Preparation method and applications of zinc and zinc oxide nanorod and carbon nano tube composite flexible membrane

A composite technology of zinc oxide nanorods and carbon nanotubes, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of non-catalytic degradation of organic matter, complex equipment, and cumbersome procedures. Achieve the effects of simple preparation process, low equipment energy consumption and convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A) The multi-walled carbon nanotubes prepared by the chemical vapor deposition method are placed in absolute ethanol and dispersed by strong ultrasonic for 20 minutes, and the multi-walled carbon nanotubes are fully dispersed and suspended in the solution. The selected multi-walled carbon nanotubes have a diameter of 5-15 nm and a length of about 100-400 μm.

[0025] B) Put the nano-zinc powder particles and zinc oxide nanorod composites prepared by vibration grinding into a three-necked flask, preheat to the reaction temperature, pass in water vapor for hydrolysis, and fully react to obtain zinc nanoparticles with a diameter of 10-50nm and a length of 1-2 Zinc oxide nanorod composite body of 5 μm, then put zinc and zinc oxide nanorod composite body in the carbon nanotube mixture prepared in step A) and mix evenly, and ultrasonically disperse for 15 minutes, wherein: zinc oxide nanorod powder and carbon nanorod powder The mass ratio of the tubes is 7:10.

[0026] C) Po...

Embodiment 2

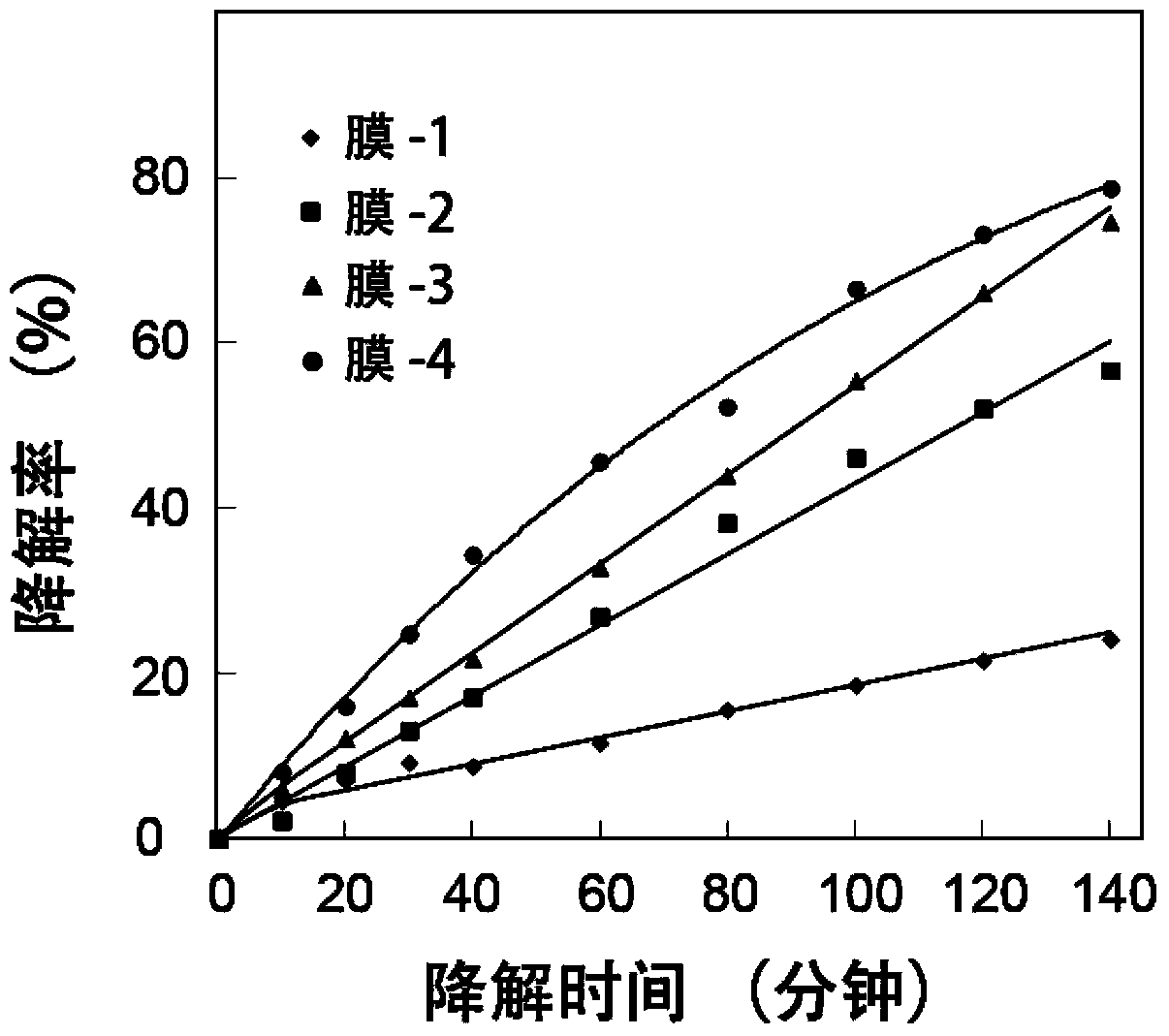

[0030] Same as [Example 1], except that step B) the mass ratio of zinc, zinc oxide nanorod powder and carbon nanotubes is 11:10; step D) fully dry the flexible film in a vacuum drying oven, remove the residual solution, and obtain Zinc oxide nanorods and carbon nanotubes are composite flexible films, and the film thickness is about 15-20 μm. Degradation effect see figure 2 As shown in the film-2 curve, the degradation rate was 56.73% in 140 minutes.

Embodiment 3

[0032] Same as [Example 1], except step B) the mass ratio of zinc, zinc oxide nanorods and carbon nanotubes is 16:10 to prepare a flexible film; step D) fully dry the flexible film in a vacuum drying oven to remove residual solution to obtain a composite flexible film of zinc oxide nanorods and carbon nanotubes, with a film thickness of about 20-22 μm. Degradation effect see figure 2 As shown in the film-3 curve, the degradation rate was 74.73% in 140 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com