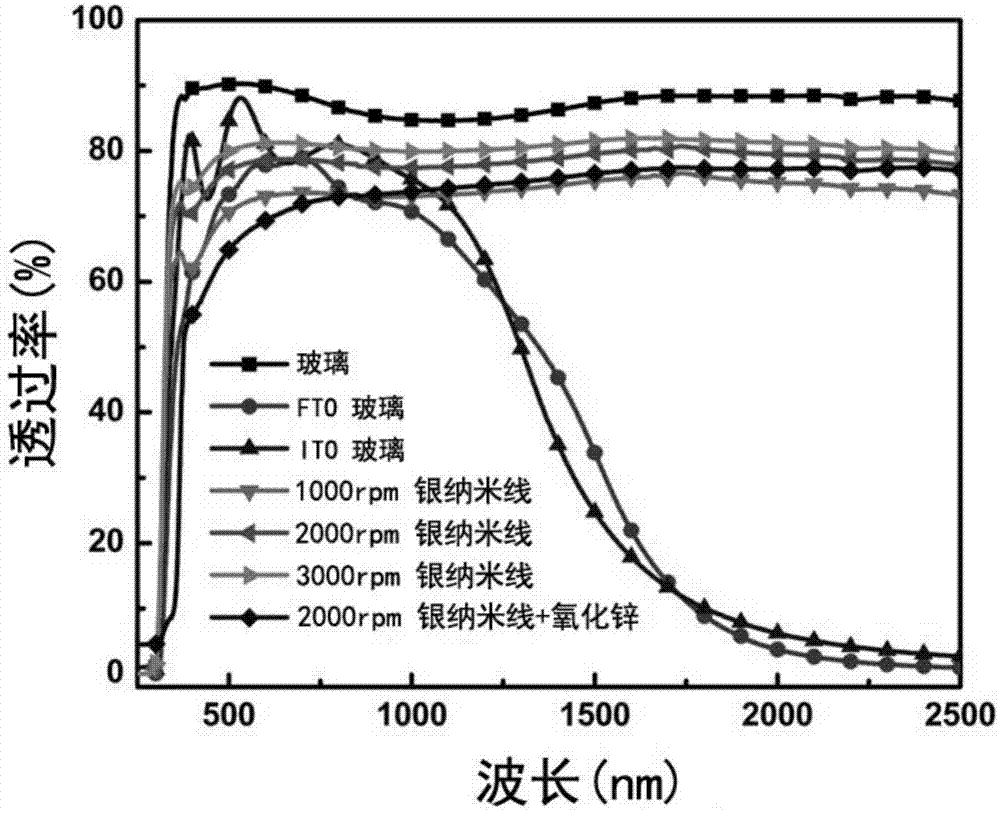

Preparation method of silver nanowire-zinc oxide composite transparent electrode

A technology of silver nanowires and transparent electrodes, which is applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of high price of ITO film, increase of film resistance, and decrease of conductivity, etc., and achieve easy control, high repeatability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: the present invention comprises the following steps:

[0034] 1) Preparation of ultra-long silver nanowires by improved polyol reduction method:

[0035] First, 0.17g of AgNO 3 Added to 10mL of ethylene glycol, using ultrasonic vibration to make AgNO 3 Dissolved in ethylene glycol, ultrasonic time is 7 minutes to form nano-silver twin crystal seeds;

[0036] Then, it was added dropwise to 10 mL containing PVP and FeCl under magnetic stirring 3 in ethylene glycol solution;

[0037] PVP uses PVP k30, and ethylene glycol uses J.T.Baker9300-01 reagent

[0038] Finally, react in an oil bath at 130°C for 45 minutes to obtain an ultra-long silver nanowire solution;

[0039] Among them, the molar ratio of PVP:AgNO 3 =1:1, AgNO 3 : FeCl 3 =1:0.001;

[0040] 2) Post-treatment process of silver nanowires:

[0041] Add 1.5 times the volume of acetone to the ultra-long silver nanowire solution obtained in step 1), centrifuge at 900 rpm for 20 minutes, pour of...

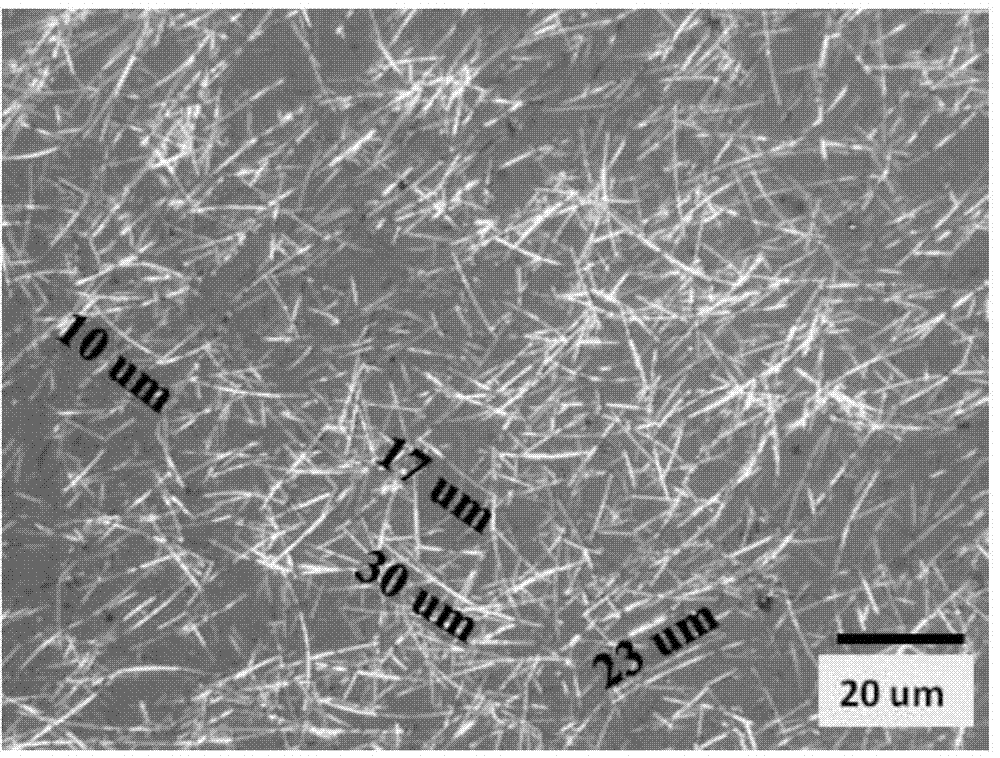

Embodiment 2

[0045] Embodiment 2: the present invention comprises the following steps:

[0046] 1) Preparation of ultra-long silver nanowires by improved polyol reduction method:

[0047] First, 0.17g of AgNO 3 Added to 10mL of ethylene glycol, using ultrasonic vibration to make AgNO 3 Dissolved in ethylene glycol, ultrasonic time is 7 minutes to form nano-silver twin crystal seeds;

[0048] Then, it was added dropwise to 10 mL containing PVP and FeCl under magnetic stirring 3 in ethylene glycol solution;

[0049] PVP uses PVP k30, and ethylene glycol uses J.T.Baker9300-01 reagent

[0050] Finally, react in an oil bath at 150°C for 30 minutes to obtain an ultra-long silver nanowire solution;

[0051] Among them, the molar ratio of PVP:AgNO 3 =1:1.5, AgNO 3 : FeCl 3 =1:0.003;

[0052] 2) Post-treatment process of silver nanowires:

[0053] Add 1.5 times the volume of acetone to the ultra-long silver nanowire solution obtained in step 1), centrifuge at 900 rpm for 20 minutes, pour ...

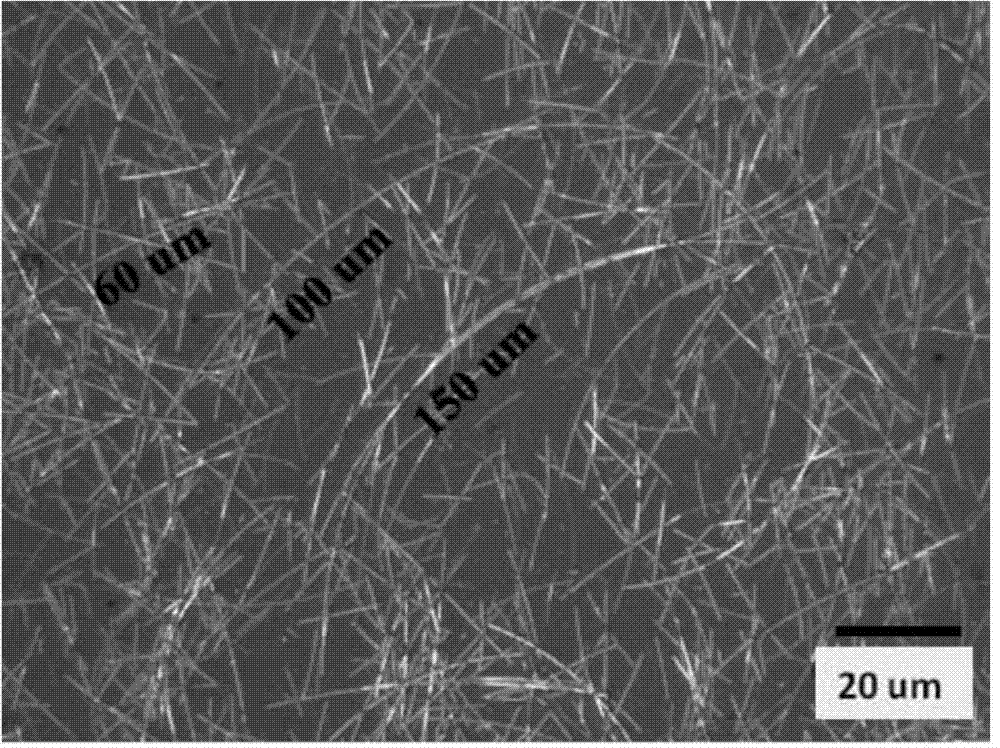

Embodiment 3

[0057] Embodiment 3: the present invention comprises the following steps:

[0058] 1) Preparation of ultra-long silver nanowires by improved polyol reduction method:

[0059] First, 0.17g of AgNO 3 Added to 10mL of ethylene glycol, using ultrasonic vibration to make AgNO 3 Dissolved in ethylene glycol, ultrasonic time is 7 minutes to form nano-silver twin crystal seeds;

[0060] Then, it was added dropwise to 10 mL containing PVP and FeCl under magnetic stirring 3 in ethylene glycol solution;

[0061] PVP uses PVP k30, and ethylene glycol uses J.T.Baker9300-01 reagent

[0062] Finally, react in an oil bath at 150°C for 30 minutes to obtain an ultra-long silver nanowire solution;

[0063] Among them, the molar ratio of PVP:AgNO 3 =1:1.2, AgNO 3 : FeCl 3 =1:0.005;

[0064] 2) Post-treatment process of silver nanowires:

[0065] Add 1.5 times the volume of acetone to the ultra-long silver nanowire solution obtained in step 1), centrifuge at 900 rpm for 20 minutes, pour ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com