Patents

Literature

131 results about "Zinc nanoparticles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanoparticle zinc oxide, ZnO, is a form of zinc oxide where the compound is formed into individual particles as small as 20 nanometers in diameter.

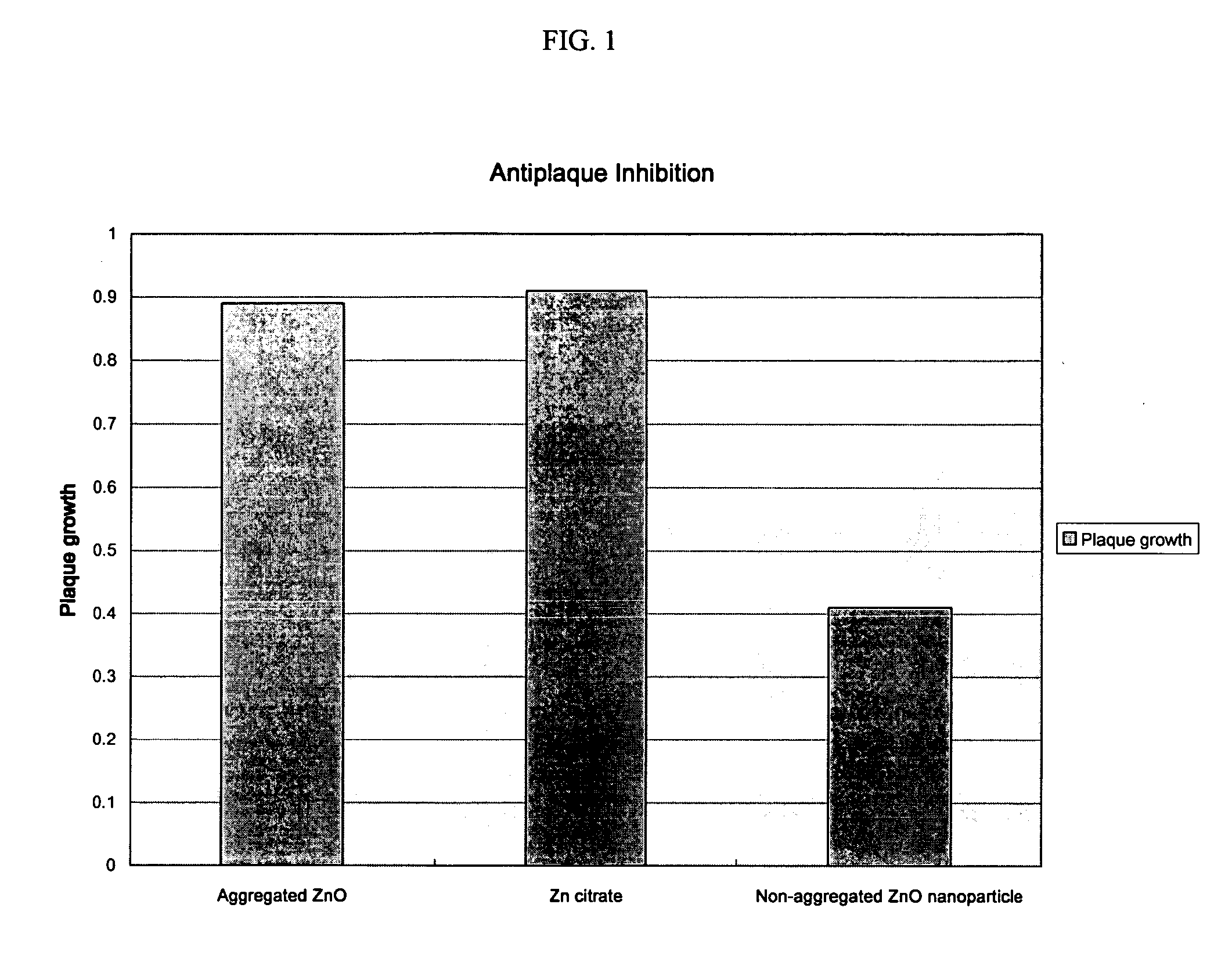

Oral composition containing non-aggregated zinc nanoparticles

An oral composition comprising a vehicle and a zinc ion source in the form of nanoparticles that are substantially non-aggregated and methods for use of such compositions are described. The composition provides antiplaque and anti malodor benefits to the user and the inclusion of nanoparticles permits a reduction in the amount of zinc ions present in the composition while maintaining efficacy.

Owner:COLGATE PALMOLIVE CO

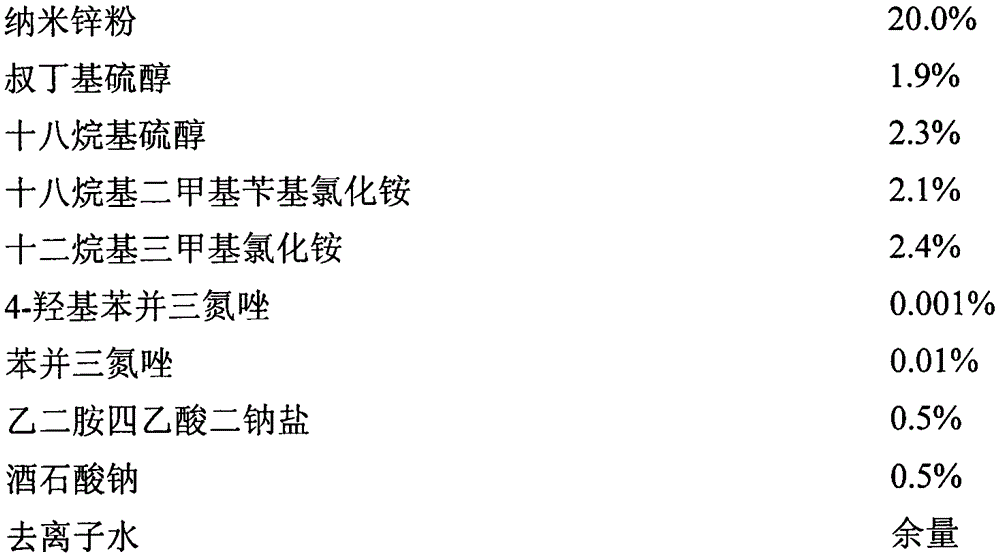

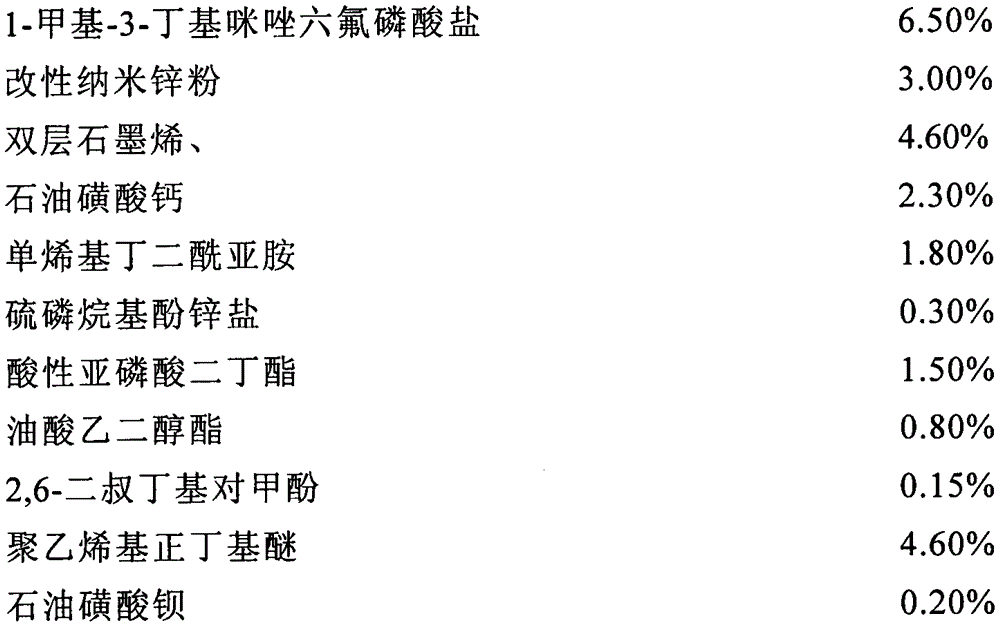

Preparation method of lubricating oil composition containing ionic liquid, modified nano-zinc powder and graphene

The invention discloses a preparation method of a lubricating oil composition containing ionic liquid, modified nano-zinc powder and graphene. According to the method, base oil, a cleaning agent, a dispersing agent, a preservative, an extreme pressure anti-wear agent, an oiliness agent, an antioxidant, a viscosity index improver, an anti-rust agent, a pour point depressant, an antifoaming agent, ionic liquid, modified nano-zinc powder and graphene are adopted for compounding to obtain the lubricating oil composition. The method has the advantages of simple and easy production process, low equipment investment, low energy consumption and no environmental pollution, and is conductive to popularization and application. The lubricating oil composition product containing the ionic liquid, modified nano-zinc powder and graphene can be widely applied in the industrial fields of mechanical industry, automobile industry, precision instruments, power industry, metallurgical industry, mold manufacturing and application industry, steel and iron industry, machine tool industry and the like, and has broad application prospects.

Owner:大庆招远圣通机械设备有限公司

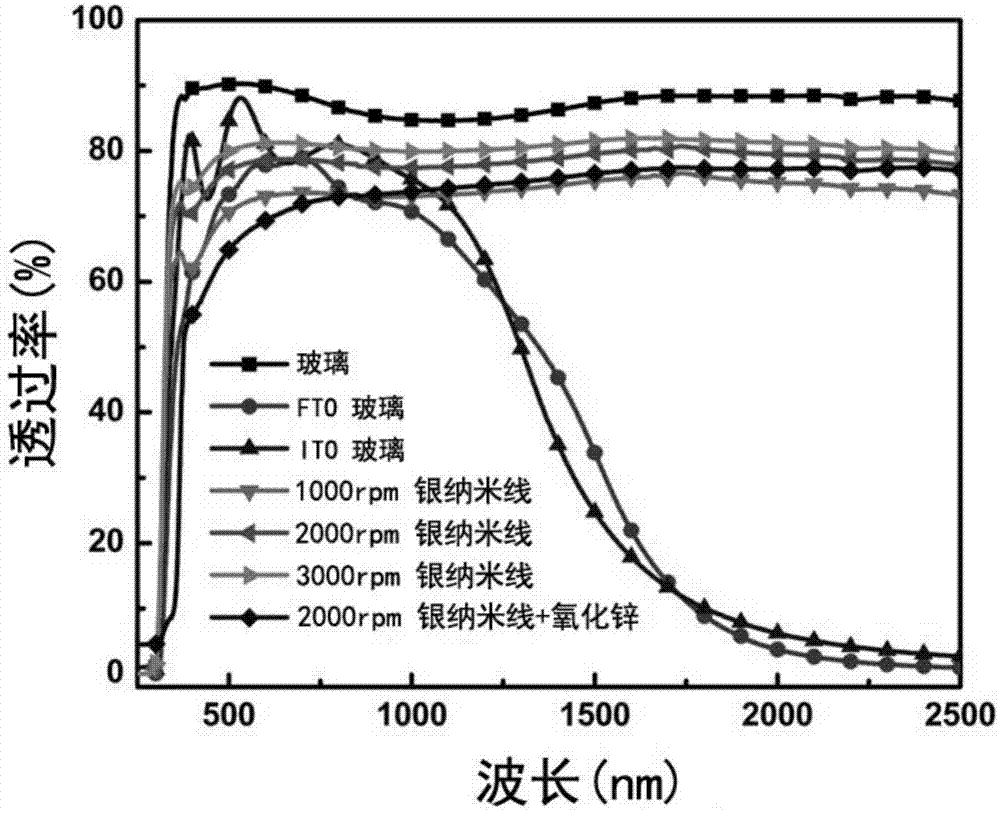

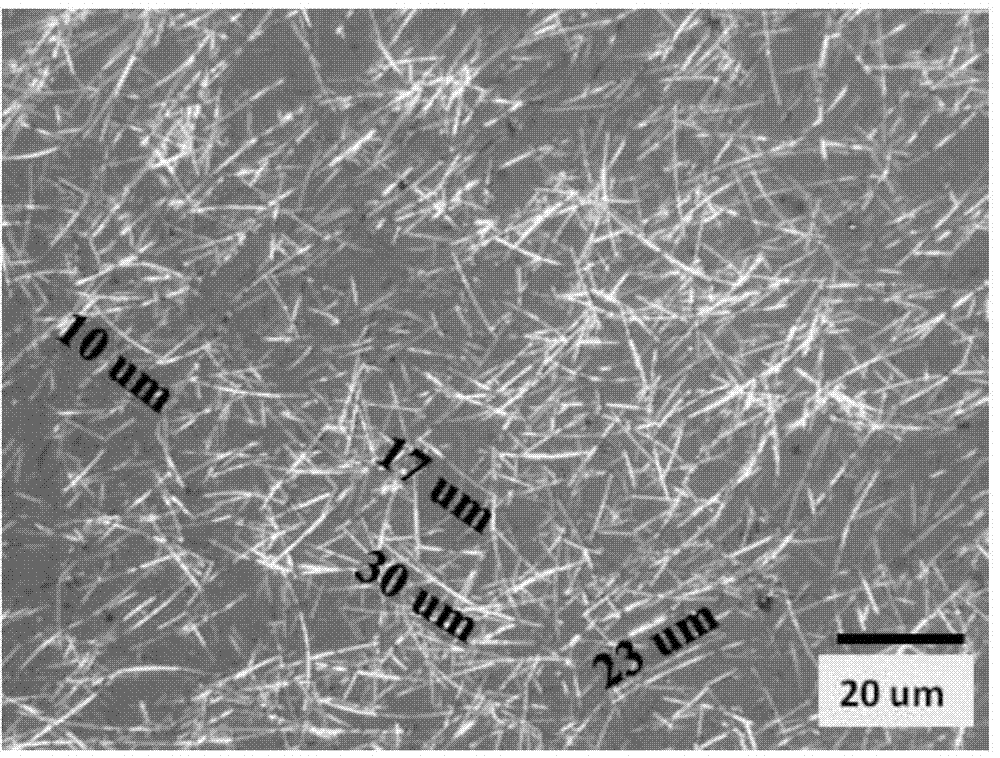

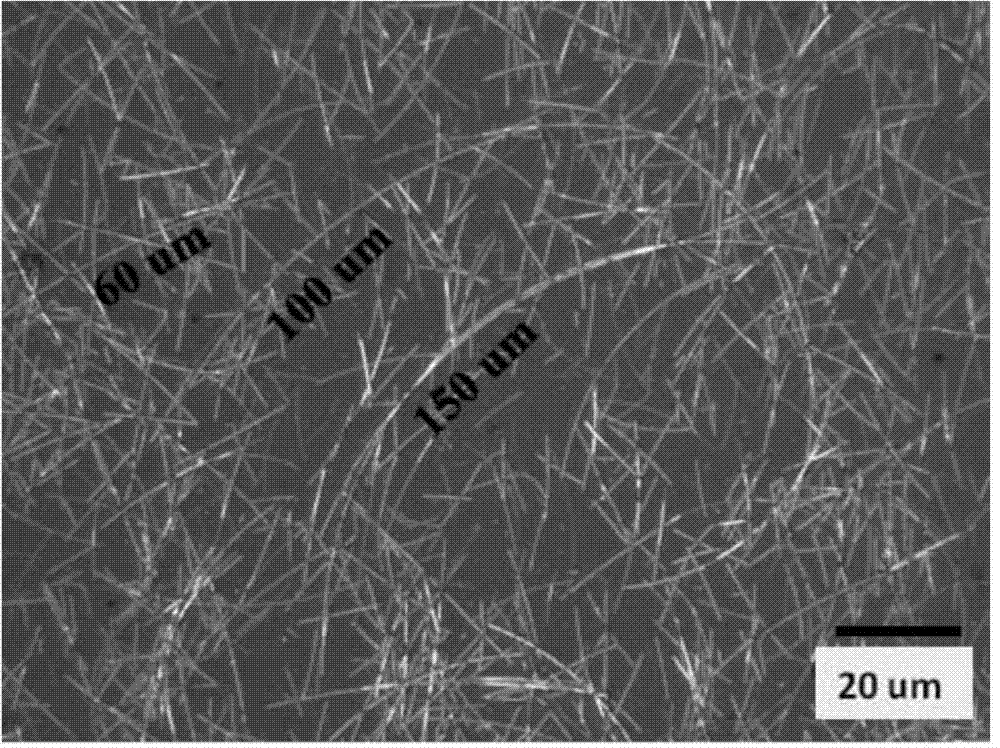

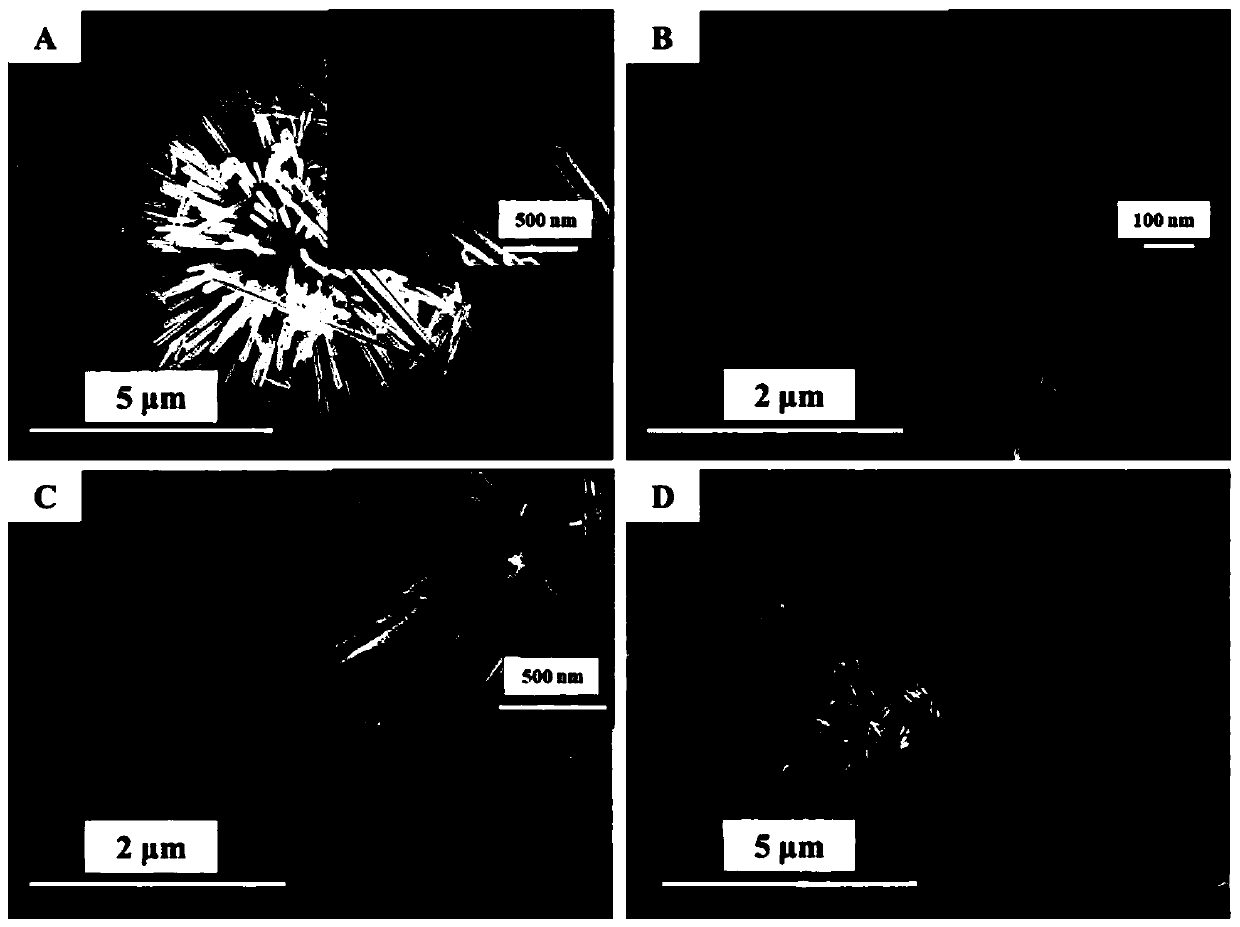

Preparation method of silver nanowire-zinc oxide composite transparent electrode

InactiveCN103700446AAvoid clustersHigh viscosityCable/conductor manufactureOxide compositeZinc nanoparticles

The invention belongs to the field of application of a nano material, particularly relates to a preparation method of a silver nanowire-zinc oxide composite transparent electrode and aims to simplify process, reduce cost and obtain the silver nanowire-zinc oxide composite transparent electrode with excellent light transmission and electrical conductivity, high wear resistance and environmental stability. The invention adopts the following technical scheme: 1, an ultra long silver nanowire is prepared by an improved polyol reduction method; 2, the silver nanowire is processed by a post-processing process; 3, a silver nanowire transparent conductive film is prepared; 4, zinc oxide nano particles are filled. The preparation method has various advantages of simple process, high repeatability, easiness for operation and control and the like.

Owner:XI AN JIAOTONG UNIV

Polylactic acid/modified graphene oxide antibacterial plastic and preparation method

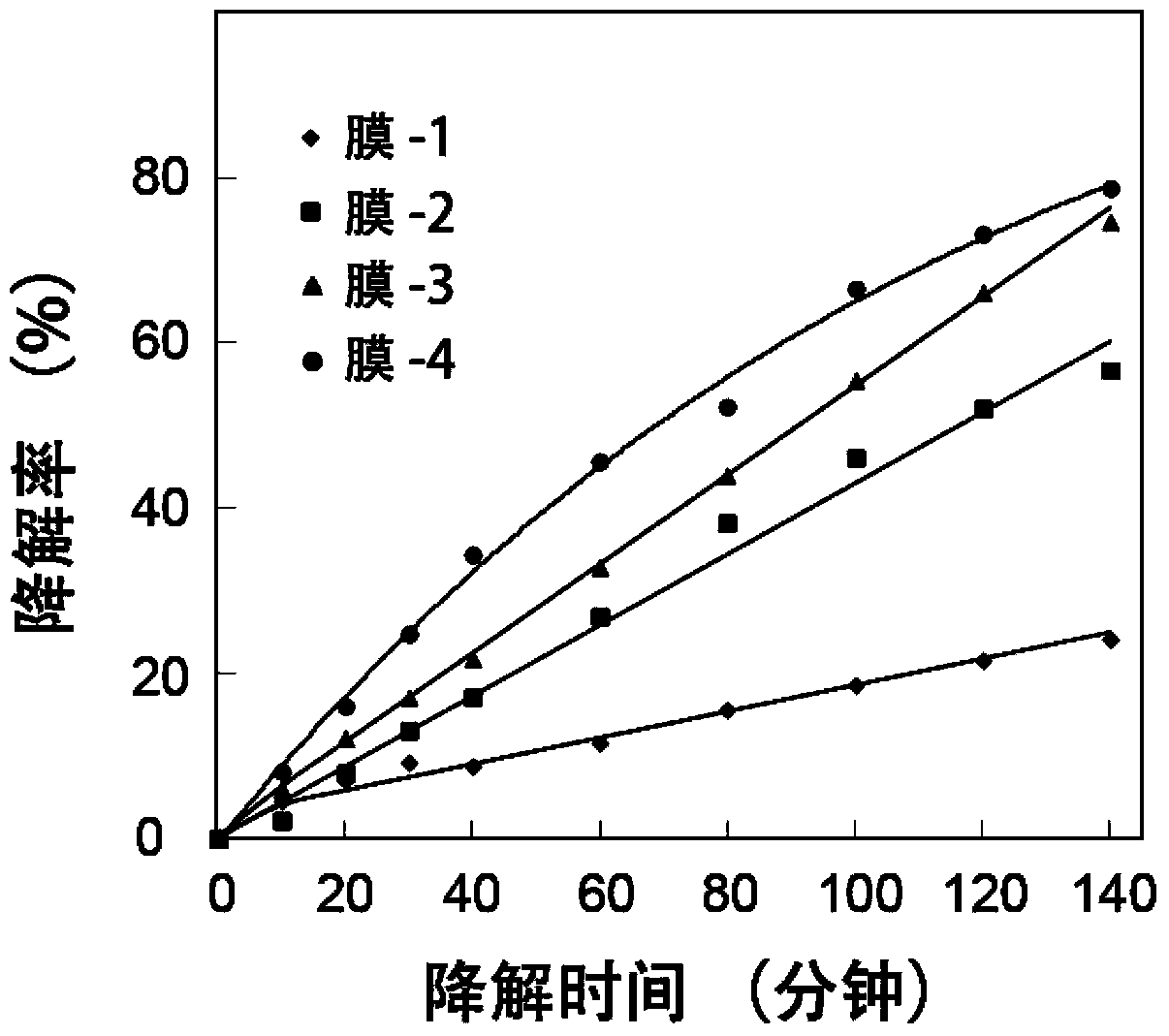

The invention discloses polylactic acid / modified graphene oxide antibacterial plastic and a preparation method. The antibacterial plastic is composed of polylactic acid matrix resin and a composite antibacterial agent. The composite antibacterial agent is graphene oxide sheets with the surfaces loaded with zinc oxide nano-particles. The preparation method of the antibacterial plastic comprises the following steps that a trichloromethane solution of polylactic acid and a trichloromethane dispersing solution of the composite antibacterial agent are blended according to a certain ratio with a solution blending method, a clean glass plate is coated with the mixed solution through an automatic coating machine, and the solution is naturally volatilized at a room temperature. The polylactic acid / modified graphene oxide antibacterial plastic is obvious in antibacterial effect, wide in antibacterial range, biodegradable, safe, reliable, free from peculiar smell, and low in degree of harm and pollution to the human body and the environment.

Owner:NANJING UNIV OF SCI & TECH

Cavity corrosion proof zinc-rich paint and preparing method thereof

InactiveCN101100569AAnti-corrosive paintsPolyurea/polyurethane coatingsCarbon nanotubeSODIUM SILICATE SOLN

A zinc-enriched coating against cavity corrosion and its production are disclosed. The coating consists of carbon nanometer tube: 0.3-4 wt%, nanometer zinc powder 3-8 wt%, and organic resin additive 12-30 wt%. The process is carried out by reflux decontaminating for carbon nanometer tube by mixed acid, soaking in diluted lithium aqueous glass, centrifugal treating, collecting or mixing carbon nanometer tube with silicon acid, ball grinding, adding carbon nanometer tube into lithium silicate-sodium silicate solution, adding into organic resin, heavy potassium chromate solution, FC80, methyl-methoxide, multifunctional accessories and de-foaming agent while agitating to obtain coating component A, mixing ordinary zinc powder with nanometer zinc powder proportionally to obtain coating component B, and mixing component A with component B proportionally to obtain final product.

Owner:HUAZHONG NORMAL UNIV

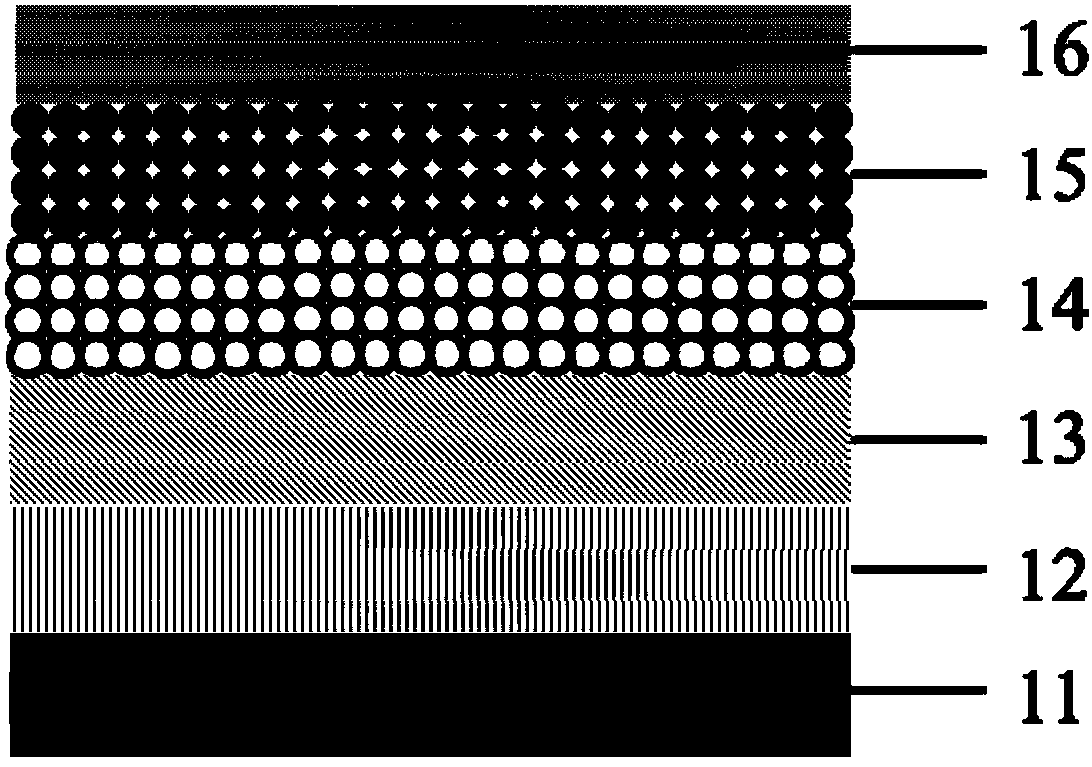

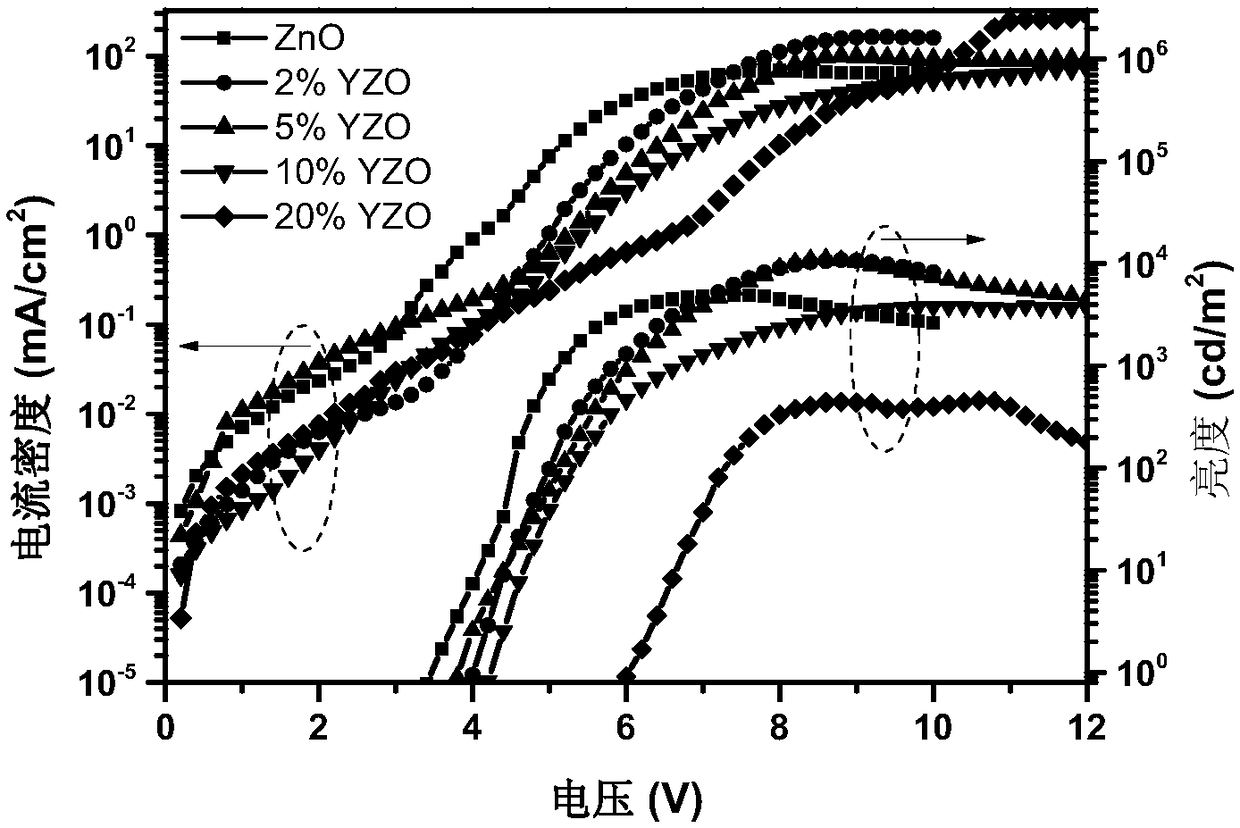

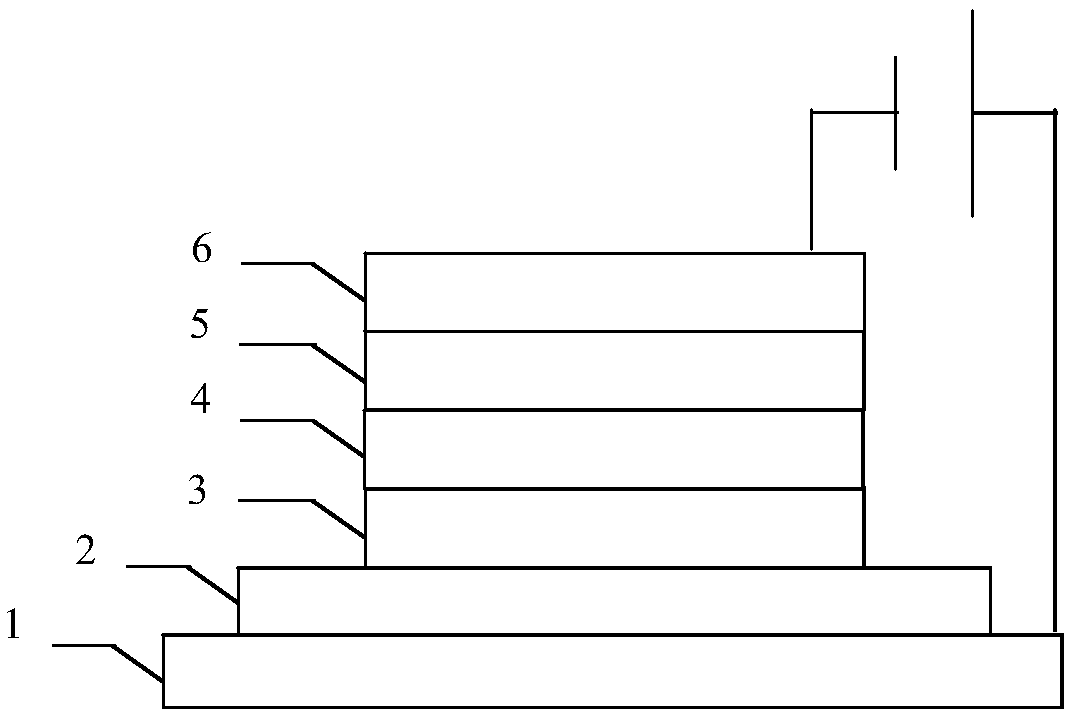

Quantum dot light emitting diode based on yttrium-doped zinc oxide electron transport layer and preparation method thereof

InactiveCN108183173ASimple processEasy to use in productionSolid-state devicesSemiconductor/solid-state device manufacturingElectron injectionHole transport layer

The invention discloses a quantum dot light emitting diode based on an yttrium-doped zinc oxide electron transport layer and a preparation method thereof. The light emitting diode is formed by lamination of a transparent conductive glass layer, a hole injection layer, a hole transport layer, a quantum dot light-emitting layer, an electron transport layer, and a metal electrode layer in sequence, the electron transport layer is an yttrium-doped zinc oxide nanometer particle layer, and the mole percentage of yttrium in yttrium-doped zinc oxide nanometer particles is 2%-20%. The quantum dot lightemitting diode is prepared through a solution processing method, and the process is simple and feasible; the process of the yttrium-doped zinc oxide particles is compatible with a conventional sol-gel method, the realization is easy, the doping amount is controllable, the adjusting range of the electron mobility of the obtained nanometer particles is wide, and the light emitting diode and the method are very applicable to quantum dot light-emitting devices so that electron injection is adjusted and carrier balance is achieved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

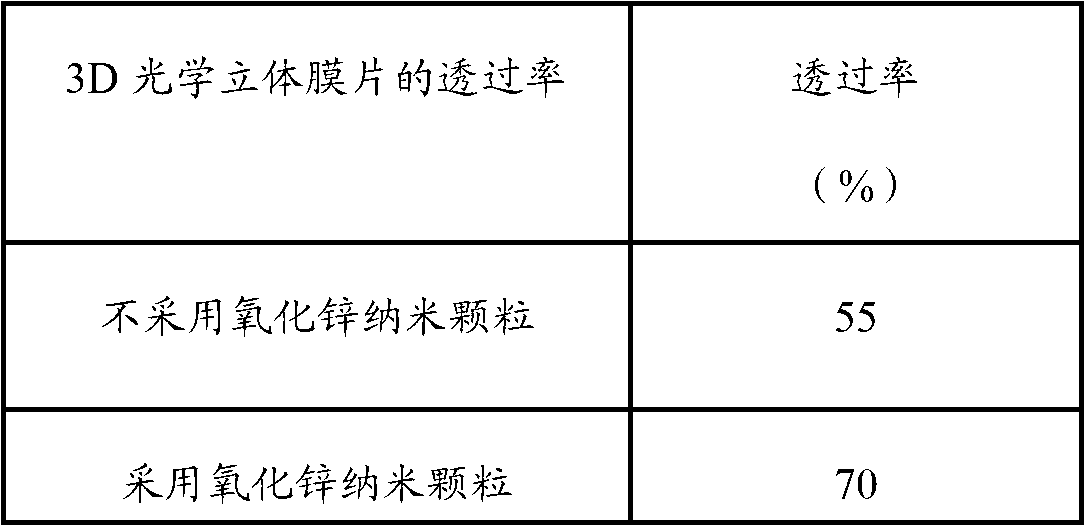

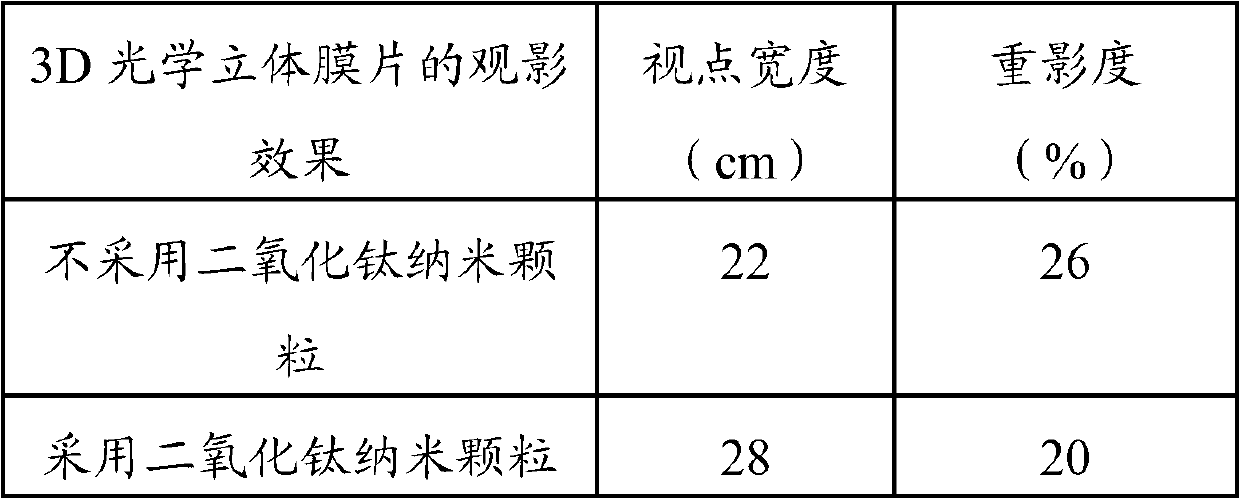

Novel 3D (three dimensional) optical stereoscopic membrane and preparation method thereof

ActiveCN102991049AImprove water and oxygen barrier performanceEasy to prepareSynthetic resin layered productsOptical elementsGratingViewpoints

The invention relates to a novel 3D (three dimensional) optical stereoscopic membrane and a preparation method thereof. The 3D optical stereoscopic membrane can be attached on a display screen of portable equipment, so that the naked 3D effect of light rays is realized through the optical transmission of the 3D optical stereoscopic membrane. The 3D optical stereoscopic membrane comprises a transparent membrane material layer and a slit grating layer on the transparent membrane material layer, wherein the transparent membrane material layer contains zinc oxide nanoparticles; and the slit grating layer is prepared from electronic ink. With the application of the zinc oxide nanoparticles, the transmittance of the transparent membrane material layer is increased, the viewpoint width of the 3D optical stereoscopic membrane is increased, and the double image degree is lowered. Therefore, the 3D display effect is enhanced.

Owner:JIANGYIN TONGLI OPTOELECTRONICS TECH

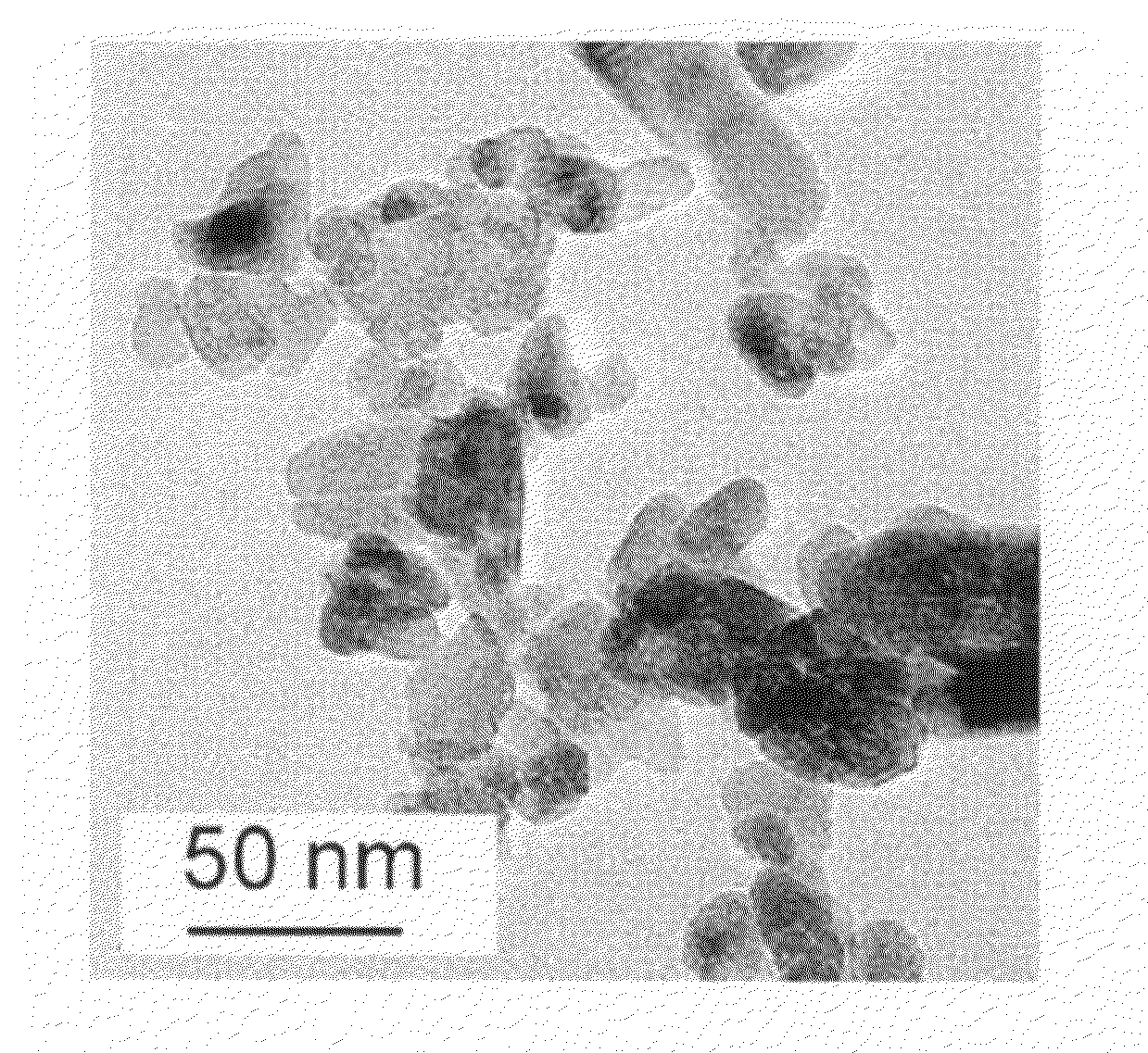

Zinc oxide polymer nanocomposites and methods of producing zinc oxide polymer nanocomposites

InactiveUS20070004840A1Material nanotechnologyOxygen/ozone/oxide/hydroxideOrganic solventZinc nanoparticles

A zinc oxide polymer nanocomposite composed of zinc oxide nanoparticles. The zinc oxide nanoparticles of the nanocomposite have an average particle size of about 1 nanometer to about 20 nanometers. Suitable polymers of the nanocomposites have less than about 500 ppm alkali metal. A process is provided for preparing the zinc oxide polymer nanocomposites comprising a) preparing a first combination comprising zinc oxide nanoparticles and a polymer; b) preparing a second combination comprising the first combination and an organic solvent; and c) precipitating the zinc oxide nanoparticles and the polymer out of the second combination. The zinc oxide nanoparticles of the first combination have an average particle size of between about 1 nanometer and about 20 nanometers.

Owner:KANEKA CORP +1

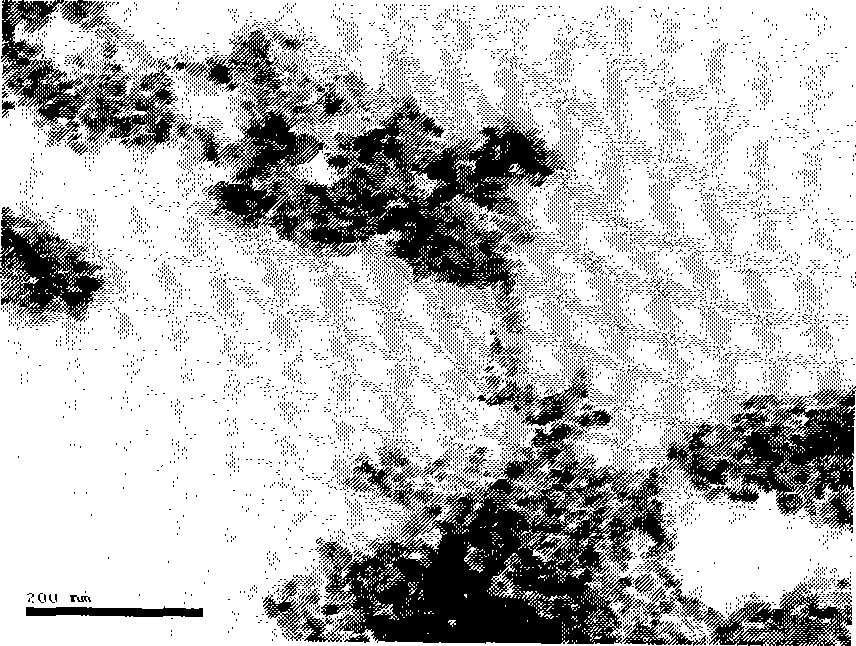

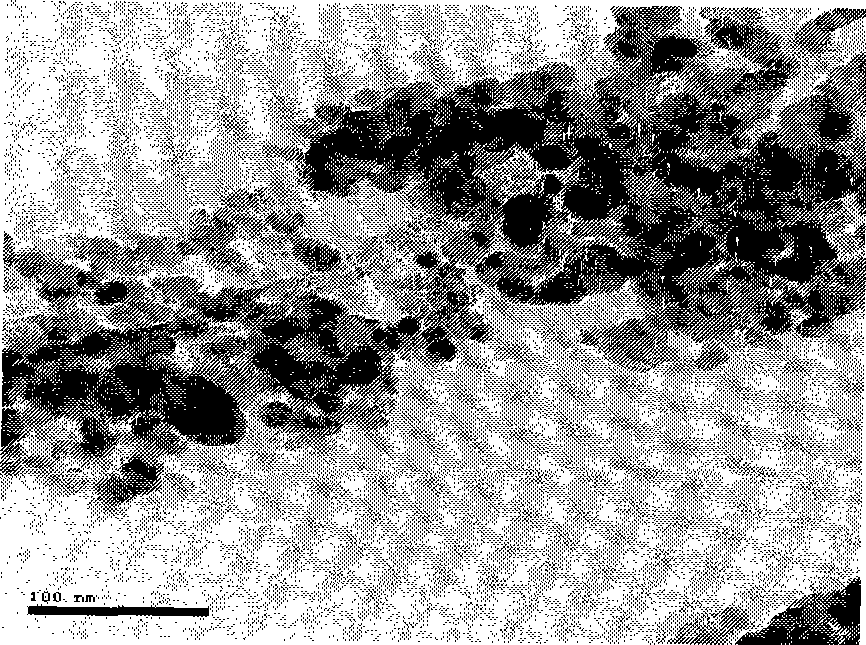

Method for coating carbon nano-tube with metal doped zinc oxide nano-particle

InactiveCN101372330ALarger than surfaceUniform particle size distributionGas detectorCarbon nanotube

The invention relates to a method for coating a carbon nanotube with metal-doped zinc oxide nano-particles, which mainly comprises the following steps: an alkaline solution and a mixed acid are adopted to treat the carbon nanotube; and then zinc acetate and metal acetate are taken as raw materials, absolute ethyl alcohol is taken as a solvent, oxalic acid is taken as a complexing agent, and co-precipitation method and subsequent heat treatment are adopted to prepare the carbon nanotube coated by the metal-doped zinc oxide nano-particles. The method utilizes a simple method to functionalize the carbon nanotube, so that the carbon nanotube is coated evenly and compactly by the zinc oxide nano-particles can be realized, and the nano-particles obtained have the advantages of even particle size distribution, small particle size, simple preparation process, low cost, etc. The major characteristic of the method is that: a surfactant is non-essential for modifying the carbon nanotube. The composite powder obtained not only can be taken as a powder raw material for preparing high-performance carbon nanotube / metal-based and carbon nanotube / ceramic-based composite materials, but also can be applied to the fields of optical devices, spinning electron devices, gas sensors, and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

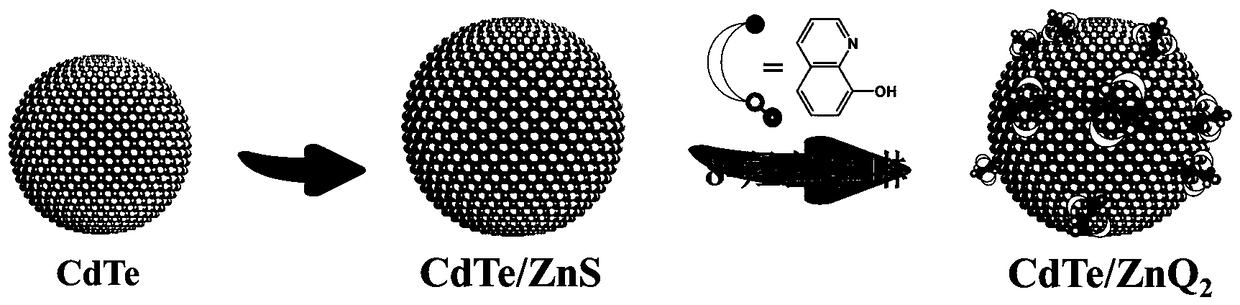

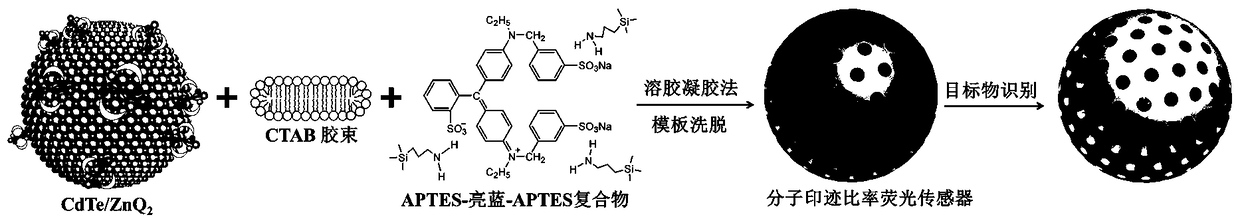

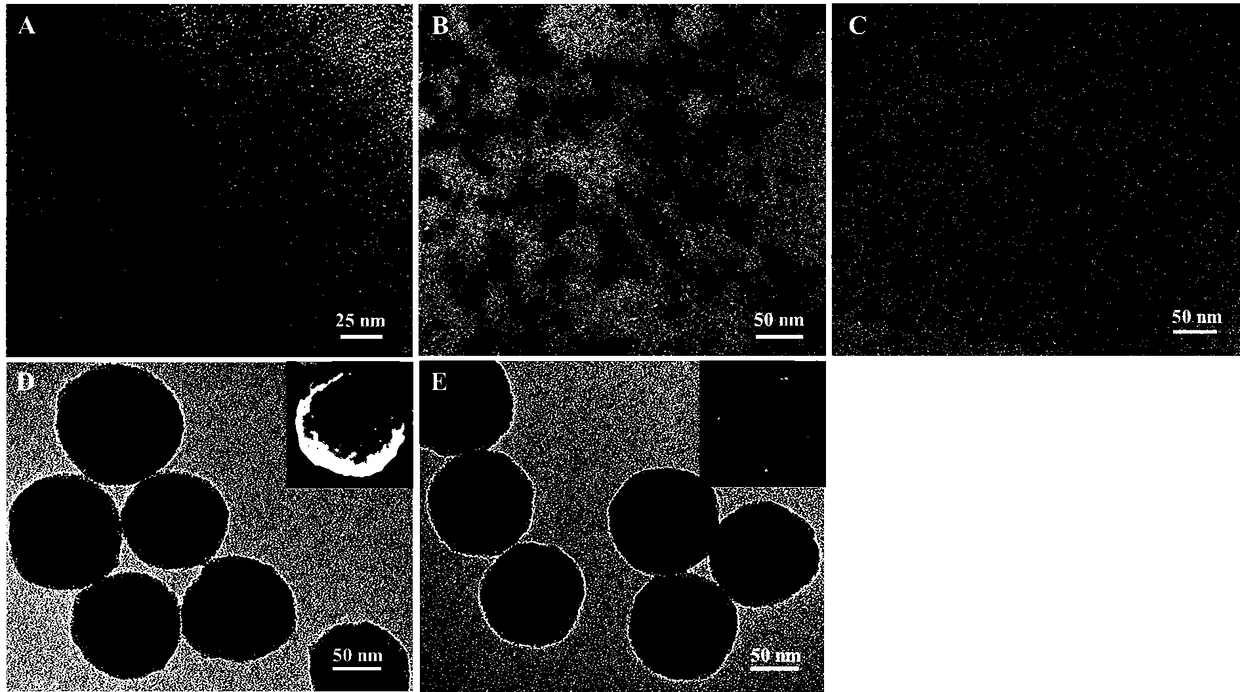

Molecular imprinting ratio fluorescent sensor, preparation and application thereof

ActiveCN109239045AExtensive testingFluorescence intensity unchangedFluorescence/phosphorescenceMicrosphereWavelength

The invention belongs to the fields of chemistry, materials and food safety, and relates to a molecular imprinting ratio fluorescent sensor, a preparation method and application thereof. The preparation method of the molecular imprinting ratio fluorescent sensor includes the steps that molecular imprinting is carried out through sol-gel polymerization, single-component dual-fluorescence emission cadmium telluride / 8-hydroxyquinoline zinc nanoparticles provide fluorescence signals, holes after eluting bright blue are recognition sites, a mesoporous structure is formed after hexadecyl trimethyl ammonium bromide is eluted, and bright blue imprinted microspheres with the mesoporous structure are obtained, that is, the molecular imprinting ratio fluorescent sensor based on the single-component dual-fluorescence emission nanoparticles. According to the molecular imprinting ratio fluorescent sensor, preparation and application thereof, the obtained sensor prepared by the preparation method candetect bright blue with high selectivity and sensitivity, and provides color evolution and self-correction functions; and in addition, by effectively adjusting the emission wavelength of the sensor,the molecular imprinting ratio fluorescent sensor can be more widely used in detection of various colored substances.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

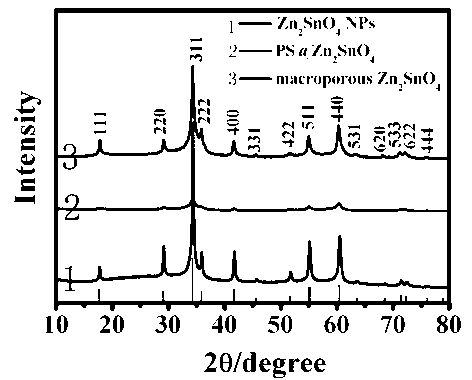

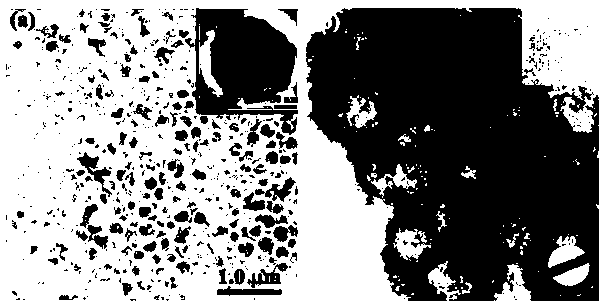

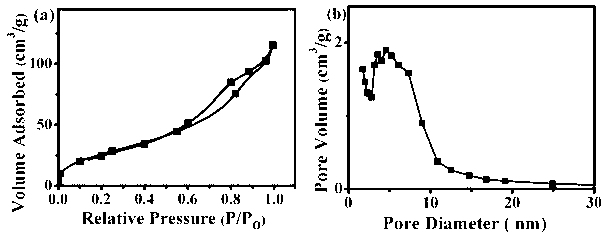

Preparation method of graded zinc stannate macroporous materials

InactiveCN103265065ASimple methodEasy and fastMaterial nanotechnologyTin compoundsMicrospherePolymethyl methacrylate

The invention relates to a preparation method of zinc stannate nano-materials, and discloses a preparation method of graded zinc stannate macroporous materials. The preparation method of the graded zinc stannate macroporous materials comprises: S1, mixing tin salts, zinc salts, and template molecules with a mixed solvent of an organic solvent and water to form a uniform mixed liquor, adjusting a pH value to be alkaline, performing a in-situ hydrothermal reaction, and then separating, washing and drying products after the reaction ends; S2, performing heating calcination or acid treatment for the products obtained in the S1 to remove the template molecules, thereby obtaining the graded zinc stannate macroporous materials composed of zinc stannate nano-particles, wherein the template molecules are polystyrene microspheres (PS), polymethyl methacrylate microspheres, carbon microspheres or silica microspheres. The preparation method provided by the invention is simple, convenient, rapid and good in reappearance; the synthesized graded zinc stannate macroporous materials can be widely applied in fields of catalysis, lithium ion batteries, solar cells and the like.

Owner:SUN YAT SEN UNIV

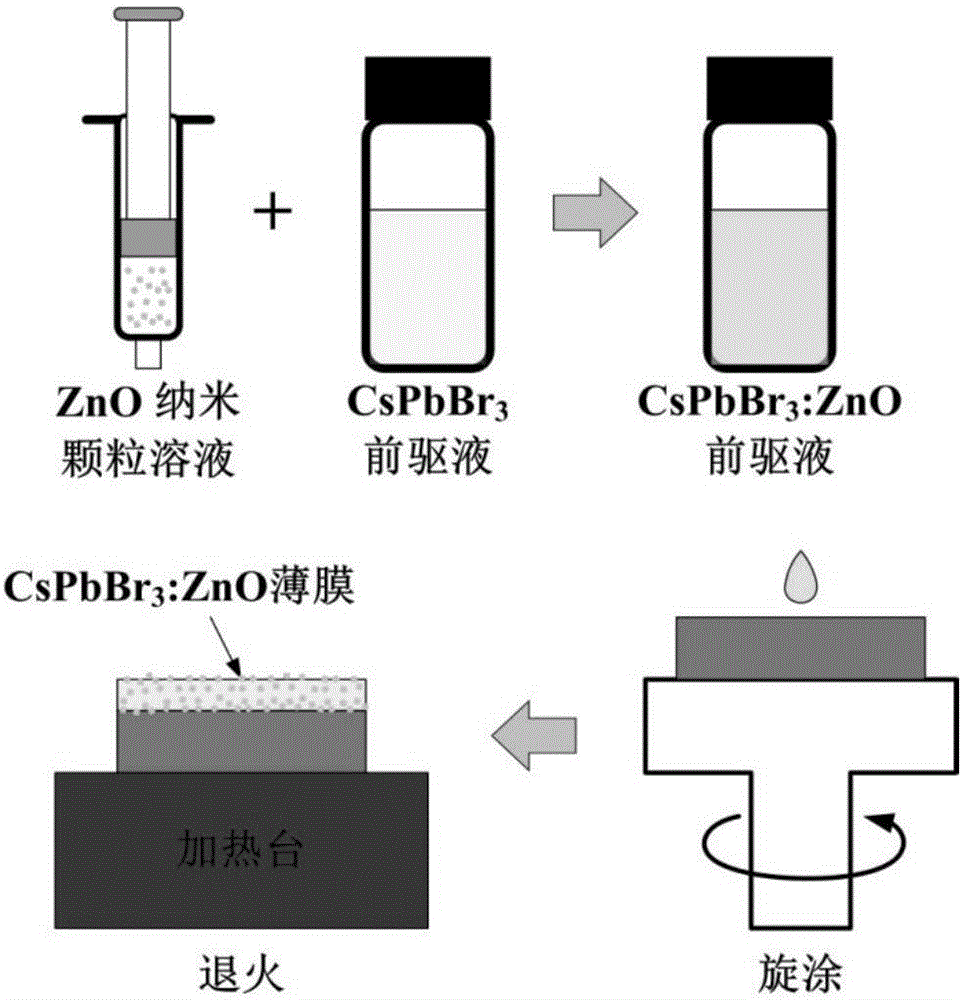

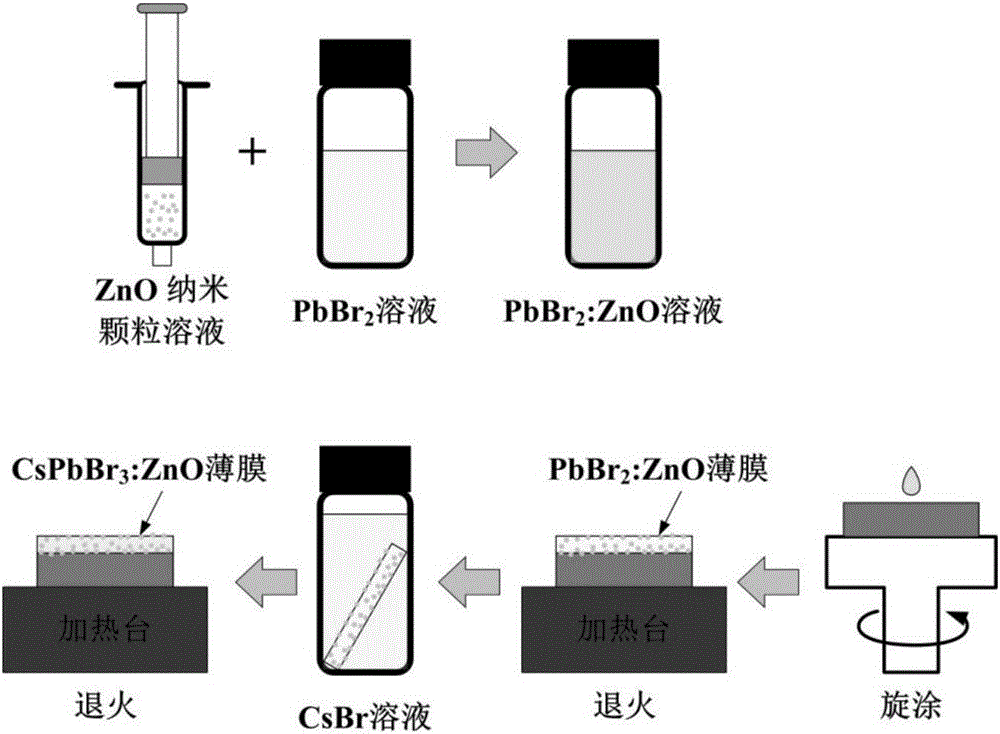

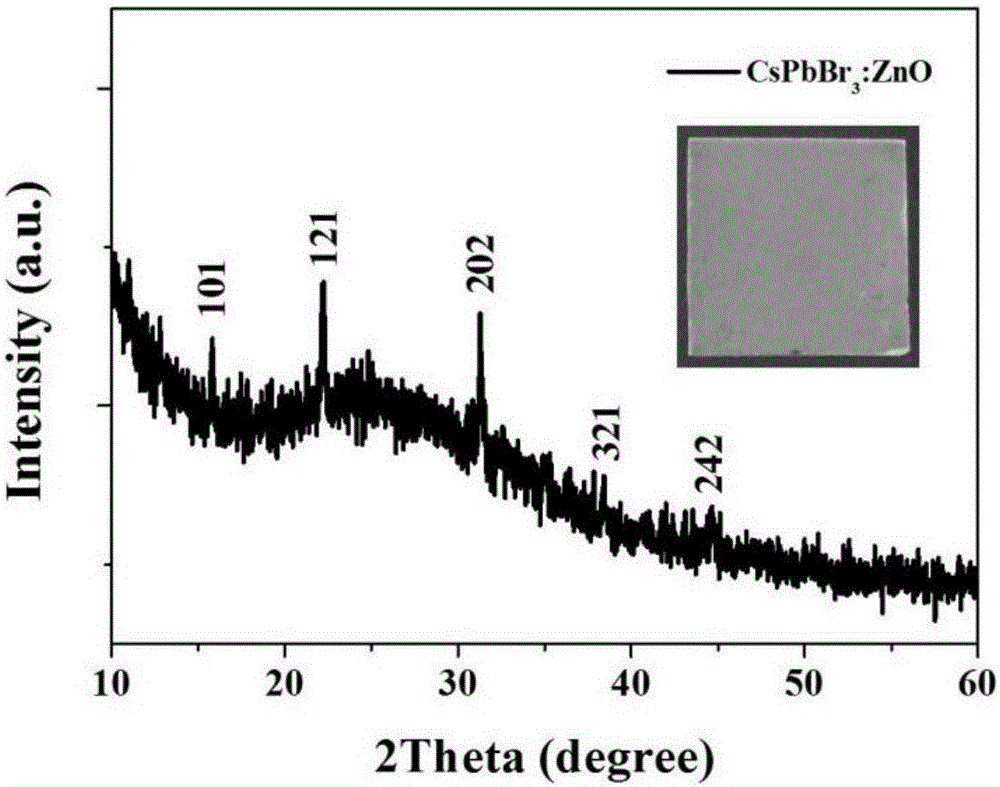

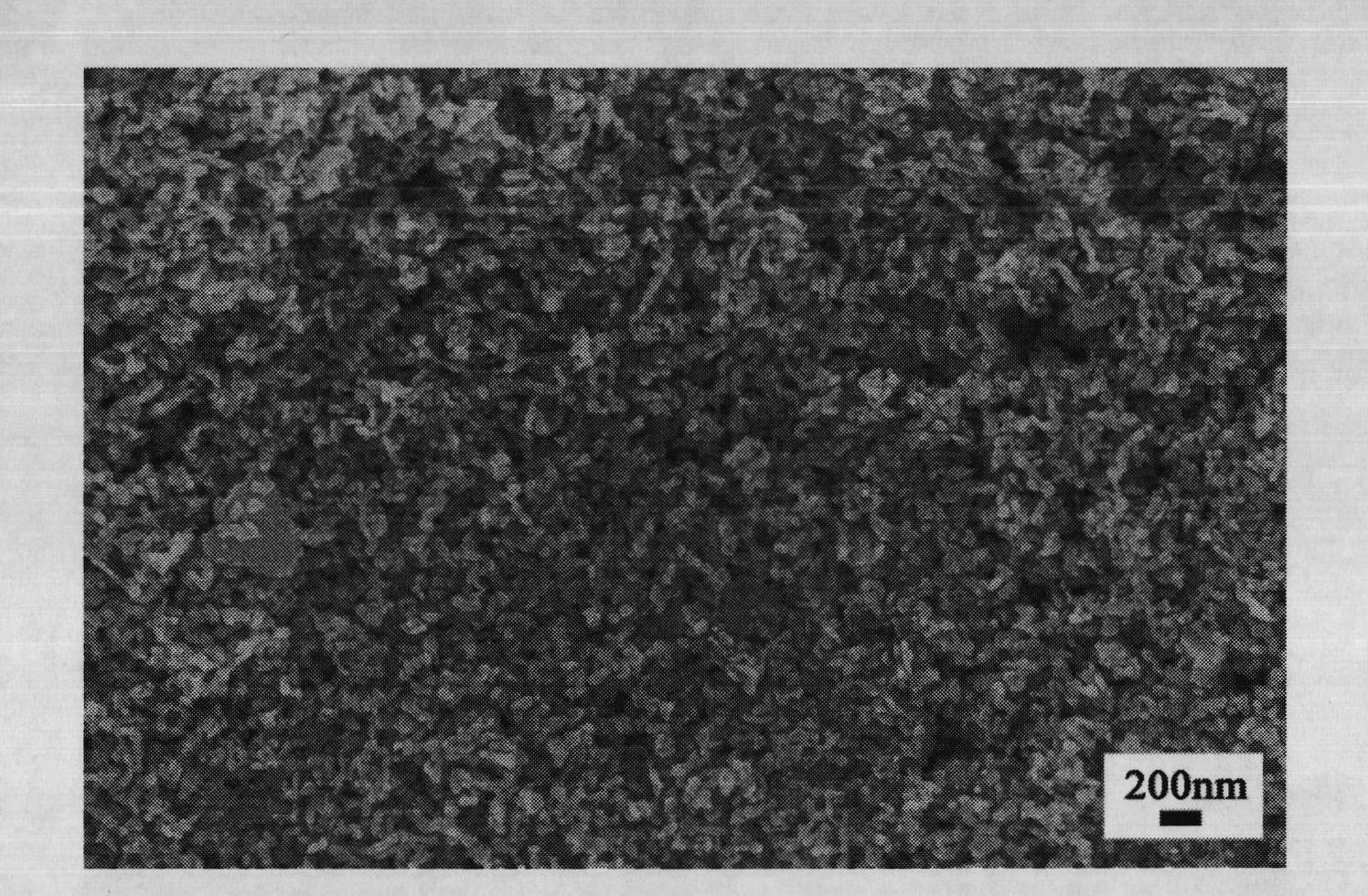

Perovskite CsPbBr3 thin film modified by zinc oxide nanoparticles and application of perovskite CsPbBr3 thin film

ActiveCN106847955AImprove compactnessIncrease coverageLaser active region structureFinal product manufactureSpectral emissionSemiconductor materials

The invention relates to a perovskite CsPbBr3 thin film modified by zinc oxide nanoparticles and application of the perovskite CsPbBr3 thin film, and belongs to the technical field of semiconductor materials. The thin film is prepared through a one-step method or a two-step method, the prepared perovskite CsPbBr3 thin film modified by the zinc oxide nanoparticles is high in compactness, large in covering rate, uniform in crystallization and high in charge carrier transferring rate, can improve the film layer quality of the side of the film, can increase the switch ratio and light response rate of an optical detector when used in the optical detector, and can improve the spectral emission intensity of a micro laser and reduce the laser excitation threshold when used in the micro laser.

Owner:北京京通光能科技有限公司

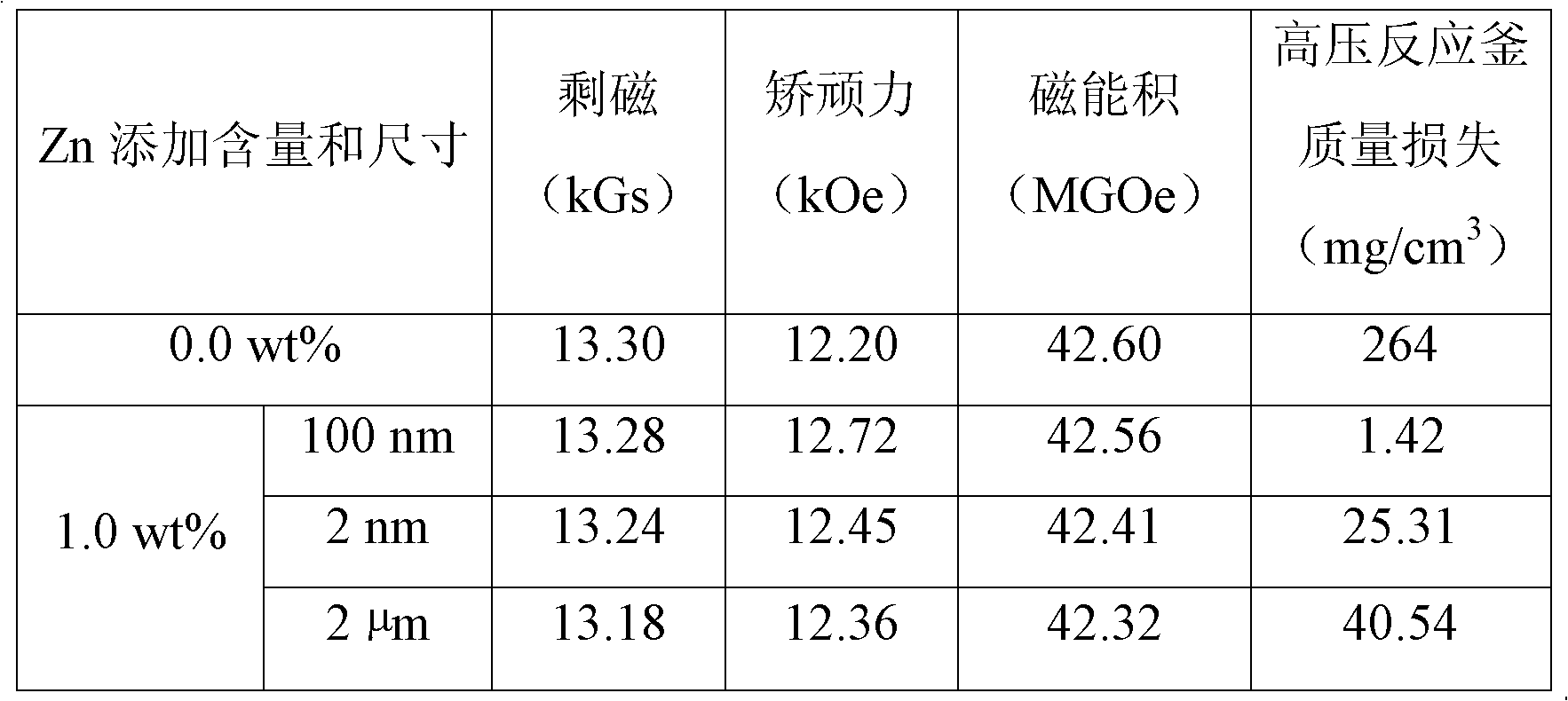

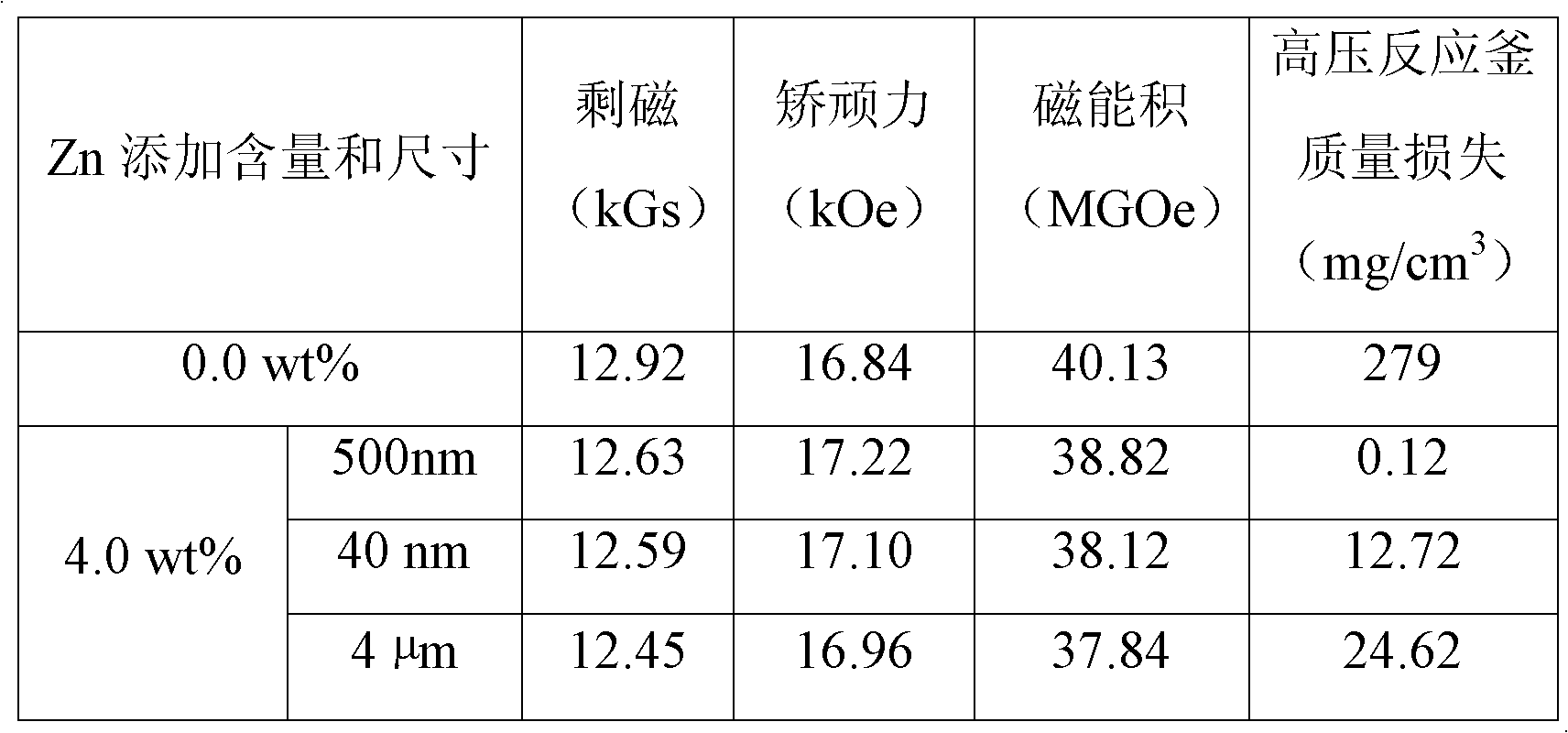

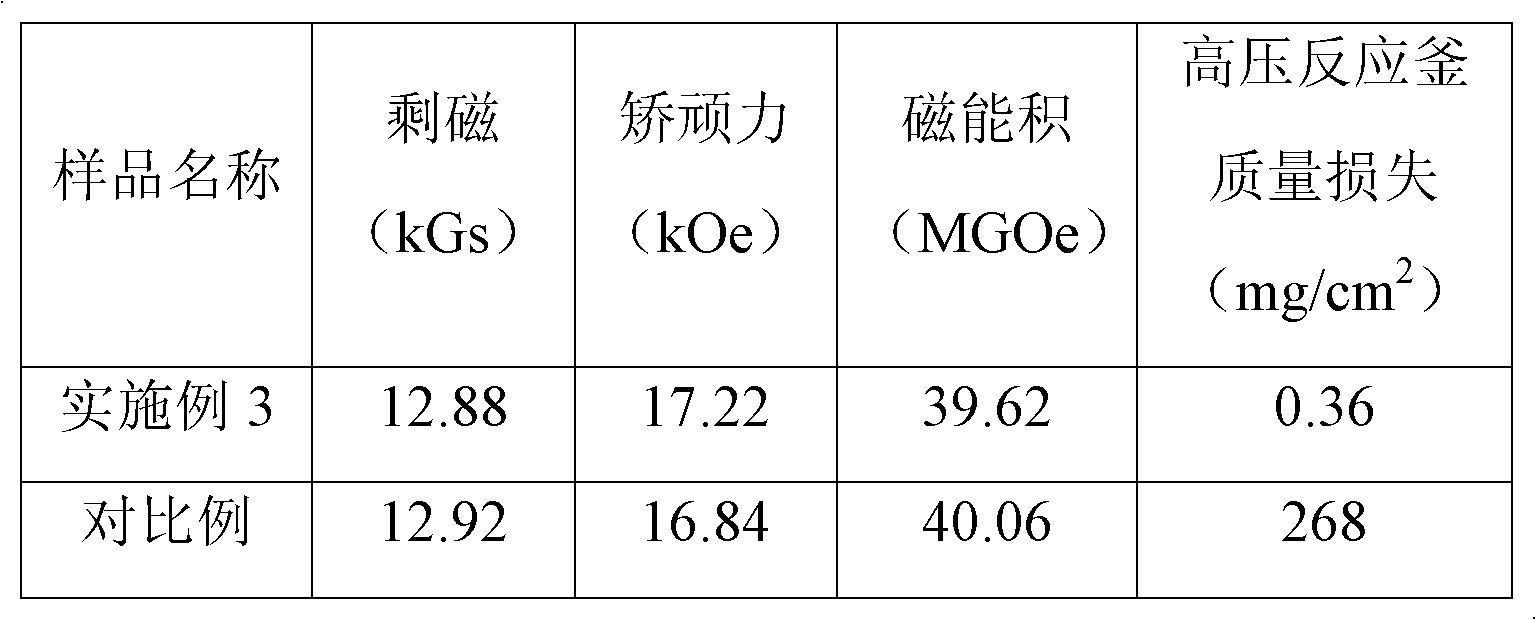

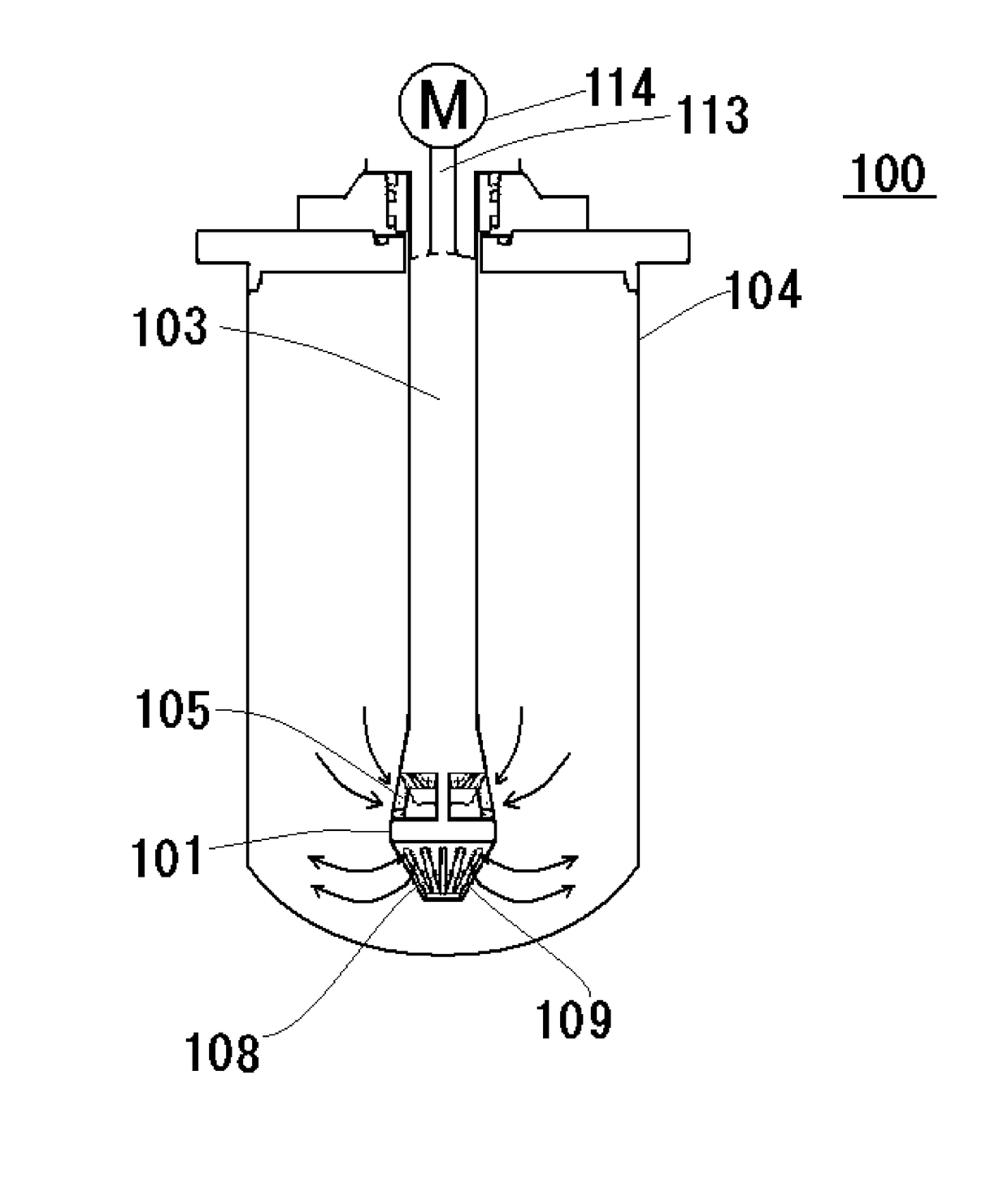

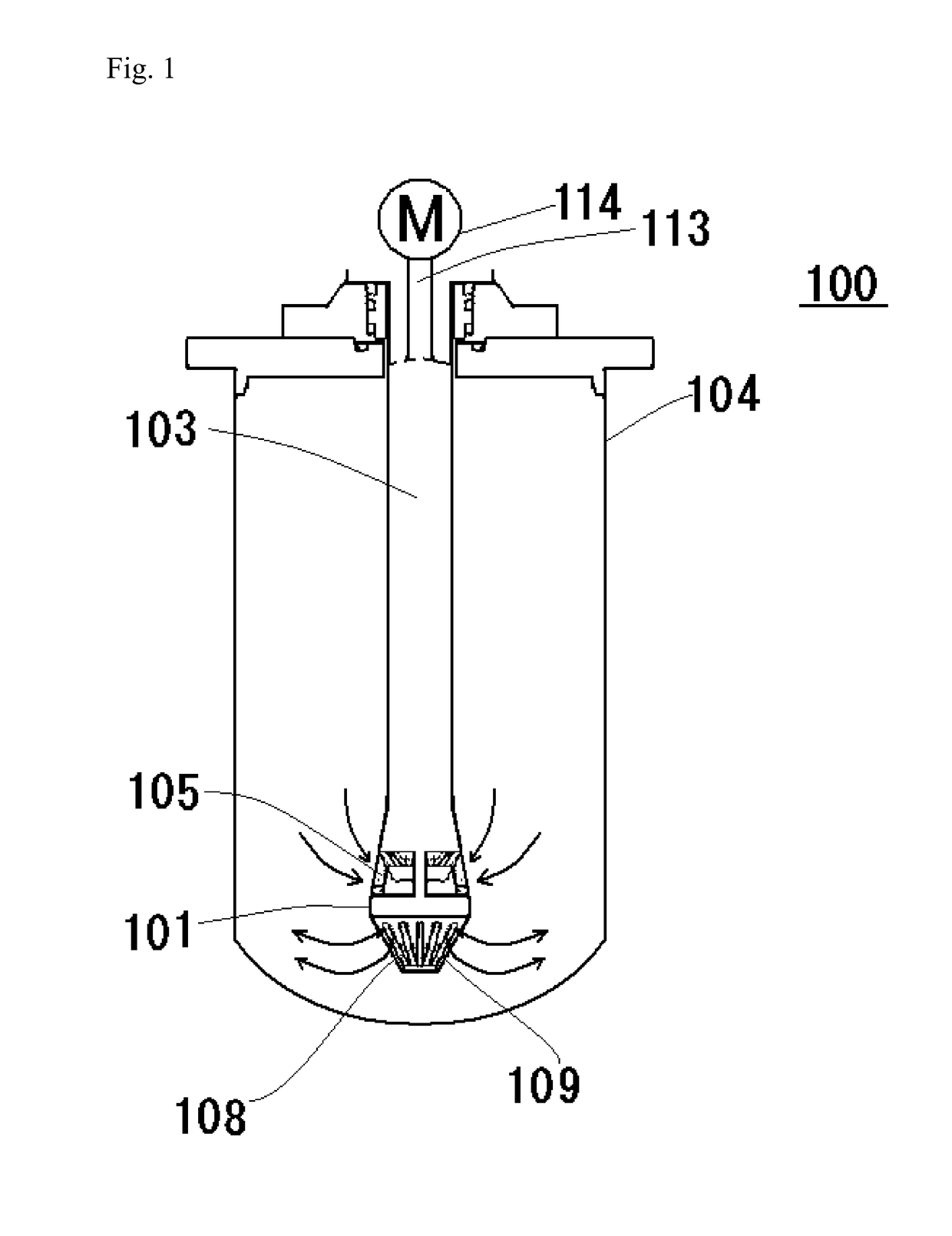

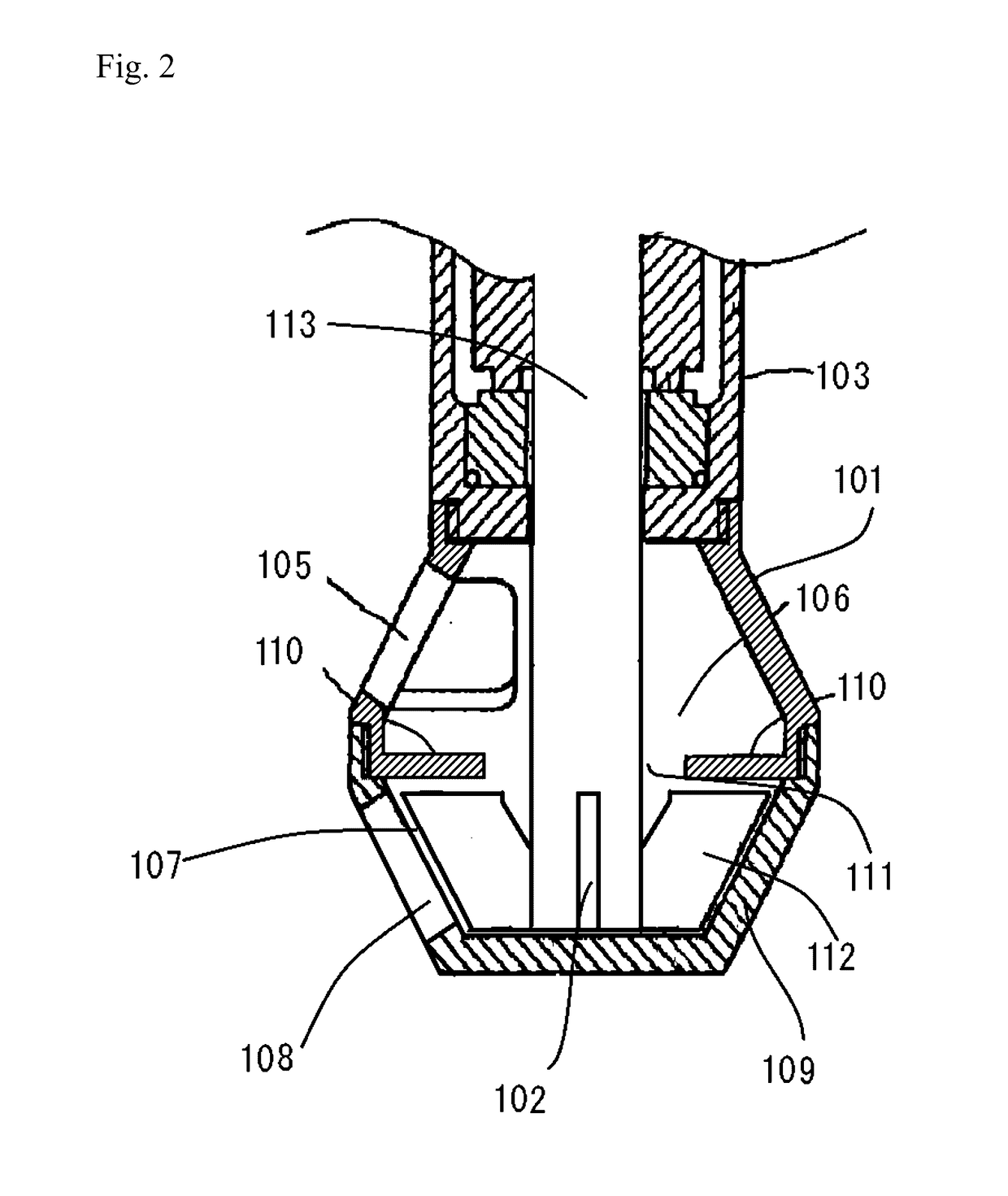

High-corrosion-resistance sintered neodymium-iron-boron-based permanent magnet material prepared by doping zinc nano-particles and preparation method thereof

The invention provides a high-corrosion-resistance sintered neodymium-iron-boron-based permanent magnet material prepared by doping zinc nano-particles and a preparation method thereof, belonging to the technical field of magnetic materials. The preparation method comprises the following steps of: adding Zn nano powder with the average diameter being 100-500 nm into neodymium-iron-boron-based powder with the size of 3-5 microns and uniformly mixing, wherein the adding amount of the Zn nano power is 1.0-4.0%; and then, orientating in a magnetic field of 2.5 T and carrying out compression molding; placing the mixture into a sintering furnace; raising the temperature to 1020-1120 DEG C and sintering for 2-4 hours; and finally, carrying out heat treatment in two stages, wherein the temperature of the first-state heat treatment is 830-930 DEG C and the time is 1-3 hours, the temperature of the second-state heat treatment is 480-630 DEG C and the time is 1-3 hours; and finally obtaining a high-corrosion-resistance sintered neodymium-iron-boron-based permanent magnet. According to the invention, the corrosion resistance of the magnet is improved and the effect that the magnet does not need to be coated is achieved. The corrosion weight loss is lower than 2 mg / cm<3> in a high-pressure accelerated corrosion experiment under the conditions of 121 DEG C, 0.2 MPa and 500 hours.

Owner:BEIJING UNIV OF TECH

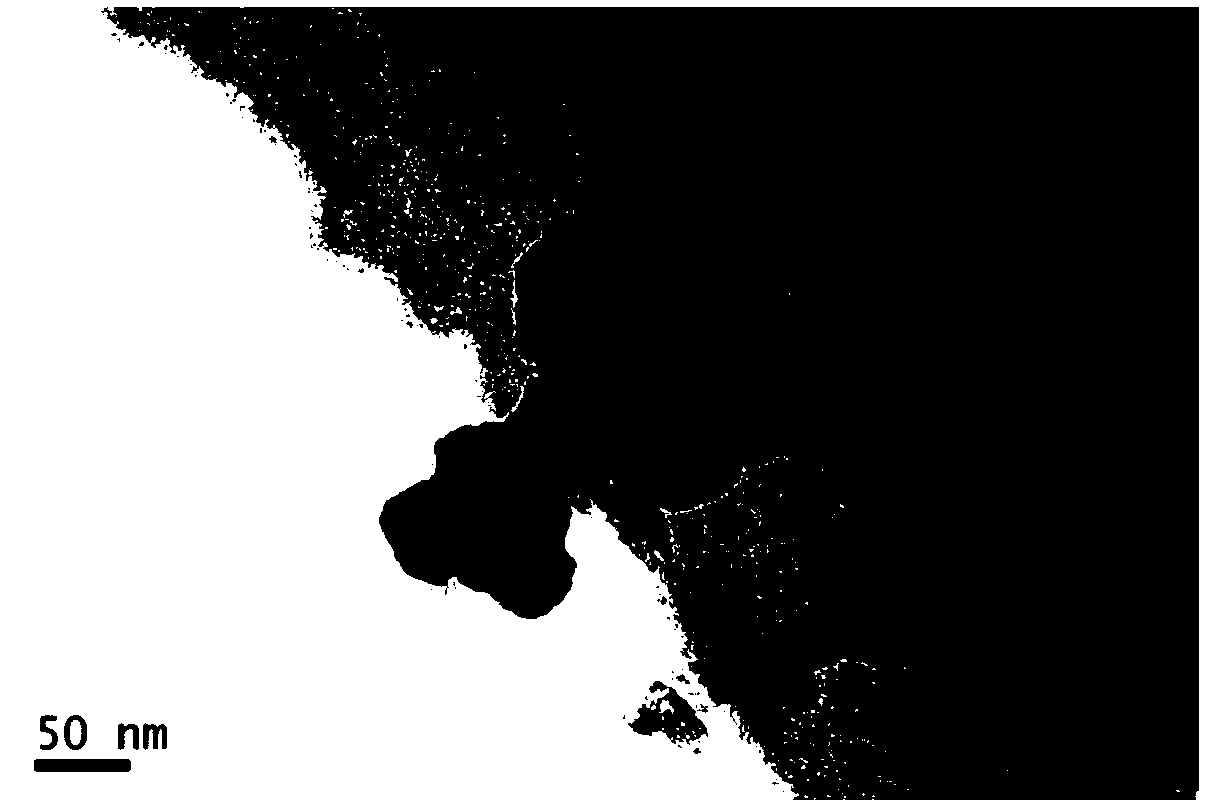

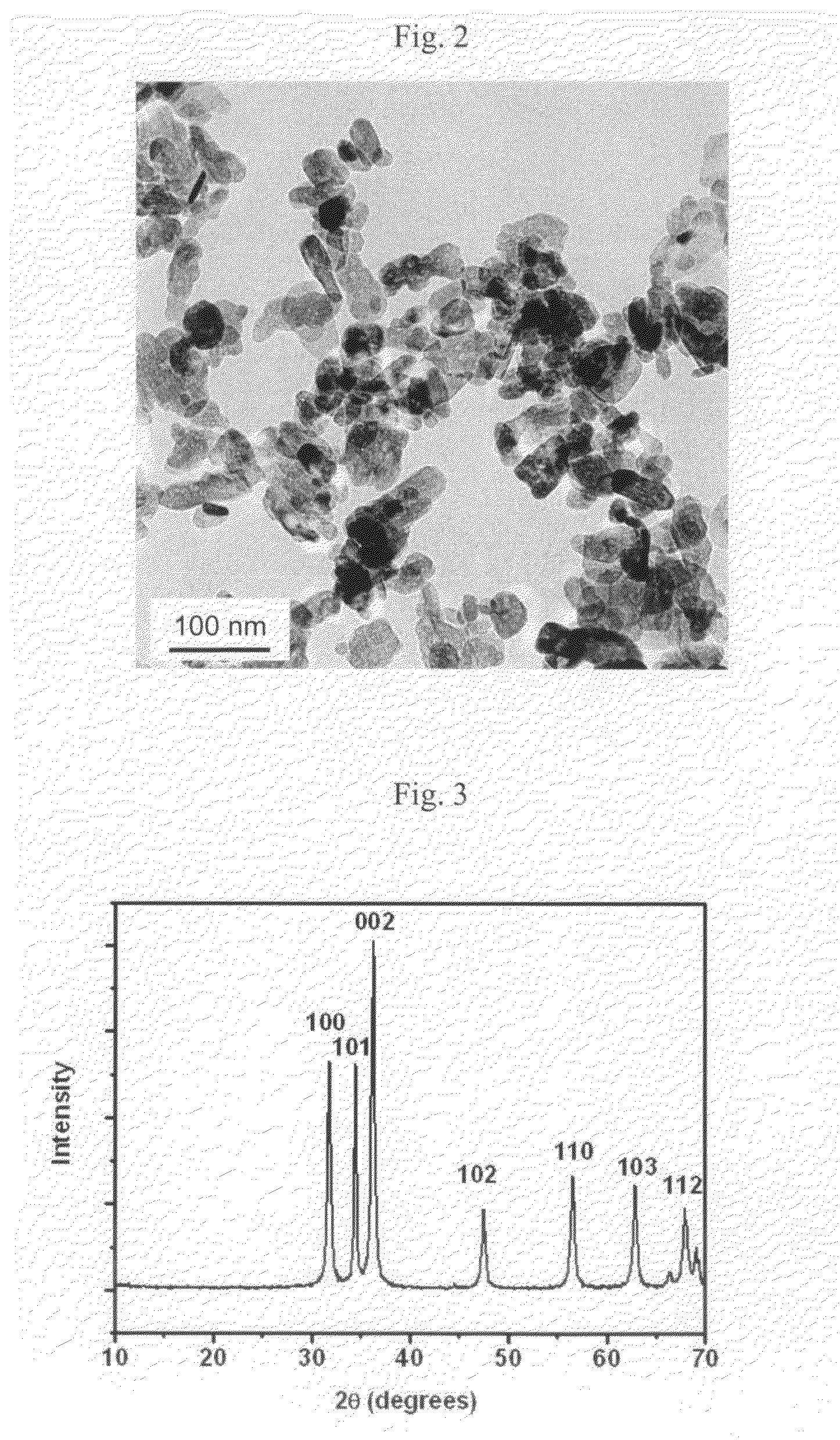

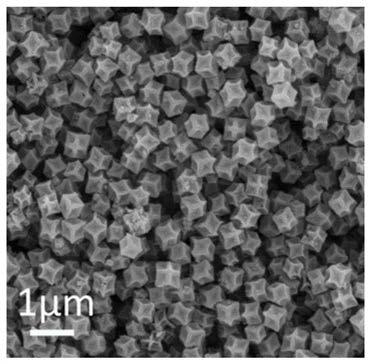

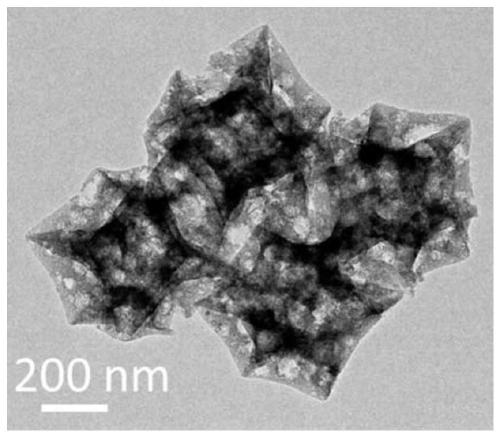

Method for producing single crystalline zinc oxide nanoparticles

ActiveUS20170130358A1Suitable for mass productionMaterial nanotechnologyPolycrystalline material growthAlcoholZinc nanoparticles

A method for producing single crystalline zinc oxide nanoparticles that is capable of mass production includes mixing, between processing surfaces which are disposed in a position facing each other so as to be able to approach and separate from each other and rotate relative to each other, a zinc oxide separating solvent prepared by homogeneously mixing an acidic substance with a solvent containing at least alcohol and a raw material solution obtained by mixing a zinc oxide nanoparticle raw material with a basic solvent or a raw material solution that is basic as a result of mixing and dissolving a zinc oxide nanoparticle raw material with and into a solvent, and discharging a mixed fluid in which zinc oxide nanoparticles have separated out from between the processing surfaces. The zinc oxide separating solvent and the raw material solution are mixed between the processing surfaces so that the mixed fluid becomes basic, and zinc oxide nanoparticles are generated by an acid-base reaction due to mixing of the acidic substance and the basic solvent.

Owner:M TECHN

Carbon nanotube/copper-zinc alloy composite material as well as preparation method and application thereof

ActiveCN109261155ALarge specific surface areaStrong chemical adsorptionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsCarbon nanotubeChemical adsorption

The invention discloses a carbon nanotube / copper-zinc alloy composite material as well as a preparation method and application thereof and belongs to the technical field of preparation of materials. The carbon nanotube / copper-zinc alloy composite material is prepared from a matrix carbon nanotube (CNT) and copper-zinc alloy nanoparticles loaded on the surface of the matrix carbon nanotube; a preparation process comprises the following steps: firstly, carrying out purification, sensitization and activation treatment on the CNT; then loading Cu nanoparticles on the CNT; plating Zn by utilizing zinc chloride; finally, carrying out alloying to obtain the carbon nanotube / copper-zinc alloy composite material. According to the carbon nanotube / copper-zinc alloy composite material, the CNTs are used for loading a nano copper-zinc alloy; on one hand, the advantages that the CNTs subjected to strong acid treatment have a relatively large specific surface area, relatively strong chemical adsorption, uniform distribution of metal elements on pipes and high thermal stability can be expressed; on the other hand, the CNTs are used as carriers of the copper-zinc nanoparticles and the property of isolating and dispersing the copper-zinc nanoparticles is realized; the distance between the copper-zinc nanoparticles is increased, the anti-sintering performance of the copper-zinc nanoparticles is improved and the agglomeration problem of nano copper-zinc alloys is solved.

Owner:CENT SOUTH UNIV

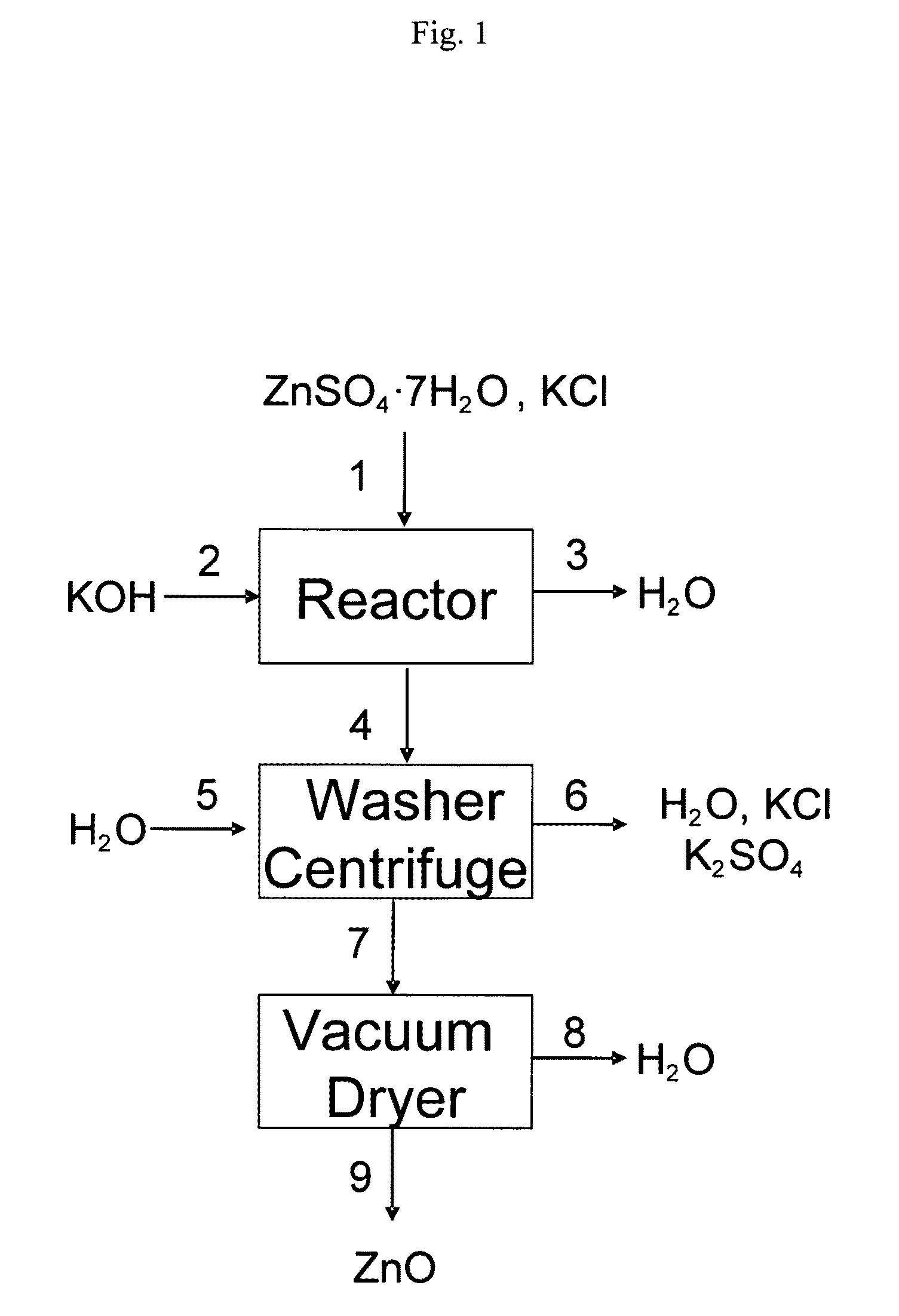

One-step, paste-state mechanochemical process for the synthesis of zinc oxide nanoparticles

InactiveUS20100034730A1Minimize agglomerationPigmenting treatmentMaterial nanotechnologyInorganic saltsUltraviolet

The present subject matter provides a time- and energy-saving paste-state mechanochemical process to synthesize zinc oxide nanoparticles. Our nanoparticles are small, have abundant surface hydroxyl groups and exhibit excellent UV blocking characteristics. One embodiment involves a process for preparing zinc oxide nanoparticles comprising grinding, milling, or a combination thereof a mixture comprising (a) at least one zinc salt, (b) at least one additional inorganic salt, and (c) at least one alkali hydroxide compound.

Owner:THE HONG KONG UNIV OF SCI & TECH

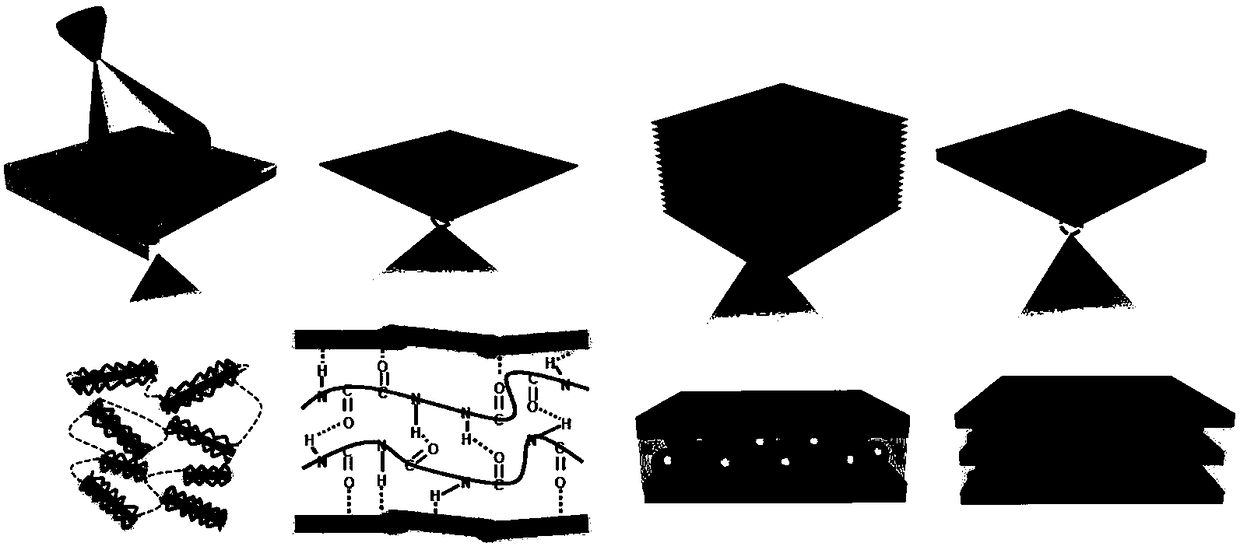

A three-dimensional shell-imitated material and a preparing method thereof

A preparing method of a three-dimensional shell-imitated material is provided. The method includes preparing a nanometer aromatic polyamide fiber dissolved solution from aromatic polyamide fibers in asolvent by utilizing stirring and stripping; mixing a mica dispersion, a surface modifier and a dispersing agent to obtain a mica sheet suspension modified with the surface modifier; mixing the micasheet suspension modified with the surface modifier with the nanometer aromatic polyamide fiber dissolved solution to obtain a mica-nanometer aromatic polyamide fiber dispersion; preparing a compositefilm by spraying the mica-nanometer aromatic polyamide fiber dispersion through a spray-assembling method; spraying the composite film with zinc oxide nanoparticles; infiltrating the composite film in epoxy resin; and performing lamination and hot press processing to obtain the three-dimensional shell-imitated material. The three-dimensional shell-imitated material has bending stress, toughness and Young modulus which are far higher than those of pure nanometer aromatic polyamide fiber block materials, and has specific stress and specific toughness which are far higher than those of shell-imitated materials of the same type. In addition, stability of properties in acidic, alkaline, high-temperature, low-temperature, radiation environments and other harsh environments is achieved.

Owner:UNIV OF SCI & TECH OF CHINA

Method for preparing high-density zinc oxide nano granules

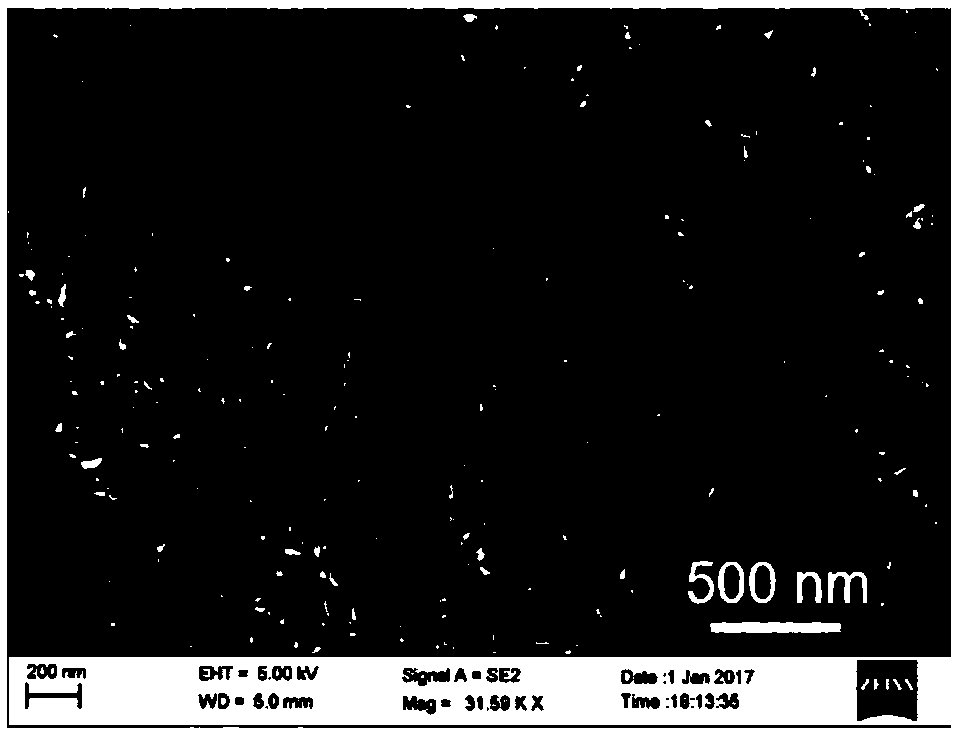

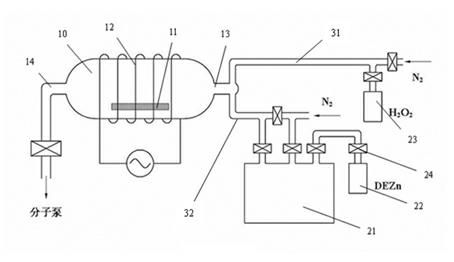

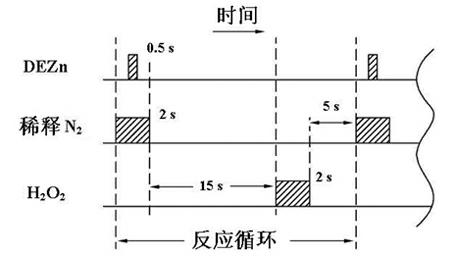

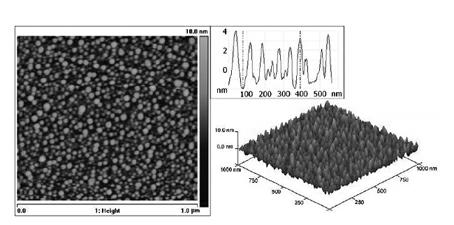

InactiveCN102153132ASmall particlesHigh densityPolycrystalline material growthZinc oxides/hydroxidesInert gas dilutionVolumetric Mass Density

The invention relates to a method for preparing high-density zinc oxide nano granules. In the method, the high-density zinc oxide nano granules are grown by using diethyl zinc steam diluted by inert gas and steam of aqueous solution of hydrogen peroxide as reaction precursors, adopting an atomic layer deposition mode and using atomic layer deposition equipment, wherein the diethyl zinc steam and the steam of the aqueous solution of the hydrogen peroxide, serving as the reaction precursors, are alternately introduced into a reaction cavity in a pulse mode, and the two kinds of steam are blown and washed by using inert gas. The high-density zinc oxide nano granules are grown by using an atomic layer deposition technology, so the process is simple, and the production cost is low; the size of the nano granules can be accurately controlled; the zinc oxide nano granules with average diameter of about 5 to 25 nanometers, height of 2 to 10 nanometers and density of 1.0*10<10> to 1.0*10<11>cm<-2> can be obtained; and the zinc oxide nano granules can be used for a photoelectric conversion material for a solar cell.

Owner:FUDAN UNIV

Preparation method of zinc oxide ternary compound nano material with yolk-eggshell structure

InactiveCN104028182AShell structure is stableObvious cavityMicroballoon preparationMicrocapsule preparationYolkEggshell

The invention relates to a preparation method of a ternary organic-inorganic zinc oxide compound micro-ball with a yolk-eggshell structure. The preparation method comprises the following steps: decorating inorganic zinc oxide nano particles with oleinic acid; ultrasonically dispersing an oil phase in a water phase containing a surfactant to obtain a uniform and stable miniemulsion system, wherein the oil phase mainly comprises the zinc oxide nano particles, a precursor of silicon oxide, styrene and a co-stabilizer; carrying out polymerization and sol-gel reaction to obtain a compound micro-ball which takes polystyrene as the core and zinc oxide and the silicon oxide as the shell and has a certain cavity. By adjusting the particle size and surface characteristics of a capsule with the yolk-eggshell structure, medicines can be controlled to slowly release; the structure provides the sufficient storage space for functionalized carrier medicines (or fluorescent substances), and probably has a wide application prospect in fields of slow release of the medicines, imaging and the like.

Owner:TONGJI UNIV

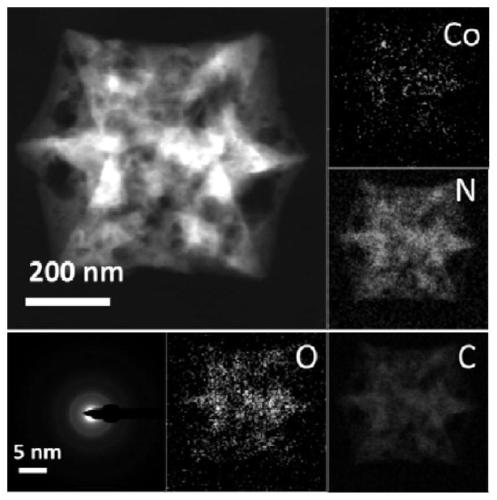

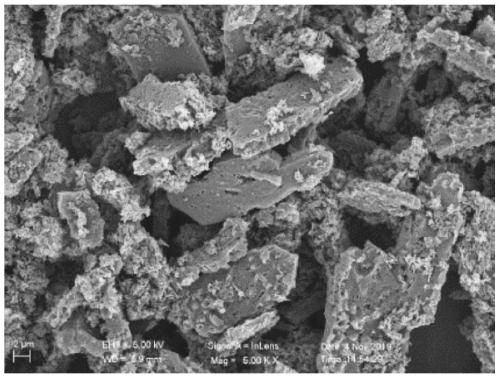

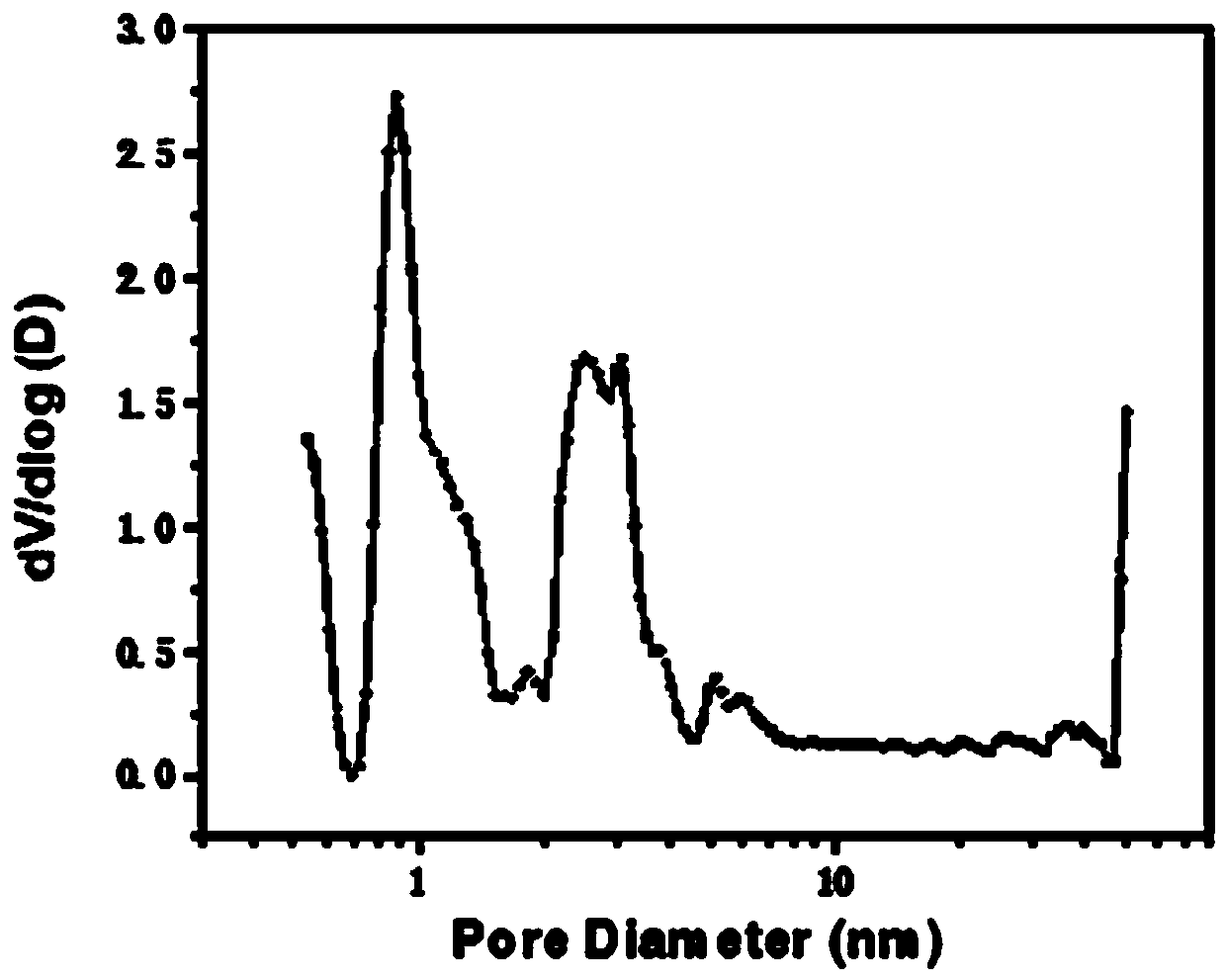

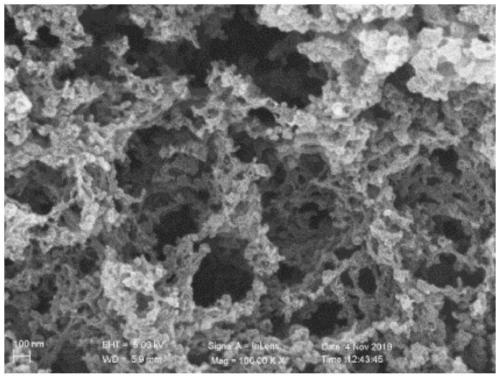

Nitrogen-doped graded porous carbon nano catalyst and preparation method thereof

InactiveCN110280286AExcellent advanced oxidation (AOPs) activityAvoid reunionPhysical/chemical process catalystsWater contaminantsNano catalystPtru catalyst

The invention discloses a nitrogen-doped graded porous carbon nano catalyst and a preparation method thereof. According to the method, a phenolic resin assisting strategy is adopted, a zeolite imidazole ester framework structure material is converted into nitrogen-doped graded porous carbon, and the nitrogen-doped graded porous carbon is applied to the advanced oxidation process. Through the coordination of the nucleation / growth rate and polymerization rate of a precursor, ZIF-67 / 8@PR composite carbon is obtained. The introduction of a phenolic resin polymer can prevent the agglomeration of cobalt and zinc nanoparticles, an evenly distributed graded porous structure is formed, and structural collapse during carbonization is prevented. The carbonized acid treatment can remove metal particles in NDHC, and the nitrogen-doped graded porous carbon is obtained. The nitrogen-doped graded porous carbon nano catalyst can effectively avoid secondary pollution caused by metal ions leached in the catalytic process, and has excellent AOPs catalytic performance.

Owner:NANJING UNIV OF SCI & TECH

Synthesis method of graded porous carbon nanometer material

ActiveCN110357068AImprove universalityThe synthesis method is simpleMaterial nanotechnologyCarbon preparation/purificationEtchingPorous carbon

The invention provides a synthesis method of a graded porous carbon nanometer material. The synthesis method of the graded porous carbon nanometer material comprises the following steps: A) mixing small organic molecules containing polychelating grou or o-hydroxyl grou and inorganic zinc salt into an alkaline aqueous solution and performing reaction to obtain a precursor which is separated out inthe form of precipitate; and B) performing high-temperature pyrolysis on the precursor to obtain the graded porous carbon nanometer material. The small organic molecules containing the polychelating group or the o-hydroxyl group and zinc are stirred in the alkaline aqueous solution at a room temperature to form a coordinate polymer or a coordinate compound serving as the precursor, the precursor in the high-temperature pyrolysis process and the chelated zinc are agglomerated to form nanoscale dispersed zinc particles to realize a template pore-forming effect, and the zinc nanoparticles can realize evaporation through further high-temperature treatment, so that the graded porous carbon nanometer material can be obtained without subsequent etching. The synthesis method provided by the invention is simple, low in cost, high in controllability, high in universality and mild in condition.

Owner:安徽枡水新能源科技有限公司

Electronic transmission film and preparation method and application thereof

InactiveCN109994620AReduce surface defectsImprove stabilityMaterial nanotechnologySolid-state devicesElectronic transmissionZno nanoparticles

The invention provides an electron transmission film, which consists of nano zinc oxide containing at least one doped metal ion, wherein the nano zinc oxide doped with the metal ion is nano zinc oxidewith the surface enriched with the metal ion. The electron transmission film provided by the invention can significantly improve the stability of zinc oxide nanoparticles, thereby avoiding the use ofsurface ligands in the zinc oxide nanoparticles, further avoiding the obstruction of the introduction of the surface ligands on the electron transmission in the zinc oxide material, and optimizing the conductivity of the nano zinc oxide electron transmission layer.

Owner:TCL CORPORATION

Sintered NdFeB magnet surface high anti-corrosion coating and preparation method thereof

ActiveCN109468576AHigh temperature resistantCorrosion resistantMolten spray coatingNanoparticlePliability

The invention provides a sintered NdFeB magnet surface high anti-corrosion coating and a preparation method thereof. The preparation method includes the following steps: nanoparticles are subjected togranulation treatment to obtain coating particles, wherein the nanoparticles are a mixture of nanometer zirconia, nanometer aluminum powder and nanometer zinc powder; the pretreated sintered NdFeB magnet surface is preheated; and a nanometer-structured coating is prepared on the preheated sintered NdFeB magnet surface by adopting a plasma spraying mode. The nanometer-structured coating composed of the nanometer-zirconia, the nanometer-aluminum powder and the nanometer-zinc powder is prepared on the preheated sintered NdFeB magnet surface by adopting the plasma spraying mode, the problems of poor anti-corrosion and environmental pollution during production, preparation and usage process of a conventional coating on the sintered NdFeB magnet surface are solved. The high anti-corrosion coating prepared according to the preparation method has good flexibility, adhesion, impact resistance, wear resistance, high-temperature resistance and anti-corrosion, and the sintered NdFeB magnet can beprevented from corrosion persistently by the anti-corrosion coating.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

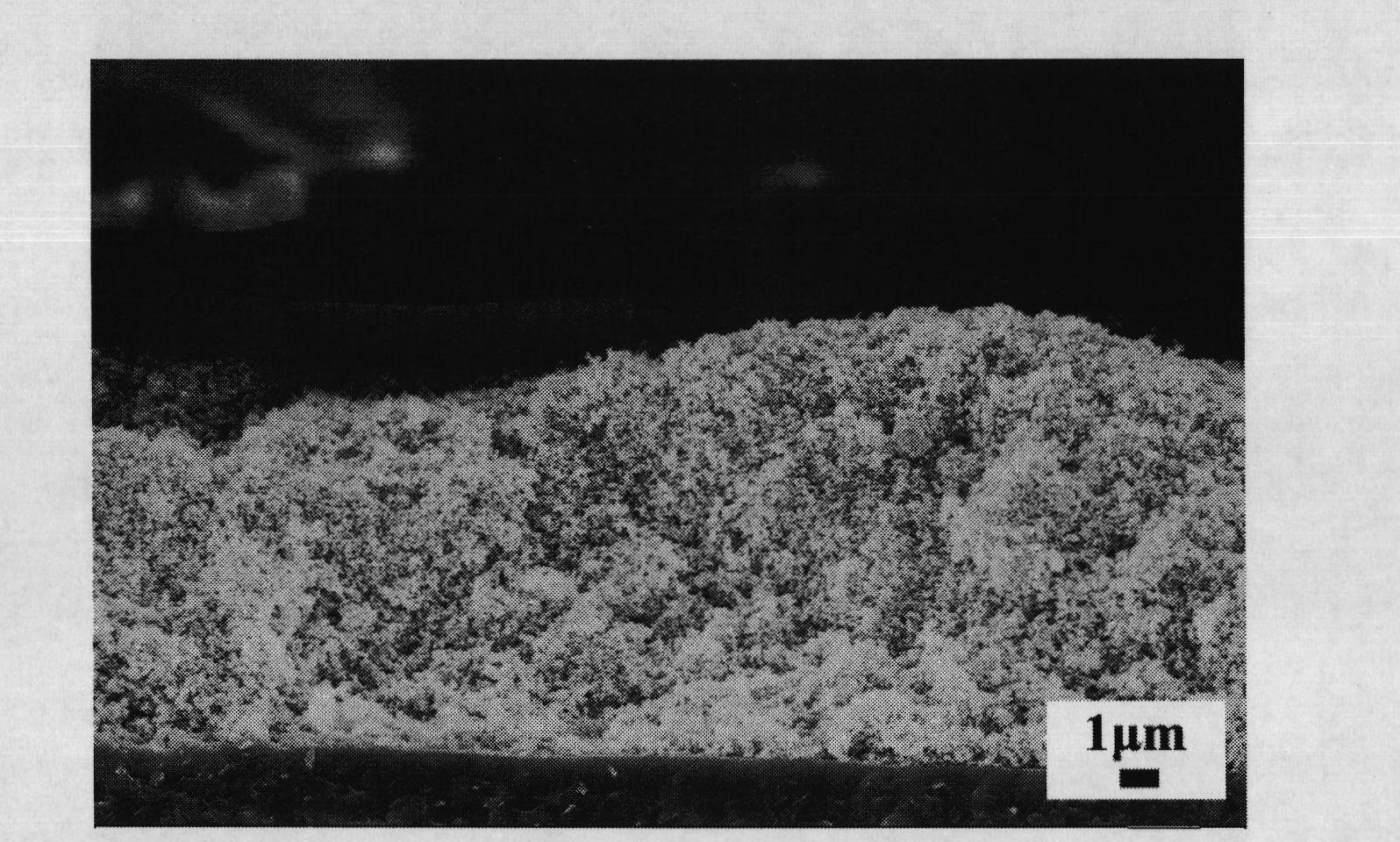

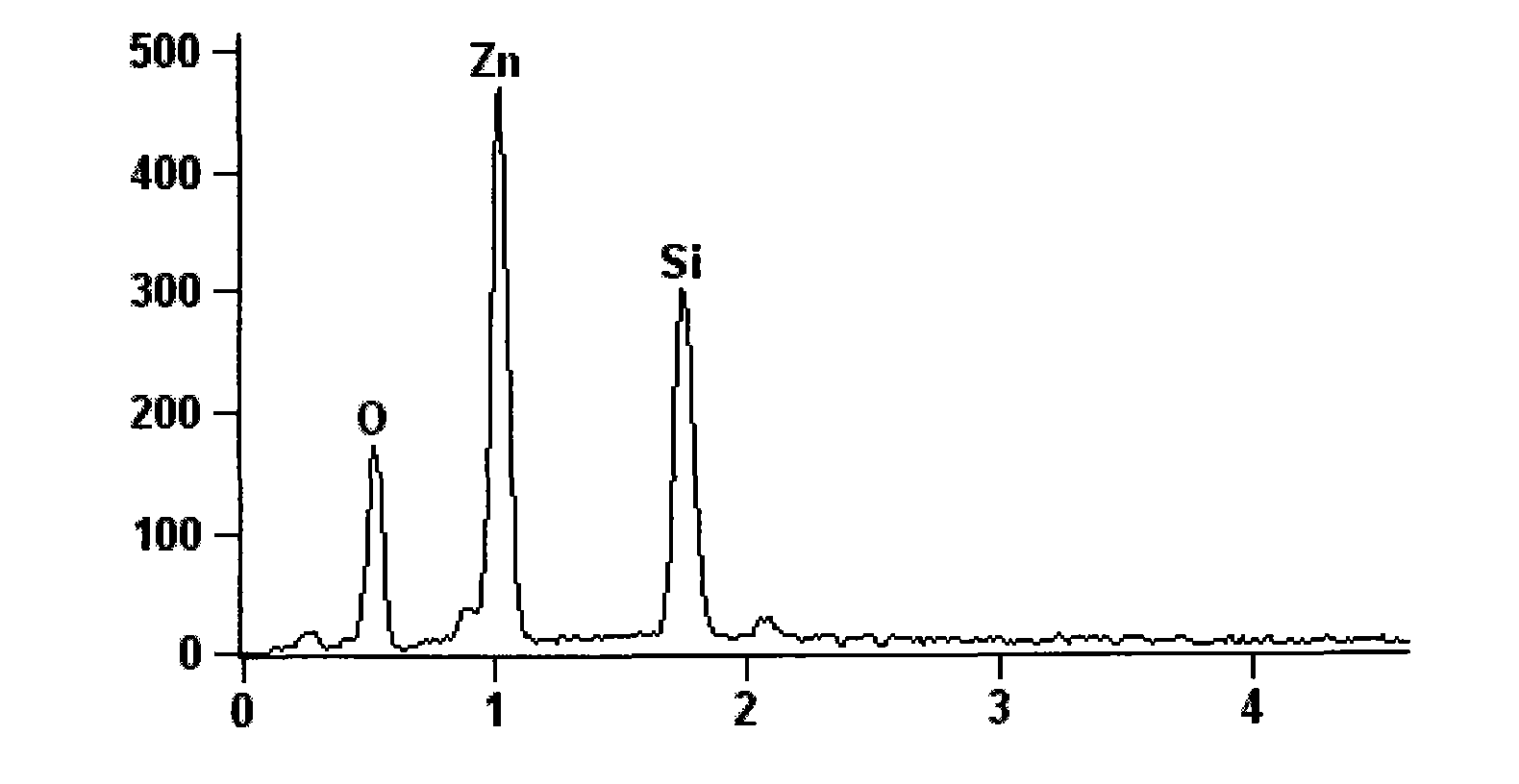

Method for preparing SiO2-modified ZnO nano-porous thin film composite electrode

InactiveCN102005303AGood acid corrosion resistanceInhibition of agglomerationLight-sensitive devicesSolid-state devicesStrong acidsZno nanoparticles

The invention belongs to the technical field of nano-materials, and relates to a method for preparing a SiO2-modified ZnO nano-porous thin film composite electrode, which is characterized in that a ZnO nano-particle porous thin film is used as the base layer of the composite electrode; a spin-coated silicon oxide sol protective layer is selected to improve the corrosion resistance of the ZnO nano-particle porous thin film in an acid dye for the stability of a dye-sensitized solar cell. The coating layer number, the sintering time and the concentration of sole are adjusted so as to reasonably control the thickness of a silicon oxide thin film coat, thereby obtaining the composite electrode with strong corrosion resistance and excellent performance. In the invention, process parameters can be adjusted according to different sensitized conditions so as to obtain the SiO2-ZnO nanoparticle porous thin film composite electrode with strong acid resistance in the process of sensitization and optimal electrode performance. The production process has the advantages of high efficiency, low cost and the like, and is suitable for future large-scale production.

Owner:UNIV OF SCI & TECH BEIJING

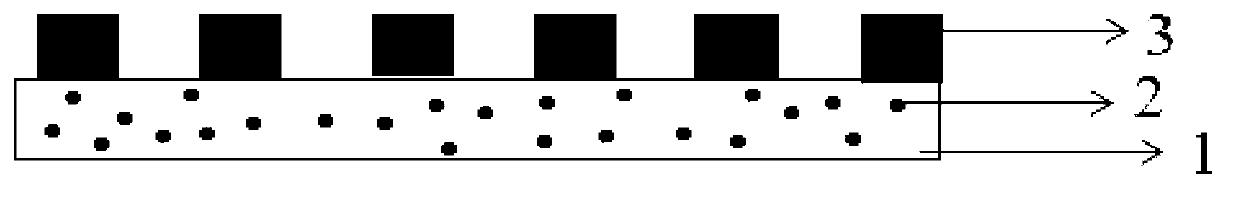

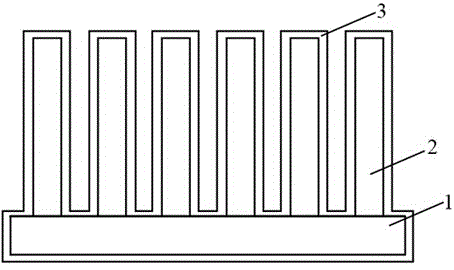

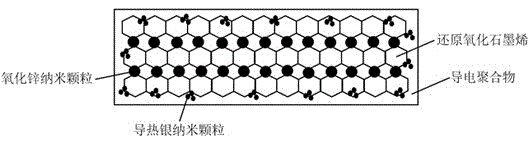

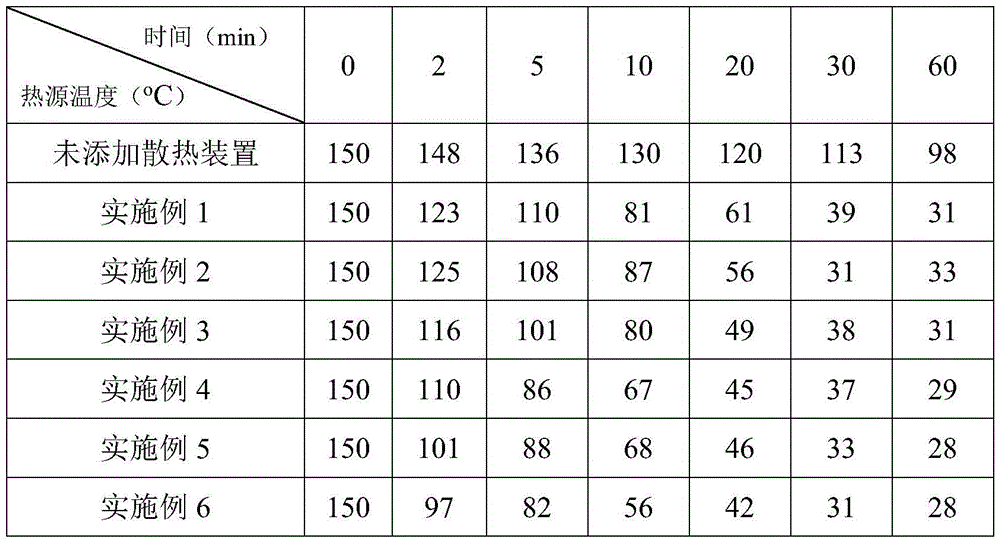

Radiator for laser display and preparation method of radiator

ActiveCN105679725ALarge specific surface areaSmall sizeSemiconductor/solid-state device detailsSolid-state devicesDefective grapheneHeat conducting

The invention discloses a radiator for laser display and a preparation method of the radiator. The radiator comprises a heat-conducting substrate (1), radiating fins (2) and an ultra-thin composite heat-conducting coating (3), wherein the ultra-thin composite heat-conducting coating is formed by combination of reduced graphene oxide, heat-conducting silver nanoparticles, zinc oxide nanoparticles and a conductive polymer at a certain ratio. The zinc oxide nanoparticles are doped into the reduced graphene oxide; a zinc oxide-graphene composite porous structure is formed through high-temperature reaction; the specific surface area of a film is increased; the radiator has super-high heat conductivity and radiating performance; meanwhile, graphene defects in the film are filled with the doped small-size heat-conducting silver nanoparticles; and the film has a uniform heat-conducting effect; the conductive polymer is doped, so that the viscosity of a heat-conducting film raw material solution is improved; the interface compatibility of the heat-conducting film and the heat-conducting substrate is improved; the film is relatively good in flatness after being prepared; and match with a heat source is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

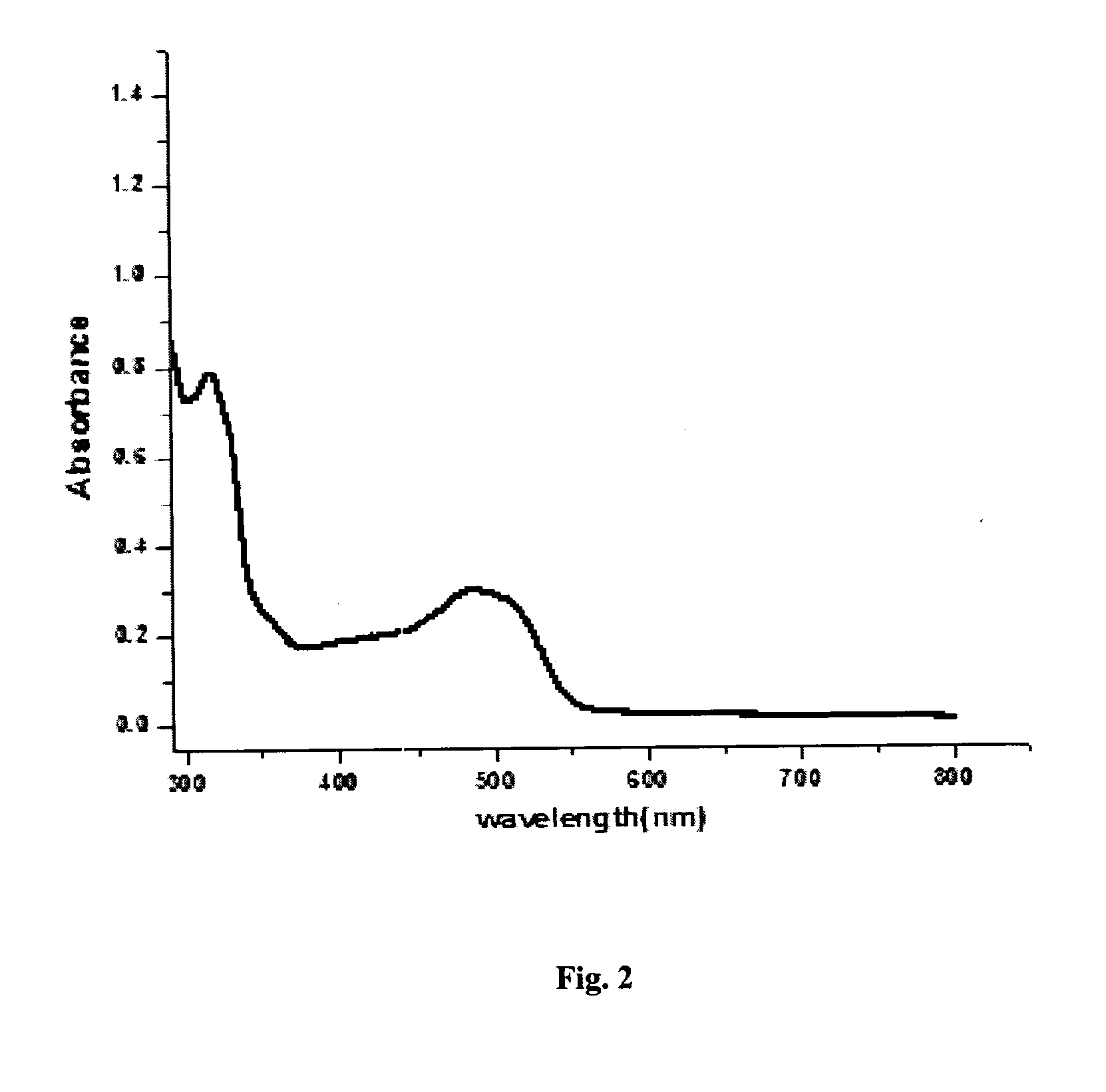

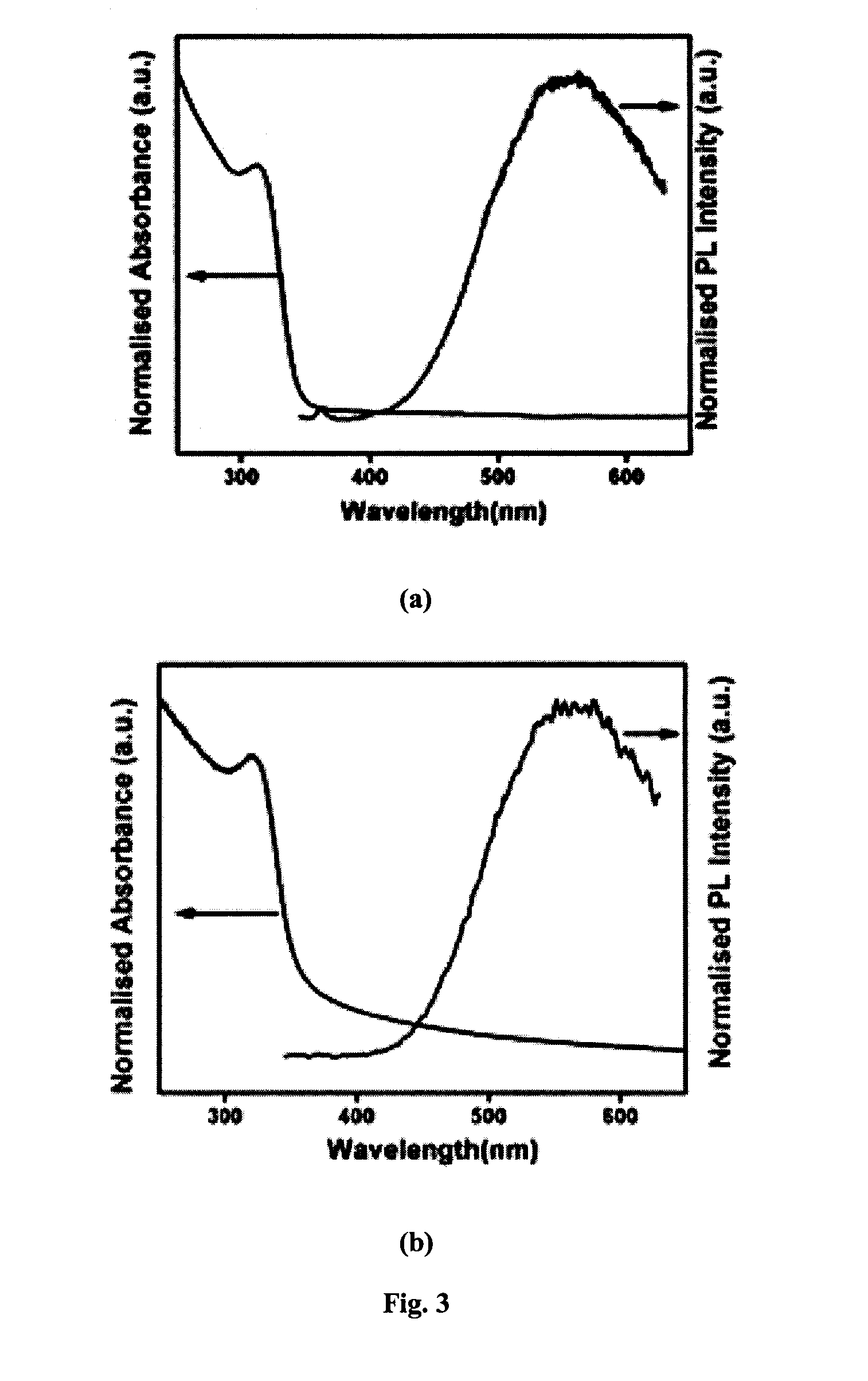

Functionalized zinc oxide nanoparticles for photocatalytic water splitting

ActiveUS20160318010A1Zinc oxides/hydroxidesOrganic-compounds/hydrides/coordination-complexes catalystsLight ActivityPhotocatalytic water splitting

The present invention relates to a photocatalyst composition having visible light activity for hydrogen production through water splitting. More particularly, the present invention discloses a photocatalyst composition comprising a zinc oxide nanoparticles and a conjugated organic moiety selected from the group consisting of oligothiophenes, azo dyes, and perylenes.

Owner:COUNCIL OF SCI & IND RES

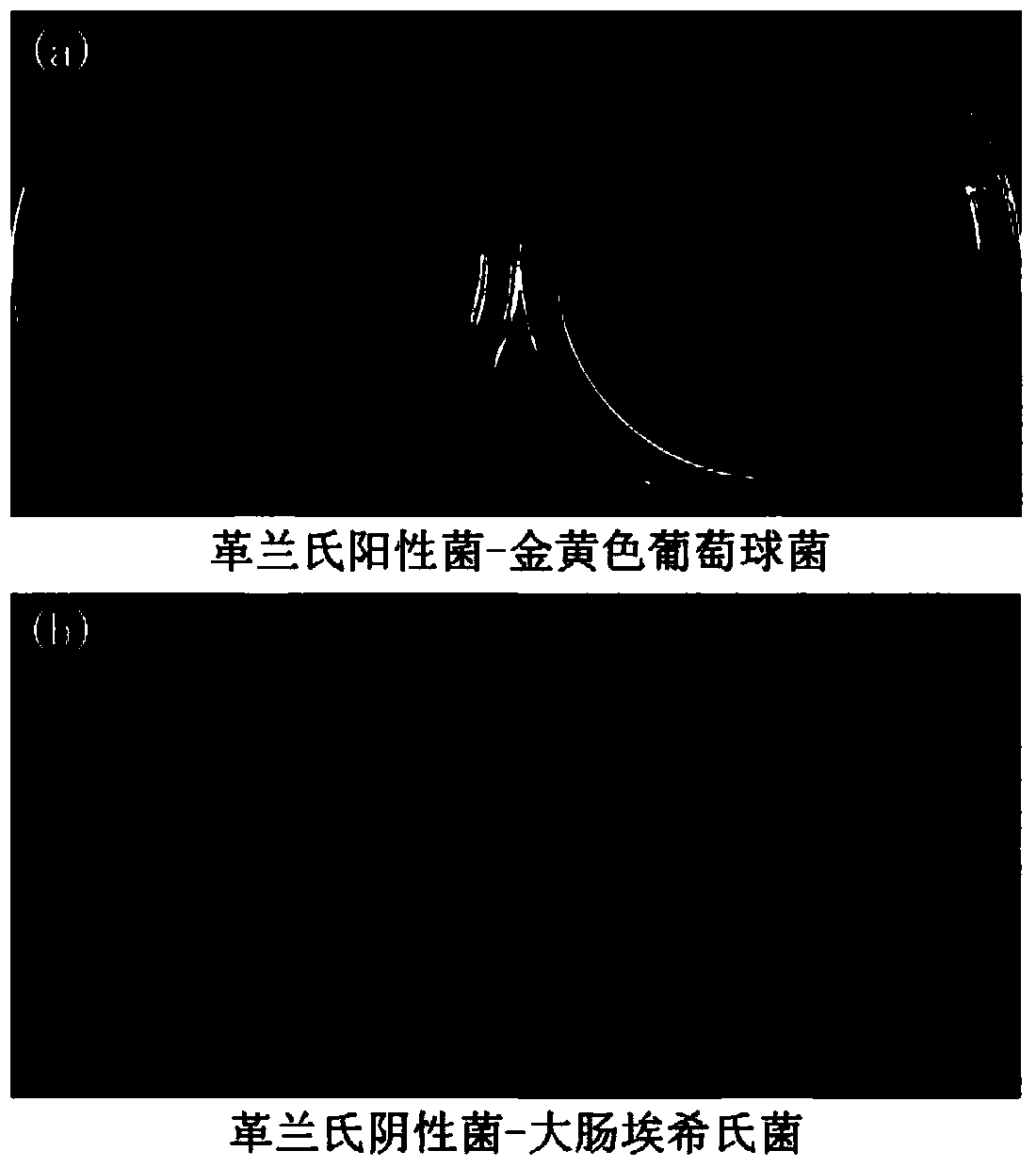

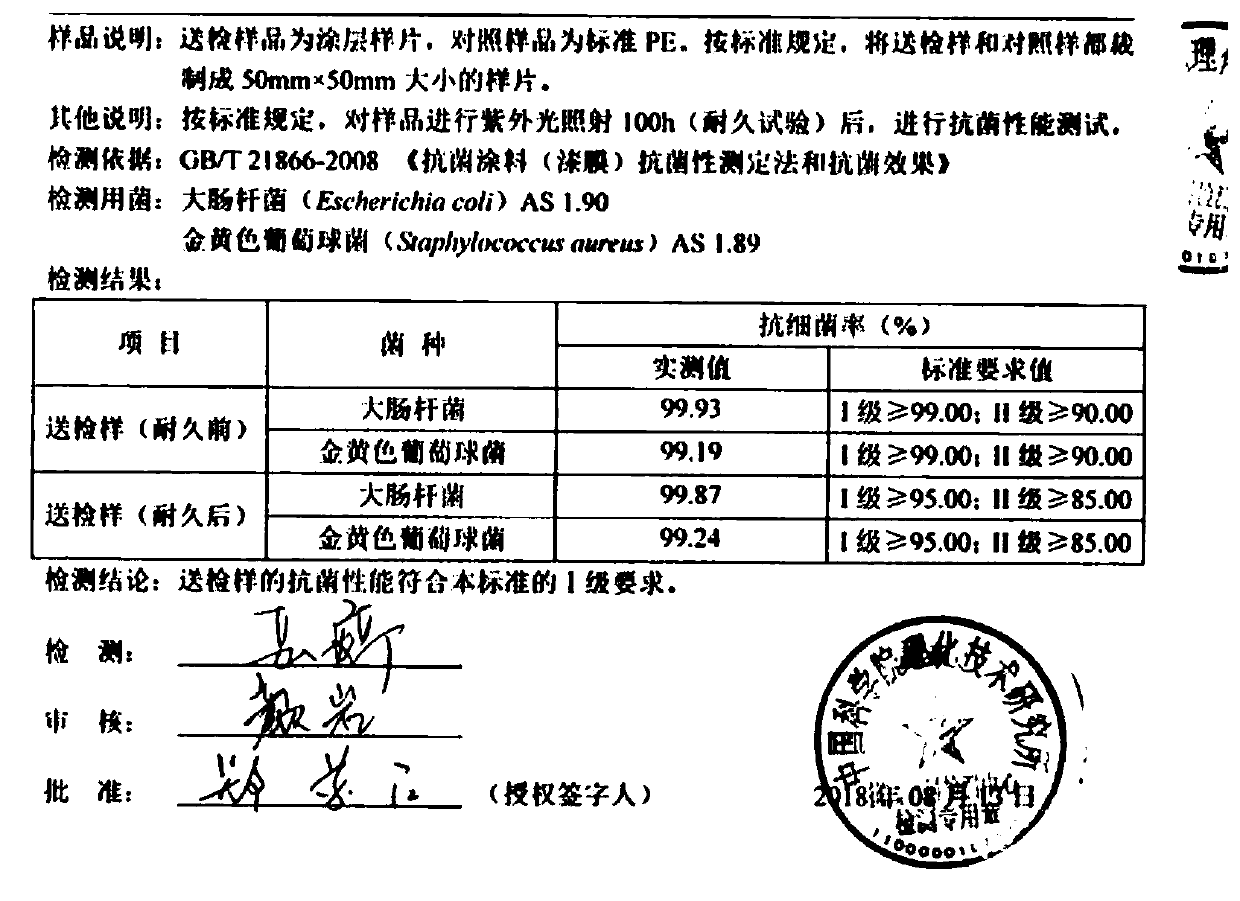

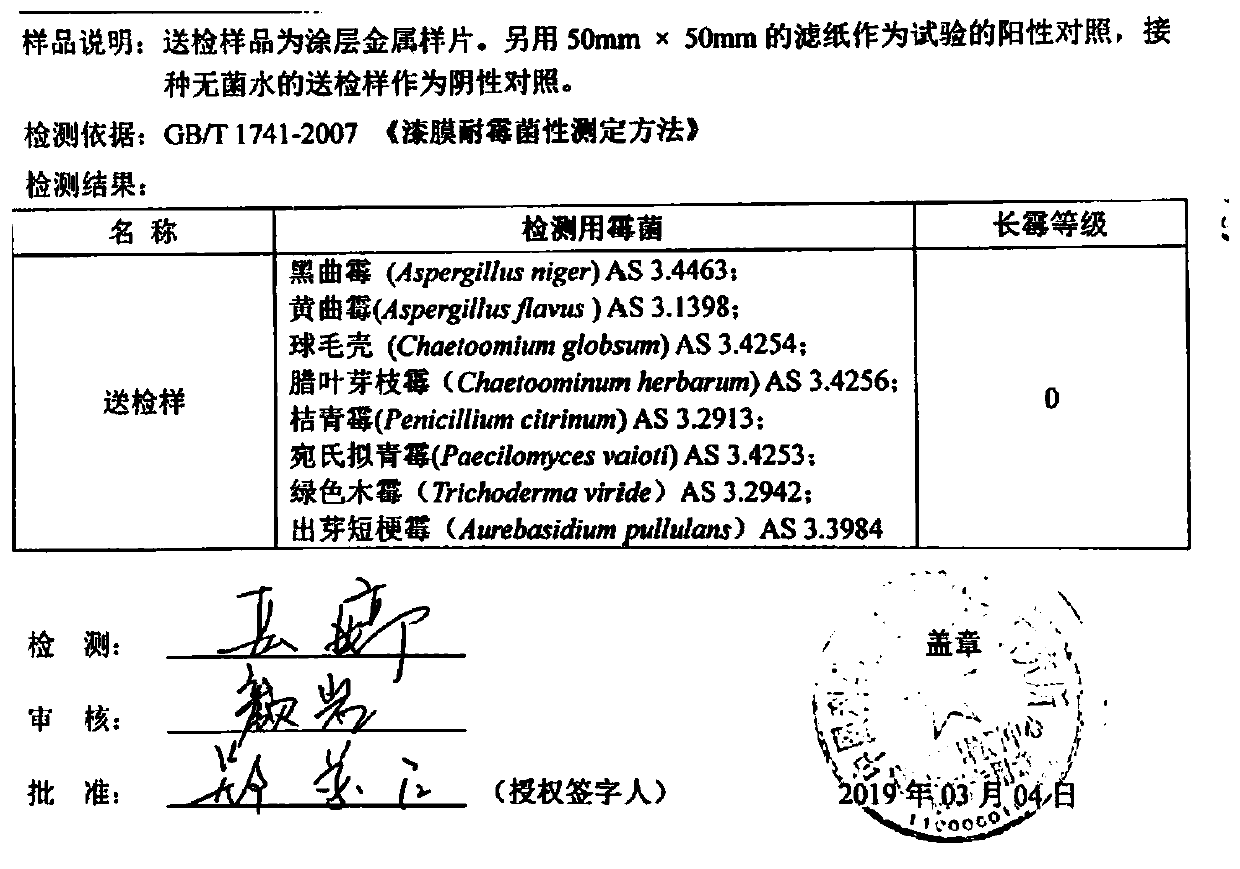

Antibacterial and anti-mildew agent, and preparation method and application thereof

ActiveCN110200013AGood antibacterial and mildew resistanceSimple preparation processMaterial nanotechnologyBiocideHigh volume manufacturingZinc nanoparticles

Owner:江西赣大材料技术研究有限公司

Preparation method and applications of zinc and zinc oxide nanorod and carbon nano tube composite flexible membrane

InactiveCN103394341ANo pollutionReduce energy consumptionMetal/metal-oxides/metal-hydroxide catalystsFiltrationCarbon nanotube

The invention discloses a preparation method and applications of a zinc and zinc oxide nanorod and a carbon nano tube composite flexible membrane. The preparation method comprises following steps: putting a raw material of zinc powder in a vibration mill to prepare zinc nano particles, subjecting the prepared zinc nano particles to carry out reactions with water steam to generate a zinc and zinc oxide nanorod complex, which has a diameter of 10 to 50 nm and a length of 1 to 5 [mu]m, putting the zinc and zinc oxide nanorod complex in the prepared carbon nano tube mixed liquid, evenly mixing, then subjecting the liquid to an ultrasonic dispersion treatment, wherein the mass ratio of the zinc and zinc oxide nanorod complex to the carbon nano tube being 7 to 87:10, pouring the prepared mixed liquid into a filtration device, making the solid to participate on the filter paper, drying and then separating out the flexible membrane, drying the flexible membrane in vacuum to remove residual solution to obtain the zinc oxide nanorod and carbon nano tube composite flexible membrane. The preparation method has the advantages of simple preparation process, low equipment cost, and easy industrialization. The prepared flexible membrane has a very good catalytic degradation effect on organic pollutants in the absence of light.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

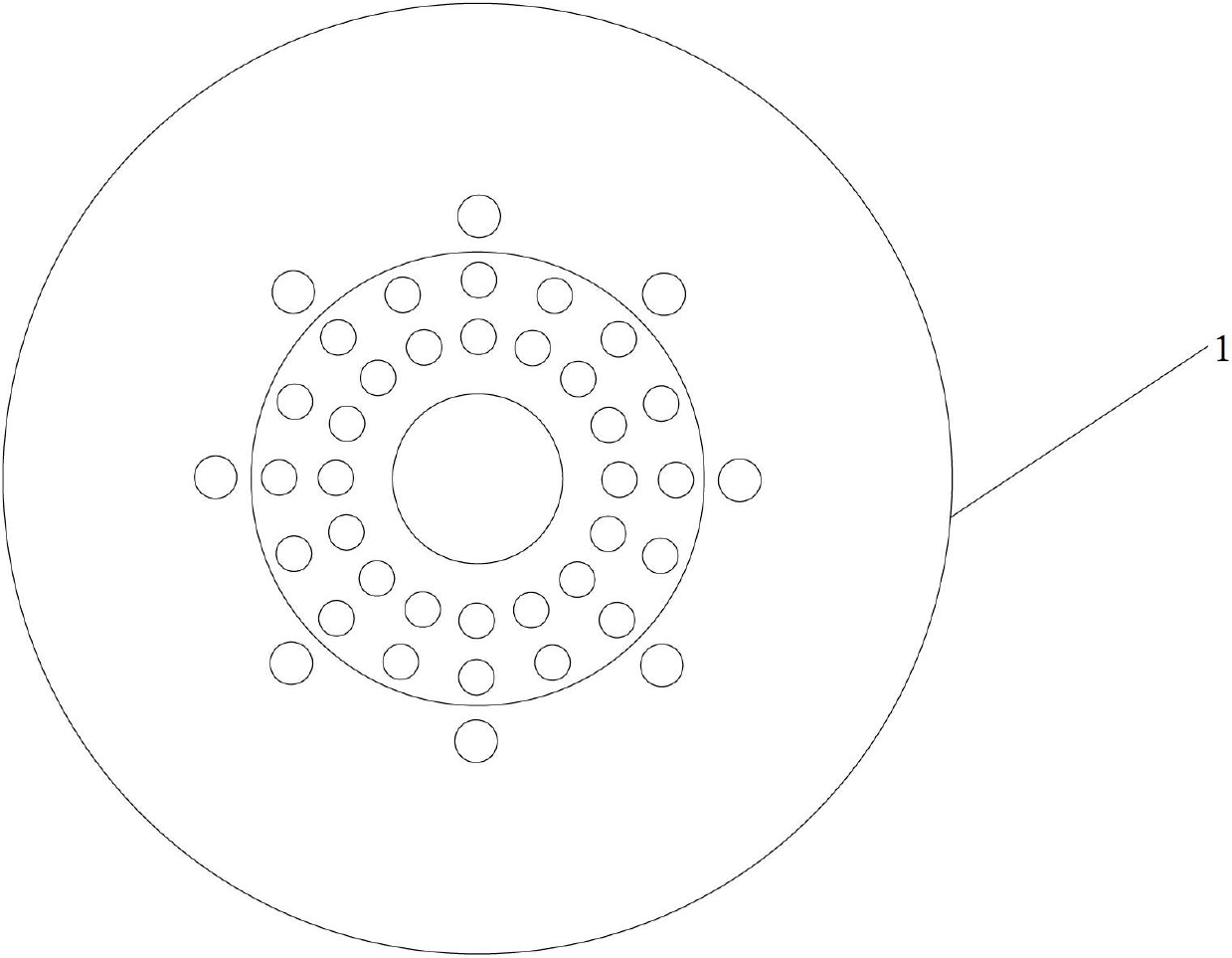

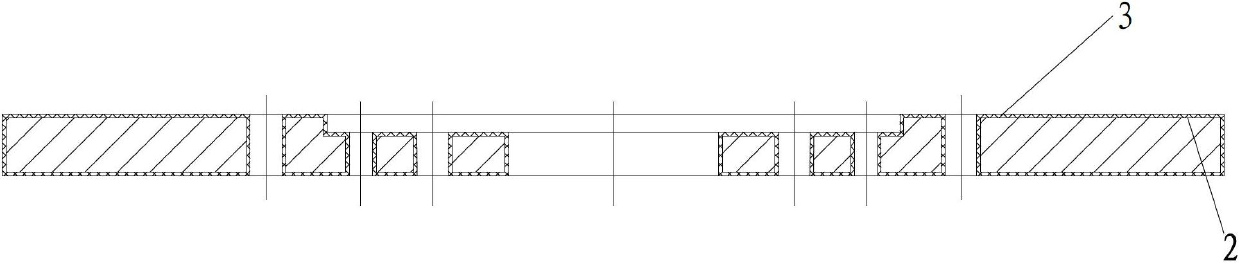

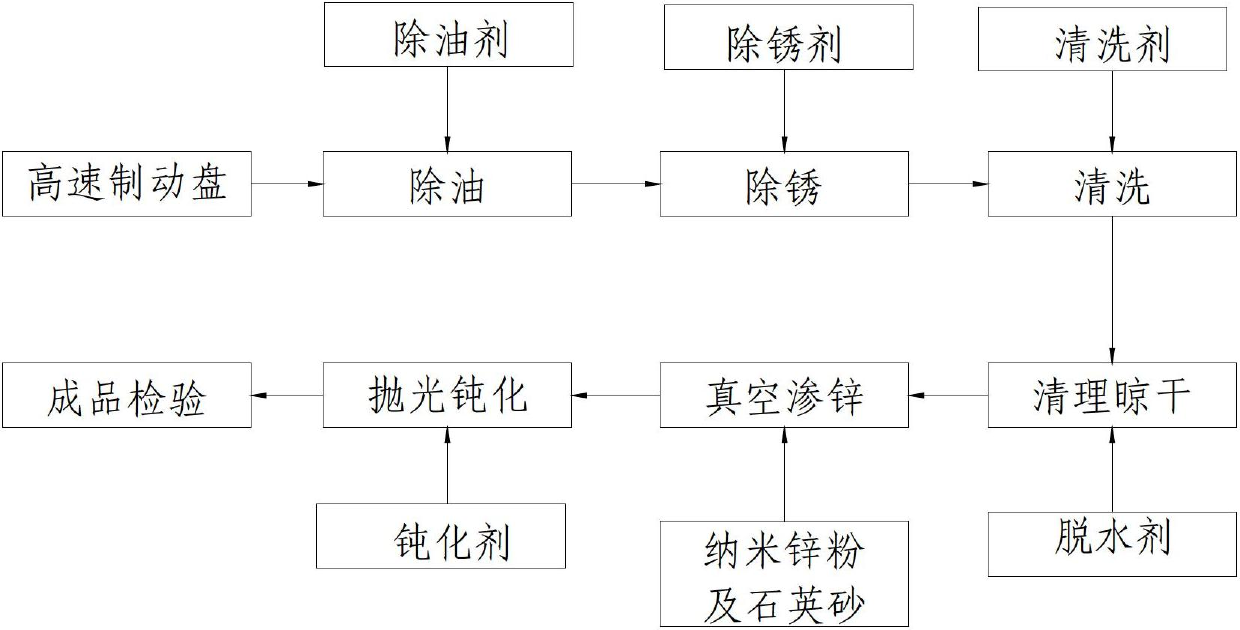

Anticorrosion protection method for high-speed braking disc of wind generating set

InactiveCN102676987AWear-resistantCorrosiveSolid state diffusion coatingSuperimposed coating processZinc nanoparticlesEngineering

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

Zinc sulfide/porous carbon nano-fiber composite material and preparation method thereof

InactiveCN109346687ATight and uniform anchoringInhibition of agglomerationMaterial nanotechnologyCell electrodesPolyvinyl alcoholPorous carbon

The invention provides a preparation method of a zinc sulfide / porous carbon nano-fiber composite material. The preparation method comprises the following steps: firstly, loading a zinc sulfide precursor on pre-oxidized polyvinyl alcohol / polytetrafluoroethylene nanofibers through a solvent thermal method; carrying out high-temperature carbonization, and synchronously generating zinc sulfide nanoparticles and porous carbon nanofibers; forming a stable corn cob-like composite structure (porous carbon nanofibers are aaaused as a carbon skeleton and the zinc sulfide nanoparticles are uniformly anchored). The composite material served as an anode of a lithium-ion battery has the beneficial effects that nano zinc sulfide with high theoretical specific capacity ensures high energy density of the material; a three-dimensional conductive network formed by porous carbon nanofibers enhances the conductivity of the material and ensures the high power density of the material; the corn cob-like structure facilitates full contact between an active material and electrolyte; meanwhile, the volume change of an active material during insertion / lithiation is effectively alleviated. In addition, the method has the advantages of simple operation, low cost, high efficiency and easiness in practical application and popularization.

Owner:TIANJIN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com