Fiber reinforced soil stirring device and stirring method

A technology of fiber reinforced soil and stirring device, which is applied in the directions of mixing methods, mixer accessories, chemical instruments and methods, etc. problem, to eliminate the interference of artificial factors, strengthen the stirring effect, and avoid the effect of static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

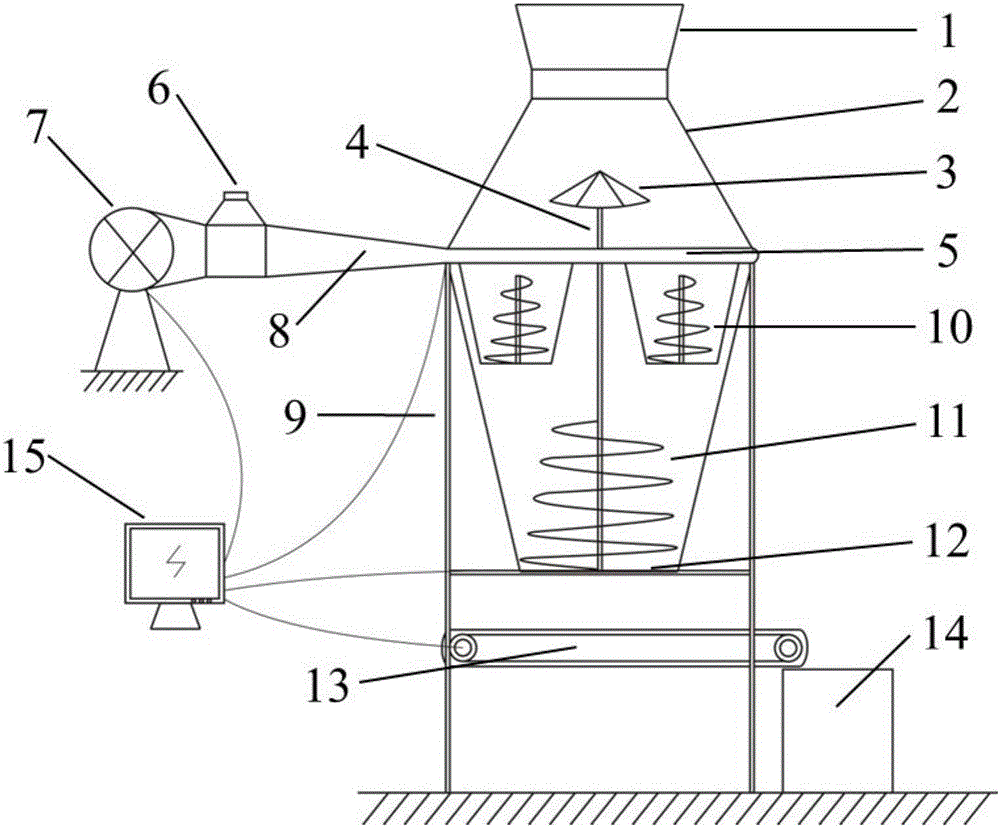

[0028] The fiber reinforced soil stirring device of the present embodiment is as figure 1 As shown, it includes: crushing soil bin 1, soil splitting bin 2, soil splitting turntable 3, soil splitting shaft 4, fiber ring tube 5, fiber bin 6, tuyere 7, fiber channel 8, bracket 9, small mixing bin 10, Large mixing bin 11, large mixing bin bottom plate 12, transmission crawler belt 13, unearthed bin 14 and computer control host 15. The broken soil bin 1 and the divided soil bin 2 are separated by a base plate.

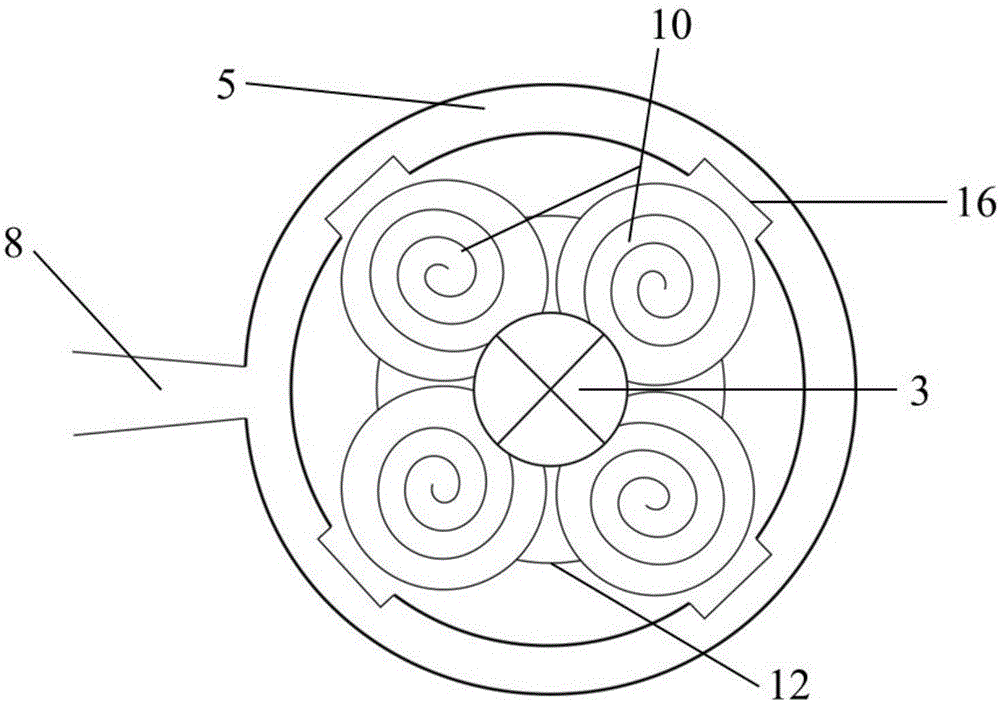

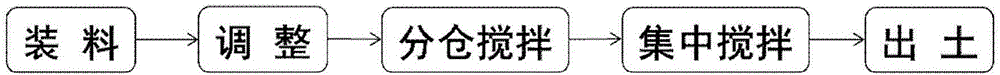

[0029] Wherein, the top view of sub-soil bin 2 is as follows: figure 2 As shown, the fiber channel 8 communicates with the fiber ring pipe 5, and at the center of the fiber ring pipe 5 facing the small mixing chamber, there is a strip-shaped fiber ring pipe outlet 16, and the top of the small mixing chamber 10 has a soil dividing turntable 3 , There is a large mixing bin bottom plate 12 below. Using the fiber-reinforced soil mixing device of the present embodiment, when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com