Preparation method of lubricating oil composition containing ionic liquid, modified nano-zinc powder and graphene

A technology of lubricating oil composition and nano-zinc powder, which is applied in the field of lubricating oil to achieve the effects of solving the difficulty of dispersion, enhancing dispersion stability, and improving dispersion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

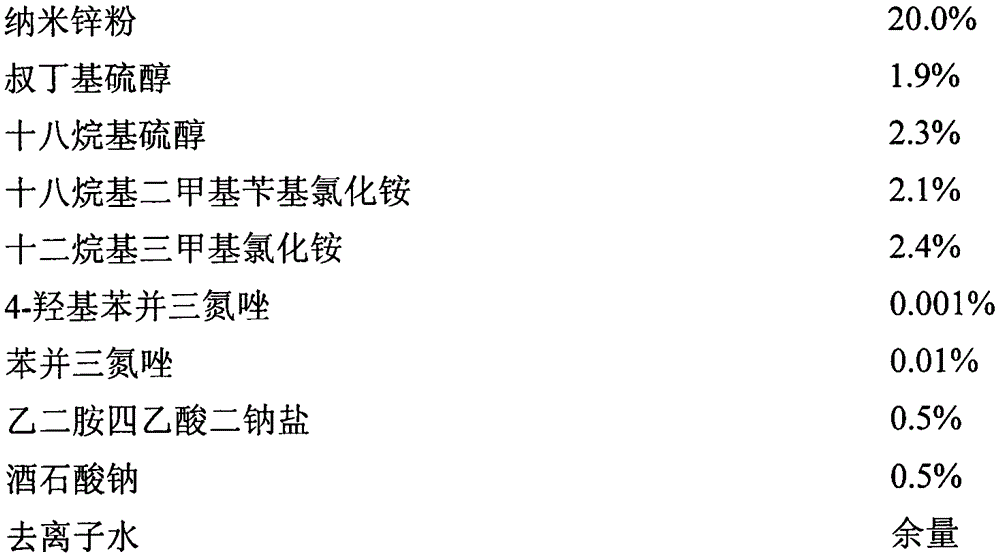

[0037] Preparation of modified nano-zinc powder:

[0038]

[0039] According to the above mass percentage, tert-butyl mercaptan, octadecyl mercaptan, octadecyl dimethyl benzyl ammonium chloride, dodecyl trimethyl ammonium chloride, 4-hydroxybenzotrimethyl ammonium Azole, benzotriazole, disodium ethylenediaminetetraacetic acid and sodium tartrate were added to deionized water, under the action of ultrasonic dispersion with a frequency of 24kHz and a power of 3kW, stirring for 0.4h, and then adding nanometer zinc powder, Further, under the action of ultrasonic dispersion with a frequency of 24kHz and a power of 3kW, it was stirred for 4.5h, and then the modified nano-zinc powder was obtained through centrifugation, deionized water washing, centrifugation, vacuum drying, grinding and sieving. The modified nano-zinc powder is ready for use;

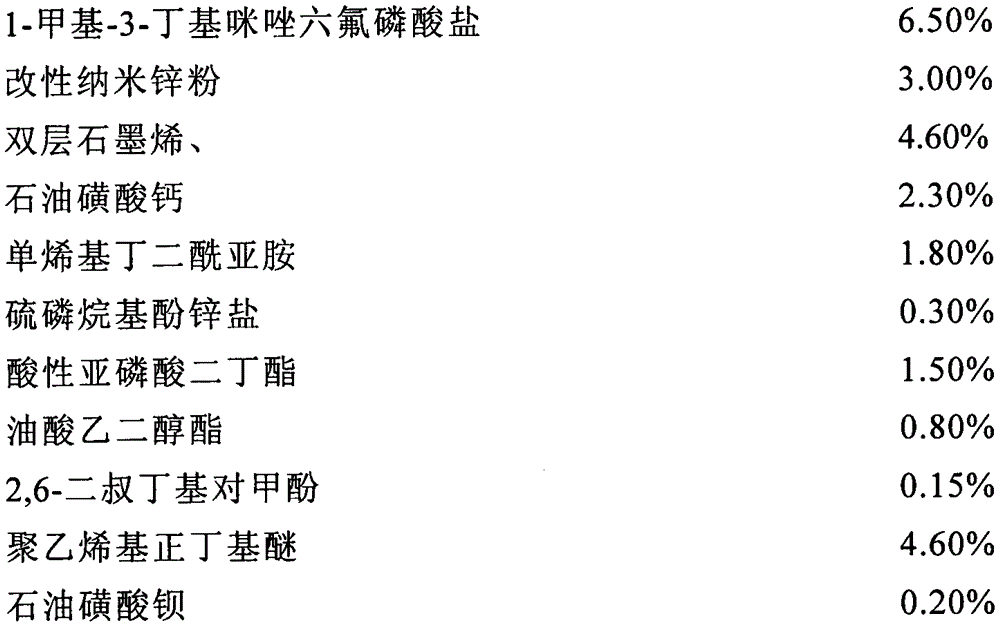

[0040] Preparation of lubricating oil composition:

[0041]

[0042]

[0043] According to the above mass percentages, 1-methyl-3...

Embodiment 2

[0045] Preparation of modified nano-zinc powder:

[0046]

[0047] According to the above mass percentage, n-butyl mercaptan, phenethyl mercaptan, dodecyltrimethylammonium bromide, tetradecyldimethylpyridinium bromide, hexadecyldimethylbenzyl Ammonium bromide, methyl benzotriazole, sodium citrate and potassium tartrate were added into deionized water, under the action of ultrasonic dispersion with a frequency of 28kHz and a power of 5kW, after stirring for 0.4h, nanometer zinc powder was added, further Under the action of ultrasonic dispersion with a frequency of 28kHz and a power of 5kW, stir for 3.0h, then undergo centrifugation, deionized water washing, centrifugation, vacuum drying, grinding and sieving to obtain modified nano-zinc powder. Modified nano-zinc powder for standby;

[0048] Preparation of lubricating oil composition:

[0049]

[0050]

[0051] According to the above mass percentage, 1-methyl-3-butylimidazole tetrafluoroborate, modified nano-zinc pow...

Embodiment 3

[0053] Preparation of modified nano-zinc powder:

[0054]

[0055] According to the above mass percentage, n-dodecyl mercaptan, n-pentyl mercaptan, dodecyl dimethyl benzyl ammonium chloride, octadecyl trimethyl ammonium bromide, N-hydroxybenzo Add triazole, benzotriazole, edetate disodium salt and potassium citrate into deionized water, stir for 0.3h under ultrasonic dispersion with a frequency of 38kHz and a power of 8kW, and then add nano-zinc Powder, further under the action of ultrasonic dispersion with a frequency of 38kHz and a power of 8kW, stirred for 2.5h, then centrifuged, washed with deionized water, centrifuged, vacuum dried, ground and sieved to obtain modified nano-zinc powder, The prepared modified nano-zinc powder is standby;

[0056] Preparation of lubricating oil composition:

[0057]

[0058]

[0059] According to the above mass percentages, N-butylpyridinium hexafluorophosphate, modified nano-zinc powder, few-layer graphene, calcium alkyl salicylat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com