Method for conglomerating particulate matters in oil

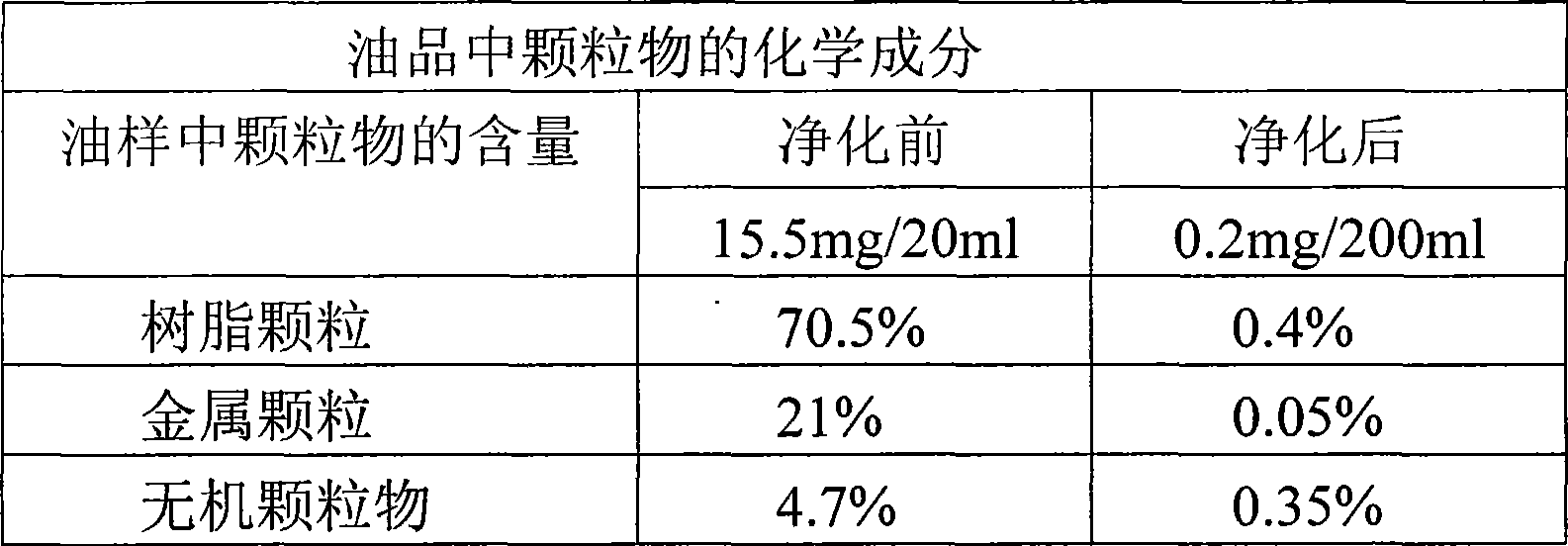

A particle and oil technology, which is applied in the field of particle coalescence in oil, can solve the problems of filter blockage, particle difficulty, and the inability to filter small particles less than 10 microns and ultra-fine particles, so as to improve quality and restore the surface tension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

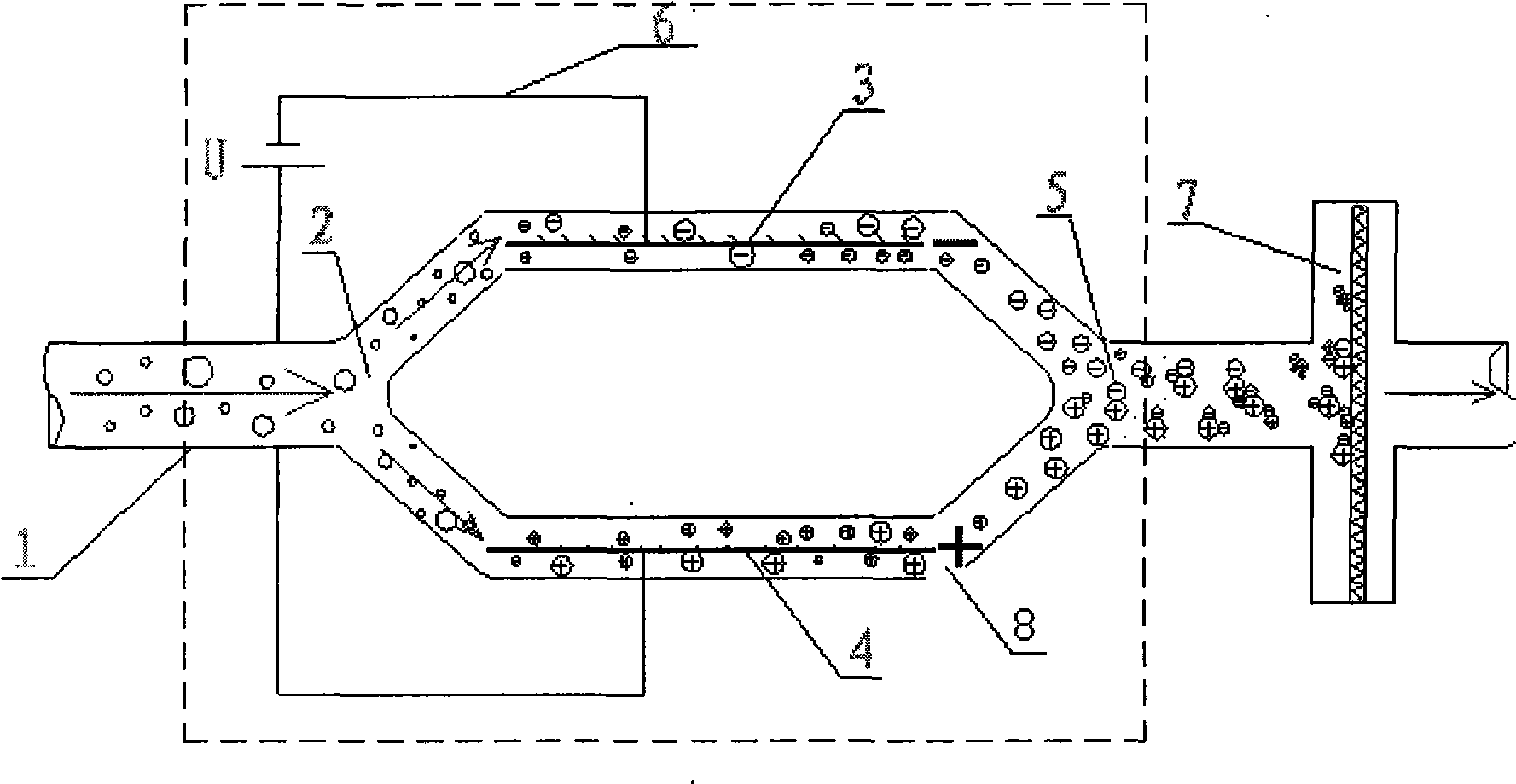

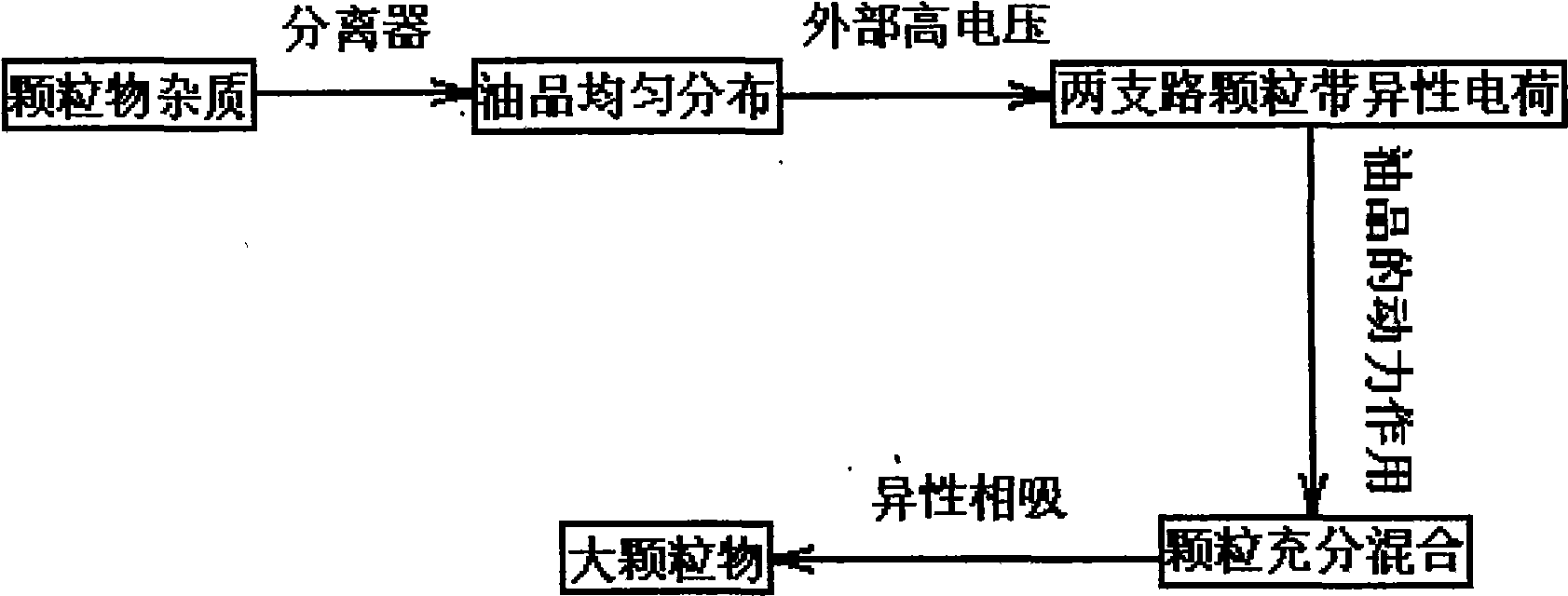

[0034] Depend on figure 1 The working schematic diagram and the agglomeration method of particulate matter in the oil product of the present invention figure 2 As can be seen from the schematic diagram of the principle of the coalescence method of the particulate matter in the oil product of the present invention, the coalescence method of the particulate matter in the oil product of the present invention comprises:

[0035] a. Lead the oil into the oil inlet pipe 1;

[0036] b. The oil product is divided into two branches through the branch circuit device 2;

[0037] c. The oil products of the two branches respectively flow into two insulating lumens 8, and the negative plate 3 and the positive plate 4 are respectively fixed in the two insulating lumens 8;

[0038] d. The external strong voltage 6 acts on the negative plate 3 and the positive plate 4, and through the negative plate 3 and the positive plate 4, the particles in the two branch oil products are respectively ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com