Disk grabbing device

A grabbing device and disc technology, which is applied in the direction of record information storage, instruments, etc., can solve the problems of low production efficiency, affecting the yield rate, and affecting the production process, so as to achieve accurate and reliable grabbing process, improve yield rate, and ensure The effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

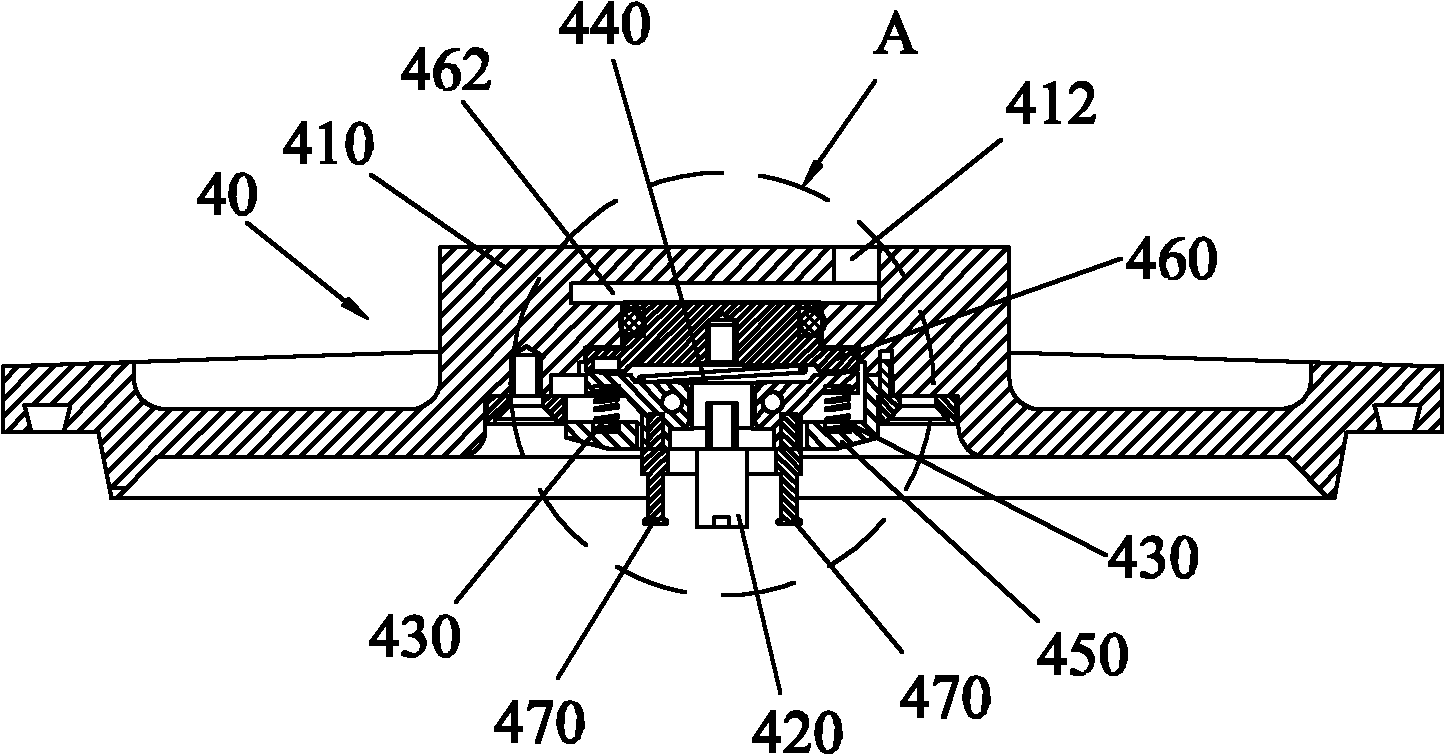

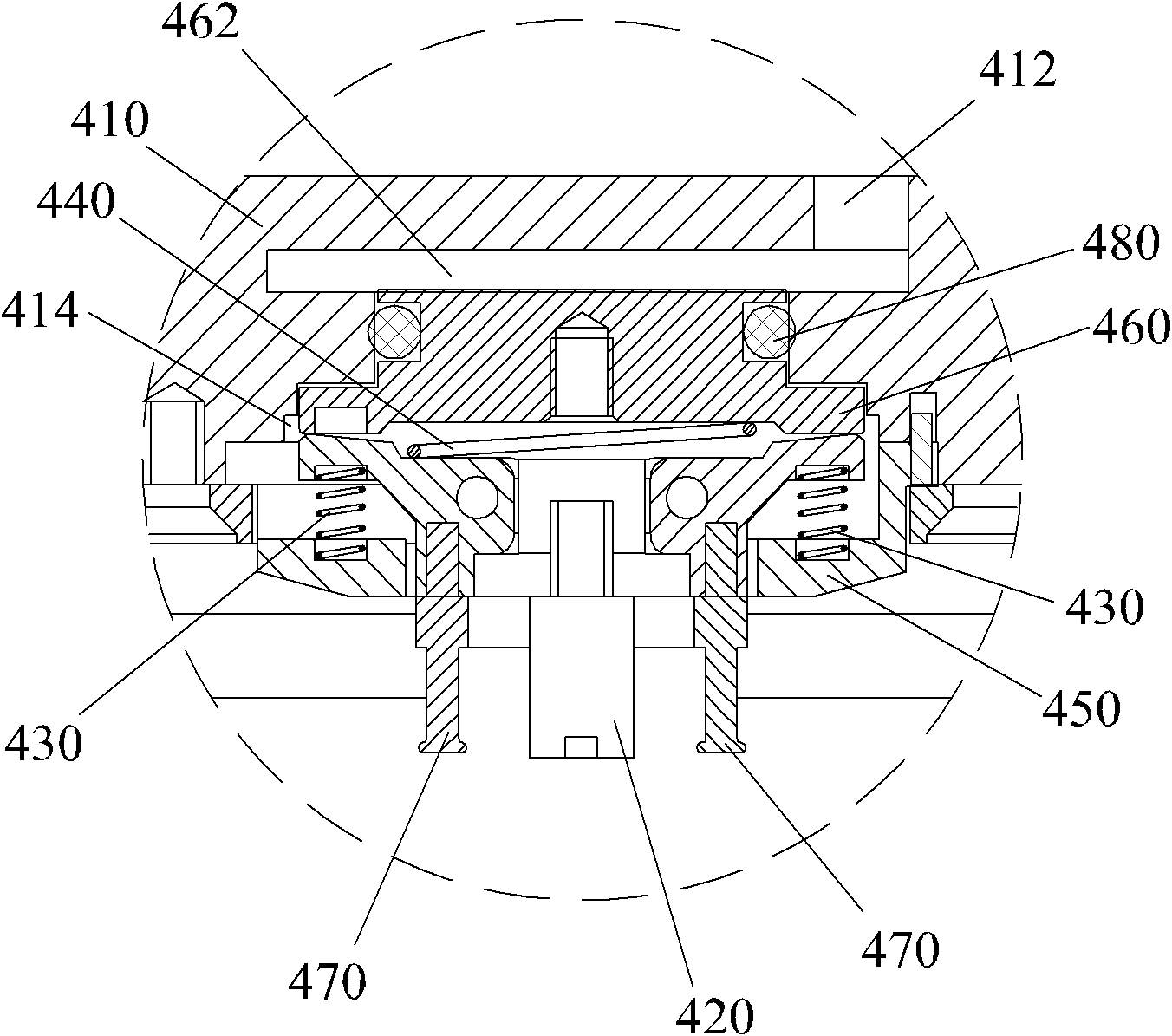

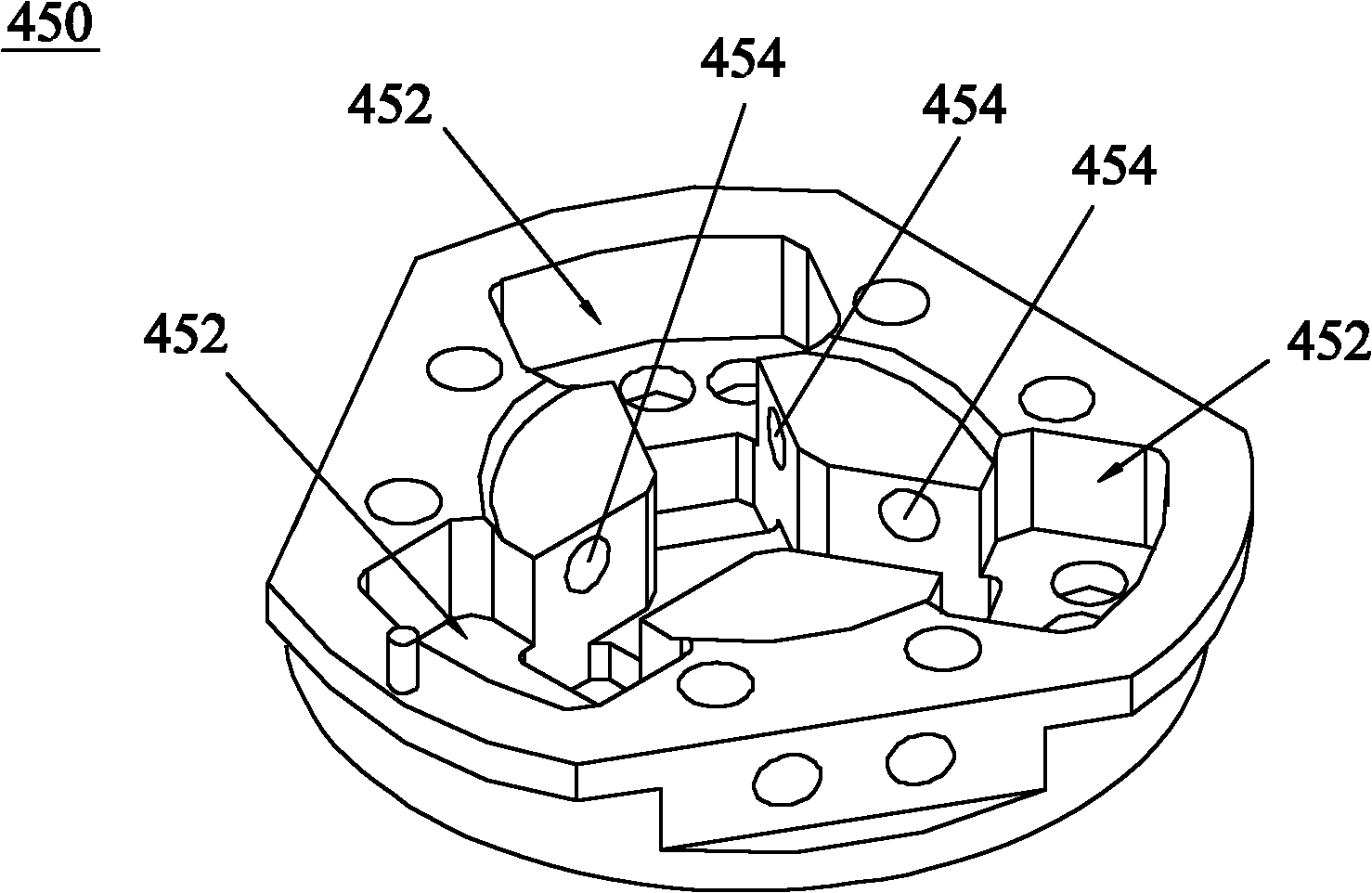

[0020] In order to describe the technical content and structural features of the present invention in detail, the following will be further described in conjunction with the embodiments and accompanying drawings, wherein the same reference numerals in different drawings represent the same components. As mentioned above, the disc grabbing device provided by the present invention uses three claw arms to pick and place the disc through the central hole of the disc, avoiding contact with the upper and lower surfaces of the disc, and ensuring the cleanliness of the disc transfer on the station , improve the disc yield, and the grasping process is accurate and reliable, ensuring the smoothness of the disc processing line and improving production efficiency.

[0021] refer to figure 1 and Figure 5 , the disc grabbing device of the preferred embodiment of the present invention is used for positioning, handling and transferring discs 20, the discs 20 are carried on the tray 10, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com