing and an orifice plate. The orifice plate is aninner hollow cylinder, wherein an opening is formed in the top. The orifice plate is arranged inside the housing with the same structure, and is in interference fit with the housing. The upper part ofthe orifice plate is provided with a groove penetrating through the inner wall and the outer wall, an adsorbent coating is arranged on the outer wall of the orifice plate, the groove in the outer wall is closed and covered by the adsorbent coating, the inner part of the cavity below the orifice plate groove is sequentially provided with a filter membrane and an adsorbent sealed to the inner wallof the orifice plate from top to bottom, through holes are coaxially arranged at the bottom of the orifice plate and the housing, and the through holes are connected with a flowmeter and an air extracting power in sequence. According to the sampling device and the concentration determination method for the semi-volatile organic matters in ambient air, gas phase SVOC and particle phase SVOC can becollected separately, and the gas phase concentration and the particle phase concentration of the SVOC can be accurately determined.

Owner:XI AN JIAOTONG UNIV

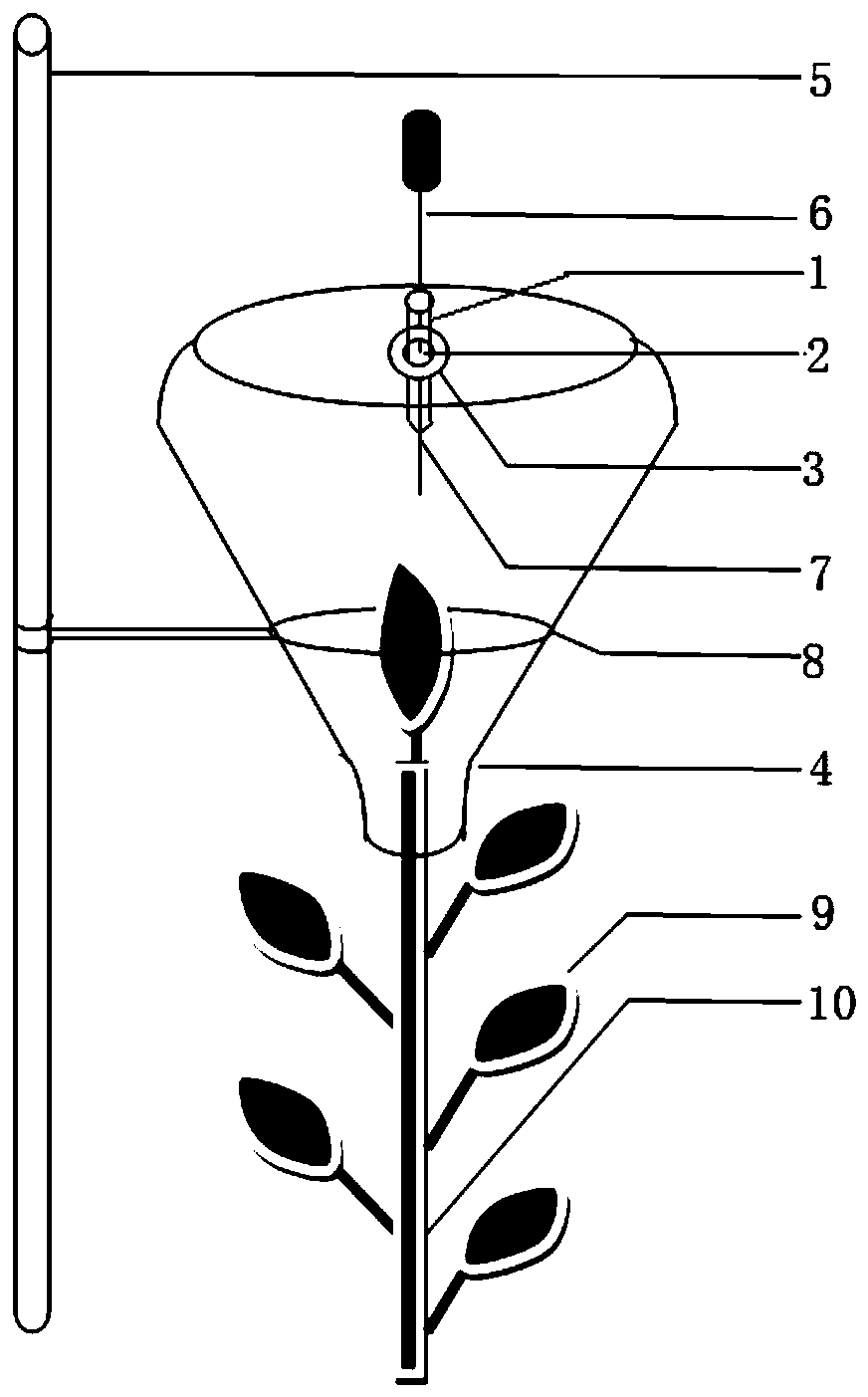

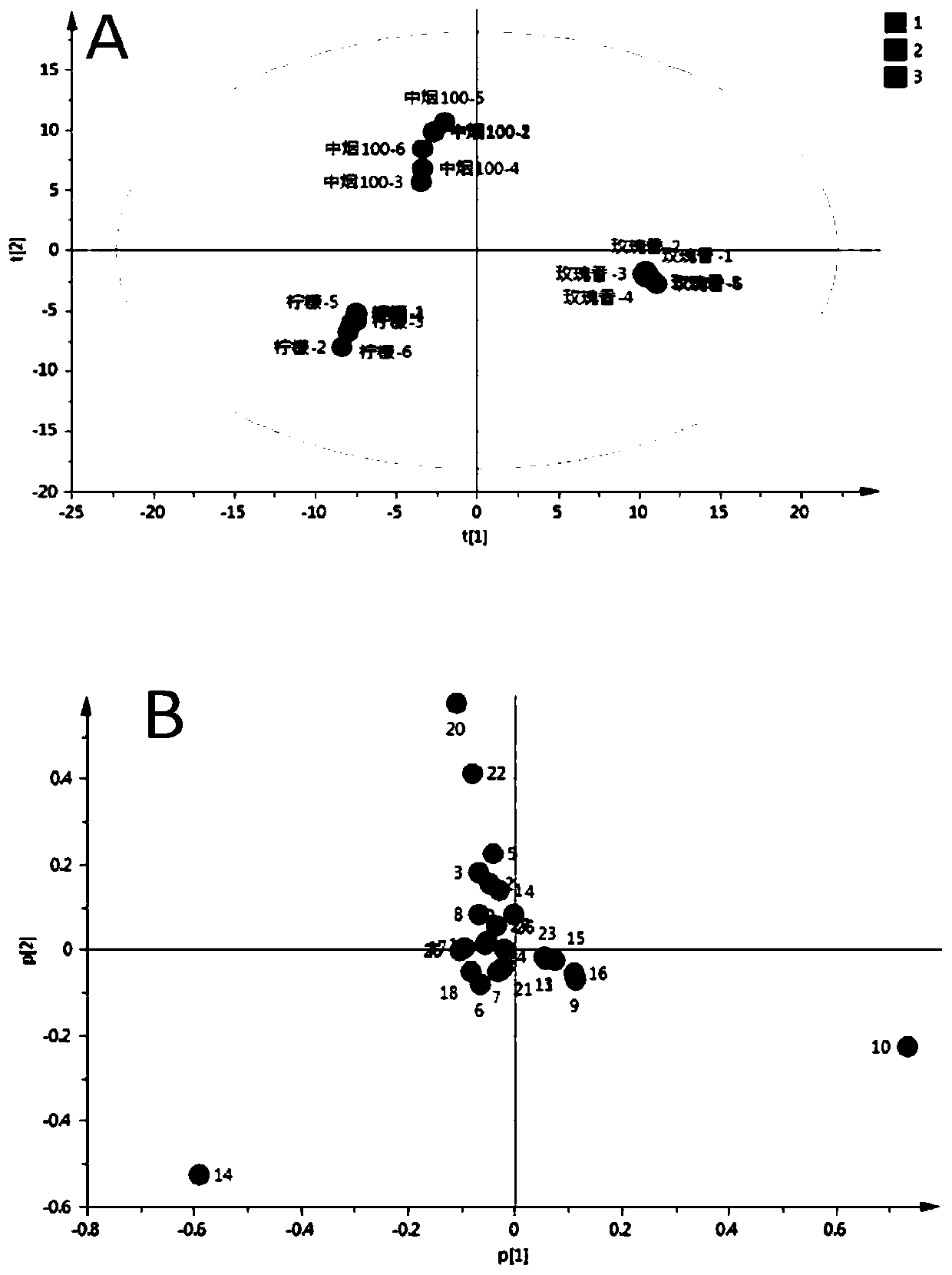

Analysis method of volatile metabolic markers in Nicotiana tabacum L. with aroma mutant based on GC-MS characteristics

PendingCN110108817AGuaranteed accuracyExpand the scope and field of applicationComponent separationFlueMutant

The invention provides an analysis method of volatile metabolic markers in Nicotiana tabacum L. with aroma mutants based on GC-MS characteristics. The problems of collection, identification and semi-quantitative detection of unstable and easily degradable active volatile matter can be effectively solved, the spatio-temporal dynamic information of plant organic volatile matter molecules is mastered, a theoretical basis is provided for studying the change, types and mechanisms of plant organic volatile metabolites, and the analysis method of the volatile metabolic markers in the Nicotiana tabacum L. with the aroma mutants based on the GC-MS characteristics is suitable for distinguishing and identifying flue-cured tobacco with the different aroma mutants; and therefore, good practical application value is achieved.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD

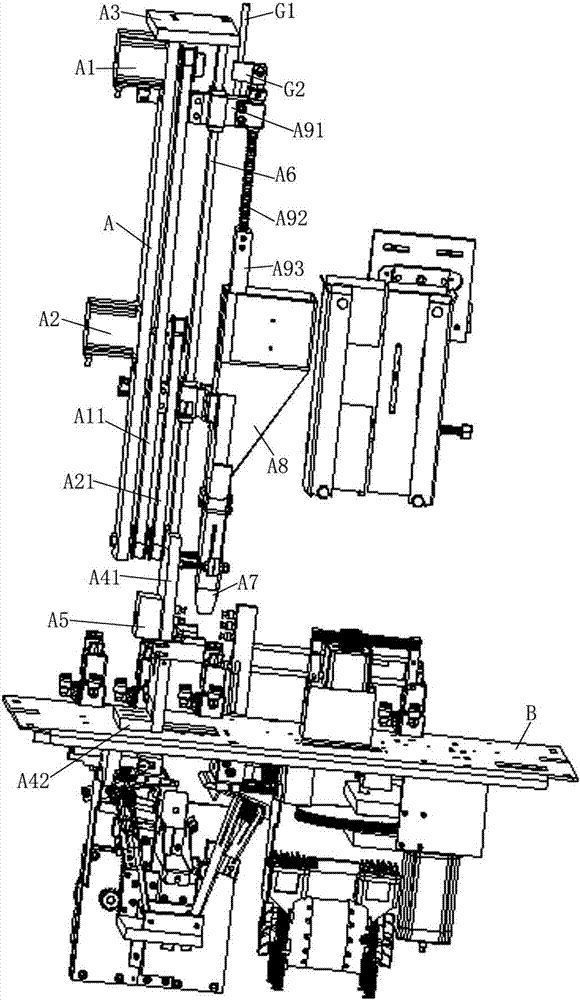

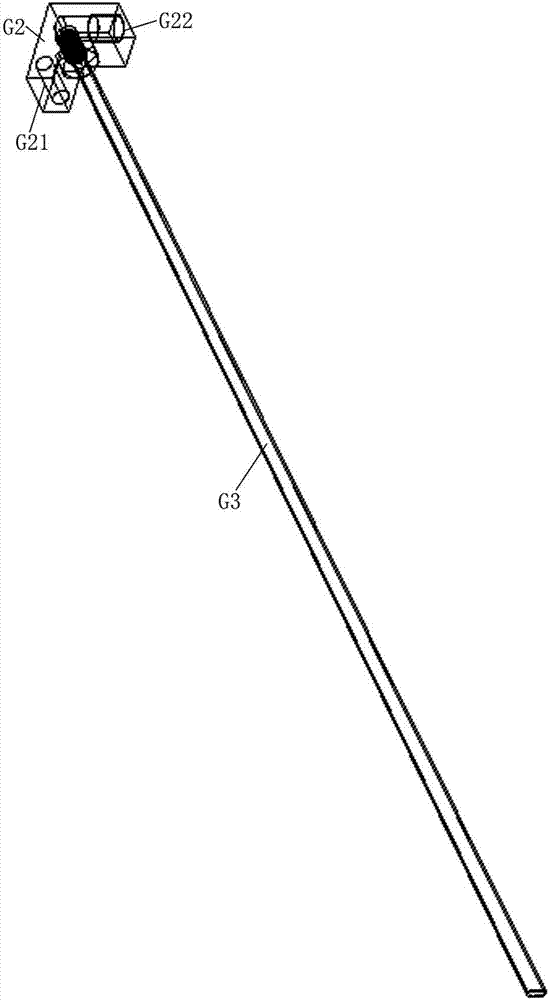

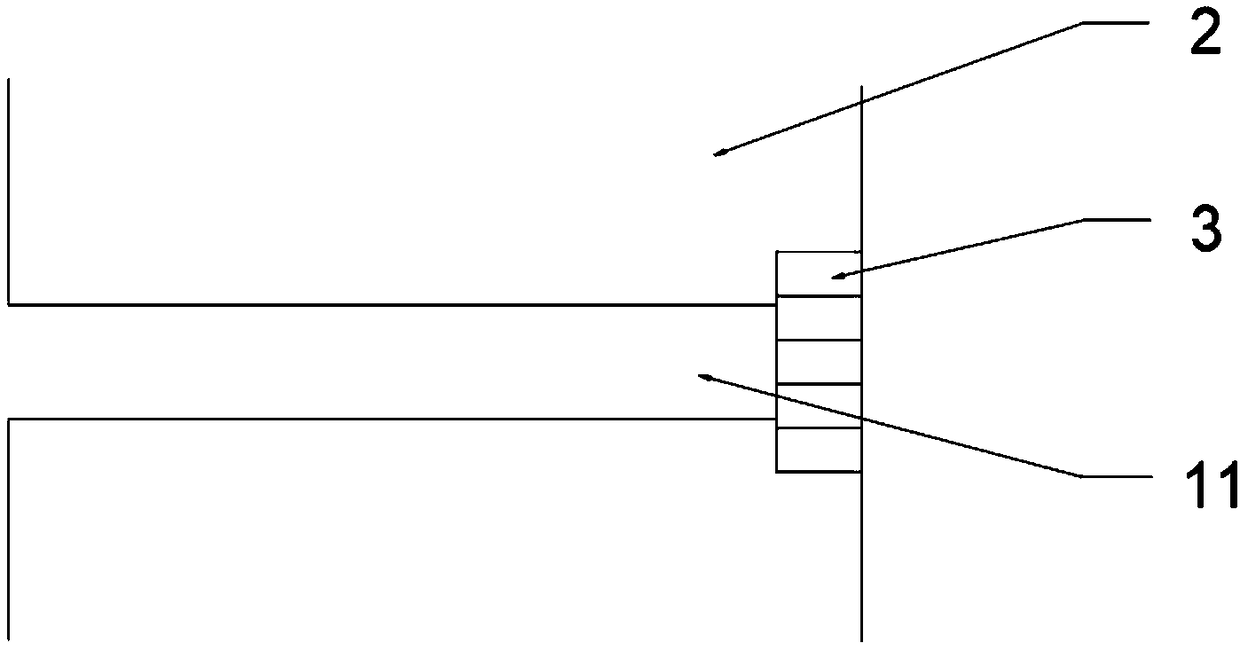

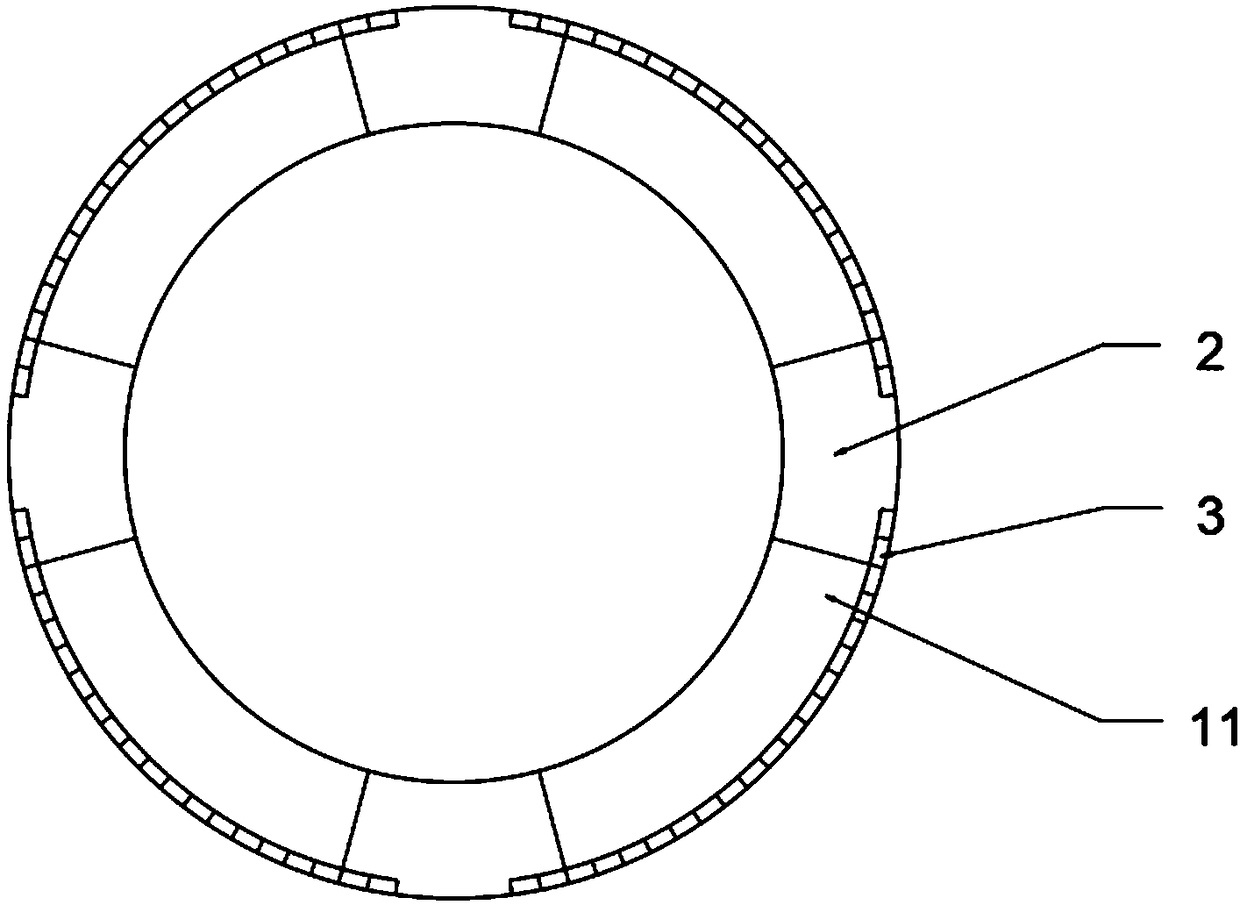

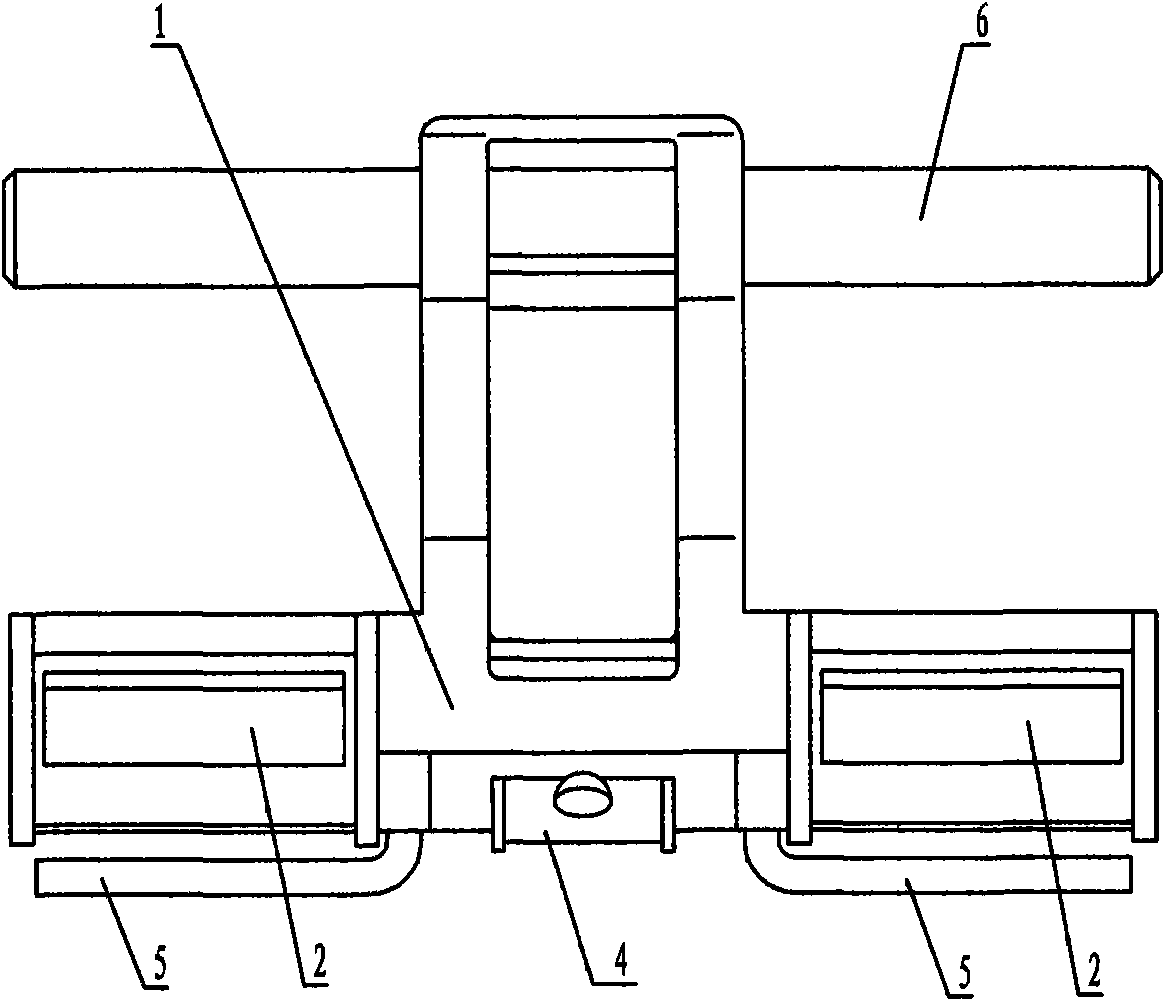

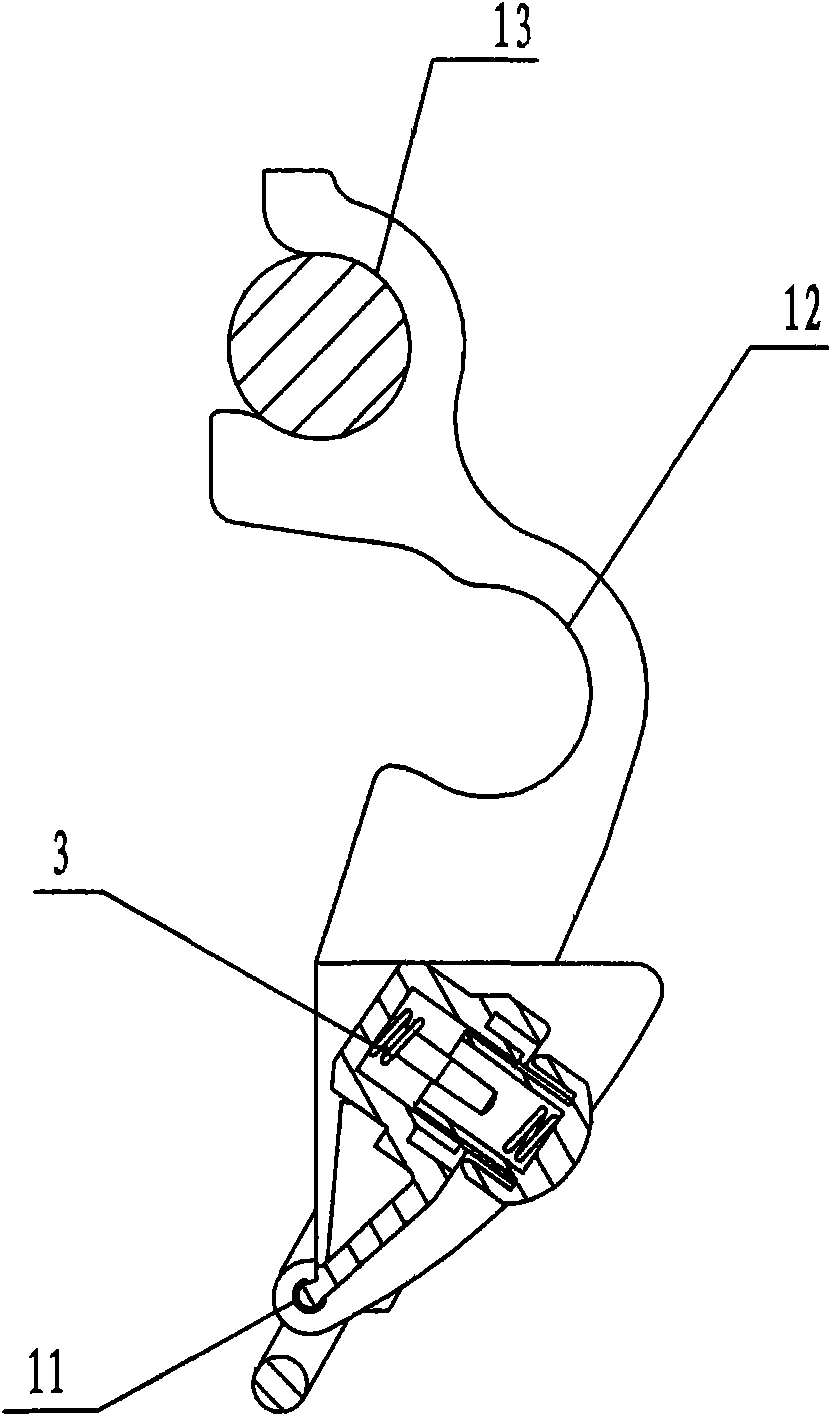

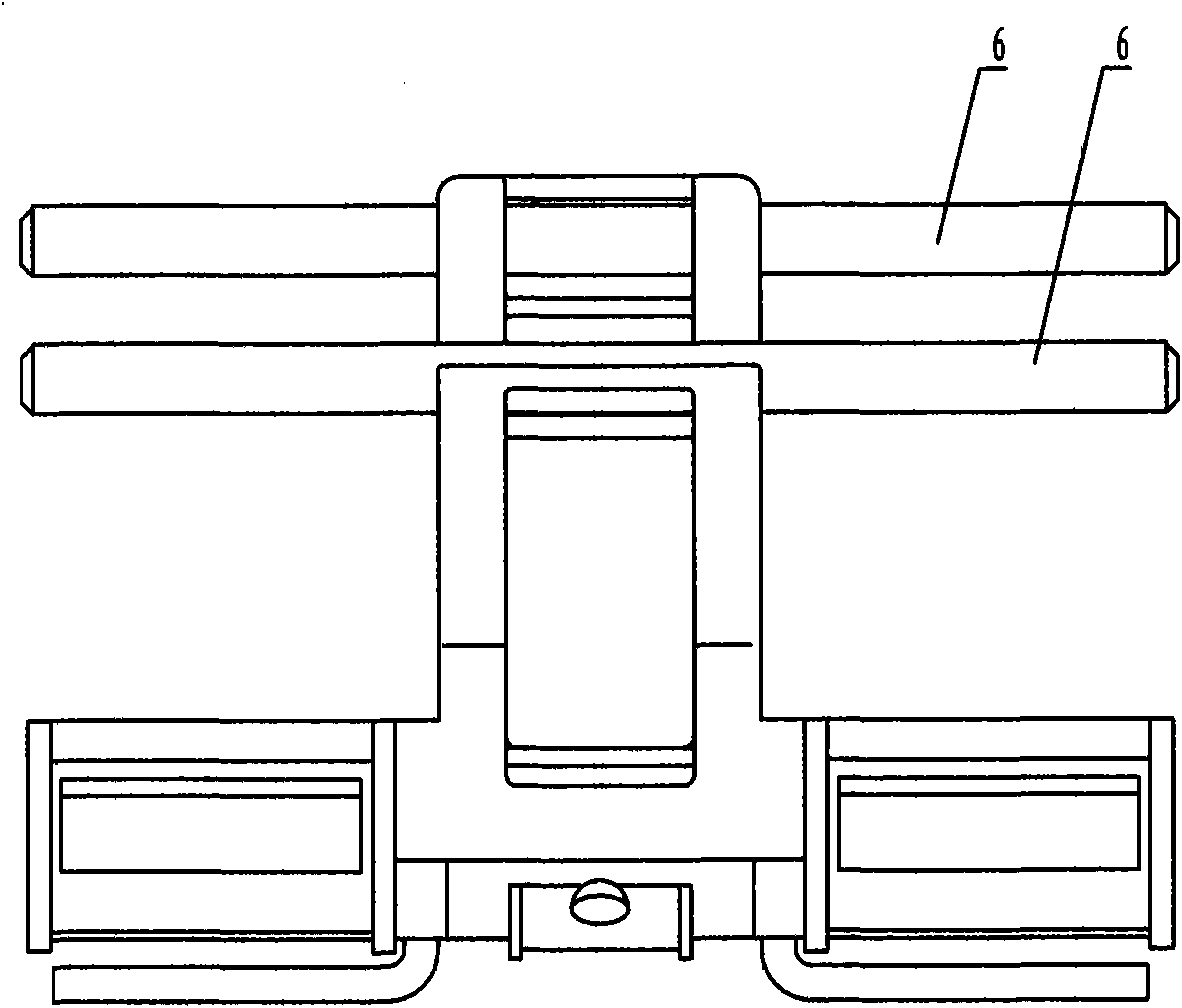

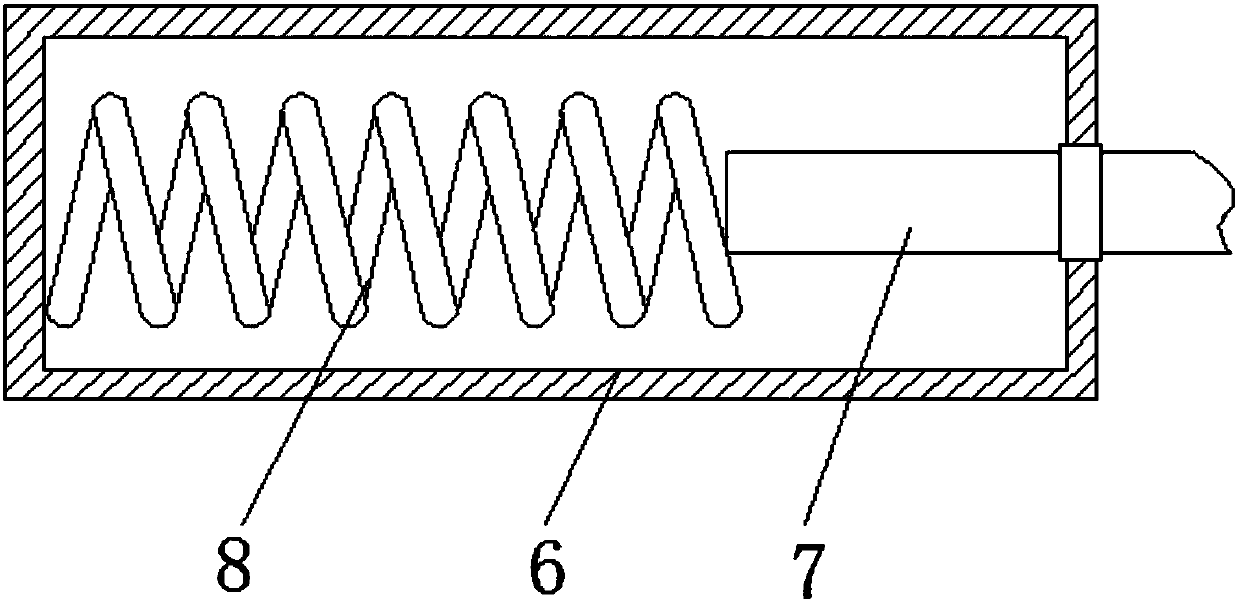

Carbon fiber upper pin assembly adopting pressure bars with combined structure and manufacturing method thereof

The invention provides a carbon fiber upper pin assembly adopting pressure bars with a combined structure and a manufacturing method thereof, which relate to the field of textile mechanical components. The carbon fiber upper pin assembly comprises an upper pin frame body, a left tension supporting plate, a right tension supporting plate, a left telescopic spring, a right telescopic spring, spacing blocks, a left pressure bar and a right pressure bar in a front area and one or two pressure bars in a back area, wherein the left pressure bar and the right pressure bar in the front area and the pressure bars in the back area are made of elongated or small tubular metals and are in injection molding connection with the combined structure of hollow cylindrical non-metal bars; a left jaw and a right jaw at the front end of the upper pin frame body are a left ferrule and a right ferrule; arched cambered surfaces are formed at the front side and the back side of the working surface of the left tension supporting plate and the right tension supporting plate, and the left side and the right side of the working surface are also arched; and the hollow cylindrical non-metal bars used as the outer structure of the left pressure bar and the right pressure bar in the front area and the pressure bars in the back area are made of phenolic molding materials. The invention has the advantages that because non-metal bars are evenly arranged on the surfaces of front and back pressure bars, the electrostatic generation can be avoided, and dust can not be adsorbed; and the surfaces of the pressure bars do not need to be finely machined and electroplated, thereby simplifying the machining process and reducing the production cost.

Owner:宁波民丰实业有限公司

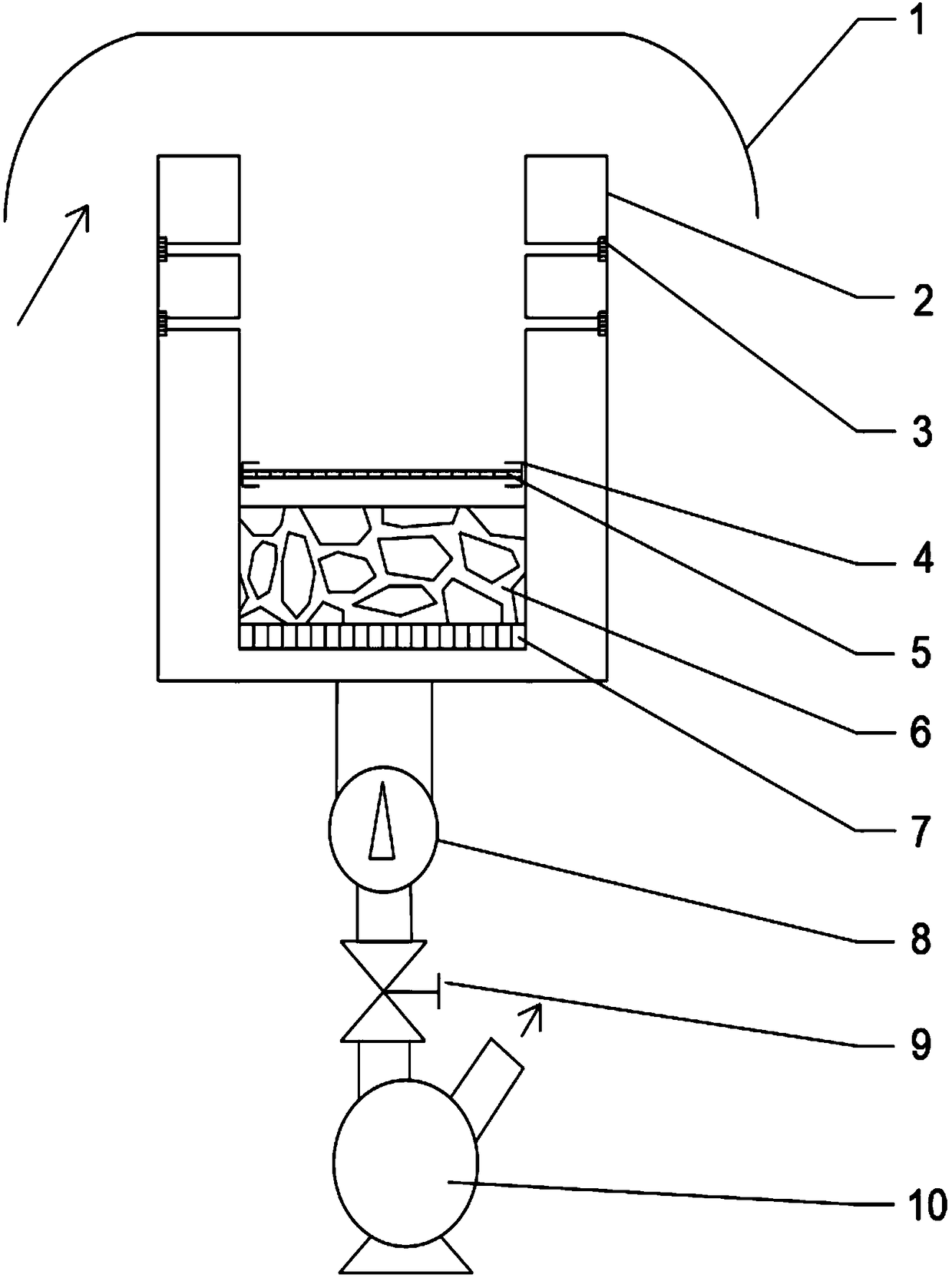

Start-up method for fluidized bed

ActiveCN102212386AAvoid cloggingAvoid breakingHydrotreatment operations starting-upHydrocarbon oil crackingWaxFluidized bed

The invention discloses a start-up method for a fluidized bed. The start-up method for the fluidized bed comprises the following steps of: bonding a micro-spherical fluidized bed catalyst into globular, hemispheric, columnar, flake or irregular catalyst particles by using a wax material, wherein the diameter of the catalyst particle is 2 to 20mm according to the equivalent volume sphericity; packing the catalyst particles in a reactor of the fluidized bed for carrying out the air tight operation; introducing starting-up oil below a melting point of the wax material in the catalyst particles and carrying out the cyclic operation; raising the temperature of the reactor of the fluidized bed to be higher than that the temperature of the melting point of the wax material in the catalyst particles by 5 to 100 DEG C; dissolving the wax material in the catalyst particles in the start-up oil; and activating the micro-spherical fluidized bed catalyst. According to the start-up method for the fluidized bed, the problem that the micro-spherical catalyst is broken due to the extrusion and collision and is polluted by dust in the process of placing the micro-spherical catalyst into the reactor is solved; the catalyst particles are prevented from being taken out from the reactor or causing stoppage in the start-up process of the device; and the start-up method has the advantages of short start-up time, high efficiency and good effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

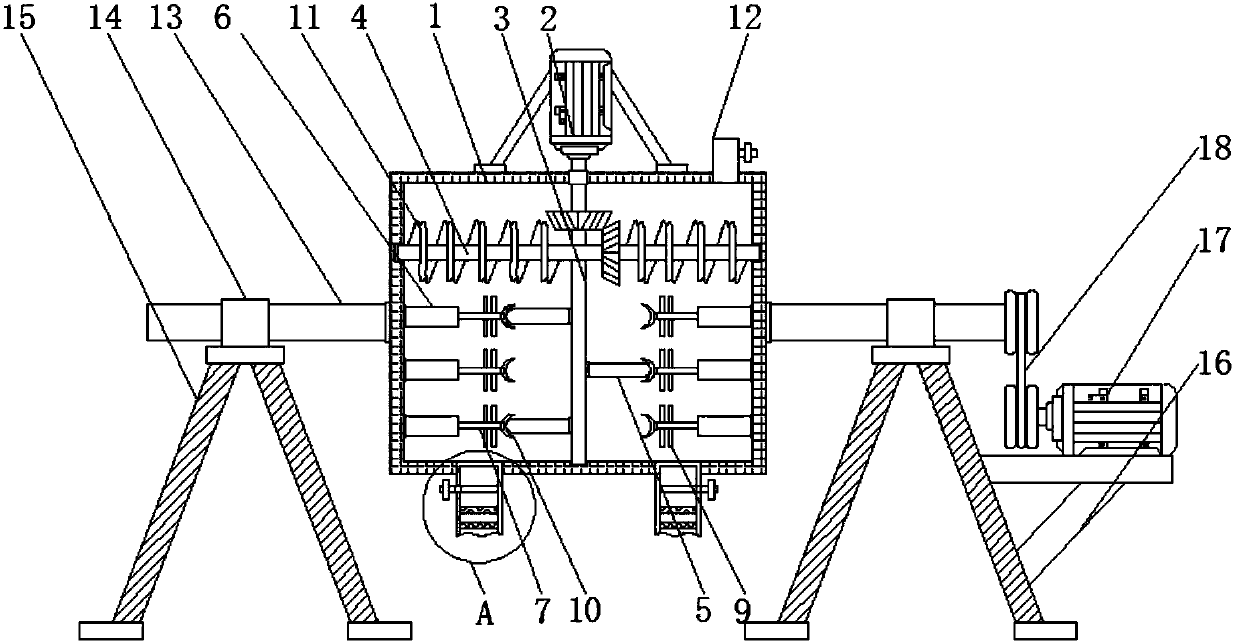

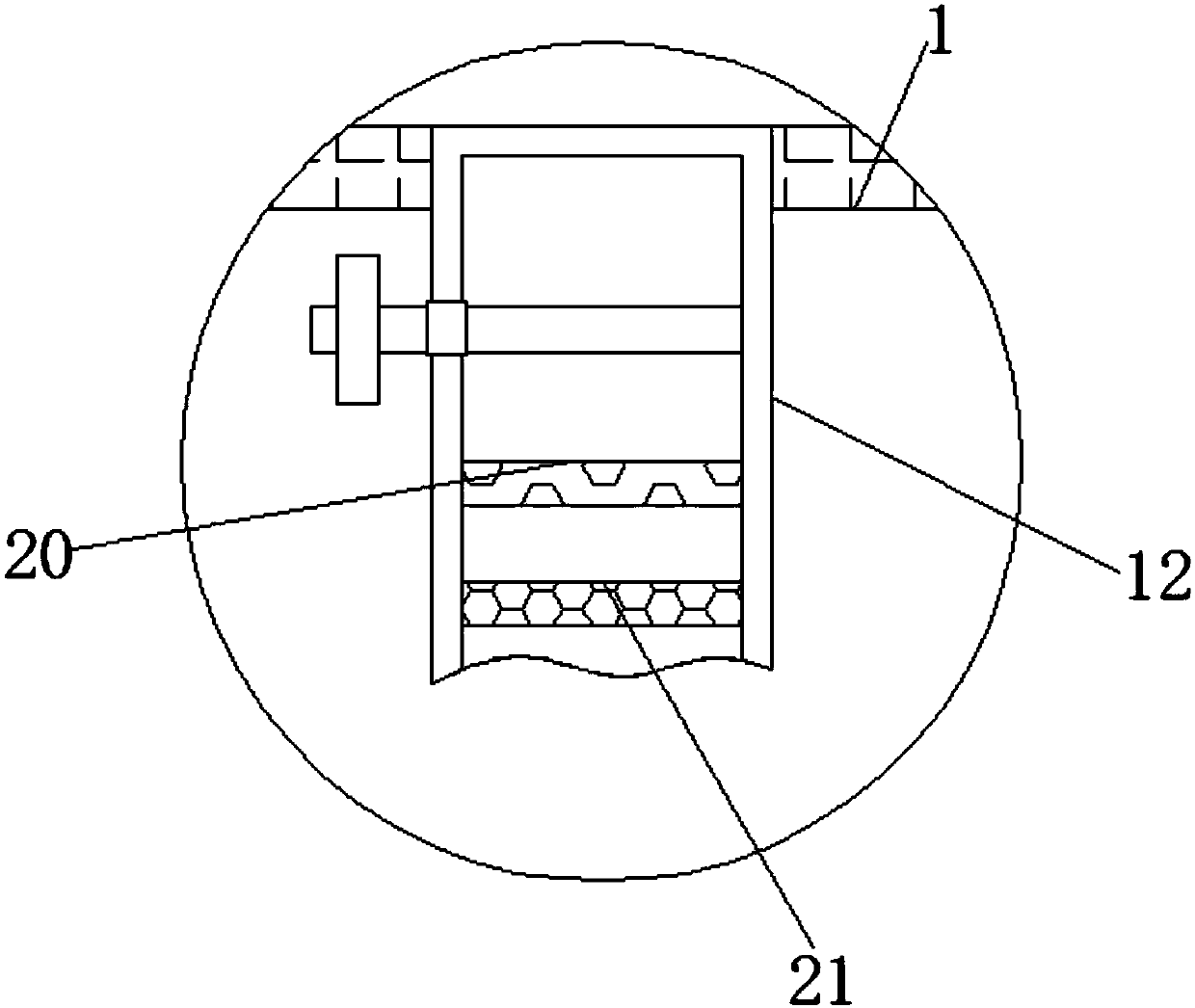

Mixing apparatus for production of lubricating oil

InactiveCN107890818AImprove stirring efficiencyImprove the mixing effectRotating receptacle mixersTransportation and packagingEngineeringRaw material

The invention discloses a mixing apparatus for production of lubricating oil. The mixing apparatus comprises a case, wherein a first motor is fixedly connected with the top of the case; one end of anoutput shaft of the first motor is fixedly connected with an agitator arm; the bottom end of the agitator arm penetrates the case and extends into the case; the top of the surface of the end, extending into the case, of the agitator arm is fixedly connected with a first bevel gear; one side of the first bevel gear is engaged with a second bevel gear; and a rotary rod penetrates the central part ofthe second bevel gear. The invention relates to the technical field of production of lubricating oil. According to the invention, the top of the case is fixedly connected with the first motor, so agitation efficiency is improved, production time is saved, and agitation effect is substantially improved; and since two sides of the case are fixedly connected with fixed rods, the case rotates duringimplementation of internal stirring, so lubricating oil does not adhere onto the inner wall of the case and raw materials are saved.

Owner:WUXI FEITIAN GREASE

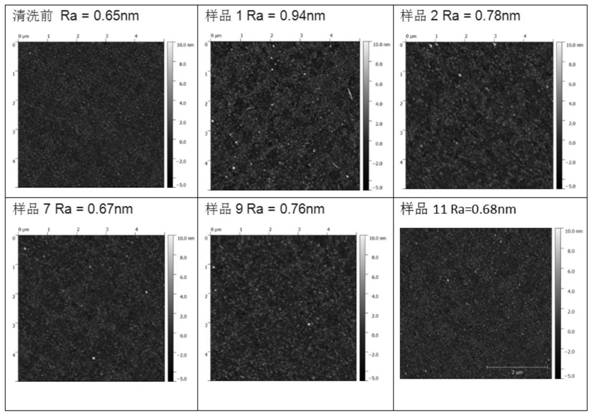

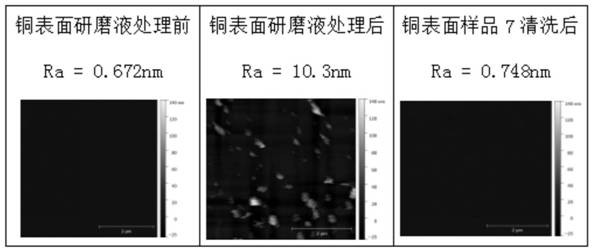

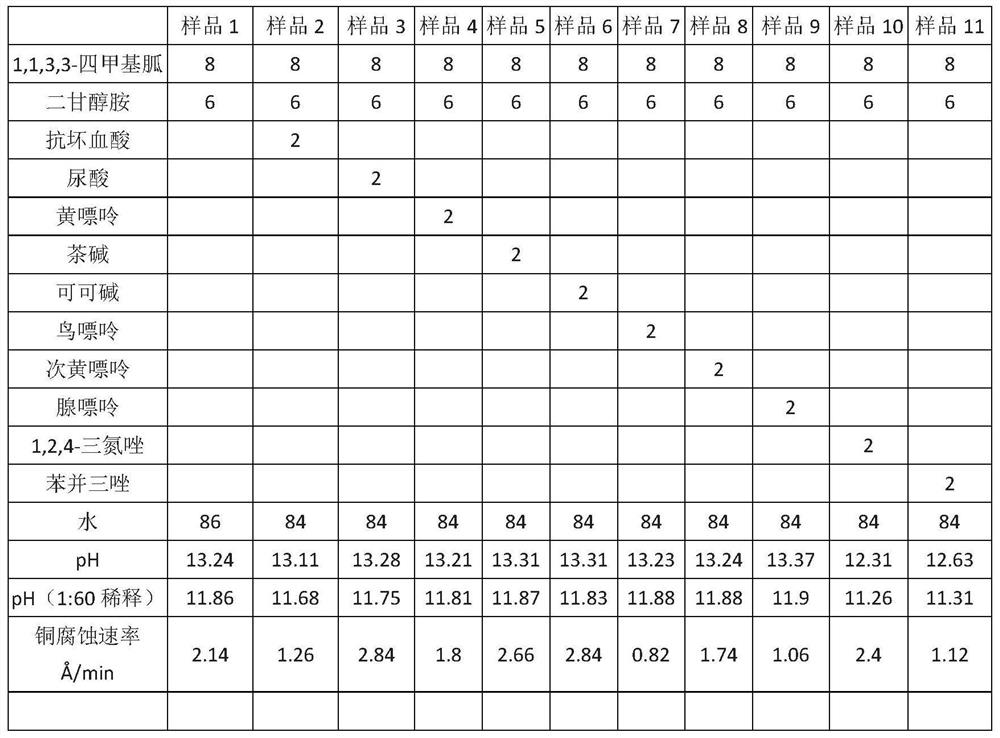

Quaternary ammonium base-free cleaning solution

ActiveCN113652316AGood environmental stabilityStrong removal abilityDetergent mixture composition preparationOrganic non-surface-active detergent compositionsEnvironmental chemistryAlkanolamine

The invention relates to a quaternary ammonium base-free cleaning solution. The cleaning solution is prepared from the following raw materials in percentage by mass: 1-20% of guanidine or guanidine derivatives, 1-20% of alkanolamine, 0.01-10% of a nitrogen-containing heterocyclic compound metal corrosion inhibitor and 60-99% of water. The cleaning solution disclosed by the invention does not contain quaternary ammonium base and easily-decomposed antioxidant metal inhibitors, has relatively high environmental stability, is capable of removing efficient copper surface organic residues and grinding particles , has relatively low copper corrosion rate and copper surface roughness, and does not generate adsorption on the copper surface.

Owner:ZHANGJIAGANG ANCHU TECH CO LTD

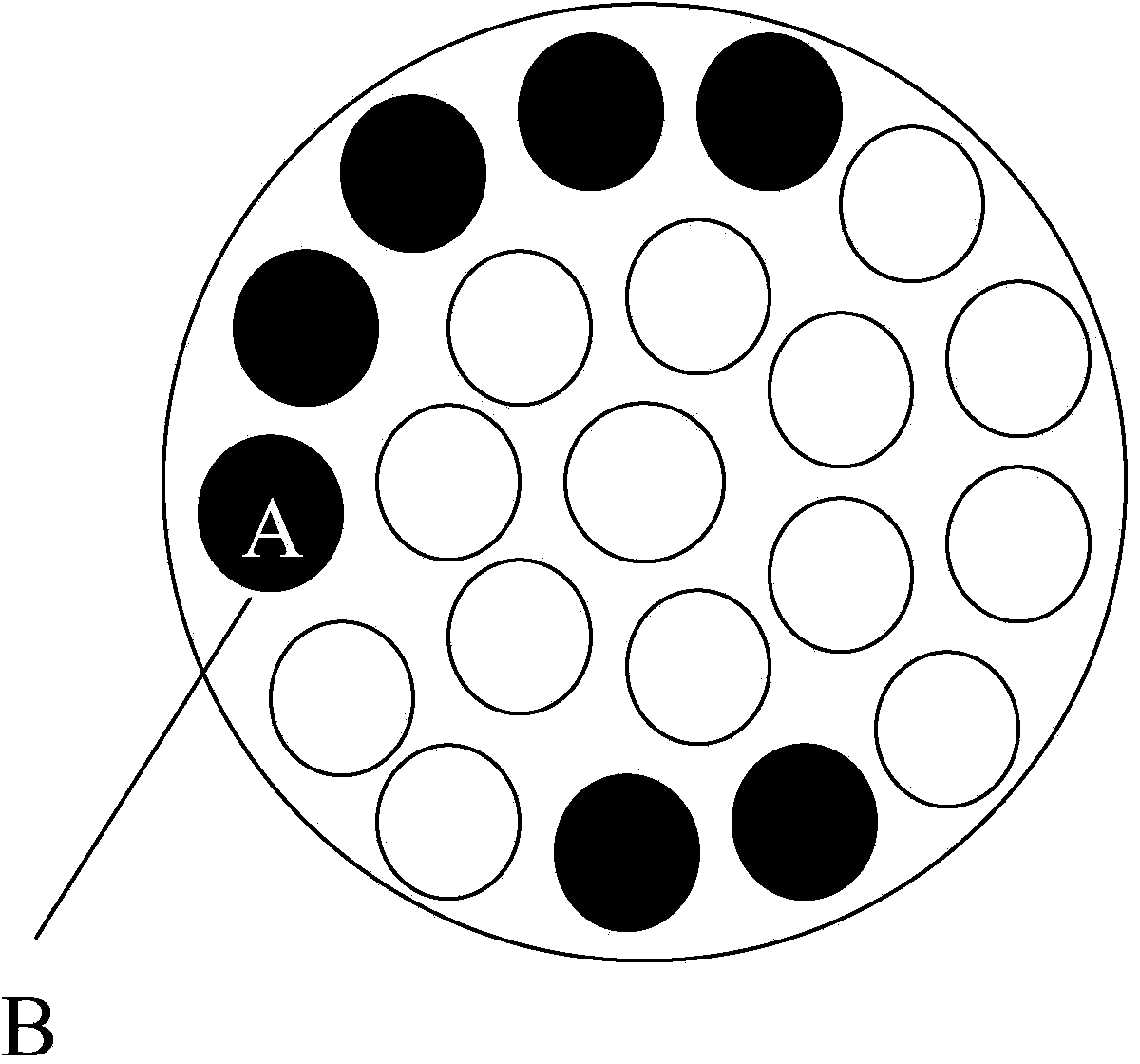

Superfine fiber filament and no-dyed chamois leather fabric

ActiveCN103966696AWill not adsorbNo fadingWeft knittingConjugated synthetic polymer artificial filamentsChamois leatherSingle fiber

The invention relates to a superfine fiber filament. A single fiber 1F comprises 20-30 colored filament-shaped components A ( the fineness of a single filament is about 0.2 d tex) and components B which surround and fill the peripheries and gaps of the components A; the mass percentage content of the components A ranges from 75% to 95%; the mass percentage content of the components B ranges from 5% to 25%; the crystallinity of the components A ranges from 60% to 90%; the crystallinity of the components B ranges from 5% to 40%. The superfine fiber filament provided by the invention has the following benefits: dye is not required, so that dyeing wastewater is not generated and the environment is not subject to the dyeing pollution; the quality of the chamois leather fabric is greatly improved.

Owner:杭州汇维仕永盛染整有限公司

Water bladder irrigation drainage tube

ActiveCN105148380BWith automatic flushing functionReduce the probability of cloggingBalloon catheterEnemata/irrigatorsNoseLarynx

The invention discloses a water-bag type nose-bile flushing drainage tube. The drainage tube comprises a main tube, a pipeline I and a balloon film, the pipeline I is located inside the main tube and provided with a closed end, and the outer wall of the main tube is sleeved with the balloon film. The cross section of the balloon film is in a plum blossom shape, a pipeline II communicated with the balloon film is further arranged inside the main tube, multiple lateral holes I and multiple lateral holes II are formed in the main tube and located in the pipe section part, above the balloon film, of the main tube, and the lateral holes II and the pipeline I are communicated. Automatic flushing is achieved, the oval lateral holes are adopted for reducing the probability of blockage, the flowing direction of flushing fluid in the bile duct is uniform with the discharging direction of bile, and it can be avoided that the flushing fluid and the bile reversely flow. The balloon film capable of being expanded and filled is arranged, in this way, the fixing force of the drainage tube is increased, an anti-slipping effect is achieved, and damage to the bile duct, intestinal canal and pharynx and larynx mucosae will not be caused in the process of taking out the drainage tube.

Owner:DALIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com