Melt granulation humic acid functional fertilizer special for corns and preparing method thereof

A special fertilizer for corn, melt granulation technology, applied in the direction of application, fertilizer form, fertilization device, etc., to achieve the effect of increasing yield, low price, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

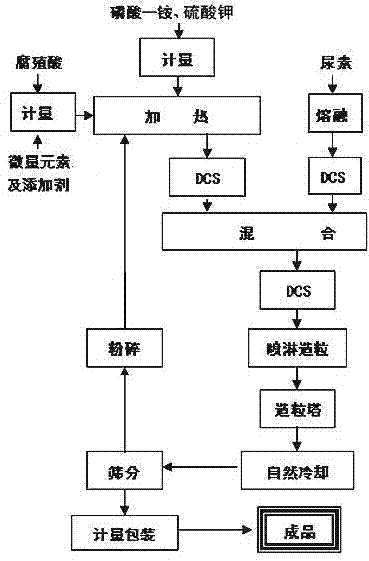

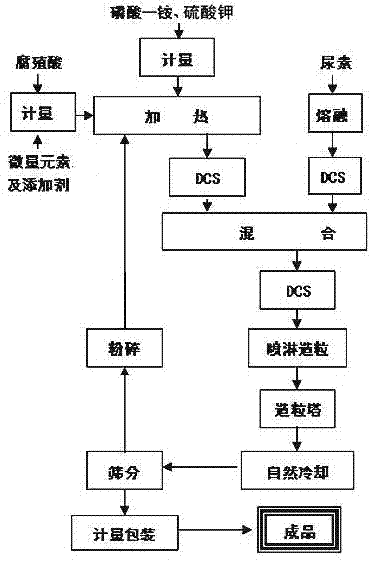

Method used

Image

Examples

Embodiment 1

[0076] Melt granulation humic acid functional corn special fertilizer, nitrogen phosphorus potassium (N-P 2 o 5 -K 2 O) contents were 20%, 9%, and 11%, respectively, all of which were percentages by mass.

[0077] (1) Melt 390 parts of urea at a high temperature to about 140°C, enter the buffer tank, pressurize it through the delivery pump, and pump it into the top mixer;

[0078] (2) 190 parts of monoammonium phosphate, 210 parts of potassium sulfate, 100 parts of humic acid, 50 parts of calcium magnesium phosphate fertilizer, 10 parts of EDTA chelated zinc, 10 parts of EDTA chelated iron, 10 parts of EDTA chelated boron, ammonium molybdate After 5 parts and 25 parts of additives are measured, they are sent to the mixer and mixed evenly. After the mixed raw materials are crushed and sieved, they are sent to the mixing heater to be heated to about 90°C, and sent to the top of the tower with a bucket elevator. warehouse;

[0079] (3) The hot mixture in the silo at the top o...

Embodiment 2

[0081] Melt granulation humic acid functional corn special fertilizer, nitrogen phosphorus potassium (N-P 2 o 5 -K 2 O) contents are 22%, 8%, 10% respectively, all are percentages by mass.

[0082] Take 440 parts of urea, 160 parts of monoammonium phosphate, 200 parts of potassium sulfate, 100 parts of humic acid, 10 parts of EDTA chelated zinc, 10 parts of EDTA chelated iron, 10 parts of EDTA chelated boron, 6 parts of ammonium molybdate and 14 parts Additives are raw materials, and the production process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com