Polylactic acid/modified graphene oxide antibacterial plastic and preparation method

A technology of antibacterial plastics and polylactic acid, which is applied in the field of polylactic acid/modified graphene oxide antibacterial plastics and its preparation, can solve the problems of affecting antibacterial performance and agglomeration of nano antibacterial agents, so as to improve antibacterial activity, good system compatibility, Wide range of antibacterial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method of polylactic acid / modified graphene oxide antibacterial plastics, comprising the following steps:

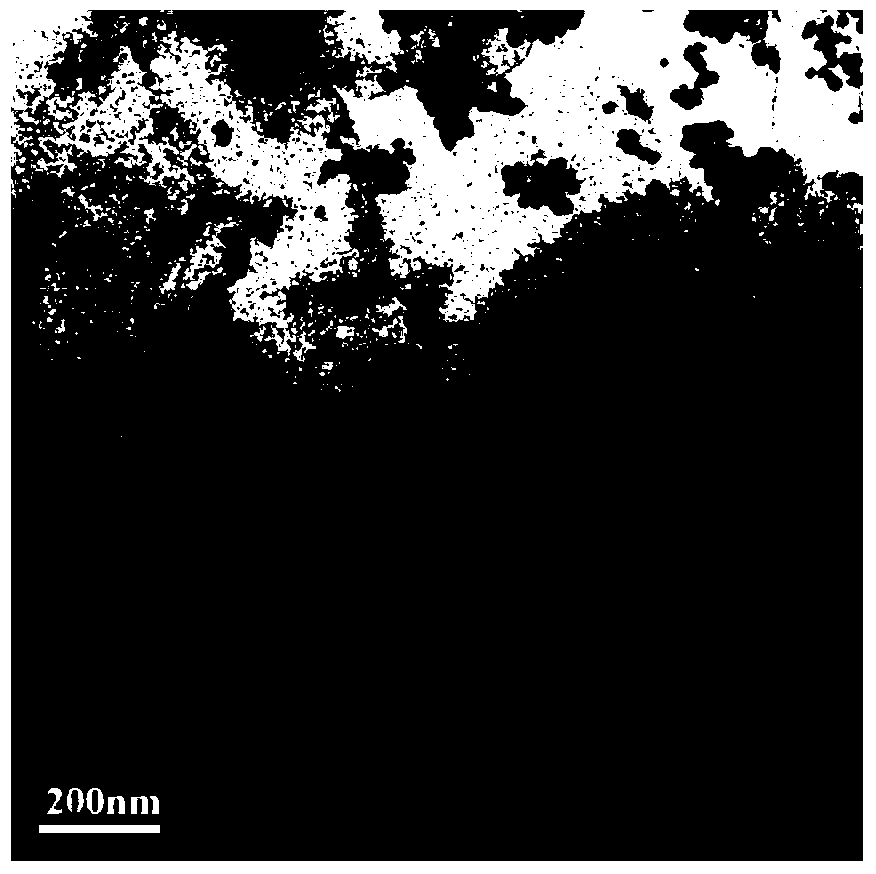

[0027] (1) Preparation of composite antibacterial agent: dry the graphene oxide prepared by the Hummers method and disperse it uniformly in ethanol by ultrasonic, add zinc acetate under heating conditions and keep stirring to make it fully mixed and dissolved, and slowly add hydrogen after the solution boils Sodium oxide solution, after the reaction is completed, the product is centrifuged and washed to neutrality, and vacuum-dried;

[0028] (2) Use the low boiling point solvent chloroform to blend the polylactic acid and the compound antibacterial agent in proportion to the solution, use an automatic film coating machine to coat the mixed solution on a clean glass plate, let the solvent evaporate naturally at room temperature, and finally put it in warm water After the film is removed in the middle, it is placed in an oven and dried to obtain the po...

Embodiment 1

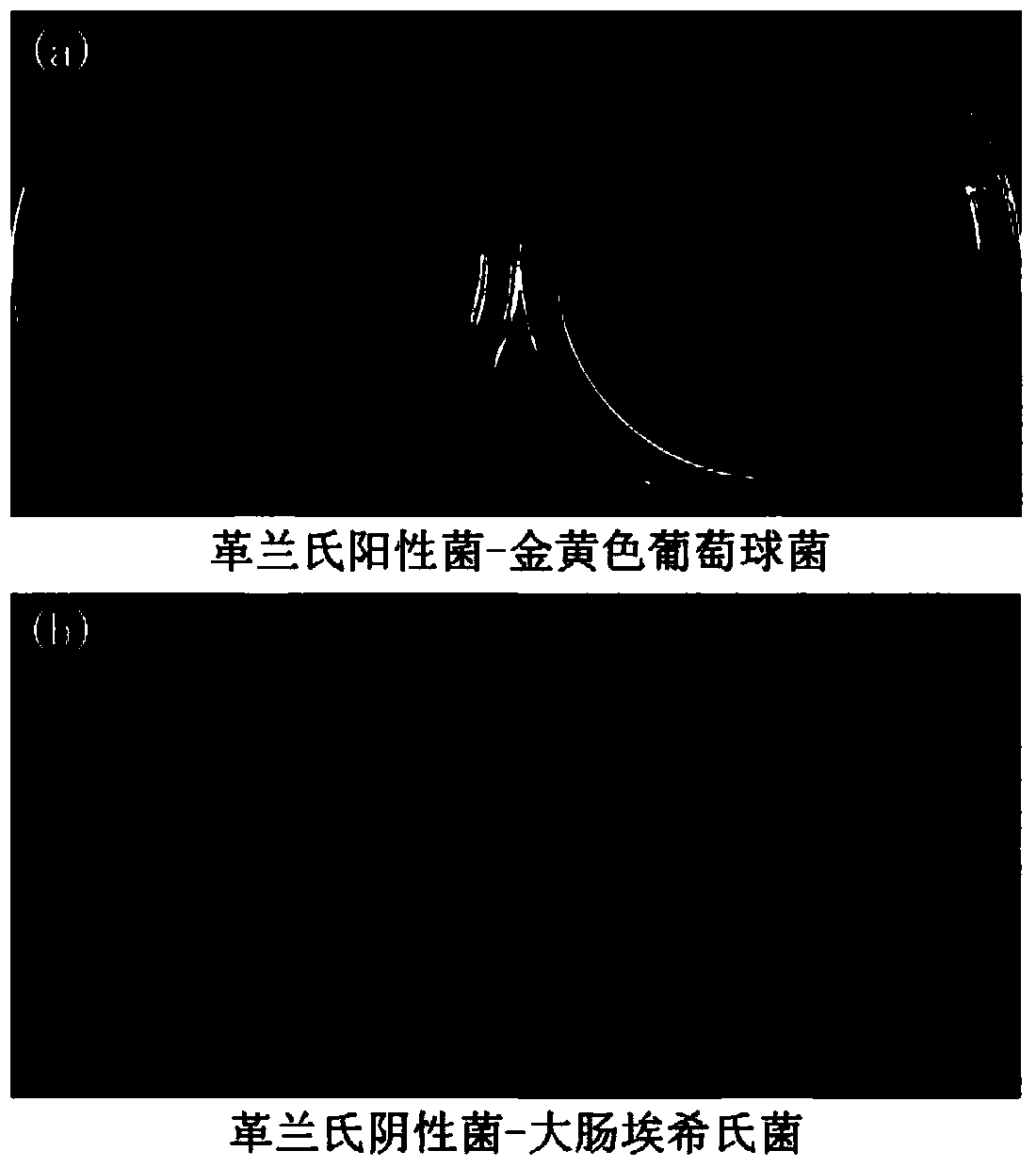

[0036] Example 1: Weigh 10g of polylactic acid and dissolve it in 40mL of chloroform, and stir it magnetically for 2 hours to fully dissolve it. Weigh 0.02g of composite antibacterial agent and disperse it in 20mL of chloroform, and ultrasonically disperse it for 1.5h to make it evenly dispersed. Then the two dispersions were mixed and stirred, and blended for 4h. Use an automatic film coater to coat the mixed solution on a glass plate into a film of 1.5 mm, then allow chloroform to volatilize naturally for 24 hours at room temperature, remove the mold with warm water, and dry it in vacuum at 60 ° C for 48 hours to obtain the polylactic acid of the present invention / Modified graphene oxide antibacterial plastic. Antibacterial rate test results: Staphylococcus aureus 99.2%; Escherichia coli 97.6%.

Embodiment 2

[0037] Example 2: Weigh 10 g of polylactic acid and dissolve it in 40 mL of chloroform, and stir it magnetically for 2 hours to fully dissolve it. Weigh 0.05g of composite antibacterial agent and disperse it in 20mL of chloroform, and ultrasonically disperse it for 1.5h to make it evenly dispersed. Then the two dispersions were mixed and stirred, and blended for 4h. Use an automatic film coater to coat the mixed solution on a glass plate into a film of 1.5 mm, then allow chloroform to volatilize naturally for 24 hours at room temperature, remove the mold with warm water, and dry it in vacuum at 60 ° C for 48 hours to obtain the polylactic acid of the present invention / Modified graphene oxide antibacterial plastic. Antibacterial rate test results: Staphylococcus aureus 99.9%; Escherichia coli 98.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com