Device for automatically cleaning guide rails of elevator

A technology for automatic cleaning and elevator guide rails, which is applied in the direction of transportation and packaging, elevators, etc., and can solve problems that affect the service life of guide shoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

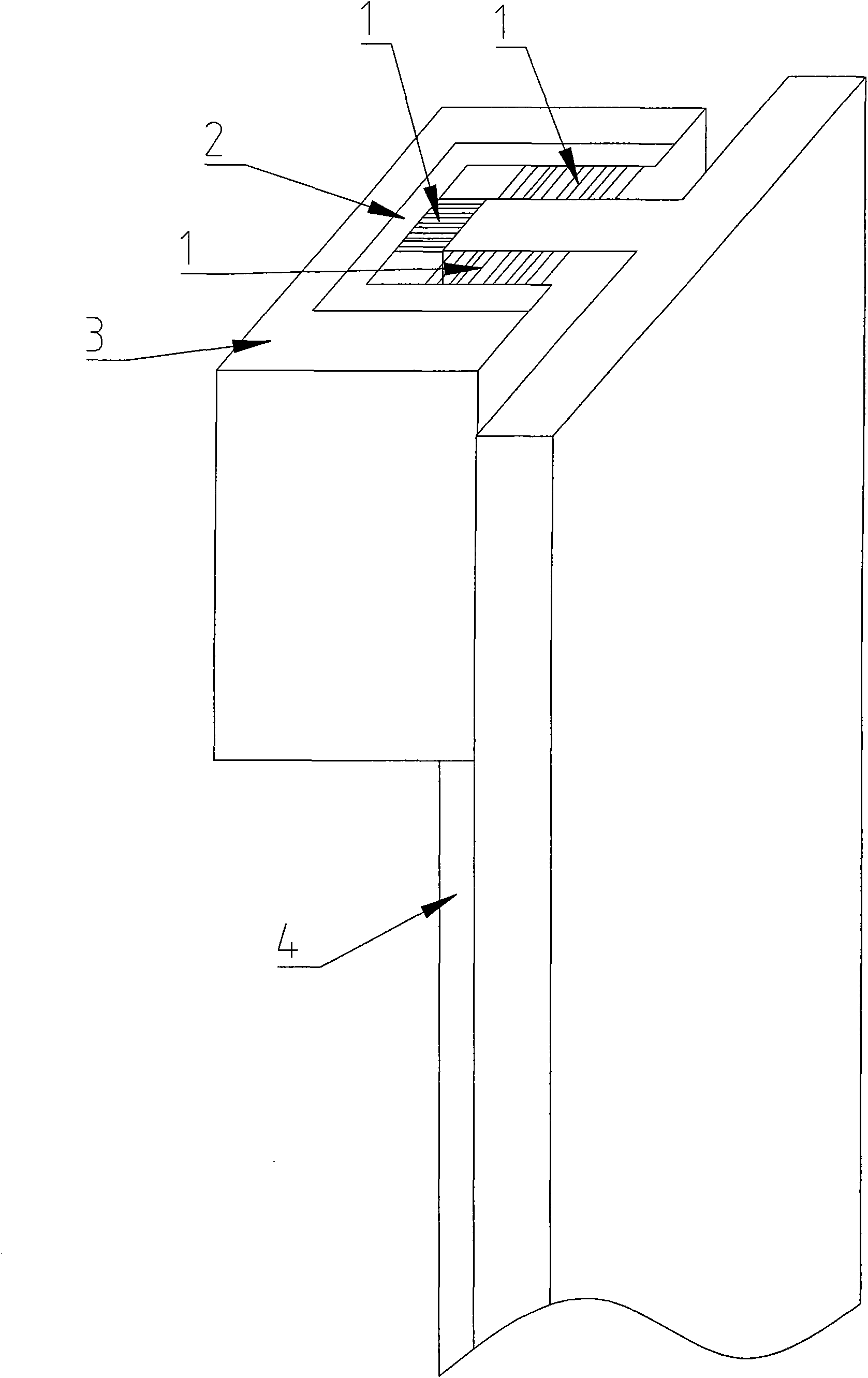

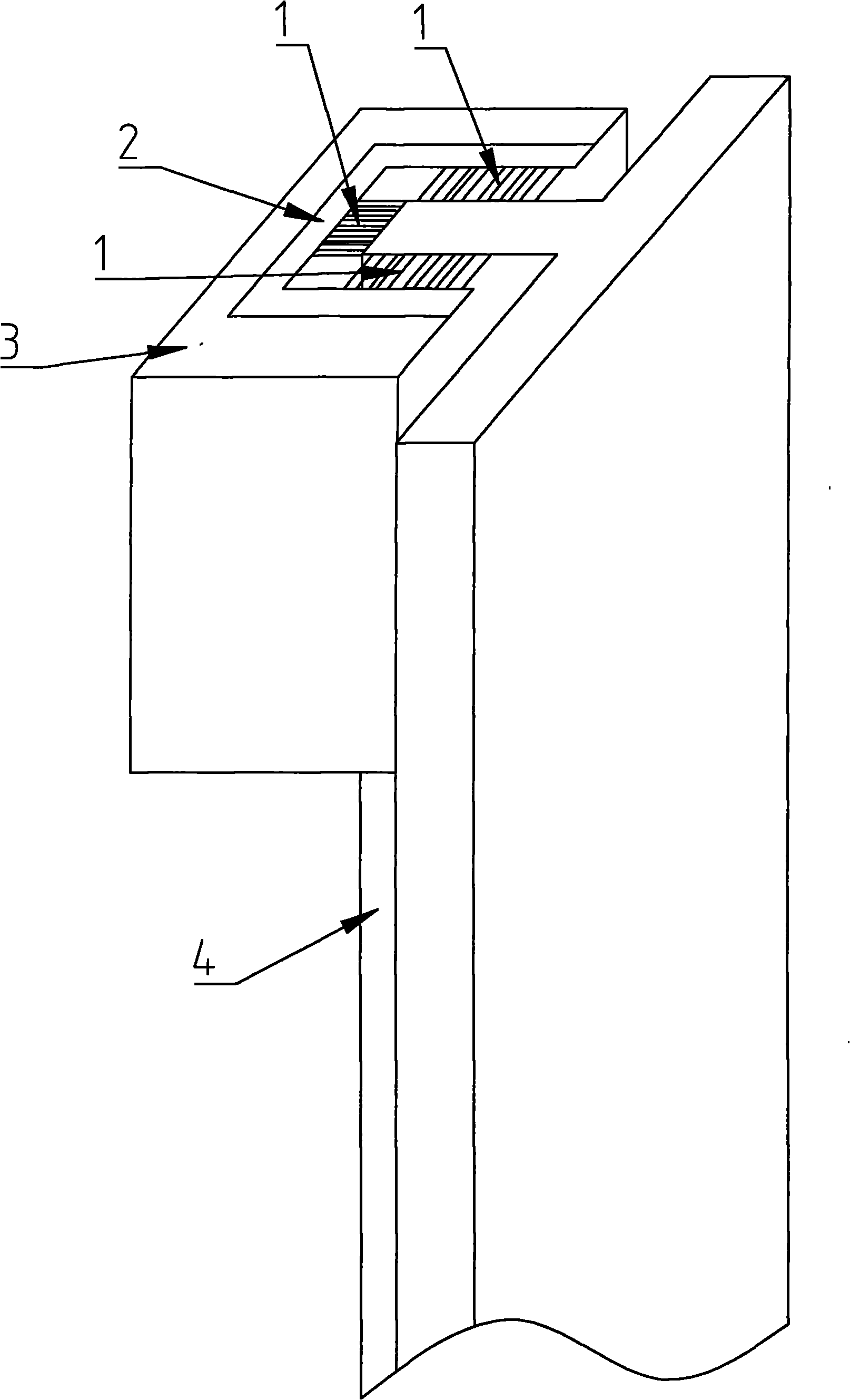

[0009] see figure 1 The shown elevator guide rail automatic cleaning device includes a brush 1 and a fixed bracket 2, and the brush is neatly installed on the fixed bracket. The brush 1 is in contact with three outer surfaces of the guide rail 4 .

[0010] The fixed bracket 2 is installed on the front end of the elevator car guide shoe (or the counterweight guide shoe) and the counterweight guide shoe 3 front ends.

[0011] The elevator guide rail automatic cleaning device moves up and down through the elevator car and the counterweight, drives the brush to move along the guide rail 4, removes or absorbs the dust and sundries on the surface of the guide rail (especially the oil-free dry guide rail), and achieves the purpose of cleaning the guide rail. In this way, the rollers or shoe linings of the guide shoes will not absorb the dust and debris on the guide rails, so as to improve the service life of the guide shoes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com