Superfine fiber filament and no-dyed chamois leather fabric

A superfine fiber and filament technology, applied in the direction of conjugated synthetic polymer rayon filament, knitting, weft knitting, etc., can solve problems such as environmental pollution, increase COD emissions, etc., achieve quality improvement, improve clothing standards and life quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Production of superfine fiber filaments:

[0021] Component A is polyethylene terephthalate, with a mass percentage of 80% and a crystallinity of 85%; the colored masterbatch is component A of carbon powder with an amount of 15% (hereinafter the same);

[0022] Component B is a polymer of terephthalic acid and ethylene glycol, with a mass percentage of 20% and a crystallinity of 30%.

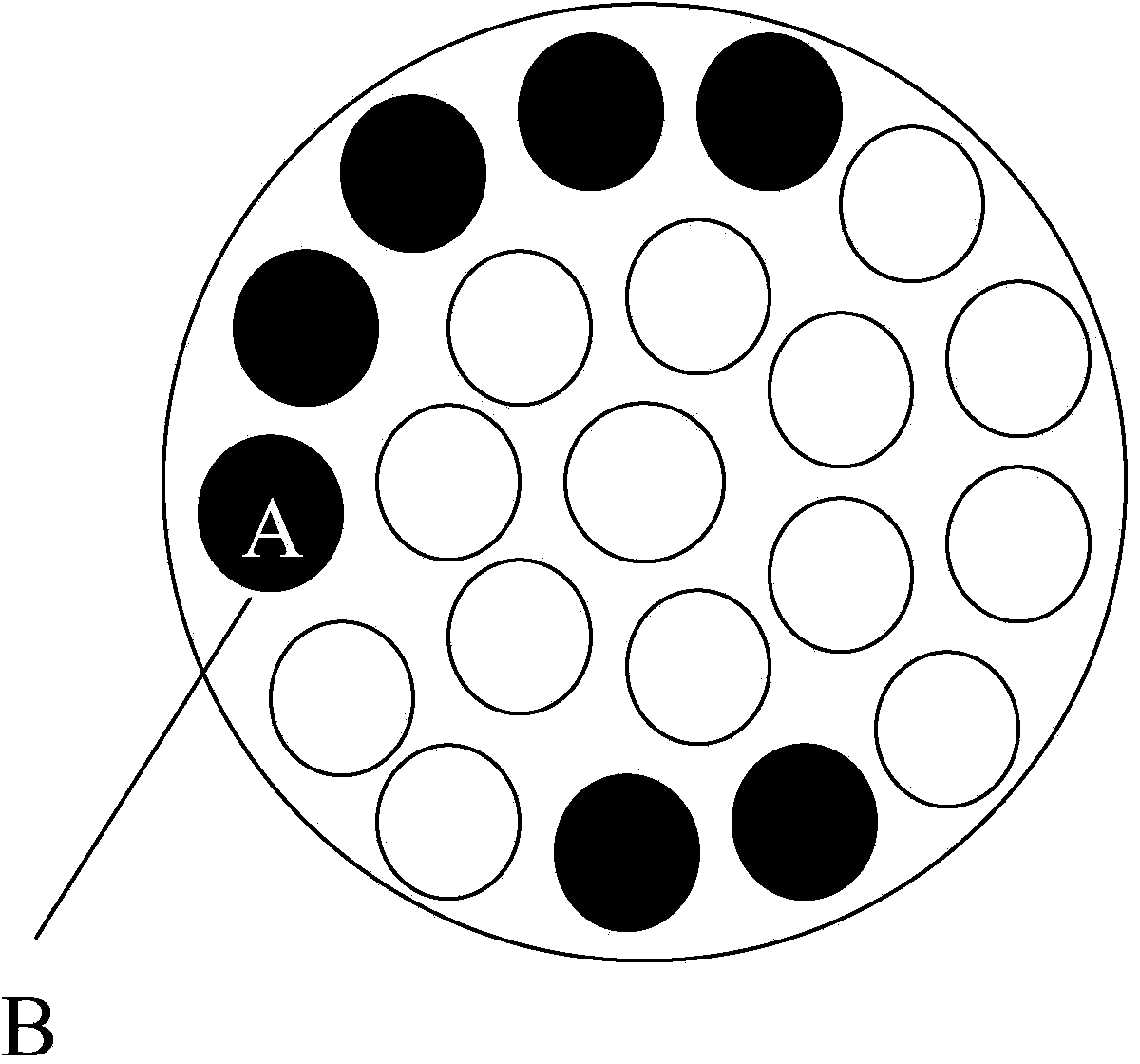

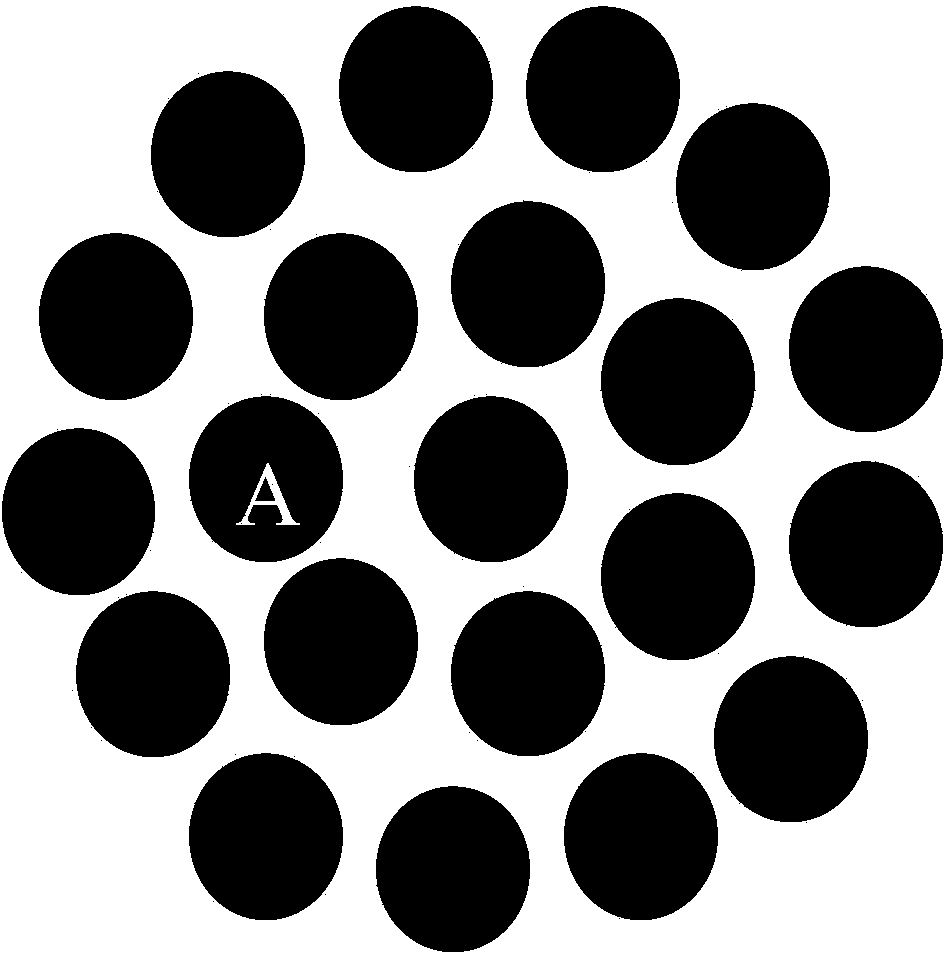

[0023] The fiber comprises a central colored polymer A and polymer B surrounding polymer A. Such as figure 1 As shown, there are 21 colored A (fineness 0.2dtex) in the fiber surrounded by B, which shows that the number of colored islands in the fiber of the present invention is 21. In actual production, the number of islands according to the fiber of the present invention can be in Between 20 and 30, the shape can be round, five-pointed star ★, trefoil Y and other shapes.

[0024] (2) Gray cloth production: make double-sided knitted circular machine cloth with the superfine fiber f...

Embodiment 2

[0028] Component A and component B raw materials are as follows:

[0029] Component A is polyethylene terephthalate, with a mass percentage of 70% and a crystallinity of 90%; the colored masterbatch is component A of carbon powder with an amount of 10%;

[0030] Component B is a polymer of terephthalic acid and ethylene glycol, with a mass percentage of 30% and a crystallinity of 30%.

[0031] The preparation method is the same as in Example 1. The main indicators of the non-dyed suede fabric finished product are as follows:

[0032] Rubbing color fastness: dry grinding 3.5, wet grinding 3.5; washing color fastness: water immersion 3.5, staining 3.5; soaping color fastness: water 3.5, staining 3.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com