Quaternary ammonium base-free cleaning solution

A technology of cleaning liquid and quaternary ammonium base, which is applied in the preparation of detergent compositions, non-surface-active detergent compositions, and detergent mixture compositions, etc., can solve problems such as affecting the cleaning effect of copper surfaces and changing the color of cleaning products. , to achieve the effect of good environmental stability, efficient removal ability, and low corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

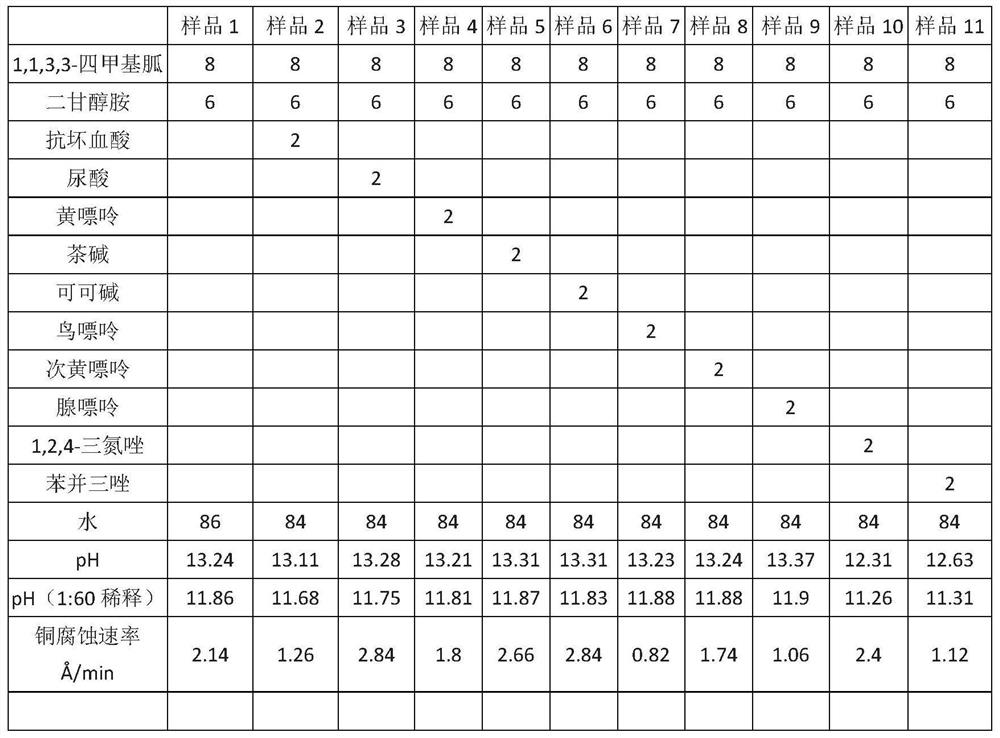

[0034] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

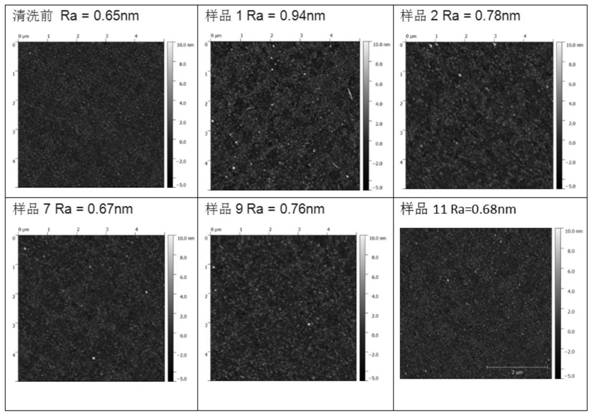

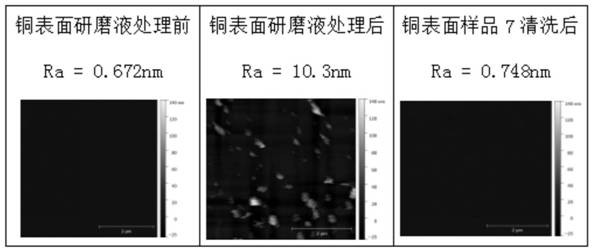

[0035] The problem to be solved by the present invention is to provide a quaternary ammonium base-free solution that can effectively clean the residues after chemical mechanical grinding on the copper surface. Furthermore, the cleaning solution can effectively clean the residues after chemical mechanical grinding on the copper surface and is highly efficient. The invention relates to a cleaning solution free of quaternary ammonium alkali, characterized in that the cleaning solution is made from the following raw materials in mass percentage: 1-20% in mass percentage of guanidine or derivatives of guanidine, alkanolamine The mass percent of the nitrogen-containing heterocyclic compound metal corrosion inhibitor is 0.01-10 percent, and the concentration of water is 60-99 percent by mass.

[0036] The beneficial effects of the present invention are that the cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com