Nitrogen-doped graded porous carbon nano catalyst and preparation method thereof

A nano-catalyst, porous carbon technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of catalyst structure collapse, limiting catalyst performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Dissolve 10.6 g of 2-methylimidazole and 0.5 mL of formaldehyde in 150 mL of deionized water, and stir for 15 min.

[0031] (2) Then 0.5g of Co(NO 3 ) 2 ·6H 2 O, 0.1g of Zn(NO 3 ) 2 ·6H 2 O and 0.3 g of 4-aminophenol were dissolved in 75 mL of solution (the ratio of deionized water to ethanol was 2:1), added to the solution in step 1, and stirred at room temperature for 12 h.

[0032] (3) Collect the brown precipitate by centrifugation at 2000r / min, centrifuge for 5min, and wash repeatedly with deionized water and ethanol, respectively, for 3 times. After drying, the composite ZIF-67 / 8@AF was obtained.

[0033] (4) Carry out high-temperature carbonization in a nitrogen atmosphere at 900 ° C, and carry out acid treatment, and finally obtain NDHC-9.

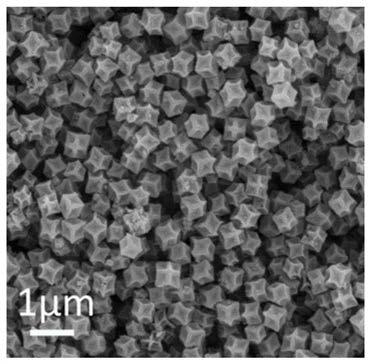

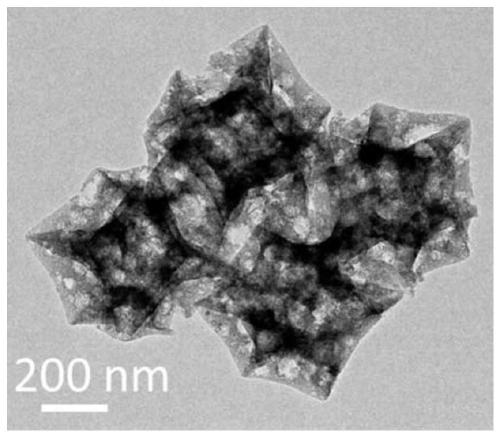

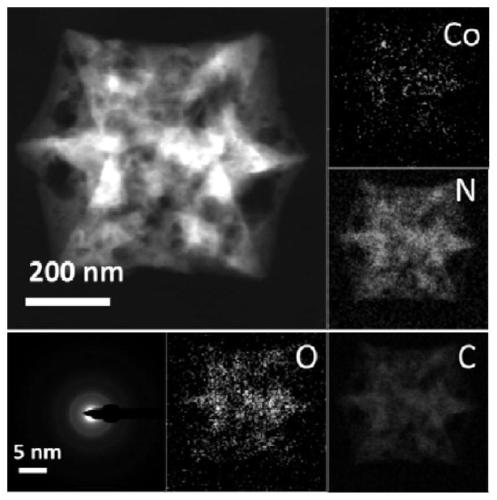

[0034] figure 1 It is the scanning electron microscope image of NDHC-9. It can be seen from the figure that after pyrolysis and acid treatment at 900°C, NDHC-9 maintains the dodecahedral structure and produces a ...

Embodiment 2

[0038]This embodiment is basically the same as Embodiment 1, the only difference is that the carbonization temperature is 700°C. Catalytic properties such as Figure 4 shown.

Embodiment 3

[0040] This embodiment is basically the same as Embodiment 1, the only difference is that the carbonization temperature is 800°C. Catalytic properties such as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com